How to Conduct Wankel Engine Emission Benchmarking?

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Emission History and Objectives

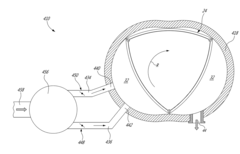

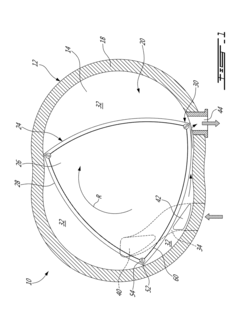

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design featuring a triangular rotor moving within an epitrochoidal housing initially promised numerous advantages, including fewer moving parts, smoother operation, and higher power-to-weight ratios. However, emission control has consistently been the Achilles' heel of this innovative engine design throughout its history.

In the 1960s and early 1970s, when Wankel engines first gained commercial traction through manufacturers like NSU and Mazda, emission regulations were relatively lenient. The inherent characteristics of the rotary design—specifically the elongated combustion chamber and moving combustion zones—resulted in higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to conventional engines of the era.

The 1970s energy crisis and subsequent tightening of emission standards in major markets posed significant challenges for Wankel engine development. The long, thin combustion chamber created inherent difficulties in achieving complete combustion, leading to unburned fuel escaping through the exhaust. Additionally, the engine's higher operating temperatures contributed to elevated nitrogen oxide (NOx) emissions, creating a complex emissions profile that proved difficult to address with the technology available at that time.

By the 1980s and 1990s, most manufacturers abandoned rotary engine development as emission standards continued to tighten globally. Mazda remained the sole significant commercial producer, investing heavily in research to overcome these challenges. Their efforts culminated in innovations such as improved apex seals, redesigned combustion chambers, and advanced catalytic converter systems specifically optimized for rotary engine emission profiles.

The 21st century brought even more stringent emission regulations, particularly regarding CO2 output and fuel efficiency. Mazda's final production rotary engine, found in the RX-8 (discontinued in 2012), incorporated numerous technological advancements but still struggled to meet increasingly strict global emission standards.

The primary objective of Wankel engine emission benchmarking is to establish standardized methodologies for accurately measuring and comparing the unique emission characteristics of rotary engines against conventional powertrains. This includes developing specialized testing protocols that account for the rotary engine's distinctive combustion process, operational temperature ranges, and emission formation mechanisms.

Secondary objectives include identifying specific technological interventions that most effectively address rotary engine emission challenges, quantifying the emission reduction potential of various design modifications, and establishing realistic performance targets for future rotary engine development that align with evolving global emission standards.

In the 1960s and early 1970s, when Wankel engines first gained commercial traction through manufacturers like NSU and Mazda, emission regulations were relatively lenient. The inherent characteristics of the rotary design—specifically the elongated combustion chamber and moving combustion zones—resulted in higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to conventional engines of the era.

The 1970s energy crisis and subsequent tightening of emission standards in major markets posed significant challenges for Wankel engine development. The long, thin combustion chamber created inherent difficulties in achieving complete combustion, leading to unburned fuel escaping through the exhaust. Additionally, the engine's higher operating temperatures contributed to elevated nitrogen oxide (NOx) emissions, creating a complex emissions profile that proved difficult to address with the technology available at that time.

By the 1980s and 1990s, most manufacturers abandoned rotary engine development as emission standards continued to tighten globally. Mazda remained the sole significant commercial producer, investing heavily in research to overcome these challenges. Their efforts culminated in innovations such as improved apex seals, redesigned combustion chambers, and advanced catalytic converter systems specifically optimized for rotary engine emission profiles.

The 21st century brought even more stringent emission regulations, particularly regarding CO2 output and fuel efficiency. Mazda's final production rotary engine, found in the RX-8 (discontinued in 2012), incorporated numerous technological advancements but still struggled to meet increasingly strict global emission standards.

The primary objective of Wankel engine emission benchmarking is to establish standardized methodologies for accurately measuring and comparing the unique emission characteristics of rotary engines against conventional powertrains. This includes developing specialized testing protocols that account for the rotary engine's distinctive combustion process, operational temperature ranges, and emission formation mechanisms.

Secondary objectives include identifying specific technological interventions that most effectively address rotary engine emission challenges, quantifying the emission reduction potential of various design modifications, and establishing realistic performance targets for future rotary engine development that align with evolving global emission standards.

