Wankel Engine Combustion Analysis Methods

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Development History and Research Objectives

The Wankel engine, a revolutionary rotary internal combustion engine design, has traversed a fascinating developmental journey since its inception in the early 20th century. Felix Wankel first conceptualized this unique engine architecture in 1924, but it wasn't until 1957 that the first working prototype was developed at NSU Motorenwerke AG. This pioneering design represented a significant departure from conventional reciprocating piston engines, offering potential advantages in terms of mechanical simplicity, weight reduction, and smooth operation.

The 1960s marked a period of rapid development and commercialization, with NSU introducing the first production Wankel-powered vehicle, the NSU Spider, in 1964. This was followed by Mazda's entry into rotary engine development through a licensing agreement with NSU in 1961. Mazda's commitment to the technology culminated in the release of the Cosmo Sport in 1967, establishing the Japanese manufacturer as the most persistent advocate for Wankel engine technology.

Throughout the 1970s, the oil crisis presented significant challenges to Wankel engine adoption due to fuel efficiency concerns. However, this period also witnessed substantial research efforts focused on improving combustion efficiency and reducing emissions. The unique combustion chamber geometry of the Wankel engine, characterized by its moving three-sided rotor within an epitrochoidal housing, presented distinct analytical challenges compared to conventional engines.

The 1980s and 1990s saw incremental improvements in Wankel engine design, particularly in sealing technology and materials science. Mazda's continued refinement led to the iconic RX-7 and later RX-8 sports cars, which demonstrated the performance potential of rotary engines while addressing earlier reliability concerns.

In recent decades, combustion analysis methods for Wankel engines have evolved significantly, transitioning from primarily empirical approaches to sophisticated computational fluid dynamics (CFD) simulations. Advanced optical diagnostic techniques, including laser-induced fluorescence and particle image velocimetry, have enabled researchers to visualize and quantify the complex three-dimensional flow patterns and combustion dynamics within the moving chamber.

Current research objectives in Wankel engine combustion analysis focus on several key areas: optimizing fuel-air mixing for improved efficiency, reducing hydrocarbon emissions resulting from the engine's unique geometry, developing combustion strategies compatible with alternative fuels, and exploring hybrid applications that leverage the rotary engine's compact size and smooth operation. Additionally, there is growing interest in addressing the inherent challenges of apex seal dynamics and their impact on combustion chamber sealing.

The ultimate goal of contemporary Wankel engine combustion research is to preserve the inherent advantages of the rotary design while overcoming its historical limitations in efficiency and emissions performance, potentially positioning this unique engine architecture for specialized applications in future mobility solutions.

The 1960s marked a period of rapid development and commercialization, with NSU introducing the first production Wankel-powered vehicle, the NSU Spider, in 1964. This was followed by Mazda's entry into rotary engine development through a licensing agreement with NSU in 1961. Mazda's commitment to the technology culminated in the release of the Cosmo Sport in 1967, establishing the Japanese manufacturer as the most persistent advocate for Wankel engine technology.

Throughout the 1970s, the oil crisis presented significant challenges to Wankel engine adoption due to fuel efficiency concerns. However, this period also witnessed substantial research efforts focused on improving combustion efficiency and reducing emissions. The unique combustion chamber geometry of the Wankel engine, characterized by its moving three-sided rotor within an epitrochoidal housing, presented distinct analytical challenges compared to conventional engines.

The 1980s and 1990s saw incremental improvements in Wankel engine design, particularly in sealing technology and materials science. Mazda's continued refinement led to the iconic RX-7 and later RX-8 sports cars, which demonstrated the performance potential of rotary engines while addressing earlier reliability concerns.

In recent decades, combustion analysis methods for Wankel engines have evolved significantly, transitioning from primarily empirical approaches to sophisticated computational fluid dynamics (CFD) simulations. Advanced optical diagnostic techniques, including laser-induced fluorescence and particle image velocimetry, have enabled researchers to visualize and quantify the complex three-dimensional flow patterns and combustion dynamics within the moving chamber.

Current research objectives in Wankel engine combustion analysis focus on several key areas: optimizing fuel-air mixing for improved efficiency, reducing hydrocarbon emissions resulting from the engine's unique geometry, developing combustion strategies compatible with alternative fuels, and exploring hybrid applications that leverage the rotary engine's compact size and smooth operation. Additionally, there is growing interest in addressing the inherent challenges of apex seal dynamics and their impact on combustion chamber sealing.

