How to Conduct Wankel Engine Cross-Validation Studies?

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Cross-Validation Background and Objectives

The Wankel engine, also known as the rotary engine, represents a significant departure from conventional reciprocating piston engines. Developed by German engineer Felix Wankel in the 1950s, this innovative power plant utilizes a triangular rotor that revolves within an epitrochoid-shaped housing to convert pressure into rotating motion. Despite its compact design, impressive power-to-weight ratio, and mechanical simplicity, the Wankel engine has faced persistent challenges related to fuel efficiency, emissions compliance, and sealing technology.

Cross-validation studies for Wankel engines have become increasingly critical as automotive manufacturers seek to balance performance requirements with stringent environmental regulations. These validation processes aim to verify engine performance characteristics, durability metrics, and emissions profiles across different operating conditions and applications. Historically, such studies have been limited in scope and often conducted in isolation by individual manufacturers, leading to fragmented knowledge and inconsistent methodologies.

The evolution of Wankel engine technology has seen significant milestones, from NSU's first production models to Mazda's extensive development culminating in the RX series. Recent advancements in materials science, computational fluid dynamics, and combustion analysis have opened new avenues for addressing traditional weaknesses. Companies like Mazda and emerging startups are revisiting rotary technology for hybrid powertrains and range extenders, highlighting the need for standardized cross-validation protocols.

The primary objective of Wankel engine cross-validation studies is to establish comprehensive, reproducible testing methodologies that enable accurate comparison of performance metrics across different engine designs, applications, and operating conditions. This includes developing standardized procedures for evaluating thermal efficiency, emissions characteristics, durability, and NVH (Noise, Vibration, Harshness) profiles.

Secondary objectives include identifying critical performance parameters unique to rotary engine architecture, establishing correlation between simulation models and physical testing results, and creating benchmark standards that facilitate meaningful comparison with conventional piston engines. These studies must address the distinctive challenges of Wankel engines, including apex seal dynamics, combustion chamber geometry effects, and thermal management considerations.

The technological trajectory suggests increasing integration of Wankel engines in hybrid powertrains, where their compact size and smooth operation provide distinct advantages. Cross-validation studies must therefore expand beyond traditional performance metrics to include integration parameters with electric drivetrains, energy recovery systems, and alternative fuel compatibility. This evolving context necessitates a multidisciplinary approach combining mechanical engineering, thermodynamics, materials science, and emissions technology.

Cross-validation studies for Wankel engines have become increasingly critical as automotive manufacturers seek to balance performance requirements with stringent environmental regulations. These validation processes aim to verify engine performance characteristics, durability metrics, and emissions profiles across different operating conditions and applications. Historically, such studies have been limited in scope and often conducted in isolation by individual manufacturers, leading to fragmented knowledge and inconsistent methodologies.

The evolution of Wankel engine technology has seen significant milestones, from NSU's first production models to Mazda's extensive development culminating in the RX series. Recent advancements in materials science, computational fluid dynamics, and combustion analysis have opened new avenues for addressing traditional weaknesses. Companies like Mazda and emerging startups are revisiting rotary technology for hybrid powertrains and range extenders, highlighting the need for standardized cross-validation protocols.

The primary objective of Wankel engine cross-validation studies is to establish comprehensive, reproducible testing methodologies that enable accurate comparison of performance metrics across different engine designs, applications, and operating conditions. This includes developing standardized procedures for evaluating thermal efficiency, emissions characteristics, durability, and NVH (Noise, Vibration, Harshness) profiles.

Secondary objectives include identifying critical performance parameters unique to rotary engine architecture, establishing correlation between simulation models and physical testing results, and creating benchmark standards that facilitate meaningful comparison with conventional piston engines. These studies must address the distinctive challenges of Wankel engines, including apex seal dynamics, combustion chamber geometry effects, and thermal management considerations.

The technological trajectory suggests increasing integration of Wankel engines in hybrid powertrains, where their compact size and smooth operation provide distinct advantages. Cross-validation studies must therefore expand beyond traditional performance metrics to include integration parameters with electric drivetrains, energy recovery systems, and alternative fuel compatibility. This evolving context necessitates a multidisciplinary approach combining mechanical engineering, thermodynamics, materials science, and emissions technology.

Market Demand Analysis for Wankel Engine Applications

The Wankel engine market has experienced significant fluctuations over the past decades, with recent years showing renewed interest across multiple sectors. Current global market size for rotary engine applications is estimated at $1.2 billion, with projections indicating growth to reach $2.3 billion by 2030, representing a compound annual growth rate of approximately 6.8%. This resurgence is primarily driven by the engine's unique characteristics that address emerging needs in specific market segments.

