How to Develop Self-diagnosing Wankel Engine Models?

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Self-Diagnosis Technology Background and Objectives

The Wankel engine, a rotary internal combustion engine design patented by German engineer Felix Wankel in 1929, has experienced a complex development trajectory over the past century. Despite its compact size, high power-to-weight ratio, and smooth operation, widespread adoption has been hindered by challenges related to sealing, emissions, and fuel efficiency. Recent technological advancements in materials science, computational modeling, and sensor technology have revitalized interest in this unique engine architecture, particularly for specialized applications.

The evolution of Wankel engine technology has been marked by significant innovations from manufacturers like NSU, Mazda, and various aerospace companies. Mazda's commitment to rotary engine development, culminating in vehicles like the RX-7 and RX-8, demonstrated both the potential and limitations of this technology. The discontinuation of mass-produced Wankel-powered vehicles in 2012 represented a turning point, shifting focus toward hybrid applications and specialized use cases where the engine's unique characteristics provide distinct advantages.

Current technological trends indicate a convergence of traditional mechanical engineering with advanced digital systems, creating opportunities for intelligent, self-monitoring engine systems. The integration of IoT capabilities, machine learning algorithms, and advanced sensor networks presents a pathway to address historical challenges through real-time diagnostics and adaptive control systems. This technological convergence aligns with broader industry movements toward predictive maintenance and condition-based monitoring.

The primary objective of developing self-diagnosing Wankel engine models is to create intelligent systems capable of real-time performance monitoring, fault detection, and predictive maintenance. These systems aim to identify potential failures before they occur, optimize performance parameters during operation, and extend engine lifespan through adaptive control strategies. By leveraging advanced sensor arrays, machine learning algorithms, and digital twin technology, self-diagnosing models can continuously monitor critical parameters such as apex seal wear, combustion efficiency, and thermal management.

Secondary objectives include reducing maintenance costs, improving reliability in specialized applications, and enabling new use cases where traditional Wankel limitations have been prohibitive. The development of these self-diagnosing capabilities also supports broader goals of emissions reduction and fuel efficiency improvement, addressing historical weaknesses of the Wankel design through intelligent system management rather than purely mechanical solutions.

The anticipated technological outcomes include comprehensive digital twin models that accurately simulate real-world engine behavior, sensor integration frameworks that balance information richness with system complexity, and machine learning algorithms capable of distinguishing between normal operational variations and early indicators of potential failure modes. These developments represent a fundamental shift from reactive to predictive maintenance paradigms for rotary engine technology.

The evolution of Wankel engine technology has been marked by significant innovations from manufacturers like NSU, Mazda, and various aerospace companies. Mazda's commitment to rotary engine development, culminating in vehicles like the RX-7 and RX-8, demonstrated both the potential and limitations of this technology. The discontinuation of mass-produced Wankel-powered vehicles in 2012 represented a turning point, shifting focus toward hybrid applications and specialized use cases where the engine's unique characteristics provide distinct advantages.

Current technological trends indicate a convergence of traditional mechanical engineering with advanced digital systems, creating opportunities for intelligent, self-monitoring engine systems. The integration of IoT capabilities, machine learning algorithms, and advanced sensor networks presents a pathway to address historical challenges through real-time diagnostics and adaptive control systems. This technological convergence aligns with broader industry movements toward predictive maintenance and condition-based monitoring.

The primary objective of developing self-diagnosing Wankel engine models is to create intelligent systems capable of real-time performance monitoring, fault detection, and predictive maintenance. These systems aim to identify potential failures before they occur, optimize performance parameters during operation, and extend engine lifespan through adaptive control strategies. By leveraging advanced sensor arrays, machine learning algorithms, and digital twin technology, self-diagnosing models can continuously monitor critical parameters such as apex seal wear, combustion efficiency, and thermal management.

Secondary objectives include reducing maintenance costs, improving reliability in specialized applications, and enabling new use cases where traditional Wankel limitations have been prohibitive. The development of these self-diagnosing capabilities also supports broader goals of emissions reduction and fuel efficiency improvement, addressing historical weaknesses of the Wankel design through intelligent system management rather than purely mechanical solutions.

