How to Innovate Wankel Engine Heat-resistant Alloys?

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Alloy Development History and Objectives

The Wankel rotary engine, first developed by Felix Wankel in the 1950s, represented a revolutionary departure from conventional reciprocating piston engines. Its unique design featuring a triangular rotor moving within an epitrochoidal housing offered significant advantages in terms of power-to-weight ratio, mechanical simplicity, and smooth operation. However, the thermal challenges inherent in the design have persistently limited its widespread adoption.

Early Wankel engines utilized conventional steel alloys similar to those found in piston engines, but quickly encountered limitations due to the rotary engine's distinctive thermal profile. The 1960s marked the first significant advancements in specialized alloys when NSU and later Mazda began developing nickel-based superalloys specifically tailored to withstand the extreme thermal conditions at rotor housing apex seals, where temperatures could exceed 900°C.

The 1970s energy crisis prompted further research into improving thermal efficiency, leading to the development of ceramic-coated aluminum alloys that offered better heat dissipation while reducing overall weight. By the 1980s, Mazda had pioneered the use of silicon-aluminum alloys with enhanced thermal stability for their production rotary engines, culminating in the successful RX-7 sports car.

The 1990s witnessed the introduction of thermal barrier coatings (TBCs) applied to base metal alloys, significantly extending component lifespan. These ceramic-based coatings provided crucial insulation for the underlying metal substrates. Concurrently, advancements in metallurgical processes enabled the creation of more homogeneous alloy microstructures with improved high-temperature creep resistance.

The early 2000s saw the emergence of single-crystal superalloys adapted from aerospace applications, offering unprecedented thermal stability but at prohibitively high manufacturing costs for mass production. More recently, powder metallurgy techniques have enabled the development of oxide dispersion strengthened (ODS) alloys that maintain structural integrity at extreme temperatures through nanoscale oxide particle reinforcement.

Current technical objectives focus on developing cost-effective heat-resistant alloys that can withstand operating temperatures above 1000°C while maintaining dimensional stability and wear resistance. Research aims to overcome the historical challenges of apex seal wear, housing distortion, and thermal efficiency losses that have limited the Wankel engine's commercial viability.

The ultimate goal is to create alloy systems that enable rotary engines to meet modern emissions standards while delivering competitive fuel efficiency, thereby leveraging the inherent advantages of the Wankel design in terms of power density, mechanical simplicity, and NVH (Noise, Vibration, Harshness) characteristics for specialized applications ranging from range extenders in electric vehicles to aviation and marine propulsion systems.

Early Wankel engines utilized conventional steel alloys similar to those found in piston engines, but quickly encountered limitations due to the rotary engine's distinctive thermal profile. The 1960s marked the first significant advancements in specialized alloys when NSU and later Mazda began developing nickel-based superalloys specifically tailored to withstand the extreme thermal conditions at rotor housing apex seals, where temperatures could exceed 900°C.

The 1970s energy crisis prompted further research into improving thermal efficiency, leading to the development of ceramic-coated aluminum alloys that offered better heat dissipation while reducing overall weight. By the 1980s, Mazda had pioneered the use of silicon-aluminum alloys with enhanced thermal stability for their production rotary engines, culminating in the successful RX-7 sports car.

The 1990s witnessed the introduction of thermal barrier coatings (TBCs) applied to base metal alloys, significantly extending component lifespan. These ceramic-based coatings provided crucial insulation for the underlying metal substrates. Concurrently, advancements in metallurgical processes enabled the creation of more homogeneous alloy microstructures with improved high-temperature creep resistance.

The early 2000s saw the emergence of single-crystal superalloys adapted from aerospace applications, offering unprecedented thermal stability but at prohibitively high manufacturing costs for mass production. More recently, powder metallurgy techniques have enabled the development of oxide dispersion strengthened (ODS) alloys that maintain structural integrity at extreme temperatures through nanoscale oxide particle reinforcement.

Current technical objectives focus on developing cost-effective heat-resistant alloys that can withstand operating temperatures above 1000°C while maintaining dimensional stability and wear resistance. Research aims to overcome the historical challenges of apex seal wear, housing distortion, and thermal efficiency losses that have limited the Wankel engine's commercial viability.

