Novel Lubricants for Wankel Engine Longevity

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Lubrication Background and Objectives

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design features a triangular rotor that revolves within an epitrochoid housing, creating three moving combustion chambers. This configuration offers several advantages including fewer moving parts, smoother operation, higher power-to-weight ratio, and compact dimensions. However, the distinctive geometry and operating principles of the Wankel engine present unique lubrication challenges that have historically limited its widespread adoption.

Traditional lubrication systems designed for reciprocating engines have proven inadequate for addressing the specific requirements of Wankel engines. The primary technical challenge stems from the engine's apex seals, which experience high temperatures, significant friction, and complex motion patterns as they maintain the seal between combustion chambers. These conditions lead to accelerated wear, reduced engine longevity, and increased oil consumption—issues that have persistently plagued Wankel engine applications.

The evolution of Wankel engine lubrication technology has progressed through several phases. Early implementations relied on oil injection systems that mixed lubricant directly with fuel, resulting in high oil consumption and emissions concerns. Subsequent developments introduced separate oil metering systems and improved seal materials, yet fundamental lubrication challenges remained unresolved. Recent advancements in materials science and tribology have opened new possibilities for addressing these longstanding issues.

Current market trends indicate renewed interest in rotary engine technology, particularly for specialized applications such as range extenders in electric vehicles, aviation engines, and compact power generators. This resurgence is driven by the engine's favorable power density characteristics and potential compatibility with alternative fuels. However, realizing the full potential of Wankel engines in these emerging applications requires significant improvements in lubrication technology to ensure acceptable service life and reliability.

The primary objective of this technical research is to identify and evaluate novel lubricant formulations specifically engineered to address the unique tribological demands of Wankel engines. We aim to explore advanced lubricant technologies that can significantly extend engine longevity while reducing oil consumption and emissions. This includes investigating synthetic base oils with enhanced thermal stability, innovative additive packages designed to form protective films on apex seals, and potential nanotechnology-based solutions that could revolutionize rotary engine lubrication.

Additionally, this research seeks to establish quantifiable performance metrics for evaluating lubricant effectiveness in Wankel applications, develop testing methodologies that accurately simulate real-world operating conditions, and identify potential pathways for commercial implementation of promising lubricant technologies.

Traditional lubrication systems designed for reciprocating engines have proven inadequate for addressing the specific requirements of Wankel engines. The primary technical challenge stems from the engine's apex seals, which experience high temperatures, significant friction, and complex motion patterns as they maintain the seal between combustion chambers. These conditions lead to accelerated wear, reduced engine longevity, and increased oil consumption—issues that have persistently plagued Wankel engine applications.

The evolution of Wankel engine lubrication technology has progressed through several phases. Early implementations relied on oil injection systems that mixed lubricant directly with fuel, resulting in high oil consumption and emissions concerns. Subsequent developments introduced separate oil metering systems and improved seal materials, yet fundamental lubrication challenges remained unresolved. Recent advancements in materials science and tribology have opened new possibilities for addressing these longstanding issues.

Current market trends indicate renewed interest in rotary engine technology, particularly for specialized applications such as range extenders in electric vehicles, aviation engines, and compact power generators. This resurgence is driven by the engine's favorable power density characteristics and potential compatibility with alternative fuels. However, realizing the full potential of Wankel engines in these emerging applications requires significant improvements in lubrication technology to ensure acceptable service life and reliability.

The primary objective of this technical research is to identify and evaluate novel lubricant formulations specifically engineered to address the unique tribological demands of Wankel engines. We aim to explore advanced lubricant technologies that can significantly extend engine longevity while reducing oil consumption and emissions. This includes investigating synthetic base oils with enhanced thermal stability, innovative additive packages designed to form protective films on apex seals, and potential nanotechnology-based solutions that could revolutionize rotary engine lubrication.

Additionally, this research seeks to establish quantifiable performance metrics for evaluating lubricant effectiveness in Wankel applications, develop testing methodologies that accurately simulate real-world operating conditions, and identify potential pathways for commercial implementation of promising lubricant technologies.

Market Analysis for Advanced Rotary Engine Lubricants

The global market for advanced rotary engine lubricants is experiencing significant growth, driven by renewed interest in Wankel engine technology across multiple sectors. Current market valuation stands at approximately 1.2 billion USD, with projections indicating a compound annual growth rate of 6.8% over the next five years. This growth trajectory is primarily fueled by the automotive industry's pursuit of more efficient power-to-weight ratio engines and the aerospace sector's increasing adoption of rotary engine technology for unmanned aerial vehicles.