Market Demand Analysis for Low-Emission Rotary Engines

The global market for low-emission rotary engines is experiencing significant growth driven by stringent environmental regulations and increasing consumer demand for cleaner transportation options. The Wankel engine, with its compact design and high power-to-weight ratio, presents a unique opportunity in this evolving landscape, particularly if its historical emission challenges can be overcome.

Current market analysis indicates that the automotive sector represents the largest potential market for improved rotary engine technology. With global vehicle emissions standards becoming increasingly strict—particularly in Europe, North America, and developed Asian markets—manufacturers are actively seeking alternative powertrain solutions that can meet these requirements while maintaining performance characteristics.

The marine industry also shows promising demand for low-emission rotary engines. This sector values the compact size and reduced vibration of Wankel engines, making them ideal for smaller watercraft where space optimization is crucial. Market research suggests that recreational boating and small commercial vessels could represent a growth segment if emissions performance can be enhanced.

Aviation represents another significant market opportunity, particularly in the unmanned aerial vehicle (UAV) and light aircraft segments. The rotary engine's favorable power-to-weight ratio makes it especially attractive for these applications, where every gram of weight impacts operational efficiency and range. Market forecasts predict substantial growth in these sectors over the next decade.

Consumer preferences are increasingly shifting toward environmentally responsible products across all transportation segments. Survey data shows that buyers are willing to pay premium prices for vehicles with reduced environmental impact, creating a viable market for advanced rotary engine technology that can deliver both performance and reduced emissions.

The stationary power generation market also presents opportunities for low-emission rotary engines, particularly in applications requiring compact, reliable power sources. Backup generators, remote power systems, and portable power units could benefit from improved rotary engine technology with lower emissions profiles.

Market competition analysis reveals that while traditional piston engines dominate current markets, there exists a significant opportunity gap for innovative powertrain solutions that combine the unique advantages of rotary engines with modern emission control technologies. Companies that can successfully bridge this gap stand to capture substantial market share in specialized segments.

Regional market assessment shows varying levels of receptiveness to rotary engine technology. Japan, with its historical connection to rotary engine development, remains a strong potential market, while emerging economies in Asia and South America show growing interest in alternative engine technologies that can meet increasingly stringent local emissions regulations.

Current market analysis indicates that the automotive sector represents the largest potential market for improved rotary engine technology. With global vehicle emissions standards becoming increasingly strict—particularly in Europe, North America, and developed Asian markets—manufacturers are actively seeking alternative powertrain solutions that can meet these requirements while maintaining performance characteristics.

The marine industry also shows promising demand for low-emission rotary engines. This sector values the compact size and reduced vibration of Wankel engines, making them ideal for smaller watercraft where space optimization is crucial. Market research suggests that recreational boating and small commercial vessels could represent a growth segment if emissions performance can be enhanced.

Aviation represents another significant market opportunity, particularly in the unmanned aerial vehicle (UAV) and light aircraft segments. The rotary engine's favorable power-to-weight ratio makes it especially attractive for these applications, where every gram of weight impacts operational efficiency and range. Market forecasts predict substantial growth in these sectors over the next decade.

Consumer preferences are increasingly shifting toward environmentally responsible products across all transportation segments. Survey data shows that buyers are willing to pay premium prices for vehicles with reduced environmental impact, creating a viable market for advanced rotary engine technology that can deliver both performance and reduced emissions.

The stationary power generation market also presents opportunities for low-emission rotary engines, particularly in applications requiring compact, reliable power sources. Backup generators, remote power systems, and portable power units could benefit from improved rotary engine technology with lower emissions profiles.

Market competition analysis reveals that while traditional piston engines dominate current markets, there exists a significant opportunity gap for innovative powertrain solutions that combine the unique advantages of rotary engines with modern emission control technologies. Companies that can successfully bridge this gap stand to capture substantial market share in specialized segments.

Regional market assessment shows varying levels of receptiveness to rotary engine technology. Japan, with its historical connection to rotary engine development, remains a strong potential market, while emerging economies in Asia and South America show growing interest in alternative engine technologies that can meet increasingly stringent local emissions regulations.

Current Emission Challenges in Wankel Technology

Wankel engines, despite their compact design and high power-to-weight ratio, face significant emission challenges that have limited their widespread adoption in modern automotive applications. The rotary engine's inherent design characteristics contribute to several emission-related issues that must be addressed through comprehensive benchmarking and innovative solutions.