The ultimate goal is to create alloy systems that enable rotary engines to meet modern emissions standards while delivering competitive fuel efficiency, thereby leveraging the inherent advantages of the Wankel design in terms of power density, mechanical simplicity, and NVH (Noise, Vibration, Harshness) characteristics for specialized applications ranging from range extenders in electric vehicles to aviation and marine propulsion systems.

Market Analysis for High-Performance Rotary Engine Applications

The global market for high-performance rotary engines continues to evolve, driven by increasing demand for lightweight, compact power solutions across multiple sectors. While Mazda's discontinuation of the RX series represented a significant market shift, rotary engine technology maintains relevance in specialized applications where power-to-weight ratio and compact design are paramount.

The aerospace sector presents substantial growth opportunities, with rotary engines finding applications in unmanned aerial vehicles (UAVs) and small aircraft. This market segment values the Wankel engine's vibration-free operation and excellent power density, with projected growth rates exceeding traditional automotive applications. Military and defense sectors similarly seek compact propulsion systems for tactical vehicles and portable power generation, creating a specialized but lucrative market niche.

Racing and motorsport applications continue to provide a testing ground for advanced rotary engine technologies. Though smaller than mainstream automotive markets, this segment drives innovation in heat-resistant alloys and cooling systems, with premium pricing supporting research investment. The performance aftermarket for rotary engine enthusiasts remains robust, particularly in Japan, Australia, and North America, where specialized parts command significant price premiums.

Emerging applications in hybrid electric vehicles represent a potentially transformative market opportunity. Several manufacturers are exploring rotary engines as range extenders, leveraging their compact size and smooth operation. This application could significantly expand market potential as electrification continues across transportation sectors.

Marine propulsion systems represent another growth vector, with rotary engines offering advantages in weight reduction and space efficiency for smaller watercraft. The recreational boating market particularly values these attributes, creating demand for specialized marine-grade heat-resistant alloys.

Market barriers include competition from conventional piston engines and electric propulsion systems, along with persistent challenges in emissions compliance. However, specialized applications where the rotary engine's unique attributes provide clear advantages continue to support premium pricing and technological investment.

Consumer willingness to pay for high-performance rotary applications varies significantly by sector, with aerospace and defense applications commanding the highest premiums, followed by motorsport and specialized marine applications. This tiered market structure suggests that development of advanced heat-resistant alloys should prioritize these premium segments to maximize return on research investment.

The aerospace sector presents substantial growth opportunities, with rotary engines finding applications in unmanned aerial vehicles (UAVs) and small aircraft. This market segment values the Wankel engine's vibration-free operation and excellent power density, with projected growth rates exceeding traditional automotive applications. Military and defense sectors similarly seek compact propulsion systems for tactical vehicles and portable power generation, creating a specialized but lucrative market niche.

Racing and motorsport applications continue to provide a testing ground for advanced rotary engine technologies. Though smaller than mainstream automotive markets, this segment drives innovation in heat-resistant alloys and cooling systems, with premium pricing supporting research investment. The performance aftermarket for rotary engine enthusiasts remains robust, particularly in Japan, Australia, and North America, where specialized parts command significant price premiums.

Emerging applications in hybrid electric vehicles represent a potentially transformative market opportunity. Several manufacturers are exploring rotary engines as range extenders, leveraging their compact size and smooth operation. This application could significantly expand market potential as electrification continues across transportation sectors.

Marine propulsion systems represent another growth vector, with rotary engines offering advantages in weight reduction and space efficiency for smaller watercraft. The recreational boating market particularly values these attributes, creating demand for specialized marine-grade heat-resistant alloys.

Market barriers include competition from conventional piston engines and electric propulsion systems, along with persistent challenges in emissions compliance. However, specialized applications where the rotary engine's unique attributes provide clear advantages continue to support premium pricing and technological investment.

Consumer willingness to pay for high-performance rotary applications varies significantly by sector, with aerospace and defense applications commanding the highest premiums, followed by motorsport and specialized marine applications. This tiered market structure suggests that development of advanced heat-resistant alloys should prioritize these premium segments to maximize return on research investment.