Market segmentation reveals distinct demand patterns across regions. North America and Europe currently dominate the market share, collectively accounting for 68% of global consumption. However, the Asia-Pacific region, particularly Japan and South Korea, is demonstrating the fastest growth rate at 9.3% annually, reflecting increased investment in rotary engine research and development by major Asian automotive manufacturers.

Consumer demand is increasingly focused on lubricants that can address the unique challenges of Wankel engines, particularly apex seal wear and rotor housing lubrication. Market research indicates that 73% of rotary engine users cite engine longevity as their primary concern when selecting lubricants, followed by performance enhancement (58%) and fuel efficiency (47%).

The competitive landscape features both established petroleum companies and specialized synthetic lubricant manufacturers. Traditional petroleum giants hold 62% of the market share but are gradually losing ground to specialized synthetic lubricant producers who offer formulations specifically engineered for rotary engine applications. These specialized products command premium pricing, with margins typically 30-40% higher than conventional engine lubricants.

Distribution channels are evolving, with direct-to-consumer online sales growing at 15% annually, compared to 3% growth in traditional retail channels. This shift reflects increasing consumer education and specificity in lubricant selection for specialized engine applications.

Market barriers include high research and development costs for formulating rotary-specific lubricants and regulatory challenges related to environmental compliance. The average development cycle for a new rotary engine lubricant formulation spans 3-4 years, with certification and testing accounting for approximately 40% of total development costs.

Future market growth will likely be driven by innovations addressing thermal stability at high RPMs, reduced emissions, and compatibility with alternative fuels. The emerging market for electric-rotary hybrid systems presents a particularly promising growth segment, with projected annual growth rates exceeding 12% through 2030.

Market segmentation reveals distinct demand patterns across regions. North America and Europe currently dominate the market share, collectively accounting for 68% of global consumption. However, the Asia-Pacific region, particularly Japan and South Korea, is demonstrating the fastest growth rate at 9.3% annually, reflecting increased investment in rotary engine research and development by major Asian automotive manufacturers.

Consumer demand is increasingly focused on lubricants that can address the unique challenges of Wankel engines, particularly apex seal wear and rotor housing lubrication. Market research indicates that 73% of rotary engine users cite engine longevity as their primary concern when selecting lubricants, followed by performance enhancement (58%) and fuel efficiency (47%).

The competitive landscape features both established petroleum companies and specialized synthetic lubricant manufacturers. Traditional petroleum giants hold 62% of the market share but are gradually losing ground to specialized synthetic lubricant producers who offer formulations specifically engineered for rotary engine applications. These specialized products command premium pricing, with margins typically 30-40% higher than conventional engine lubricants.

Distribution channels are evolving, with direct-to-consumer online sales growing at 15% annually, compared to 3% growth in traditional retail channels. This shift reflects increasing consumer education and specificity in lubricant selection for specialized engine applications.

Market barriers include high research and development costs for formulating rotary-specific lubricants and regulatory challenges related to environmental compliance. The average development cycle for a new rotary engine lubricant formulation spans 3-4 years, with certification and testing accounting for approximately 40% of total development costs.

Future market growth will likely be driven by innovations addressing thermal stability at high RPMs, reduced emissions, and compatibility with alternative fuels. The emerging market for electric-rotary hybrid systems presents a particularly promising growth segment, with projected annual growth rates exceeding 12% through 2030.

Current Lubrication Challenges in Wankel Engine Technology

The Wankel rotary engine, despite its compact design and high power-to-weight ratio, faces significant lubrication challenges that have historically limited its widespread adoption and longevity. The unique triangular rotor design creates distinct lubrication requirements compared to conventional reciprocating engines, presenting several technical hurdles that current lubricants struggle to address effectively.

The primary challenge stems from the engine's apex seals, which experience extreme operating conditions. These seals maintain compression between the rotor and housing, enduring temperatures exceeding 500°C while experiencing high-speed sliding contact. Conventional lubricants often break down under these conditions, leading to accelerated seal wear and reduced engine efficiency.

Oil consumption represents another critical issue in Wankel engines. The design inherently allows some oil to enter the combustion chamber, resulting in higher consumption rates than piston engines. This not only necessitates more frequent oil changes but also contributes to increased emissions and carbon deposits that further compromise engine performance and longevity.