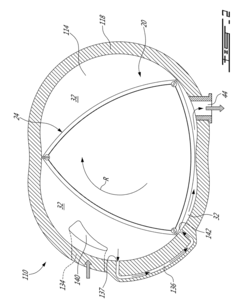

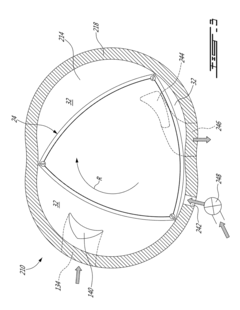

The combustion chamber geometry of Wankel engines presents a fundamental challenge for emissions control. The elongated combustion chamber creates thermal inefficiencies and incomplete combustion, resulting in higher hydrocarbon (HC) emissions compared to conventional piston engines. This geometric constraint leads to fuel being trapped in the rotor housing crevices, where it escapes the combustion process and exits as unburned hydrocarbons.

Oil consumption represents another critical emission challenge. The apex seals in Wankel engines require continuous lubrication, resulting in oil being introduced into the combustion chamber. This oil is partially burned during operation, contributing to particulate matter (PM) emissions and increased hydrocarbon levels. Modern emission standards, particularly Euro 6d and EPA Tier 3, have established stringent limits for these pollutants that are challenging for rotary engine designs to meet.

Nitrogen oxide (NOx) emissions present a complex challenge for Wankel technology. The high operating temperatures of rotary engines promote NOx formation, yet conventional NOx reduction strategies like exhaust gas recirculation (EGR) can exacerbate the already problematic hydrocarbon emissions. This creates a technical dilemma where addressing one emission type often worsens another.

Cold-start emissions are particularly problematic for Wankel engines. The large surface area-to-volume ratio of the combustion chamber leads to significant heat loss during startup, resulting in extended periods of incomplete combustion and elevated emissions before reaching optimal operating temperature. This characteristic makes meeting the increasingly strict cold-start emission requirements particularly challenging.

The thermal efficiency limitations of Wankel engines directly impact CO2 emissions. With typical thermal efficiencies ranging from 15-25% compared to modern piston engines achieving 35-40%, Wankel engines produce more CO2 per unit of power output. As global regulations increasingly focus on greenhouse gas reduction, this efficiency gap represents a significant hurdle for rotary technology.

Catalyst technology compatibility presents additional challenges. The higher exhaust temperatures and unique emission profile of Wankel engines require specialized catalytic converter designs. Standard three-way catalysts often demonstrate reduced durability and conversion efficiency when applied to rotary engines without significant modifications to account for these differences.

The combustion chamber geometry of Wankel engines presents a fundamental challenge for emissions control. The elongated combustion chamber creates thermal inefficiencies and incomplete combustion, resulting in higher hydrocarbon (HC) emissions compared to conventional piston engines. This geometric constraint leads to fuel being trapped in the rotor housing crevices, where it escapes the combustion process and exits as unburned hydrocarbons.

Oil consumption represents another critical emission challenge. The apex seals in Wankel engines require continuous lubrication, resulting in oil being introduced into the combustion chamber. This oil is partially burned during operation, contributing to particulate matter (PM) emissions and increased hydrocarbon levels. Modern emission standards, particularly Euro 6d and EPA Tier 3, have established stringent limits for these pollutants that are challenging for rotary engine designs to meet.

Nitrogen oxide (NOx) emissions present a complex challenge for Wankel technology. The high operating temperatures of rotary engines promote NOx formation, yet conventional NOx reduction strategies like exhaust gas recirculation (EGR) can exacerbate the already problematic hydrocarbon emissions. This creates a technical dilemma where addressing one emission type often worsens another.

Cold-start emissions are particularly problematic for Wankel engines. The large surface area-to-volume ratio of the combustion chamber leads to significant heat loss during startup, resulting in extended periods of incomplete combustion and elevated emissions before reaching optimal operating temperature. This characteristic makes meeting the increasingly strict cold-start emission requirements particularly challenging.

The thermal efficiency limitations of Wankel engines directly impact CO2 emissions. With typical thermal efficiencies ranging from 15-25% compared to modern piston engines achieving 35-40%, Wankel engines produce more CO2 per unit of power output. As global regulations increasingly focus on greenhouse gas reduction, this efficiency gap represents a significant hurdle for rotary technology.