Current Heat-resistant Alloy Limitations and Technical Barriers

The current heat-resistant alloys used in Wankel engines face significant limitations that hinder optimal performance and longevity. Conventional nickel-based superalloys, while effective in many high-temperature applications, struggle to maintain structural integrity under the unique thermal cycling conditions of rotary engines. These alloys typically exhibit thermal fatigue after prolonged exposure to temperatures exceeding 800°C, which is common in Wankel engine apex seals and rotor housings.

Material degradation mechanisms present a formidable challenge, with oxidation and hot corrosion accelerating at the extreme temperature gradients characteristic of Wankel operation. The triangular rotor design creates uneven heat distribution, subjecting alloys to thermal stresses that conventional materials engineering approaches have not adequately addressed. Current alloys show microstructural instability, with precipitate coarsening and phase transformations occurring during service, compromising mechanical properties.

Weight-to-performance ratio remains suboptimal with existing alloys. The density of traditional heat-resistant materials contributes significantly to the overall engine weight, affecting the power-to-weight advantage that should theoretically benefit Wankel designs. This limitation becomes particularly problematic in aerospace and performance automotive applications where weight considerations are paramount.

Manufacturing constraints further complicate advancement in this field. The complex geometries of Wankel engine components demand alloys with excellent castability and machinability, properties often at odds with superior heat resistance. Current manufacturing processes struggle to produce components with consistent microstructural properties throughout, leading to premature failure at weak points.

Cost factors present another substantial barrier. High-performance nickel and cobalt-based superalloys incorporate expensive elements like rhenium, hafnium, and tantalum, making widespread adoption economically challenging. The specialized processing requirements, including vacuum melting and precision heat treatments, further escalate production expenses.

Environmental considerations also impose limitations on current alloy systems. Many traditional heat-resistant alloys contain elements facing increasing regulatory scrutiny, such as chromium and cobalt, necessitating alternative compositions that maintain performance while reducing environmental impact.

The technical gap between theoretical requirements and practical implementations remains substantial. While computational models predict the need for materials stable at operating temperatures up to 1000°C with excellent fatigue resistance, current commercially viable alloys fall short by 150-200°C in sustained performance capability. This performance deficit directly impacts engine efficiency, emissions control, and service intervals.

Material degradation mechanisms present a formidable challenge, with oxidation and hot corrosion accelerating at the extreme temperature gradients characteristic of Wankel operation. The triangular rotor design creates uneven heat distribution, subjecting alloys to thermal stresses that conventional materials engineering approaches have not adequately addressed. Current alloys show microstructural instability, with precipitate coarsening and phase transformations occurring during service, compromising mechanical properties.

Weight-to-performance ratio remains suboptimal with existing alloys. The density of traditional heat-resistant materials contributes significantly to the overall engine weight, affecting the power-to-weight advantage that should theoretically benefit Wankel designs. This limitation becomes particularly problematic in aerospace and performance automotive applications where weight considerations are paramount.

Manufacturing constraints further complicate advancement in this field. The complex geometries of Wankel engine components demand alloys with excellent castability and machinability, properties often at odds with superior heat resistance. Current manufacturing processes struggle to produce components with consistent microstructural properties throughout, leading to premature failure at weak points.

Cost factors present another substantial barrier. High-performance nickel and cobalt-based superalloys incorporate expensive elements like rhenium, hafnium, and tantalum, making widespread adoption economically challenging. The specialized processing requirements, including vacuum melting and precision heat treatments, further escalate production expenses.

Environmental considerations also impose limitations on current alloy systems. Many traditional heat-resistant alloys contain elements facing increasing regulatory scrutiny, such as chromium and cobalt, necessitating alternative compositions that maintain performance while reducing environmental impact.

The technical gap between theoretical requirements and practical implementations remains substantial. While computational models predict the need for materials stable at operating temperatures up to 1000°C with excellent fatigue resistance, current commercially viable alloys fall short by 150-200°C in sustained performance capability. This performance deficit directly impacts engine efficiency, emissions control, and service intervals.