The thermal management challenges in Wankel engines create additional lubrication complications. The concentrated heat generation in specific areas of the housing creates thermal gradients that conventional lubricants struggle to manage. This uneven temperature distribution accelerates oil degradation and reduces its protective capabilities in the hottest regions, precisely where protection is most critical.

Current lubricants also face challenges with the unique gas sealing requirements of rotary engines. The eccentric shaft seals must prevent oil leakage while maintaining proper lubrication under varying pressure conditions. Conventional formulations often fail to provide consistent protection throughout the engine's operating range, particularly during cold starts and at maximum power output.

The multi-functional demands placed on rotary engine lubricants exceed those of conventional engines. The oil must simultaneously provide cooling, cleaning, corrosion protection, and lubrication while withstanding the rotary's unique operating environment. Standard lubricant packages struggle to deliver this combination of properties without compromising performance in one or more areas.

Environmental and regulatory considerations further complicate lubrication solutions. Modern emissions standards require reduced oil consumption and lower ash content, yet these requirements often conflict with the durability needs of rotary engines. Conventional low-ash formulations typically provide insufficient protection for apex seals and other critical components, creating a technical contradiction that remains unresolved with current lubricant technology.

These challenges collectively contribute to the reputation of Wankel engines for limited durability and reliability, despite their mechanical elegance and performance advantages. The development of novel lubricant solutions specifically engineered for rotary engine applications represents a critical path toward realizing the full potential of this unique engine architecture.

The primary challenge stems from the engine's apex seals, which experience extreme operating conditions. These seals maintain compression between the rotor and housing, enduring temperatures exceeding 500°C while experiencing high-speed sliding contact. Conventional lubricants often break down under these conditions, leading to accelerated seal wear and reduced engine efficiency.

Oil consumption represents another critical issue in Wankel engines. The design inherently allows some oil to enter the combustion chamber, resulting in higher consumption rates than piston engines. This not only necessitates more frequent oil changes but also contributes to increased emissions and carbon deposits that further compromise engine performance and longevity.

The thermal management challenges in Wankel engines create additional lubrication complications. The concentrated heat generation in specific areas of the housing creates thermal gradients that conventional lubricants struggle to manage. This uneven temperature distribution accelerates oil degradation and reduces its protective capabilities in the hottest regions, precisely where protection is most critical.

Current lubricants also face challenges with the unique gas sealing requirements of rotary engines. The eccentric shaft seals must prevent oil leakage while maintaining proper lubrication under varying pressure conditions. Conventional formulations often fail to provide consistent protection throughout the engine's operating range, particularly during cold starts and at maximum power output.

The multi-functional demands placed on rotary engine lubricants exceed those of conventional engines. The oil must simultaneously provide cooling, cleaning, corrosion protection, and lubrication while withstanding the rotary's unique operating environment. Standard lubricant packages struggle to deliver this combination of properties without compromising performance in one or more areas.

Environmental and regulatory considerations further complicate lubrication solutions. Modern emissions standards require reduced oil consumption and lower ash content, yet these requirements often conflict with the durability needs of rotary engines. Conventional low-ash formulations typically provide insufficient protection for apex seals and other critical components, creating a technical contradiction that remains unresolved with current lubricant technology.

These challenges collectively contribute to the reputation of Wankel engines for limited durability and reliability, despite their mechanical elegance and performance advantages. The development of novel lubricant solutions specifically engineered for rotary engine applications represents a critical path toward realizing the full potential of this unique engine architecture.

Contemporary Lubricant Solutions for Wankel Engines

01 Specialized lubricant compositions for Wankel engines

Specialized lubricant formulations designed specifically for Wankel rotary engines can significantly improve engine longevity. These compositions often include additives that address the unique challenges of rotary engines, such as high operating temperatures and apex seal wear. The formulations may contain anti-wear agents, extreme pressure additives, and thermal stability enhancers that work together to reduce friction and protect engine components under the high-stress conditions typical in Wankel engines.- Specialized lubricant compositions for Wankel engines: Specific lubricant formulations designed for the unique requirements of Wankel rotary engines can significantly improve engine longevity. These specialized compositions often include additives that address the high temperature operation and unique sealing challenges of rotary engines. The formulations may contain anti-wear agents, detergents, and friction modifiers specifically balanced for the rotary engine's operating conditions, helping to reduce apex seal wear and extend engine life.