Catalyst technology compatibility presents additional challenges. The higher exhaust temperatures and unique emission profile of Wankel engines require specialized catalytic converter designs. Standard three-way catalysts often demonstrate reduced durability and conversion efficiency when applied to rotary engines without significant modifications to account for these differences.

Existing Emission Benchmarking Methodologies

01 Emission control systems for Wankel engines

Various emission control systems have been developed specifically for Wankel engines to reduce harmful exhaust emissions. These systems include catalytic converters, exhaust gas recirculation (EGR) systems, and specialized aftertreatment devices designed to address the unique combustion characteristics of rotary engines. These technologies help Wankel engines meet increasingly stringent emission standards by effectively treating exhaust gases before they are released into the atmosphere.- Emission control systems for Wankel engines: Various emission control systems have been developed specifically for Wankel engines to reduce harmful exhaust emissions. These systems include catalytic converters, exhaust gas recirculation (EGR) systems, and specialized aftertreatment devices designed to address the unique combustion characteristics of rotary engines. These technologies help Wankel engines meet increasingly stringent emission standards by effectively treating exhaust gases before they are released into the atmosphere.

- Combustion chamber design improvements: Innovations in the combustion chamber design of Wankel engines have been developed to improve combustion efficiency and reduce emissions. These include modifications to the rotor geometry, housing configuration, and sealing systems. By optimizing the combustion chamber shape and improving the sealing between chambers, more complete combustion can be achieved, resulting in lower hydrocarbon and carbon monoxide emissions while improving fuel efficiency.

- Fuel injection and ignition system enhancements: Advanced fuel injection and ignition systems have been developed for Wankel engines to optimize the air-fuel mixture and combustion timing. These systems include direct injection technology, variable timing ignition, and multiple spark plug configurations. By precisely controlling fuel delivery and ignition timing, these enhancements help reduce emissions by promoting more complete combustion and minimizing the formation of pollutants during the combustion process.

- Thermal management solutions: Thermal management solutions have been developed to address the unique cooling challenges of Wankel engines and their impact on emissions. These include advanced cooling systems, heat recovery mechanisms, and thermal barrier coatings. By maintaining optimal operating temperatures throughout the engine, these solutions help prevent overheating issues that can lead to increased emissions, while also improving overall engine efficiency and durability.

- Alternative fuel adaptations: Wankel engines have been adapted to operate on alternative fuels to reduce emissions. These adaptations include modifications for hydrogen, natural gas, biofuels, and even electric hybrid configurations. The unique characteristics of the Wankel engine make it particularly suitable for certain alternative fuels, potentially offering significant emissions benefits compared to traditional gasoline or diesel operation while maintaining the rotary engine's inherent advantages of compact size and smooth operation.

02 Combustion chamber design improvements

Innovations in the combustion chamber design of Wankel engines have been implemented to improve combustion efficiency and reduce emissions. These improvements include modified rotor geometry, optimized chamber shapes, and enhanced sealing systems that minimize leakage. By improving the combustion process, these design enhancements lead to more complete fuel burning, resulting in lower levels of unburned hydrocarbons and carbon monoxide in the exhaust emissions.Expand Specific Solutions03 Fuel injection and mixture formation technologies

Advanced fuel injection systems and mixture formation technologies have been developed for Wankel engines to optimize the air-fuel ratio and improve combustion efficiency. These include direct injection systems, stratified charge configurations, and precise electronic control of fuel delivery. By ensuring more complete combustion and better fuel atomization, these technologies significantly reduce emissions of unburned hydrocarbons and particulate matter while improving overall engine efficiency.Expand Specific Solutions04 Thermal management solutions

Thermal management solutions have been developed to address the unique cooling challenges of Wankel engines and their impact on emissions. These include advanced cooling systems, heat recovery mechanisms, and thermal barrier coatings that help maintain optimal operating temperatures. Proper thermal management prevents overheating of engine components, reduces oil consumption, and minimizes the formation of nitrogen oxides (NOx) emissions by controlling combustion temperatures.Expand Specific Solutions05 Hybrid and alternative fuel adaptations