Current Heat-resistant Alloy Solutions for Wankel Engines

01 Nickel-based superalloys for Wankel engine components

Nickel-based superalloys are utilized in Wankel engines due to their exceptional heat resistance properties. These alloys contain various elements such as chromium, cobalt, and molybdenum that enhance their high-temperature strength and oxidation resistance. The microstructure of these superalloys provides stability at elevated temperatures, making them suitable for critical components in Wankel engines that are exposed to extreme thermal conditions.- Heat-resistant alloys for Wankel engine components: Specialized heat-resistant alloys have been developed specifically for Wankel engine components that are exposed to high temperatures. These alloys typically contain combinations of nickel, chromium, and other elements to withstand the thermal stresses and maintain structural integrity during operation. The materials are designed to resist deformation, oxidation, and thermal fatigue in the unique operating environment of rotary engines.

- Coating technologies for thermal protection: Various coating technologies have been developed to enhance the heat resistance of Wankel engine components. These include thermal barrier coatings, ceramic coatings, and specialized surface treatments that can be applied to the base alloy. These coatings provide an additional layer of thermal protection, reducing heat transfer to the underlying metal and protecting against oxidation and corrosion at high temperatures.

- Rotor housing and apex seal materials: The rotor housing and apex seals in Wankel engines require particularly heat-resistant materials due to their direct exposure to combustion. Advanced alloys and composites have been developed specifically for these components, incorporating elements such as molybdenum, tungsten, and silicon nitride. These materials are designed to maintain dimensional stability and sealing properties while withstanding the extreme temperature gradients present during engine operation.

- Manufacturing processes for heat-resistant components: Specialized manufacturing processes have been developed for producing heat-resistant components for Wankel engines. These include precision casting techniques, powder metallurgy, and advanced machining methods that preserve the material properties while achieving the required dimensional accuracy. Heat treatment processes are also crucial for optimizing the microstructure of the alloys to maximize their heat resistance and durability in high-temperature applications.

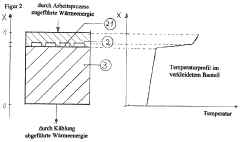

- Cooling system integration with heat-resistant materials: The integration of cooling systems with heat-resistant materials has been a focus of Wankel engine development. This approach combines advanced cooling channel designs, heat dissipation techniques, and strategic material selection to manage thermal loads. By optimizing the interaction between cooling systems and heat-resistant alloys, engineers can extend component life, improve efficiency, and maintain performance under extreme operating conditions.

02 Ceramic coatings and thermal barrier systems

Ceramic coatings and thermal barrier systems are applied to Wankel engine components to enhance heat resistance. These coatings, typically composed of materials like zirconia or alumina, provide insulation and protect the underlying metal from high temperatures. The application of these ceramic layers significantly improves the durability of engine components and allows for higher operating temperatures, thereby increasing engine efficiency and performance.Expand Specific Solutions03 Titanium alloys with heat-resistant properties

Titanium alloys are employed in Wankel engines for their combination of light weight and heat resistance. These alloys are modified with elements such as aluminum, vanadium, and molybdenum to enhance their high-temperature performance. The resulting materials exhibit excellent strength-to-weight ratios while maintaining structural integrity at elevated temperatures, making them particularly suitable for rotary engine applications where weight reduction is critical.Expand Specific Solutions04 Advanced cooling systems for heat management

Advanced cooling systems are integrated with heat-resistant alloys to manage thermal loads in Wankel engines. These systems include innovative designs for coolant flow paths, oil cooling mechanisms, and heat exchangers that work in conjunction with the metallurgical properties of the engine components. The combination of material selection and cooling technology allows for effective heat dissipation and temperature control, extending the service life of engine components under extreme operating conditions.Expand Specific Solutions05 Surface treatment and alloying techniques

Surface treatment and alloying techniques are employed to enhance the heat resistance of Wankel engine components. These processes include nitriding, carburizing, and the application of specialized coatings that modify the surface properties of the base materials. Additionally, innovative alloying methods are used to create gradient materials with varying compositions throughout the component, optimizing heat resistance where it is most needed while maintaining other mechanical properties in less thermally stressed areas.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rotary Engine Metallurgy