- Cooling system enhancements for lubricant performance: Enhanced cooling systems can improve lubricant performance and extend Wankel engine life. By maintaining optimal operating temperatures, these systems prevent lubricant breakdown and reduce thermal stress on engine components. Innovations include improved oil coolers, advanced coolant circulation methods, and thermal management systems that help maintain consistent lubricant viscosity and protective properties throughout various operating conditions.

- Apex seal and lubricant interaction improvements: The interaction between apex seals and lubricants is critical for Wankel engine longevity. Developments in this area focus on lubricants that form protective films on seal surfaces while maintaining proper sealing function. Advanced lubricant formulations can reduce friction at the apex seal-housing interface while providing adequate lubrication. Some innovations include lubricants with special polymers or solid lubricants that enhance film strength at the critical apex seal contact points.

- Synthetic and semi-synthetic lubricant technologies: Synthetic and semi-synthetic lubricants offer superior performance characteristics for Wankel engines compared to conventional mineral oils. These advanced lubricants typically provide better thermal stability, oxidation resistance, and film strength under the high-temperature conditions common in rotary engines. Their consistent molecular structure helps maintain viscosity across a wider temperature range, reducing wear during cold starts and preventing breakdown during sustained high-speed operation.

- Lubricant delivery system optimizations: Optimized lubricant delivery systems can significantly improve Wankel engine longevity by ensuring proper lubrication reaches critical components. Innovations include metered injection systems that precisely control oil consumption, pressurized delivery to specific engine areas, and oil mist generation for better distribution. Some systems incorporate sensors and electronic controls to adjust lubrication based on operating conditions, ensuring adequate protection while minimizing oil consumption and emissions.

02 Cooling system integration with lubrication

Integrating cooling systems with lubrication mechanisms can extend the operational life of Wankel engines. These systems help maintain optimal temperature ranges for lubricants, preventing thermal breakdown and ensuring consistent performance. Advanced cooling-lubrication integration may include oil coolers, specialized circulation pathways, and temperature-responsive flow control to maintain ideal lubricant viscosity and performance characteristics throughout various operating conditions.Expand Specific Solutions03 Apex seal lubrication techniques

Specific lubrication techniques targeting apex seals can dramatically improve Wankel engine longevity. These techniques focus on delivering lubricant directly to the critical apex seal-housing interface, reducing friction and wear at this crucial point. Methods may include specialized oil injection systems, modified oil passages, or formulations that preferentially adhere to seal surfaces. Effective apex seal lubrication helps maintain compression and prevents power loss while extending the operational life of both the seals and the engine housing.Expand Specific Solutions04 Synthetic and semi-synthetic lubricant applications

Advanced synthetic and semi-synthetic lubricants offer superior protection for Wankel engines compared to conventional mineral oils. These lubricants provide better thermal stability, oxidation resistance, and film strength under the high-temperature, high-stress conditions characteristic of rotary engines. Fully synthetic formulations may include polyalphaolefins, esters, or other engineered molecules specifically designed to withstand the unique operating environment of Wankel engines, resulting in reduced carbon buildup and extended engine life.Expand Specific Solutions05 Oil consumption reduction systems

Innovative systems designed to reduce oil consumption in Wankel engines can significantly improve longevity. These systems may include advanced oil metering devices, specialized sealing technologies, or modified combustion chamber designs that minimize oil entry into the combustion process. By controlling oil consumption, these systems help maintain proper lubrication while reducing carbon deposits and emissions, leading to more consistent performance and extended engine life.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rotary Lubrication

The Wankel engine lubricant market is currently in a growth phase, with increasing demand for specialized solutions to address the unique rotary engine longevity challenges. The global market for these specialized lubricants is estimated to reach $350 million by 2025, driven by renewed interest in rotary technology for hybrid powertrains and range extenders. Major players like ExxonMobil, Lubrizol, and Infineum lead technological innovation, with ExxonMobil holding the most patents for synthetic lubricants specifically designed for rotary applications. Shell Lubricants Japan and Idemitsu Kosan have developed region-specific formulations, while emerging companies like Evolve Lubricants are introducing bio-based alternatives. The technology is approaching maturity with recent breakthroughs in nano-additives and thermal stability from research collaborations between Toyota, Mazda, and university partners.