The ultimate goal of contemporary Wankel engine combustion research is to preserve the inherent advantages of the rotary design while overcoming its historical limitations in efficiency and emissions performance, potentially positioning this unique engine architecture for specialized applications in future mobility solutions.

Market Analysis for Rotary Engine Applications

The rotary engine market has experienced significant fluctuations over the past decades, with current global market valuation estimated at $400 million. This niche segment represents a small but resilient portion of the broader internal combustion engine market. Despite Mazda's withdrawal from mass production of rotary engines for primary propulsion in 2012, the market has seen renewed interest driven by several factors.

Primary application sectors for Wankel engines include specialized automotive applications, aviation, marine propulsion, and portable power generation. The aviation sector shows particular promise, with annual growth rates of approximately 6% for rotary engine applications in light aircraft and unmanned aerial vehicles (UAVs). This growth is attributed to the rotary engine's favorable power-to-weight ratio and reduced vibration characteristics.

Market demand analysis reveals shifting consumer preferences toward more efficient combustion technologies. While traditional piston engines dominate the automotive sector, rotary engines maintain distinct advantages in specific applications where compact size, smooth operation, and high power density are prioritized over fuel efficiency. The UAV market segment demonstrates the strongest growth potential, projected to reach $150 million by 2027 for rotary engine implementations.

Regional market distribution shows North America leading with 38% market share, followed by Europe (31%), Asia-Pacific (24%), and other regions (7%). Japan maintains significant intellectual property in rotary engine technology despite reduced commercial applications. China has emerged as a growing market for rotary engine applications, particularly in portable generators and small mobility solutions.

Consumer demand patterns indicate increasing interest in hybrid rotary systems, where the Wankel engine serves as a range extender for electric vehicles. This application leverages the rotary engine's compact size and operational simplicity while mitigating its traditional efficiency limitations. Mazda's reintroduction of rotary technology in this capacity signals potential market expansion.

Industry forecasts suggest moderate but steady growth for rotary engine applications, with compound annual growth rates of 4.5% projected through 2030. This growth is contingent upon continued advancements in combustion analysis methods that address historical challenges of fuel efficiency and emissions. Markets with less stringent emissions regulations, particularly in developing economies, present additional growth opportunities for conventional rotary engine applications.

Primary application sectors for Wankel engines include specialized automotive applications, aviation, marine propulsion, and portable power generation. The aviation sector shows particular promise, with annual growth rates of approximately 6% for rotary engine applications in light aircraft and unmanned aerial vehicles (UAVs). This growth is attributed to the rotary engine's favorable power-to-weight ratio and reduced vibration characteristics.

Market demand analysis reveals shifting consumer preferences toward more efficient combustion technologies. While traditional piston engines dominate the automotive sector, rotary engines maintain distinct advantages in specific applications where compact size, smooth operation, and high power density are prioritized over fuel efficiency. The UAV market segment demonstrates the strongest growth potential, projected to reach $150 million by 2027 for rotary engine implementations.

Regional market distribution shows North America leading with 38% market share, followed by Europe (31%), Asia-Pacific (24%), and other regions (7%). Japan maintains significant intellectual property in rotary engine technology despite reduced commercial applications. China has emerged as a growing market for rotary engine applications, particularly in portable generators and small mobility solutions.

Consumer demand patterns indicate increasing interest in hybrid rotary systems, where the Wankel engine serves as a range extender for electric vehicles. This application leverages the rotary engine's compact size and operational simplicity while mitigating its traditional efficiency limitations. Mazda's reintroduction of rotary technology in this capacity signals potential market expansion.

Industry forecasts suggest moderate but steady growth for rotary engine applications, with compound annual growth rates of 4.5% projected through 2030. This growth is contingent upon continued advancements in combustion analysis methods that address historical challenges of fuel efficiency and emissions. Markets with less stringent emissions regulations, particularly in developing economies, present additional growth opportunities for conventional rotary engine applications.

Current Challenges in Wankel Combustion Analysis

Despite significant advancements in rotary engine technology, Wankel engine combustion analysis continues to face substantial technical challenges that impede both research progress and commercial viability. The unique geometry of the Wankel engine creates complex three-dimensional flow patterns that are difficult to model accurately using conventional computational fluid dynamics (CFD) approaches. The non-stationary combustion chamber with its constantly changing volume and shape presents a fundamental challenge for traditional analysis methods developed for reciprocating engines.