The Wankel engine heat-resistant alloy innovation landscape is currently in a growth phase, with the market expected to reach significant expansion due to increasing demand for lightweight, efficient engines in automotive and aerospace sectors. The technology maturity varies across different applications, with companies like Honda Motor Co., Rolls-Royce, and Mitsubishi Power leading commercial implementations. Research institutions including Beihang University, Shanghai Jiao Tong University, and the Institute of Metal Research Chinese Academy of Sciences are advancing fundamental materials science. Specialized materials manufacturers such as Daido Steel, Proterial Ltd., and L.E. Jones Co. are developing proprietary alloy formulations with enhanced heat resistance and durability. The competitive landscape features collaboration between academic institutions and industry players to overcome technical challenges related to apex seal wear and thermal management.

Daido Steel Co., Ltd.

Technical Solution: Daido Steel has developed specialized heat-resistant alloys for Wankel engine applications through their proprietary powder metallurgy process. Their technology focuses on creating materials with exceptional thermal stability and wear resistance specifically for rotary engine apex seals and rotor housings. The company's PM-HSA (Powder Metallurgy High-Speed Alloy) series incorporates precise distributions of carbide-forming elements like tungsten, molybdenum, and vanadium within a nickel-cobalt matrix. This microstructure provides outstanding resistance to thermal fatigue and oxidation at the extreme temperatures (up to 900°C) experienced in Wankel engines. Daido's innovation includes a controlled solidification technique that minimizes segregation and ensures uniform distribution of strengthening precipitates throughout the alloy structure. Their materials undergo specialized heat treatments that optimize the precipitation of γ' and γ" phases, critical for maintaining mechanical properties at elevated temperatures. Additionally, Daido has developed surface treatment technologies that enhance tribological properties of apex seals, reducing friction and improving sealing performance under the severe sliding conditions present in rotary engines.

Strengths: Superior microstructural stability at high temperatures and excellent wear resistance in sliding contact applications. Their powder metallurgy approach allows for precise control of alloy composition and properties. Weaknesses: Higher manufacturing costs compared to conventional casting methods and limited production capacity for specialized rotary engine components.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed advanced heat-resistant alloys specifically for Wankel engines, focusing on improving the apex seal durability and rotor housing materials. Their proprietary nickel-based superalloys incorporate precise amounts of molybdenum, tungsten, and rhenium to enhance creep resistance at high temperatures (800-900°C) encountered in rotary engine operation. Honda's innovation includes a specialized thermal spray coating process that applies ceramic-reinforced metallic layers to critical components, creating a thermal barrier while maintaining necessary tribological properties. Their materials engineering team has implemented a microstructural optimization technique that controls grain boundary morphology to prevent premature failure under thermal cycling conditions. Additionally, Honda has pioneered a novel casting method that reduces internal defects in complex rotor housing geometries, allowing for thinner walls and improved heat dissipation characteristics while maintaining structural integrity.

Strengths: Exceptional thermal fatigue resistance and superior apex seal durability compared to conventional alloys. Integrated manufacturing approach ensures material properties match specific rotary engine requirements. Weaknesses: Higher production costs compared to conventional piston engine materials, and limited scalability for mass production due to complex processing requirements.

Key Metallurgical Innovations for Rotary Engine Applications

Internal combustion engine i.e. rotary piston engine, has isolating elements and engine components such as piston, of combustion chamber structure made of metallic and/or high resistant alloy such as heat resistant steel and titanium

PatentInactiveDE102007063566A1

Innovation

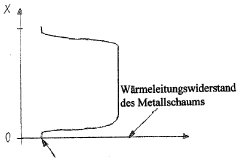

- Implementing heat-resistant metallic linings with low thermal conductivity and insulating layers on engine components, such as pistons, cylinder heads, and valves, using materials like high-temperature alloys and foamed materials with cellular structures to reduce heat flow and enhance insulation.