The anticipated technological outcomes include comprehensive digital twin models that accurately simulate real-world engine behavior, sensor integration frameworks that balance information richness with system complexity, and machine learning algorithms capable of distinguishing between normal operational variations and early indicators of potential failure modes. These developments represent a fundamental shift from reactive to predictive maintenance paradigms for rotary engine technology.

Market Demand Analysis for Smart Rotary Engine Systems

The global market for smart rotary engine systems is experiencing significant growth driven by increasing demands for more efficient, reliable, and environmentally friendly propulsion technologies. The Wankel rotary engine, despite its historical challenges, is witnessing renewed interest due to its compact design, high power-to-weight ratio, and potential for integration with advanced diagnostic systems.

Current market analysis indicates that the automotive sector represents the largest potential market for self-diagnosing Wankel engines, particularly in hybrid electric vehicles where rotary engines can serve as efficient range extenders. This application alone is projected to grow substantially as automotive manufacturers seek innovative solutions to extend electric vehicle range without significant weight penalties.

The aerospace and unmanned aerial vehicle (UAV) sectors also demonstrate strong demand potential, valuing the rotary engine's favorable power-to-weight characteristics and the enhanced reliability that self-diagnostic capabilities would provide. Military applications, particularly in tactical UAVs and portable power generation, constitute another significant market segment where operational reliability in remote environments is paramount.

Marine propulsion systems represent an emerging market, with particular interest from manufacturers of personal watercraft and small recreational boats seeking more efficient and reliable power solutions. The industrial sector, specifically portable power generation equipment, also shows considerable interest in smart rotary engine technology.

Market research reveals that end-users across these sectors consistently prioritize several key features in next-generation engine systems: real-time performance monitoring, predictive maintenance capabilities, fuel efficiency optimization, and seamless integration with existing digital infrastructure. Self-diagnosing capabilities rank particularly high among desired features, with potential customers expressing willingness to pay premium prices for systems that can predict failures before they occur.

Consumer sentiment analysis indicates growing acceptance of rotary engine technology when coupled with modern diagnostic systems that address historical concerns about reliability and maintenance requirements. This represents a significant shift in market perception that manufacturers can leverage.

Regional market analysis shows particularly strong growth potential in North America and Asia-Pacific regions, with Europe following closely behind due to stringent emissions regulations driving innovation in propulsion technologies. Emerging markets in South America and parts of Asia also show increasing interest as industrialization accelerates and transportation infrastructure expands.

The total addressable market for smart rotary engine systems is expected to expand significantly over the next decade, driven by technological advancements in materials science, sensor technology, and artificial intelligence that enable truly self-diagnosing capabilities. This growth trajectory presents substantial opportunities for early movers who can successfully develop and commercialize self-diagnosing Wankel engine models.

Current market analysis indicates that the automotive sector represents the largest potential market for self-diagnosing Wankel engines, particularly in hybrid electric vehicles where rotary engines can serve as efficient range extenders. This application alone is projected to grow substantially as automotive manufacturers seek innovative solutions to extend electric vehicle range without significant weight penalties.

The aerospace and unmanned aerial vehicle (UAV) sectors also demonstrate strong demand potential, valuing the rotary engine's favorable power-to-weight characteristics and the enhanced reliability that self-diagnostic capabilities would provide. Military applications, particularly in tactical UAVs and portable power generation, constitute another significant market segment where operational reliability in remote environments is paramount.

Marine propulsion systems represent an emerging market, with particular interest from manufacturers of personal watercraft and small recreational boats seeking more efficient and reliable power solutions. The industrial sector, specifically portable power generation equipment, also shows considerable interest in smart rotary engine technology.

Market research reveals that end-users across these sectors consistently prioritize several key features in next-generation engine systems: real-time performance monitoring, predictive maintenance capabilities, fuel efficiency optimization, and seamless integration with existing digital infrastructure. Self-diagnosing capabilities rank particularly high among desired features, with potential customers expressing willingness to pay premium prices for systems that can predict failures before they occur.

Consumer sentiment analysis indicates growing acceptance of rotary engine technology when coupled with modern diagnostic systems that address historical concerns about reliability and maintenance requirements. This represents a significant shift in market perception that manufacturers can leverage.