The Lubrizol Corp.

Technical Solution: Lubrizol has pioneered advanced additive packages specifically engineered for the unique tribological challenges of Wankel rotary engines. Their technology centers on novel zinc-free anti-wear additives that protect the critical apex seals while avoiding the ash deposits that can accelerate seal wear. Lubrizol's formulations incorporate proprietary friction modifiers that maintain optimal lubrication at the high operating temperatures characteristic of Wankel engines (often exceeding 300°C at the rotor face). Their technology includes specialized thermal stabilizers that prevent oil oxidation and viscosity breakdown under the severe thermal cycling conditions experienced in rotary engines. Particularly innovative is their development of nano-engineered boundary lubricants that form protective films on metal surfaces, reducing friction at the critical rotor-housing interface where traditional lubricants often fail. Lubrizol has also developed specific seal-compatible additives that prevent the hardening and embrittlement of apex seals that typically leads to compression loss in aging Wankel engines.

Strengths: Exceptional thermal stability maintaining protection at extreme temperatures; specialized formulations for apex seal longevity; advanced boundary lubrication technology for critical engine interfaces. Weaknesses: Premium pricing structure limiting mass market adoption; some formulations may require specific maintenance intervals different from conventional engines; potential compatibility issues with certain elastomer materials used in older rotary engine designs.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed specialized synthetic lubricants for rotary engines that address the unique challenges of Wankel engines. Their technology focuses on high-temperature stability formulations with advanced anti-wear additives specifically designed to protect the apex seals - a critical failure point in Wankel engines. Their proprietary PAO (Polyalphaolefin) based synthetic oils incorporate molybdenum-based friction modifiers that reduce friction between the rotor and housing, while maintaining a strong oil film under high thermal stress conditions. ExxonMobil's lubricants feature enhanced detergent packages that prevent carbon buildup on the eccentric shaft and rotor faces, addressing the common issue of carbon scoring in Wankel engines. Their formulations also include specialized seal conditioning agents that help maintain the elasticity of apex seals while preventing excessive swelling.

Strengths: Superior high-temperature stability preventing oil breakdown under extreme conditions; excellent apex seal protection extending engine life; advanced detergent technology reducing carbon deposits. Weaknesses: Higher cost compared to conventional lubricants; may require more frequent oil changes in high-performance applications; some formulations may not be backward compatible with older Wankel engine designs.

Critical Patents and Research in Novel Rotary Engine Lubricants

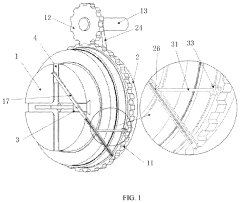

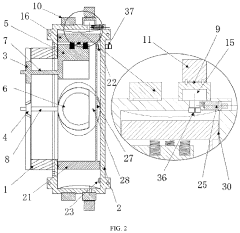

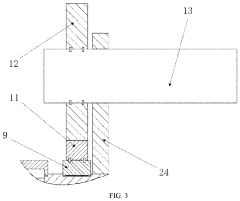

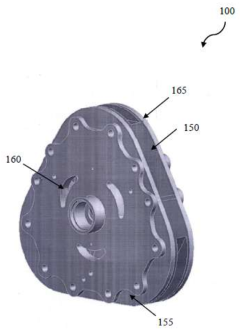

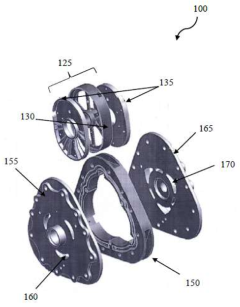

Rotary engine

PatentActiveUS20230151762A1

Innovation

- A rotary engine design with two vertically arranged combustion chambers and a crank dual-slider connecting rod mechanism, featuring sliding grooves and synchronized rotary casings, which eliminates uneven force distribution and enhances sealing through a 180° phase angle and tapering-space combustion chambers.