Rotors having flow-modifying members for use in rotary engines

PatentInactiveEP1933016A3

Innovation

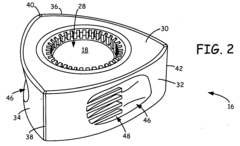

- The introduction of flow-modifying members, such as ramp-shaped, V-shaped, bluff body, and indented structures on the rotor faces, which create vortex flows and turbulence to enhance fuel/air mixing and flame propagation, are integrated into the rotor design to control combustion rates and improve efficiency.

Environmental Impact and Emissions Regulations Affecting Wankel Technology

The Wankel engine, with its unique rotary design, faces significant challenges in meeting increasingly stringent environmental regulations worldwide. These regulations have become a critical factor in the development trajectory of heat-resistant alloys for Wankel engines, as manufacturers must balance performance with compliance requirements.

Emissions standards such as Euro 7 in Europe, Tier 3 in the United States, and China 6 have progressively tightened limits on nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter. The Wankel engine's inherent combustion characteristics, including its elongated combustion chamber and higher surface-to-volume ratio, traditionally result in higher hydrocarbon emissions and fuel consumption compared to conventional piston engines.

These regulatory pressures have accelerated research into advanced heat-resistant alloys that can withstand higher operating temperatures while enabling more complete combustion. Materials that maintain structural integrity at elevated temperatures allow for optimization of the combustion process, potentially reducing emissions through more efficient fuel utilization and reduced oil consumption.

The European Union's commitment to carbon neutrality by 2050 has particularly impacted Wankel technology development, as manufacturers must demonstrate substantial improvements in emissions performance to justify continued investment. Japan's regulatory framework has similarly evolved, affecting Mazda's approach to rotary engine development since they have historically been the primary commercial producer of Wankel engines.

Recent regulatory shifts toward lifecycle emissions assessment rather than solely tailpipe emissions have created new considerations for heat-resistant alloy development. Materials must now be evaluated not only for their performance characteristics but also for their environmental impact during production, use, and end-of-life recycling.

The emergence of hybrid and range-extender applications for Wankel engines represents a regulatory adaptation strategy. In these configurations, the rotary engine operates in a narrower, more optimized range, potentially allowing for compliance with emissions standards while leveraging the engine's compact size and smooth operation. Heat-resistant alloys developed specifically for these applications must prioritize durability under frequent start-stop cycles and rapid temperature fluctuations.

California's zero-emission vehicle mandates and similar policies in other jurisdictions have further complicated the regulatory landscape for Wankel technology. Manufacturers pursuing heat-resistant alloy innovations must consider these regional variations in regulatory requirements, potentially necessitating different material solutions for different markets.

Emissions standards such as Euro 7 in Europe, Tier 3 in the United States, and China 6 have progressively tightened limits on nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter. The Wankel engine's inherent combustion characteristics, including its elongated combustion chamber and higher surface-to-volume ratio, traditionally result in higher hydrocarbon emissions and fuel consumption compared to conventional piston engines.

These regulatory pressures have accelerated research into advanced heat-resistant alloys that can withstand higher operating temperatures while enabling more complete combustion. Materials that maintain structural integrity at elevated temperatures allow for optimization of the combustion process, potentially reducing emissions through more efficient fuel utilization and reduced oil consumption.

The European Union's commitment to carbon neutrality by 2050 has particularly impacted Wankel technology development, as manufacturers must demonstrate substantial improvements in emissions performance to justify continued investment. Japan's regulatory framework has similarly evolved, affecting Mazda's approach to rotary engine development since they have historically been the primary commercial producer of Wankel engines.

Recent regulatory shifts toward lifecycle emissions assessment rather than solely tailpipe emissions have created new considerations for heat-resistant alloy development. Materials must now be evaluated not only for their performance characteristics but also for their environmental impact during production, use, and end-of-life recycling.

The emergence of hybrid and range-extender applications for Wankel engines represents a regulatory adaptation strategy. In these configurations, the rotary engine operates in a narrower, more optimized range, potentially allowing for compliance with emissions standards while leveraging the engine's compact size and smooth operation. Heat-resistant alloys developed specifically for these applications must prioritize durability under frequent start-stop cycles and rapid temperature fluctuations.