Regional market analysis shows particularly strong growth potential in North America and Asia-Pacific regions, with Europe following closely behind due to stringent emissions regulations driving innovation in propulsion technologies. Emerging markets in South America and parts of Asia also show increasing interest as industrialization accelerates and transportation infrastructure expands.

The total addressable market for smart rotary engine systems is expected to expand significantly over the next decade, driven by technological advancements in materials science, sensor technology, and artificial intelligence that enable truly self-diagnosing capabilities. This growth trajectory presents substantial opportunities for early movers who can successfully develop and commercialize self-diagnosing Wankel engine models.

Current State and Challenges in Wankel Engine Diagnostics

The Wankel rotary engine, despite its unique advantages in power-to-weight ratio and mechanical simplicity, has faced significant challenges in widespread adoption due to issues with fuel efficiency, emissions, and reliability. Current diagnostic approaches for Wankel engines remain relatively underdeveloped compared to conventional reciprocating engines, creating a substantial technological gap in the industry.

Globally, research institutions and automotive manufacturers have made varied progress in Wankel engine diagnostics. Japanese manufacturers, particularly Mazda, have historically led development efforts with their RX series vehicles. European research centers have focused on theoretical modeling approaches, while North American institutions have contributed significantly to sensor technology integration for rotary engines.

The primary technical challenges in Wankel engine diagnostics stem from its unique geometry and operating principles. The three-dimensional flame propagation patterns and complex sealing dynamics create monitoring difficulties not present in conventional engines. Current sensor placement strategies often fail to capture the distinctive thermal gradients and pressure distributions within the epitrochoidal housing.

Real-time monitoring presents another significant hurdle, as the high rotational speeds and distinctive combustion characteristics of Wankel engines require specialized sensing technologies with exceptional response rates. Conventional knock sensors and pressure transducers designed for reciprocating engines frequently prove inadequate for capturing the unique vibration signatures of rotary engines.

Data interpretation frameworks for Wankel engines remain underdeveloped, with most diagnostic algorithms still relying on adaptations of reciprocating engine models rather than purpose-built analytical frameworks. This results in reduced diagnostic accuracy and limited failure prediction capabilities.

Emissions monitoring represents a particularly challenging aspect, as the elongated combustion chamber and inherent oil consumption characteristics create unique exhaust profiles that standard diagnostic systems struggle to interpret correctly. This has implications for both regulatory compliance and performance optimization.

The integration of diagnostic systems with engine control units (ECUs) faces compatibility issues, as most commercial engine management systems are designed around the four-stroke cycle of conventional engines rather than the unique three-phase cycle of the Wankel design. This necessitates custom software development and calibration procedures.

Material limitations also impact diagnostic capabilities, as the high operating temperatures and unique wear patterns of apex seals require specialized monitoring approaches. Current non-invasive techniques often lack the resolution to detect early-stage seal degradation before performance is significantly compromised.

Despite these challenges, recent advancements in computational fluid dynamics (CFD), machine learning algorithms, and miniaturized sensor technologies offer promising pathways for developing more effective self-diagnostic capabilities for Wankel engines, potentially revitalizing interest in this unique powerplant design.

Globally, research institutions and automotive manufacturers have made varied progress in Wankel engine diagnostics. Japanese manufacturers, particularly Mazda, have historically led development efforts with their RX series vehicles. European research centers have focused on theoretical modeling approaches, while North American institutions have contributed significantly to sensor technology integration for rotary engines.

The primary technical challenges in Wankel engine diagnostics stem from its unique geometry and operating principles. The three-dimensional flame propagation patterns and complex sealing dynamics create monitoring difficulties not present in conventional engines. Current sensor placement strategies often fail to capture the distinctive thermal gradients and pressure distributions within the epitrochoidal housing.

Real-time monitoring presents another significant hurdle, as the high rotational speeds and distinctive combustion characteristics of Wankel engines require specialized sensing technologies with exceptional response rates. Conventional knock sensors and pressure transducers designed for reciprocating engines frequently prove inadequate for capturing the unique vibration signatures of rotary engines.

Data interpretation frameworks for Wankel engines remain underdeveloped, with most diagnostic algorithms still relying on adaptations of reciprocating engine models rather than purpose-built analytical frameworks. This results in reduced diagnostic accuracy and limited failure prediction capabilities.