Wankel engines have been adapted to work with hybrid powertrains and alternative fuels to reduce emissions. These adaptations include integration with electric motors in hybrid configurations, modifications for hydrogen fuel operation, and compatibility with biofuels. By leveraging the compact size and smooth operation of Wankel engines in combination with cleaner energy sources or electrification, these approaches significantly reduce carbon dioxide and other harmful emissions compared to conventional rotary engine designs.Expand Specific Solutions

Key Manufacturers and Research Institutions

The Wankel engine emission benchmarking landscape is currently in a growth phase, with an estimated market size of $300-500 million annually. The technology maturity varies significantly across key players, with established automotive giants like GM Global Technology Operations and Robert Bosch GmbH leading with advanced emission control solutions. Specialized testing equipment providers such as HORIBA Instruments and HORIBA MIRA offer sophisticated benchmarking tools, while research institutions like China Automotive Technology & Research Center and IFP Energies Nouvelles contribute significant R&D advancements. Asian manufacturers including Weichai Power and Dongfeng Cummins are rapidly closing the technology gap, particularly in cost-effective emission reduction systems. The competitive landscape is further shaped by stringent global emission regulations driving innovation in rotary engine technology.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed comprehensive emission testing systems specifically adapted for Wankel engines, focusing on their unique combustion characteristics. Their approach integrates real-time monitoring systems with specialized sensors designed to accurately measure the triangular rotor engine's emissions profile. Bosch's technology employs advanced gas analyzers capable of detecting hydrocarbons, NOx, CO, and particulate matter with high precision despite the Wankel's distinctive combustion chamber geometry. Their benchmarking methodology incorporates both laboratory dynamometer testing and real-world driving cycles to establish correlations between controlled and actual operating conditions. Bosch has also pioneered specialized fuel injection systems for Wankel engines that significantly reduce hydrocarbon emissions by optimizing the fuel spray pattern to match the elongated combustion chamber.

Strengths: Industry-leading sensor technology with exceptional accuracy for rotary engine applications; comprehensive testing protocols that account for Wankel-specific emission characteristics. Weaknesses: Higher implementation costs compared to conventional engine testing systems; requires specialized calibration for different Wankel engine variants.

HORIBA Instruments, Inc.

Technical Solution: HORIBA has developed specialized emission measurement systems tailored for Wankel engine testing, addressing the unique challenges posed by rotary engine combustion dynamics. Their MEXA series gas analyzers have been adapted with specific sampling protocols to accurately capture the emissions profile of Wankel engines, which differ significantly from reciprocating engines due to their continuous combustion process and distinctive chamber geometry. HORIBA's approach incorporates high-frequency sampling techniques to capture the rapid emission fluctuations characteristic of rotary engines, particularly during transitional operating states. Their systems feature specialized thermal management for sample lines to prevent hydrocarbon condensation—a critical factor in Wankel testing due to higher unburned hydrocarbon emissions. Additionally, HORIBA has developed specific test cycles that account for the Wankel engine's unique power delivery characteristics and thermal behavior, enabling more accurate benchmarking against conventional engines.

Strengths: Unparalleled expertise in emission measurement equipment with systems specifically calibrated for rotary engine characteristics; comprehensive global testing standards compliance. Weaknesses: High equipment acquisition costs; requires specialized technical expertise for proper implementation and data interpretation.

Critical Patents in Wankel Emission Reduction

Rotary internal combustion engine

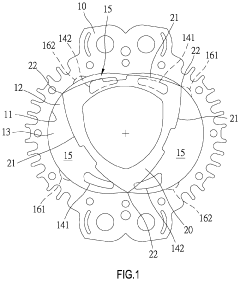

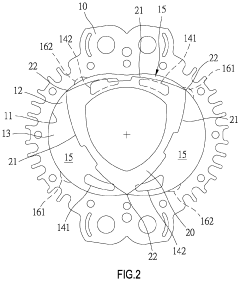

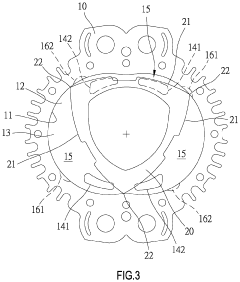

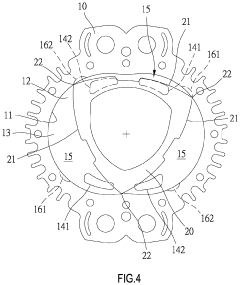

PatentActiveUS20180045110A1

Innovation

- The implementation of a rotary engine design with a primary inlet port, a secondary inlet port (purge port) positioned rearwardly of the primary inlet port and forwardly of the exhaust port, and independently closable communications between air sources and these ports, allowing simultaneous air intake and exhaust gas purging through the secondary inlet port.