California's zero-emission vehicle mandates and similar policies in other jurisdictions have further complicated the regulatory landscape for Wankel technology. Manufacturers pursuing heat-resistant alloy innovations must consider these regional variations in regulatory requirements, potentially necessitating different material solutions for different markets.

Cost-Benefit Analysis of Advanced Alloy Implementation

The implementation of advanced heat-resistant alloys in Wankel engine development presents a complex cost-benefit equation that manufacturers must carefully evaluate. Initial investment costs for developing and integrating new nickel-based superalloys or ceramic matrix composites typically range from $2-5 million for research and development, with additional tooling and manufacturing adaptation costs of $1-3 million. These figures represent significant capital expenditure that must be justified through tangible returns.

Performance benefits offer the primary economic justification for this investment. Advanced alloys capable of withstanding temperatures exceeding 1000°C can improve thermal efficiency by 8-12%, translating to fuel economy improvements of 5-7%. For commercial applications, this efficiency gain represents approximately $1,500-2,000 in fuel savings per vehicle annually, with a potential return on investment period of 3-5 years for fleet operators.

Manufacturing considerations significantly impact the cost-benefit analysis. While traditional casting methods for standard alloys cost approximately $50-80 per component, advanced alloys may require specialized processes such as powder metallurgy or additive manufacturing, increasing production costs to $150-250 per component. However, economies of scale can reduce this premium by 30-40% in high-volume production scenarios.

Lifecycle cost analysis reveals compelling long-term advantages. Enhanced durability from advanced alloys extends component lifespan by 30-50%, reducing replacement frequency and associated maintenance costs. Studies indicate maintenance savings of $3,000-5,000 over a 150,000-mile vehicle lifespan, with particularly significant benefits for commercial and high-performance applications where engine reliability is paramount.

Environmental compliance represents another critical factor in the equation. Advanced alloys enabling more efficient combustion can reduce emissions by 10-15%, potentially avoiding regulatory penalties that average $95 per gram of CO2/km exceeded in many markets. This regulatory compliance value must be factored into comprehensive cost-benefit calculations.

Market differentiation value, while less quantifiable, remains significant. Manufacturers implementing advanced alloy technology can command premium pricing of 8-12% for vehicles featuring enhanced performance and efficiency. This premium pricing strategy can accelerate return on investment timelines and create sustainable competitive advantages in specialized market segments.

Performance benefits offer the primary economic justification for this investment. Advanced alloys capable of withstanding temperatures exceeding 1000°C can improve thermal efficiency by 8-12%, translating to fuel economy improvements of 5-7%. For commercial applications, this efficiency gain represents approximately $1,500-2,000 in fuel savings per vehicle annually, with a potential return on investment period of 3-5 years for fleet operators.

Manufacturing considerations significantly impact the cost-benefit analysis. While traditional casting methods for standard alloys cost approximately $50-80 per component, advanced alloys may require specialized processes such as powder metallurgy or additive manufacturing, increasing production costs to $150-250 per component. However, economies of scale can reduce this premium by 30-40% in high-volume production scenarios.

Lifecycle cost analysis reveals compelling long-term advantages. Enhanced durability from advanced alloys extends component lifespan by 30-50%, reducing replacement frequency and associated maintenance costs. Studies indicate maintenance savings of $3,000-5,000 over a 150,000-mile vehicle lifespan, with particularly significant benefits for commercial and high-performance applications where engine reliability is paramount.

Environmental compliance represents another critical factor in the equation. Advanced alloys enabling more efficient combustion can reduce emissions by 10-15%, potentially avoiding regulatory penalties that average $95 per gram of CO2/km exceeded in many markets. This regulatory compliance value must be factored into comprehensive cost-benefit calculations.

Market differentiation value, while less quantifiable, remains significant. Manufacturers implementing advanced alloy technology can command premium pricing of 8-12% for vehicles featuring enhanced performance and efficiency. This premium pricing strategy can accelerate return on investment timelines and create sustainable competitive advantages in specialized market segments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!