Emissions monitoring represents a particularly challenging aspect, as the elongated combustion chamber and inherent oil consumption characteristics create unique exhaust profiles that standard diagnostic systems struggle to interpret correctly. This has implications for both regulatory compliance and performance optimization.

The integration of diagnostic systems with engine control units (ECUs) faces compatibility issues, as most commercial engine management systems are designed around the four-stroke cycle of conventional engines rather than the unique three-phase cycle of the Wankel design. This necessitates custom software development and calibration procedures.

Material limitations also impact diagnostic capabilities, as the high operating temperatures and unique wear patterns of apex seals require specialized monitoring approaches. Current non-invasive techniques often lack the resolution to detect early-stage seal degradation before performance is significantly compromised.

Despite these challenges, recent advancements in computational fluid dynamics (CFD), machine learning algorithms, and miniaturized sensor technologies offer promising pathways for developing more effective self-diagnostic capabilities for Wankel engines, potentially revitalizing interest in this unique powerplant design.

Current Self-Diagnostic Methodologies for Wankel Engines

01 Self-diagnostic systems for Wankel engines

Wankel engines can be equipped with self-diagnostic systems that monitor various parameters such as temperature, pressure, and rotational speed to detect potential issues. These systems use sensors placed at strategic locations within the engine to collect real-time data. The data is then processed by control units that can identify abnormalities and alert the user to potential problems before they lead to engine failure. This proactive approach to engine monitoring helps in maintaining optimal performance and extending the engine's lifespan.- Diagnostic systems for Wankel engine performance monitoring: Diagnostic systems for Wankel engines can monitor various performance parameters in real-time to detect potential issues before they lead to engine failure. These systems typically use sensors to collect data on temperature, pressure, rotational speed, and exhaust emissions. The collected data is then analyzed by onboard computers to identify abnormal operating conditions, allowing for early intervention and maintenance. These self-diagnostic capabilities help optimize engine performance and extend the operational life of Wankel engines.

- Vibration analysis and fault detection in rotary engines: Vibration analysis is a key method for self-diagnosis in Wankel engines. By monitoring the characteristic vibration patterns of the rotary engine during operation, abnormalities can be detected early. Advanced systems use accelerometers and vibration sensors strategically placed on the engine housing to capture data. Machine learning algorithms can then compare these vibration signatures against baseline patterns to identify specific faults such as rotor imbalance, apex seal wear, or bearing issues. This non-intrusive diagnostic approach allows for continuous monitoring without affecting engine performance.

- Combustion monitoring and analysis systems: Self-diagnosing Wankel engine models incorporate advanced combustion monitoring systems that analyze the quality and efficiency of the combustion process. These systems use pressure sensors within the combustion chambers to measure pressure curves and detect irregularities. Infrared sensors may also be employed to monitor flame propagation and temperature distribution. By analyzing these parameters, the system can identify issues such as poor fuel mixture, ignition timing problems, or seal leakage. This real-time combustion analysis enables automatic adjustments to optimize performance and reduce emissions.

- Integrated sensor networks for comprehensive engine health monitoring: Modern self-diagnosing Wankel engines utilize integrated sensor networks that provide comprehensive health monitoring capabilities. These networks combine multiple sensor types including temperature, pressure, position, and exhaust gas sensors to create a complete picture of engine condition. The data from these sensors is processed by dedicated electronic control units that can identify correlations between different parameters to diagnose complex issues. Some advanced systems also incorporate oil quality sensors to monitor lubrication effectiveness and detect contamination, which is particularly important for the unique sealing challenges in rotary engines.

- Predictive maintenance systems using historical data analysis: Predictive maintenance systems for Wankel engines leverage historical operating data to forecast potential failures before they occur. These systems collect and store performance data over time, establishing baseline parameters and identifying trends that may indicate developing problems. By applying statistical analysis and machine learning algorithms to this historical dataset, the system can predict when components like apex seals or bearings might fail. This approach allows for scheduled maintenance based on actual engine condition rather than fixed intervals, optimizing maintenance costs and minimizing unexpected downtime.