Pistonless rotary motor for air compressor

PatentActiveUS20220282622A1

Innovation

- Incorporating radially spaced grooves in the peripheral wall of the rotor cavity, with first grooves configured to release pressurized air at the top dead center during the compression stroke and second grooves for releasing air during the exhaust stroke, allowing for controlled pressure management and reduced air resistance.

Regulatory Compliance Framework

Regulatory compliance for Wankel engine emissions benchmarking operates within a complex framework of international, national, and regional standards that manufacturers must navigate. The global landscape is dominated by three major regulatory regimes: the European Union's Euro standards, the United States EPA regulations, and Japan's emission control standards. Each jurisdiction implements increasingly stringent limits on pollutants including carbon monoxide (CO), nitrogen oxides (NOx), hydrocarbons (HC), and particulate matter (PM).

The EU's Euro standards have progressed through multiple iterations, with Euro 6d currently representing the most demanding requirements for light-duty vehicles. These standards incorporate both laboratory testing via the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and real-world driving emissions (RDE) testing to address the historical discrepancy between laboratory and on-road performance.

In the United States, the EPA's Tier 3 standards work in conjunction with California Air Resources Board (CARB) regulations, which often establish more rigorous requirements that subsequently influence federal standards. The EPA's testing protocols include the Federal Test Procedure (FTP-75) and the Supplemental Federal Test Procedure (SFTP), designed to evaluate emissions under various driving conditions.

For Wankel engines specifically, compliance presents unique challenges due to their distinctive combustion characteristics. The rotary design creates elongated combustion chambers that can lead to higher hydrocarbon emissions from unburned fuel in the exhaust. Additionally, the engine's inherent oil consumption contributes to particulate matter emissions that must be carefully managed to meet current standards.

Benchmarking protocols must incorporate specialized testing methodologies that account for these unique characteristics. This includes modified cold-start procedures, extended high-speed operation assessments, and particular attention to oil consumption rates during emissions testing. The correlation between laboratory results and real-world performance requires careful calibration of testing equipment and procedures.

Manufacturers must also consider future regulatory developments, including the potential phase-out of internal combustion engines in various markets and increasingly strict CO2 emission targets linked to climate change mitigation efforts. Several jurisdictions have announced plans to ban sales of new internal combustion vehicles between 2030 and 2040, creating a critical timeline for Wankel engine development or hybridization strategies.

Effective emissions benchmarking therefore requires not only compliance with current standards but also anticipation of regulatory evolution across global markets, necessitating a forward-looking approach to Wankel engine development and emissions control technologies.

The EU's Euro standards have progressed through multiple iterations, with Euro 6d currently representing the most demanding requirements for light-duty vehicles. These standards incorporate both laboratory testing via the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and real-world driving emissions (RDE) testing to address the historical discrepancy between laboratory and on-road performance.

In the United States, the EPA's Tier 3 standards work in conjunction with California Air Resources Board (CARB) regulations, which often establish more rigorous requirements that subsequently influence federal standards. The EPA's testing protocols include the Federal Test Procedure (FTP-75) and the Supplemental Federal Test Procedure (SFTP), designed to evaluate emissions under various driving conditions.

For Wankel engines specifically, compliance presents unique challenges due to their distinctive combustion characteristics. The rotary design creates elongated combustion chambers that can lead to higher hydrocarbon emissions from unburned fuel in the exhaust. Additionally, the engine's inherent oil consumption contributes to particulate matter emissions that must be carefully managed to meet current standards.

Benchmarking protocols must incorporate specialized testing methodologies that account for these unique characteristics. This includes modified cold-start procedures, extended high-speed operation assessments, and particular attention to oil consumption rates during emissions testing. The correlation between laboratory results and real-world performance requires careful calibration of testing equipment and procedures.

Manufacturers must also consider future regulatory developments, including the potential phase-out of internal combustion engines in various markets and increasingly strict CO2 emission targets linked to climate change mitigation efforts. Several jurisdictions have announced plans to ban sales of new internal combustion vehicles between 2030 and 2040, creating a critical timeline for Wankel engine development or hybridization strategies.