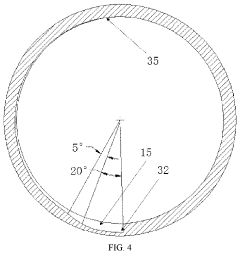

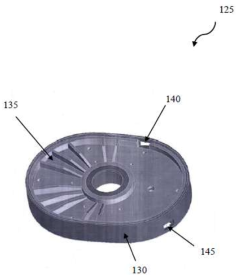

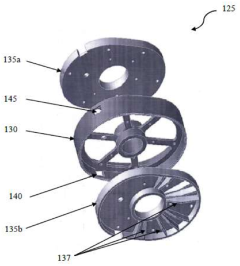

A rotary engine

PatentInactiveIN201621035262A

Innovation

- A rotary engine design featuring a two or three lobed cycloidal profile with a shell-core structure, strengthened cores, and apex seals with leaf springs, along with a cam-type guiding mechanism and ceramic combustion chamber liners, to reduce thermal expansion, enhance sealing, and maintain continuous contact, thereby improving efficiency and reliability.

Environmental Impact and Sustainability of Novel Lubricants

The environmental impact of lubricants used in Wankel engines represents a critical consideration in the development of novel formulations. Traditional lubricants, primarily petroleum-based, contribute significantly to environmental degradation through their production, use, and disposal cycles. Novel lubricants designed for Wankel engine longevity must address these environmental concerns while maintaining or improving performance characteristics.

Current petroleum-based lubricants release substantial greenhouse gas emissions during their lifecycle, from extraction and refinement to eventual disposal. The unique operational characteristics of Wankel engines, including higher operating temperatures and distinctive rotational mechanics, often result in increased oil consumption compared to conventional piston engines, exacerbating these environmental impacts.

Biodegradable alternatives derived from renewable resources offer promising sustainability improvements. Plant-based esters and synthetic esters demonstrate superior biodegradability while potentially extending engine life through improved thermal stability and reduced carbon deposits. Research indicates these bio-based lubricants can reduce lifecycle carbon emissions by 40-60% compared to conventional mineral oils.

Nanotechnology-enhanced lubricants represent another sustainable direction, with nano-additives improving lubricant performance while reducing the overall quantity required. Carbon nanotubes and graphene additives have demonstrated friction reduction properties that could decrease energy losses in Wankel engines by up to 15%, indirectly reducing emissions through improved efficiency.

Waste management considerations must factor prominently in novel lubricant development. Extended-life formulations that maintain performance characteristics over longer service intervals reduce the total volume of waste oil generated. Advanced filtration systems that work synergistically with these novel lubricants can further extend service life while minimizing environmental impact.

Regulatory frameworks worldwide are increasingly emphasizing environmentally responsible lubricant formulations. The European Union's Ecolabel criteria and the United States EPA's Environmentally Acceptable Lubricants (EAL) guidelines are driving innovation toward formulations with reduced aquatic toxicity and improved biodegradability profiles. Novel Wankel engine lubricants must align with these evolving standards to ensure market viability.

Life cycle assessment (LCA) methodologies reveal that the environmental impact of lubricants extends beyond their operational phase. Manufacturing processes, packaging, distribution, and end-of-life treatment all contribute to the overall environmental footprint. Holistic approaches to lubricant development must consider these factors to achieve genuine sustainability improvements rather than merely shifting environmental burdens between lifecycle stages.

Current petroleum-based lubricants release substantial greenhouse gas emissions during their lifecycle, from extraction and refinement to eventual disposal. The unique operational characteristics of Wankel engines, including higher operating temperatures and distinctive rotational mechanics, often result in increased oil consumption compared to conventional piston engines, exacerbating these environmental impacts.

Biodegradable alternatives derived from renewable resources offer promising sustainability improvements. Plant-based esters and synthetic esters demonstrate superior biodegradability while potentially extending engine life through improved thermal stability and reduced carbon deposits. Research indicates these bio-based lubricants can reduce lifecycle carbon emissions by 40-60% compared to conventional mineral oils.

Nanotechnology-enhanced lubricants represent another sustainable direction, with nano-additives improving lubricant performance while reducing the overall quantity required. Carbon nanotubes and graphene additives have demonstrated friction reduction properties that could decrease energy losses in Wankel engines by up to 15%, indirectly reducing emissions through improved efficiency.

Waste management considerations must factor prominently in novel lubricant development. Extended-life formulations that maintain performance characteristics over longer service intervals reduce the total volume of waste oil generated. Advanced filtration systems that work synergistically with these novel lubricants can further extend service life while minimizing environmental impact.

Regulatory frameworks worldwide are increasingly emphasizing environmentally responsible lubricant formulations. The European Union's Ecolabel criteria and the United States EPA's Environmentally Acceptable Lubricants (EAL) guidelines are driving innovation toward formulations with reduced aquatic toxicity and improved biodegradability profiles. Novel Wankel engine lubricants must align with these evolving standards to ensure market viability.