02 Vibration analysis for fault detection in rotary engines

Vibration analysis is a key method for self-diagnosis in Wankel engines. By monitoring the vibration patterns during operation, the system can detect irregularities that may indicate issues such as rotor imbalance, apex seal wear, or bearing problems. Advanced algorithms compare the vibration signatures to baseline patterns of normal operation, allowing for early detection of developing faults. This technique is particularly effective for rotary engines due to their unique motion characteristics and can be implemented using accelerometers mounted on the engine housing.Expand Specific Solutions03 Combustion monitoring and analysis systems

Self-diagnosing Wankel engine models incorporate combustion monitoring systems that analyze the efficiency and quality of the combustion process. These systems use pressure sensors in the combustion chamber and exhaust gas analyzers to evaluate combustion parameters. By monitoring factors such as combustion timing, pressure curves, and exhaust composition, the system can identify issues related to fuel delivery, ignition timing, or seal leakage. This information helps optimize engine performance and reduce emissions while providing diagnostic capabilities for maintenance purposes.Expand Specific Solutions04 Oil condition monitoring for rotary engines

Oil condition monitoring is crucial for Wankel engines due to their unique lubrication requirements. Self-diagnosing models incorporate sensors that monitor oil quality parameters such as viscosity, contamination levels, and temperature. These systems can detect when oil degradation reaches critical levels or when metal particles indicating internal wear are present. By continuously analyzing the lubricant condition, the system can recommend maintenance actions before engine damage occurs, which is particularly important for rotary engines where proper lubrication is essential for apex seal function and overall reliability.Expand Specific Solutions05 Integrated electronic control units for real-time diagnostics

Modern Wankel engine models feature integrated electronic control units (ECUs) that perform real-time diagnostics across multiple engine systems. These ECUs collect data from various sensors throughout the engine and use sophisticated algorithms to analyze performance patterns. The systems can identify deviations from normal operating parameters and store diagnostic trouble codes for later retrieval. Some advanced models include wireless connectivity for remote diagnostics and predictive maintenance scheduling. This comprehensive approach to engine monitoring helps maintain optimal performance while reducing downtime through preventive maintenance.Expand Specific Solutions

Key Industry Players in Rotary Engine Diagnostic Solutions

The Wankel engine self-diagnostics market is currently in a growth phase, with increasing demand for more efficient rotary engine monitoring systems. The market size is expanding as automotive and aerospace industries seek advanced diagnostic solutions for these specialized engines. Technologically, the field shows varying maturity levels across players. Continental Automotive and Robert Bosch lead commercial development with established sensor and diagnostic platforms, while Toyota and Mazda maintain significant proprietary technologies. Academic institutions like Nanjing University of Aeronautics & Astronautics and Xi'an Jiaotong University are advancing theoretical modeling approaches. Pratt & Whitney Canada represents aerospace applications with specialized diagnostic requirements. The competitive landscape combines established industrial players with emerging academic research centers, creating a dynamic environment for innovation in rotary engine diagnostics.

Continental Automotive GmbH

Technical Solution: Continental has developed a comprehensive self-diagnosing system for Wankel engines that leverages their expertise in automotive electronics and sensor technology. Their approach centers on a distributed sensor network that monitors the unique geometric and thermodynamic characteristics of rotary engines. Continental's system employs high-precision infrared thermal imaging to create detailed temperature profiles of the rotor housing, enabling early detection of cooling system inefficiencies and potential hot spots that could lead to apex seal failure. The diagnostic model incorporates advanced signal processing algorithms that can isolate and identify specific frequency signatures associated with different failure modes in Wankel engines. Continental has implemented a hierarchical diagnostic architecture that processes data at multiple levels - from raw sensor inputs to complex pattern recognition - allowing for both immediate fault detection and long-term predictive maintenance capabilities. Their system also features adaptive threshold adjustment that accounts for engine aging and environmental conditions, reducing false positives while maintaining sensitivity to genuine issues. Continental's diagnostic platform integrates with their broader vehicle management systems, enabling coordinated responses to detected issues across multiple vehicle subsystems.