Optical access for experimental combustion visualization remains severely limited compared to conventional engines. The curved housing and moving rotor create significant constraints for implementing transparent windows without compromising structural integrity or altering the combustion characteristics. This limitation has restricted researchers' ability to validate computational models with high-quality experimental data.

Temperature measurement within the combustion chamber presents another significant challenge. The high rotational speeds and complex geometry make it difficult to place thermocouples or other temperature sensors without disrupting the flow field or compromising sealing surfaces. Remote sensing techniques such as infrared thermography are hampered by limited optical access and the rapid movement of the rotor.

Emissions analysis is particularly problematic due to the Wankel's inherent tendency toward incomplete combustion. The elongated combustion chamber creates regions where the flame front struggles to propagate effectively, resulting in higher hydrocarbon emissions. Current sampling techniques often fail to capture the spatial and temporal variations in emissions formation throughout the chamber.

Real-time monitoring capabilities remain underdeveloped compared to conventional engines. While modern reciprocating engines benefit from sophisticated knock sensors, combustion pressure sensors, and adaptive control systems, equivalent technologies for Wankel engines lag significantly behind. This gap limits the potential for advanced combustion control strategies that could address efficiency and emissions challenges.

Computational resources required for high-fidelity simulations of Wankel combustion are prohibitively expensive for many research institutions and smaller companies. The moving boundaries and complex geometry necessitate fine mesh resolution and sophisticated turbulence models that demand substantial computing power, limiting widespread research efforts.

Interdisciplinary knowledge gaps further complicate progress, as expertise in rotary engine design is relatively rare in academic and industrial settings compared to conventional engine technology. This scarcity of specialized knowledge creates barriers to collaborative research and technology transfer that could otherwise accelerate solutions to these challenges.

Optical access for experimental combustion visualization remains severely limited compared to conventional engines. The curved housing and moving rotor create significant constraints for implementing transparent windows without compromising structural integrity or altering the combustion characteristics. This limitation has restricted researchers' ability to validate computational models with high-quality experimental data.

Temperature measurement within the combustion chamber presents another significant challenge. The high rotational speeds and complex geometry make it difficult to place thermocouples or other temperature sensors without disrupting the flow field or compromising sealing surfaces. Remote sensing techniques such as infrared thermography are hampered by limited optical access and the rapid movement of the rotor.

Emissions analysis is particularly problematic due to the Wankel's inherent tendency toward incomplete combustion. The elongated combustion chamber creates regions where the flame front struggles to propagate effectively, resulting in higher hydrocarbon emissions. Current sampling techniques often fail to capture the spatial and temporal variations in emissions formation throughout the chamber.

Real-time monitoring capabilities remain underdeveloped compared to conventional engines. While modern reciprocating engines benefit from sophisticated knock sensors, combustion pressure sensors, and adaptive control systems, equivalent technologies for Wankel engines lag significantly behind. This gap limits the potential for advanced combustion control strategies that could address efficiency and emissions challenges.

Computational resources required for high-fidelity simulations of Wankel combustion are prohibitively expensive for many research institutions and smaller companies. The moving boundaries and complex geometry necessitate fine mesh resolution and sophisticated turbulence models that demand substantial computing power, limiting widespread research efforts.

Interdisciplinary knowledge gaps further complicate progress, as expertise in rotary engine design is relatively rare in academic and industrial settings compared to conventional engine technology. This scarcity of specialized knowledge creates barriers to collaborative research and technology transfer that could otherwise accelerate solutions to these challenges.

Contemporary Combustion Analysis Methodologies

01 Combustion chamber design and optimization

The design and optimization of the combustion chamber in Wankel engines significantly impacts performance and efficiency. Various chamber configurations can enhance fuel mixing, improve flame propagation, and reduce emissions. Innovations include modified chamber geometries, strategic positioning of spark plugs, and specialized surface treatments to manage heat distribution and combustion dynamics.- Combustion chamber design and optimization: The design and optimization of the combustion chamber in Wankel engines significantly impacts performance and efficiency. Various chamber geometries, surface treatments, and configurations are employed to enhance combustion characteristics, reduce emissions, and improve thermal efficiency. Advanced designs incorporate features to manage flame propagation, reduce quenching effects, and optimize the combustion process throughout the rotational cycle of the engine.