Effective emissions benchmarking therefore requires not only compliance with current standards but also anticipation of regulatory evolution across global markets, necessitating a forward-looking approach to Wankel engine development and emissions control technologies.

Comparative Analysis with Conventional Engines

When benchmarking Wankel engine emissions, a comprehensive comparative analysis with conventional engines is essential to understand its environmental performance in context. The rotary Wankel engine fundamentally differs from reciprocating piston engines in combustion dynamics, which directly impacts emission profiles.

Conventional piston engines, whether gasoline or diesel, operate with well-defined combustion chambers and relatively consistent thermal conditions. In contrast, the Wankel's elongated combustion chamber creates varying thermal zones that affect combustion efficiency and emission formation. This geometric difference results in distinctive hydrocarbon (HC) emission patterns, with Wankel engines historically producing higher unburned hydrocarbon emissions due to combustion chamber crevices and seal leakage.

Nitrogen oxide (NOx) emissions present another significant contrast point. Piston engines typically generate higher NOx levels due to higher peak combustion temperatures, while Wankel engines often show lower NOx but elevated carbon monoxide (CO) emissions. This trade-off stems from the Wankel's unique combustion characteristics and represents a critical comparison metric in benchmarking studies.

Particulate matter emissions also differ substantially between engine types. Diesel piston engines traditionally produce higher particulate emissions than gasoline engines, while Wankel engines generally emit fewer particulates than comparable diesel engines but may exceed modern gasoline direct injection systems under certain operating conditions.

Cold-start emissions behavior provides another essential comparison point. Wankel engines typically reach operating temperature more rapidly than conventional engines due to their compact design and higher surface-to-volume ratio, potentially offering advantages in real-world driving cycles where cold-start emissions constitute a significant portion of total emissions.

Fuel efficiency must be evaluated alongside emissions, as the Wankel's historically lower thermal efficiency affects its overall environmental impact. Modern improvements in apex seal technology and combustion chamber design have narrowed this gap, but comparative analysis must account for the emissions-per-kilometer metric rather than solely focusing on emissions-per-combustion-cycle.

Emissions aftertreatment compatibility represents another crucial comparison factor. Conventional engines benefit from decades of catalytic converter optimization, while Wankel engines may require specialized catalyst formulations to address their unique exhaust gas composition and temperature profiles. This technological adaptation gap must be quantified in comprehensive benchmarking studies.

Conventional piston engines, whether gasoline or diesel, operate with well-defined combustion chambers and relatively consistent thermal conditions. In contrast, the Wankel's elongated combustion chamber creates varying thermal zones that affect combustion efficiency and emission formation. This geometric difference results in distinctive hydrocarbon (HC) emission patterns, with Wankel engines historically producing higher unburned hydrocarbon emissions due to combustion chamber crevices and seal leakage.

Nitrogen oxide (NOx) emissions present another significant contrast point. Piston engines typically generate higher NOx levels due to higher peak combustion temperatures, while Wankel engines often show lower NOx but elevated carbon monoxide (CO) emissions. This trade-off stems from the Wankel's unique combustion characteristics and represents a critical comparison metric in benchmarking studies.

Particulate matter emissions also differ substantially between engine types. Diesel piston engines traditionally produce higher particulate emissions than gasoline engines, while Wankel engines generally emit fewer particulates than comparable diesel engines but may exceed modern gasoline direct injection systems under certain operating conditions.

Cold-start emissions behavior provides another essential comparison point. Wankel engines typically reach operating temperature more rapidly than conventional engines due to their compact design and higher surface-to-volume ratio, potentially offering advantages in real-world driving cycles where cold-start emissions constitute a significant portion of total emissions.

Fuel efficiency must be evaluated alongside emissions, as the Wankel's historically lower thermal efficiency affects its overall environmental impact. Modern improvements in apex seal technology and combustion chamber design have narrowed this gap, but comparative analysis must account for the emissions-per-kilometer metric rather than solely focusing on emissions-per-combustion-cycle.

Emissions aftertreatment compatibility represents another crucial comparison factor. Conventional engines benefit from decades of catalytic converter optimization, while Wankel engines may require specialized catalyst formulations to address their unique exhaust gas composition and temperature profiles. This technological adaptation gap must be quantified in comprehensive benchmarking studies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!