Strengths: Continental's solution excels at integrating diagnostic data with other vehicle systems for comprehensive health monitoring. Their thermal imaging approach provides exceptional insight into the critical thermal management challenges of Wankel engines. Weaknesses: The system requires specialized sensors that add cost and complexity to engine design, potentially limiting adoption in cost-sensitive applications.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered self-diagnosing Wankel engine models through their advanced Engine Control Unit (ECU) systems that incorporate specialized rotary engine diagnostics. Their approach focuses on integrating comprehensive sensor networks with sophisticated signal processing algorithms specifically calibrated for the unique operating characteristics of Wankel engines. Bosch's system monitors critical parameters including rotor position, combustion timing, and seal integrity through a combination of pressure sensors, thermal imaging, and acoustic monitoring. The diagnostic model employs a multi-stage analysis framework that first establishes baseline performance parameters, then continuously compares real-time data against these baselines to identify deviations. Their technology incorporates adaptive learning algorithms that evolve with the engine's operational history, allowing for increasingly precise diagnostics as the system accumulates data. Bosch has developed specialized fuel injection mapping for Wankel engines that can be dynamically adjusted based on diagnostic feedback, enabling the engine to compensate for developing issues and maintain optimal performance even as components begin to wear.

Strengths: Bosch's extensive experience in automotive diagnostics provides a robust foundation for their Wankel-specific systems. Their integration with existing ECU architecture allows for relatively straightforward implementation in vehicles. Weaknesses: The system's complexity requires specialized knowledge for maintenance and calibration, potentially limiting widespread adoption outside of premium applications.

Core Patents and Research in Rotary Engine Monitoring

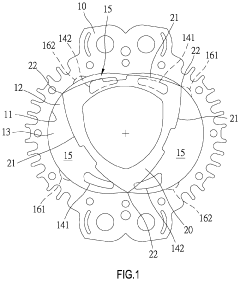

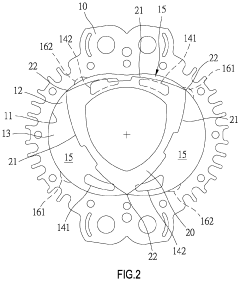

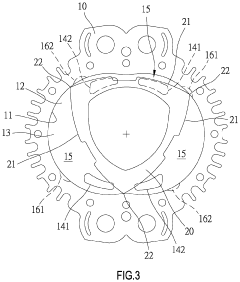

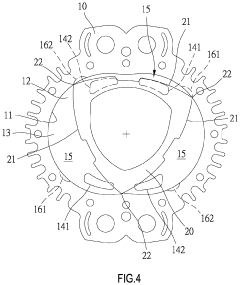

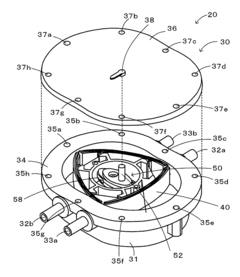

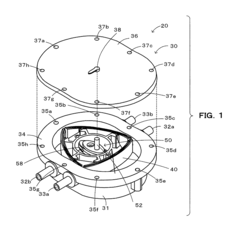

Pistonless rotary motor for air compressor

PatentActiveUS20220282622A1

Innovation

- Incorporating radially spaced grooves in the peripheral wall of the rotor cavity, with first grooves configured to release pressurized air at the top dead center during the compression stroke and second grooves for releasing air during the exhaust stroke, allowing for controlled pressure management and reduced air resistance.

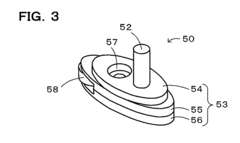

Wankel rotary engine

PatentInactiveUS20110126794A1

Innovation

- Incorporating an eccentric member with a rotating support shaft and a rotating member, such as a roller or ball bearing, that reduces sliding resistance between the rotor's inner periphery and the eccentric member, along with strategically placed fluid intake and exhaust ports, allows efficient rotation of the rotor even with low energy input.

Environmental Impact and Emissions Compliance Considerations

The environmental impact of Wankel engines has historically been a significant concern, with these engines traditionally exhibiting higher emissions compared to conventional piston engines. Self-diagnosing Wankel engine models must incorporate sophisticated emissions monitoring and compliance systems to address these challenges in today's increasingly stringent regulatory landscape.