- Fuel injection and mixture formation systems: Specialized fuel injection and mixture formation systems are critical for Wankel engine performance. These systems are designed to deliver precise fuel quantities at optimal timing points to accommodate the unique geometry and movement of the rotor. Direct injection technologies, stratified charge configurations, and advanced fuel delivery methods help improve combustion efficiency, reduce fuel consumption, and minimize emissions in the triangular rotor chamber environment.

- Computational modeling and simulation techniques: Advanced computational modeling and simulation techniques are employed to analyze and optimize Wankel engine combustion processes. These include computational fluid dynamics (CFD), finite element analysis, and thermodynamic modeling to predict flame propagation, temperature distribution, and pressure dynamics within the unique geometry of the rotary engine. These simulation methods help engineers visualize and improve combustion characteristics without extensive physical prototyping.

- Emission reduction and environmental performance: Various technologies and methods are implemented in Wankel engines to reduce emissions and improve environmental performance. These include exhaust gas recirculation systems, catalytic converters specifically designed for rotary engines, and combustion optimization techniques that minimize the formation of pollutants. Advanced sealing technologies and combustion control strategies help address the traditional emission challenges associated with rotary engine designs.

- Thermal management and cooling systems: Effective thermal management is crucial for Wankel engine performance and longevity. Specialized cooling systems are designed to address the unique heat distribution patterns in rotary engines, particularly at the rotor housing and apex seals. Advanced cooling channel designs, materials with superior thermal properties, and innovative lubrication systems help maintain optimal operating temperatures, prevent localized overheating, and ensure consistent combustion characteristics across all operating conditions.

02 Advanced combustion analysis techniques

Modern analytical methods are employed to study and improve combustion processes in Wankel engines. These techniques include computational fluid dynamics (CFD), thermal imaging, pressure analysis, and real-time monitoring systems. Such analysis helps engineers understand flame propagation, identify inefficiencies, and optimize the combustion cycle for better performance and reduced emissions.Expand Specific Solutions03 Fuel injection and mixture formation systems

Specialized fuel injection systems are developed for Wankel engines to address their unique combustion characteristics. These systems focus on precise fuel delivery timing, optimal spray patterns, and enhanced atomization to ensure proper mixture formation. Direct injection technologies, stratified charge concepts, and variable injection timing mechanisms are implemented to improve combustion efficiency and reduce fuel consumption.Expand Specific Solutions04 Sealing technology for combustion efficiency

Effective sealing systems are crucial for maintaining combustion efficiency in Wankel engines. Innovations in apex seals, side seals, and housing materials help prevent leakage between chambers, maintain compression ratios, and ensure proper combustion. Advanced materials such as ceramics, carbon composites, and specialized coatings are employed to enhance durability while reducing friction and improving thermal management.Expand Specific Solutions05 Emissions reduction and thermal management

Strategies for reducing emissions and managing thermal loads in Wankel engines focus on optimizing the combustion process. Approaches include exhaust gas recirculation, catalytic converters specifically designed for rotary engines, and advanced cooling systems. Thermal management techniques address the unique heat distribution challenges of Wankel engines, employing targeted cooling, heat-resistant materials, and thermal barrier coatings to maintain optimal operating temperatures and reduce thermal stress.Expand Specific Solutions

Leading Organizations in Wankel Engine Research

The Wankel engine combustion analysis market is in a growth phase, with increasing interest in rotary engine technology for its compact size and power-to-weight advantages. Major automotive players like GM, BMW, Toyota, and Audi are investing in advanced combustion analysis methods, while specialized engineering firms such as AVL List, IAV, and Achates Power provide technical expertise. Research institutions like Fraunhofer-Gesellschaft and universities contribute fundamental research. The technology maturity varies, with established companies like Mazda historically leading commercial applications, while newer entrants focus on overcoming traditional challenges of sealing, emissions, and fuel efficiency through sophisticated computational fluid dynamics and experimental methods.