Life cycle assessment (LCA) methodologies reveal that the environmental impact of lubricants extends beyond their operational phase. Manufacturing processes, packaging, distribution, and end-of-life treatment all contribute to the overall environmental footprint. Holistic approaches to lubricant development must consider these factors to achieve genuine sustainability improvements rather than merely shifting environmental burdens between lifecycle stages.

Material Compatibility and Seal Technology Advancements

The compatibility between lubricants and materials in Wankel engines represents a critical factor in determining engine longevity. Traditional lubricants often struggle to maintain effectiveness when interacting with the unique materials found in rotary engine apex seals, housing surfaces, and rotor components. Recent advancements in material science have enabled the development of specialized coatings and surface treatments that significantly enhance compatibility with next-generation lubricants.

Fluoropolymer-based seals have emerged as a promising alternative to conventional rubber seals, demonstrating superior resistance to chemical degradation when exposed to synthetic lubricants containing advanced additive packages. These materials maintain their structural integrity at higher temperatures (up to 300°C) compared to traditional nitrile rubber seals (limited to approximately 150°C), allowing for more aggressive lubricant formulations without compromising seal performance.

Ceramic-reinforced apex seals represent another significant advancement, with silicon nitride and silicon carbide composites showing exceptional wear resistance when paired with molybdenum-based lubricants. Laboratory testing indicates up to 40% reduction in wear rates compared to conventional carbon-based seals when operating with these specialized lubricant formulations. This synergistic relationship between advanced materials and tailored lubricants addresses one of the most persistent failure points in Wankel engine design.

Surface engineering technologies have also evolved to complement novel lubricant chemistry. Diamond-like carbon (DLC) coatings applied to rotor housing surfaces have demonstrated remarkable compatibility with ester-based synthetic lubricants, reducing friction coefficients by up to 30% compared to untreated surfaces. These coatings create a more favorable tribological environment that enhances lubricant performance while minimizing material degradation.

Nanotechnology has enabled the development of self-healing seal materials that can repair minor damage through chemical interactions with specific lubricant additives. These materials incorporate microcapsules containing reactive compounds that are released when wear occurs, forming protective films that extend seal life by up to 25% in accelerated testing environments.

The integration of computational modeling has accelerated material-lubricant compatibility research, allowing engineers to predict interactions at the molecular level before physical prototyping. These simulation techniques have identified promising combinations of novel elastomers and bio-based lubricants that maintain seal integrity while meeting increasingly stringent environmental regulations.

Fluoropolymer-based seals have emerged as a promising alternative to conventional rubber seals, demonstrating superior resistance to chemical degradation when exposed to synthetic lubricants containing advanced additive packages. These materials maintain their structural integrity at higher temperatures (up to 300°C) compared to traditional nitrile rubber seals (limited to approximately 150°C), allowing for more aggressive lubricant formulations without compromising seal performance.

Ceramic-reinforced apex seals represent another significant advancement, with silicon nitride and silicon carbide composites showing exceptional wear resistance when paired with molybdenum-based lubricants. Laboratory testing indicates up to 40% reduction in wear rates compared to conventional carbon-based seals when operating with these specialized lubricant formulations. This synergistic relationship between advanced materials and tailored lubricants addresses one of the most persistent failure points in Wankel engine design.

Surface engineering technologies have also evolved to complement novel lubricant chemistry. Diamond-like carbon (DLC) coatings applied to rotor housing surfaces have demonstrated remarkable compatibility with ester-based synthetic lubricants, reducing friction coefficients by up to 30% compared to untreated surfaces. These coatings create a more favorable tribological environment that enhances lubricant performance while minimizing material degradation.

Nanotechnology has enabled the development of self-healing seal materials that can repair minor damage through chemical interactions with specific lubricant additives. These materials incorporate microcapsules containing reactive compounds that are released when wear occurs, forming protective films that extend seal life by up to 25% in accelerated testing environments.

The integration of computational modeling has accelerated material-lubricant compatibility research, allowing engineers to predict interactions at the molecular level before physical prototyping. These simulation techniques have identified promising combinations of novel elastomers and bio-based lubricants that maintain seal integrity while meeting increasingly stringent environmental regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!