Wankel engines face unique environmental challenges due to their combustion chamber geometry. The elongated combustion chamber creates thermal efficiency issues and incomplete combustion, resulting in higher hydrocarbon (HC) and carbon monoxide (CO) emissions. Additionally, the oil lubrication system often leads to increased oil consumption, contributing to particulate matter emissions. Self-diagnosing models must specifically monitor these emission patterns to identify deviations that indicate potential environmental compliance issues.

Regulatory frameworks worldwide continue to evolve with increasingly strict emissions standards. Euro 7, China 7, and EPA Tier 3 regulations all demand significant reductions in NOx, HC, CO, and particulate matter emissions. Self-diagnosing Wankel engine models must incorporate predictive capabilities to ensure compliance with these standards throughout the engine's operational life, not just during certification testing.

Real-time emissions monitoring represents a critical component of self-diagnosing systems. Advanced sensor technologies, including wide-band oxygen sensors, NOx sensors, and particulate matter sensors, must be integrated into the diagnostic architecture. These sensors provide continuous data streams that, when analyzed through machine learning algorithms, can detect subtle changes in emissions patterns before they exceed regulatory thresholds.

Thermal management plays a crucial role in emissions control for Wankel engines. Self-diagnosing models should incorporate temperature monitoring across multiple engine zones to optimize combustion efficiency and catalyst performance. Predictive models can anticipate when thermal conditions might lead to increased emissions and proactively adjust engine parameters to maintain compliance.

Catalyst aging and efficiency degradation represent significant long-term environmental concerns. Self-diagnosing systems must track catalyst performance over time, using on-board diagnostic capabilities to estimate remaining catalyst life and efficiency. This predictive maintenance approach ensures emissions compliance throughout the vehicle's operational lifespan while optimizing replacement intervals.

Carbon footprint considerations extend beyond tailpipe emissions to include lifecycle assessment. Modern self-diagnosing Wankel engine models should incorporate carbon accounting capabilities that track fuel consumption patterns and calculate CO2 emissions. This data can inform both regulatory compliance reporting and consumer-facing efficiency metrics, addressing growing market demand for environmental transparency.

Wankel engines face unique environmental challenges due to their combustion chamber geometry. The elongated combustion chamber creates thermal efficiency issues and incomplete combustion, resulting in higher hydrocarbon (HC) and carbon monoxide (CO) emissions. Additionally, the oil lubrication system often leads to increased oil consumption, contributing to particulate matter emissions. Self-diagnosing models must specifically monitor these emission patterns to identify deviations that indicate potential environmental compliance issues.

Regulatory frameworks worldwide continue to evolve with increasingly strict emissions standards. Euro 7, China 7, and EPA Tier 3 regulations all demand significant reductions in NOx, HC, CO, and particulate matter emissions. Self-diagnosing Wankel engine models must incorporate predictive capabilities to ensure compliance with these standards throughout the engine's operational life, not just during certification testing.

Real-time emissions monitoring represents a critical component of self-diagnosing systems. Advanced sensor technologies, including wide-band oxygen sensors, NOx sensors, and particulate matter sensors, must be integrated into the diagnostic architecture. These sensors provide continuous data streams that, when analyzed through machine learning algorithms, can detect subtle changes in emissions patterns before they exceed regulatory thresholds.

Thermal management plays a crucial role in emissions control for Wankel engines. Self-diagnosing models should incorporate temperature monitoring across multiple engine zones to optimize combustion efficiency and catalyst performance. Predictive models can anticipate when thermal conditions might lead to increased emissions and proactively adjust engine parameters to maintain compliance.

Catalyst aging and efficiency degradation represent significant long-term environmental concerns. Self-diagnosing systems must track catalyst performance over time, using on-board diagnostic capabilities to estimate remaining catalyst life and efficiency. This predictive maintenance approach ensures emissions compliance throughout the vehicle's operational lifespan while optimizing replacement intervals.

Carbon footprint considerations extend beyond tailpipe emissions to include lifecycle assessment. Modern self-diagnosing Wankel engine models should incorporate carbon accounting capabilities that track fuel consumption patterns and calculate CO2 emissions. This data can inform both regulatory compliance reporting and consumer-facing efficiency metrics, addressing growing market demand for environmental transparency.