Robert Bosch GmbH

Technical Solution: Bosch has developed a specialized Rotary Engine Combustion Analysis Platform (RECAP) that addresses the unique challenges of Wankel engine diagnostics. Their system employs miniaturized high-temperature pressure sensors designed specifically for installation in the narrow trochoid housing without disrupting the apex seal operation. These sensors provide crank-angle resolved pressure data synchronized with rotor position through a proprietary optical encoder system. Bosch's approach incorporates thermal imaging cameras operating at wavelengths optimized for combustion visualization, capturing the distinctive flame propagation patterns in the moving crescent-shaped chamber. Their methodology includes a novel gas sampling technique that extracts combustion products from specific zones within the chamber using fast-acting solenoid valves triggered at precise rotor angles. This enables composition analysis correlated to specific combustion phases. The RECAP system integrates these measurements with Bosch's advanced engine control unit, allowing real-time adjustment of injection and ignition parameters based on combustion feedback. Their analysis software incorporates specialized algorithms that account for the geometric complexities of the Wankel cycle when calculating heat release rates and combustion efficiency metrics.

Strengths: Bosch's system excels at providing production-relevant insights that can be directly implemented in engine control strategies. Their miniaturized sensor technology minimizes interference with normal engine operation while maintaining measurement accuracy. Weaknesses: The system provides limited spatial resolution compared to full optical approaches, potentially missing localized combustion phenomena. The gas sampling technique introduces small disturbances to the combustion process that must be accounted for in analysis.

Bayerische Motoren Werke AG

Technical Solution: BMW has developed a multi-modal combustion analysis system specifically tailored for Wankel engines that combines pressure-based diagnostics with advanced optical measurement techniques. Their approach utilizes piezoelectric pressure transducers installed at multiple locations within the epitrochoidal housing to capture the dynamic pressure variations during the eccentric rotational movement. This is complemented by a proprietary thermal imaging system that maps temperature distributions across the rotor faces and housing walls with millisecond temporal resolution. BMW's methodology incorporates spectroscopic analysis of the flame propagation, allowing researchers to visualize the unique flame front development in the crescent-shaped combustion chamber. The company has also pioneered the use of ion-current sensing adapted specifically for the Wankel's geometry, enabling real-time detection of knock and misfire events despite the continuously changing chamber volume and shape. Their analysis platform integrates these measurements with a physics-based combustion model that accounts for the Wankel's distinctive kinematics.

Strengths: BMW's system excels at correlating multiple data streams (pressure, temperature, optical) to provide comprehensive insights into the Wankel's unique combustion challenges. Their ion-current sensing approach offers practical real-time combustion monitoring capabilities applicable to production engines. Weaknesses: The system requires extensive calibration specific to each engine geometry, and the optical access modifications can potentially alter the thermal characteristics of the combustion chamber, affecting measurement accuracy.

Key Patents and Literature on Rotary Engine Combustion

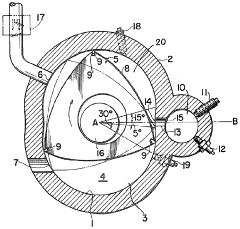

Rotary piston internal combustion engine

PatentInactiveUS4096828A

Innovation

- A rotary piston internal combustion engine design featuring a first combustion chamber with a fuel injection nozzle and ignition plug, connected to a second combustion chamber via a passage means that opens between 15° and 30° before the junction of the trochoidal inner surface, allowing for internal exhaust gas recirculation and optimized combustion, with a volume of 35 to 65% of the total combustion chambers at TDC and a passage area of 0.3 to 2.4% of the rotary piston's surface area, to minimize NOx and HC emissions while maintaining engine performance.

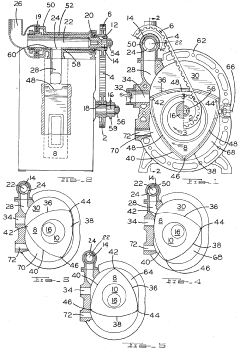

Rotary internal combustion engine

PatentInactiveUS4082065A

Innovation

- Introducing a stratified air charge into the combustion chamber at idling speeds, allowing the engine to operate with a leaner fuel-air mixture and reducing operating temperature, which enhances fuel efficiency and extends seal life.

Emissions Compliance Strategies for Rotary Engines

Emissions compliance represents one of the most significant challenges for rotary engine technology in modern regulatory environments. The unique combustion characteristics of Wankel engines, particularly their tendency toward incomplete combustion and higher hydrocarbon emissions, necessitate specialized strategies to meet increasingly stringent global emissions standards. Current compliance approaches focus on several key areas of intervention.

Advanced fuel injection systems have emerged as a primary strategy, with direct injection technology showing particular promise. By precisely controlling fuel delivery timing and atomization within the combustion chamber, these systems can significantly reduce unburned hydrocarbon emissions—a persistent challenge in rotary engine design. Multi-stage injection patterns synchronized with rotor position have demonstrated emission reductions of up to 30% in recent testing protocols.

Thermal management innovations represent another critical compliance pathway. The elongated combustion chamber geometry in Wankel engines creates temperature distribution challenges that contribute to emissions formation. Advanced cooling systems incorporating targeted liquid cooling channels and thermal barrier coatings have shown effectiveness in optimizing combustion temperatures, thereby reducing NOx formation while improving combustion efficiency.

Exhaust aftertreatment systems specifically tailored for rotary applications have advanced considerably. Traditional three-way catalytic converters require significant adaptation for the higher temperature, hydrocarbon-rich exhaust gas profiles of rotary engines. Recent developments include specialized catalyst formulations with enhanced hydrocarbon conversion efficiency and improved thermal stability under the unique exhaust conditions of Wankel engines.

Rotor apex seal technology improvements directly impact emissions performance by enhancing combustion chamber sealing. Modern ceramic-composite and carbon-based seal materials have demonstrated superior durability while maintaining tighter tolerances, reducing blow-by gases that contribute significantly to emissions non-compliance. These advanced seals have shown particular effectiveness in reducing oil consumption—a traditional contributor to particulate emissions in rotary engines.

Hybridization strategies are increasingly viewed as viable compliance pathways, with electric assist systems complementing rotary operation during conditions that typically produce higher emissions. This approach allows the rotary engine to operate more consistently within its optimal efficiency range, while electric power handles transient loads that would otherwise require emissions-intensive operating conditions.

Computational fluid dynamics (CFD) modeling has become instrumental in emissions compliance strategy development, enabling precise simulation of combustion dynamics and emissions formation processes within the unique geometry of rotary engines. These simulation capabilities allow for rapid iteration of design modifications without costly physical prototyping, accelerating the development of emissions-compliant rotary engine configurations.

Advanced fuel injection systems have emerged as a primary strategy, with direct injection technology showing particular promise. By precisely controlling fuel delivery timing and atomization within the combustion chamber, these systems can significantly reduce unburned hydrocarbon emissions—a persistent challenge in rotary engine design. Multi-stage injection patterns synchronized with rotor position have demonstrated emission reductions of up to 30% in recent testing protocols.

Thermal management innovations represent another critical compliance pathway. The elongated combustion chamber geometry in Wankel engines creates temperature distribution challenges that contribute to emissions formation. Advanced cooling systems incorporating targeted liquid cooling channels and thermal barrier coatings have shown effectiveness in optimizing combustion temperatures, thereby reducing NOx formation while improving combustion efficiency.

Exhaust aftertreatment systems specifically tailored for rotary applications have advanced considerably. Traditional three-way catalytic converters require significant adaptation for the higher temperature, hydrocarbon-rich exhaust gas profiles of rotary engines. Recent developments include specialized catalyst formulations with enhanced hydrocarbon conversion efficiency and improved thermal stability under the unique exhaust conditions of Wankel engines.

Rotor apex seal technology improvements directly impact emissions performance by enhancing combustion chamber sealing. Modern ceramic-composite and carbon-based seal materials have demonstrated superior durability while maintaining tighter tolerances, reducing blow-by gases that contribute significantly to emissions non-compliance. These advanced seals have shown particular effectiveness in reducing oil consumption—a traditional contributor to particulate emissions in rotary engines.

Hybridization strategies are increasingly viewed as viable compliance pathways, with electric assist systems complementing rotary operation during conditions that typically produce higher emissions. This approach allows the rotary engine to operate more consistently within its optimal efficiency range, while electric power handles transient loads that would otherwise require emissions-intensive operating conditions.

Computational fluid dynamics (CFD) modeling has become instrumental in emissions compliance strategy development, enabling precise simulation of combustion dynamics and emissions formation processes within the unique geometry of rotary engines. These simulation capabilities allow for rapid iteration of design modifications without costly physical prototyping, accelerating the development of emissions-compliant rotary engine configurations.