Integration with IoT and Connected Vehicle Ecosystems

The integration of self-diagnosing Wankel engine models with IoT and connected vehicle ecosystems represents a transformative approach to engine management and maintenance. By leveraging the expansive capabilities of IoT infrastructure, Wankel engines can transmit real-time diagnostic data to cloud platforms, enabling continuous monitoring and predictive maintenance. This connectivity creates a feedback loop where engine performance data informs both immediate operational adjustments and long-term design improvements.

Current IoT integration frameworks for Wankel engines typically employ a multi-layered architecture. At the hardware level, specialized sensors monitor critical parameters such as rotor eccentricity, apex seal wear, and combustion chamber temperatures. These sensors connect to edge computing devices that perform preliminary data processing before transmission to cloud platforms via secure communication protocols like MQTT or OPC UA.

The connected vehicle ecosystem extends beyond simple data collection, incorporating machine learning algorithms that analyze operational patterns across fleets of vehicles. These algorithms can identify anomalies that might indicate impending failures before traditional diagnostic systems would detect problems. For Wankel engines, with their unique rotary design, this predictive capability is particularly valuable in monitoring the distinctive wear patterns of apex seals and rotor housings.

Vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communications further enhance the self-diagnostic capabilities of Wankel engines. By comparing performance metrics across similar vehicles operating under varying conditions, the system can distinguish between normal variations and genuine malfunctions. This collaborative diagnostics approach is especially beneficial for Wankel engines, which have historically presented unique maintenance challenges.

Security considerations remain paramount in IoT integration for Wankel engine diagnostics. Implementing robust encryption, authentication protocols, and secure over-the-air update mechanisms helps protect against unauthorized access to engine management systems. As these engines often power high-performance vehicles, security breaches could have significant safety implications.

The standardization of data formats and communication protocols represents another critical challenge. Organizations like AutoSAR and IEEE are developing standards specifically for rotary engine telemetry, aiming to create interoperable systems that function across different vehicle manufacturers and service providers. These standards will facilitate broader adoption of connected diagnostics for Wankel engines.

Looking forward, the integration of blockchain technology offers promising solutions for secure, tamper-proof maintenance records and parts authentication. This could address historical concerns about Wankel engine reliability by creating verifiable service histories and validating the authenticity of replacement components, particularly important for the specialized parts used in rotary engines.

Current IoT integration frameworks for Wankel engines typically employ a multi-layered architecture. At the hardware level, specialized sensors monitor critical parameters such as rotor eccentricity, apex seal wear, and combustion chamber temperatures. These sensors connect to edge computing devices that perform preliminary data processing before transmission to cloud platforms via secure communication protocols like MQTT or OPC UA.

The connected vehicle ecosystem extends beyond simple data collection, incorporating machine learning algorithms that analyze operational patterns across fleets of vehicles. These algorithms can identify anomalies that might indicate impending failures before traditional diagnostic systems would detect problems. For Wankel engines, with their unique rotary design, this predictive capability is particularly valuable in monitoring the distinctive wear patterns of apex seals and rotor housings.

Vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communications further enhance the self-diagnostic capabilities of Wankel engines. By comparing performance metrics across similar vehicles operating under varying conditions, the system can distinguish between normal variations and genuine malfunctions. This collaborative diagnostics approach is especially beneficial for Wankel engines, which have historically presented unique maintenance challenges.

Security considerations remain paramount in IoT integration for Wankel engine diagnostics. Implementing robust encryption, authentication protocols, and secure over-the-air update mechanisms helps protect against unauthorized access to engine management systems. As these engines often power high-performance vehicles, security breaches could have significant safety implications.

The standardization of data formats and communication protocols represents another critical challenge. Organizations like AutoSAR and IEEE are developing standards specifically for rotary engine telemetry, aiming to create interoperable systems that function across different vehicle manufacturers and service providers. These standards will facilitate broader adoption of connected diagnostics for Wankel engines.

Looking forward, the integration of blockchain technology offers promising solutions for secure, tamper-proof maintenance records and parts authentication. This could address historical concerns about Wankel engine reliability by creating verifiable service histories and validating the authenticity of replacement components, particularly important for the specialized parts used in rotary engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!