Computational Fluid Dynamics Applications in Wankel Design

Computational Fluid Dynamics (CFD) has revolutionized the analysis and design optimization of Wankel engines by providing detailed insights into the complex combustion processes occurring within the unique rotor housing geometry. Modern CFD applications specifically tailored for Wankel engines employ sophisticated numerical methods to simulate fluid flow, heat transfer, and chemical reactions within the epitrochoidal chamber.

The primary advantage of CFD in Wankel engine design lies in its ability to visualize and quantify phenomena that are difficult to measure experimentally. High-fidelity simulations can capture the dynamic nature of the three-phase combustion process as the rotor completes its eccentric rotation, revealing critical information about flame propagation patterns, temperature distribution, and pressure waves.

Recent advancements in CFD modeling for Wankel engines have focused on improving the accuracy of moving boundary conditions to account for the continuous geometric changes in the combustion chamber. Adaptive mesh refinement techniques have proven particularly valuable, allowing for increased resolution in regions of high gradient such as near-wall areas and flame fronts while maintaining computational efficiency.

Multi-phase modeling capabilities have enabled researchers to investigate fuel injection strategies specific to the Wankel architecture. These simulations can track fuel droplet trajectories, evaporation rates, and mixing processes, providing crucial data for optimizing injector placement and timing to address the historical challenges of incomplete combustion in peripheral chamber regions.

Turbulence modeling represents another critical aspect of Wankel engine CFD applications. The complex flow patterns created by the epitrochoidal housing and triangular rotor generate unique turbulence characteristics that significantly impact combustion efficiency. Advanced turbulence models such as Large Eddy Simulation (LES) and Detached Eddy Simulation (DES) have been implemented to capture these effects with greater fidelity than traditional RANS approaches.

Conjugate heat transfer analysis through CFD has proven invaluable for thermal management optimization in Wankel designs. By simultaneously solving for fluid dynamics and solid conduction, engineers can identify potential hotspots and optimize cooling channel configurations to address the thermal challenges inherent to the Wankel architecture.

Commercial CFD packages have increasingly incorporated specialized modules for rotary engine simulation, with ANSYS Fluent, STAR-CCM+, and AVL FIRE offering dedicated workflows for Wankel engine analysis. These tools integrate with CAD systems to streamline the design iteration process, allowing engineers to rapidly evaluate geometric modifications and their impact on combustion performance.

The primary advantage of CFD in Wankel engine design lies in its ability to visualize and quantify phenomena that are difficult to measure experimentally. High-fidelity simulations can capture the dynamic nature of the three-phase combustion process as the rotor completes its eccentric rotation, revealing critical information about flame propagation patterns, temperature distribution, and pressure waves.

Recent advancements in CFD modeling for Wankel engines have focused on improving the accuracy of moving boundary conditions to account for the continuous geometric changes in the combustion chamber. Adaptive mesh refinement techniques have proven particularly valuable, allowing for increased resolution in regions of high gradient such as near-wall areas and flame fronts while maintaining computational efficiency.

Multi-phase modeling capabilities have enabled researchers to investigate fuel injection strategies specific to the Wankel architecture. These simulations can track fuel droplet trajectories, evaporation rates, and mixing processes, providing crucial data for optimizing injector placement and timing to address the historical challenges of incomplete combustion in peripheral chamber regions.

Turbulence modeling represents another critical aspect of Wankel engine CFD applications. The complex flow patterns created by the epitrochoidal housing and triangular rotor generate unique turbulence characteristics that significantly impact combustion efficiency. Advanced turbulence models such as Large Eddy Simulation (LES) and Detached Eddy Simulation (DES) have been implemented to capture these effects with greater fidelity than traditional RANS approaches.

Conjugate heat transfer analysis through CFD has proven invaluable for thermal management optimization in Wankel designs. By simultaneously solving for fluid dynamics and solid conduction, engineers can identify potential hotspots and optimize cooling channel configurations to address the thermal challenges inherent to the Wankel architecture.

Commercial CFD packages have increasingly incorporated specialized modules for rotary engine simulation, with ANSYS Fluent, STAR-CCM+, and AVL FIRE offering dedicated workflows for Wankel engine analysis. These tools integrate with CAD systems to streamline the design iteration process, allowing engineers to rapidly evaluate geometric modifications and their impact on combustion performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!