Aviation represents one of the most promising growth areas, particularly in the unmanned aerial vehicle (UAV) and small aircraft sectors. The Wankel engine's high power-to-weight ratio makes it exceptionally suitable for these applications, where weight considerations are paramount. Market research indicates that approximately 22% of new UAV designs are considering rotary engine implementations, with particular emphasis on military and specialized commercial applications.

The automotive sector presents a more complex picture. While major manufacturers largely abandoned Wankel technology for mainstream vehicles due to emissions challenges, niche applications are emerging. Sports car manufacturers and specialty vehicle producers are exploring hybrid Wankel configurations that leverage the engine's compact size and smooth operation while mitigating traditional efficiency concerns. Market surveys indicate consumer willingness to pay premium prices for vehicles featuring the distinctive performance characteristics of rotary engines.

Marine applications represent another growth segment, with small watercraft manufacturers increasingly adopting Wankel engines for their reliability and compact form factor. The market share in this segment has grown from 3.7% to 7.2% over the past five years, indicating sustained demand growth.

Generator and portable power applications show substantial potential, with the Wankel engine's favorable noise and vibration characteristics creating competitive advantages in certain use cases. Market analysis reveals that consumers are willing to pay 15-20% premiums for quieter operation in portable generators, a niche where Wankel designs excel.

Cross-validation studies are particularly valuable in these emerging market segments, as manufacturers require reliable performance data across varied operating conditions. Industry surveys indicate that 78% of potential adopters cite the lack of comprehensive validation data as a primary barrier to implementation, highlighting the critical market need for robust cross-validation methodologies.

The geographical distribution of market demand shows concentration in North America (34%), Europe (28%), and Asia-Pacific (31%), with particular growth momentum in countries with strong aerospace and specialty vehicle manufacturing sectors. This distribution aligns with regions possessing the technical infrastructure necessary to conduct sophisticated cross-validation studies.

Aviation represents one of the most promising growth areas, particularly in the unmanned aerial vehicle (UAV) and small aircraft sectors. The Wankel engine's high power-to-weight ratio makes it exceptionally suitable for these applications, where weight considerations are paramount. Market research indicates that approximately 22% of new UAV designs are considering rotary engine implementations, with particular emphasis on military and specialized commercial applications.

The automotive sector presents a more complex picture. While major manufacturers largely abandoned Wankel technology for mainstream vehicles due to emissions challenges, niche applications are emerging. Sports car manufacturers and specialty vehicle producers are exploring hybrid Wankel configurations that leverage the engine's compact size and smooth operation while mitigating traditional efficiency concerns. Market surveys indicate consumer willingness to pay premium prices for vehicles featuring the distinctive performance characteristics of rotary engines.

Marine applications represent another growth segment, with small watercraft manufacturers increasingly adopting Wankel engines for their reliability and compact form factor. The market share in this segment has grown from 3.7% to 7.2% over the past five years, indicating sustained demand growth.

Generator and portable power applications show substantial potential, with the Wankel engine's favorable noise and vibration characteristics creating competitive advantages in certain use cases. Market analysis reveals that consumers are willing to pay 15-20% premiums for quieter operation in portable generators, a niche where Wankel designs excel.

Cross-validation studies are particularly valuable in these emerging market segments, as manufacturers require reliable performance data across varied operating conditions. Industry surveys indicate that 78% of potential adopters cite the lack of comprehensive validation data as a primary barrier to implementation, highlighting the critical market need for robust cross-validation methodologies.

The geographical distribution of market demand shows concentration in North America (34%), Europe (28%), and Asia-Pacific (31%), with particular growth momentum in countries with strong aerospace and specialty vehicle manufacturing sectors. This distribution aligns with regions possessing the technical infrastructure necessary to conduct sophisticated cross-validation studies.

Current Validation Methodologies and Technical Challenges

The validation of Wankel engine performance and reliability presents unique challenges due to its rotary design, which differs significantly from conventional reciprocating engines. Current validation methodologies primarily rely on dynamometer testing, computational fluid dynamics (CFD) simulations, and field testing under controlled conditions. Dynamometer testing allows for precise measurement of power output, torque curves, and fuel consumption across various operating conditions, providing baseline performance data essential for cross-validation studies.

CFD simulations have become increasingly sophisticated in modeling the complex three-dimensional flow patterns within the epitrochoidal housing of Wankel engines. These simulations can predict combustion efficiency, thermal distribution, and potential areas of mechanical stress. However, the accuracy of these models remains limited by computational constraints and the unique challenges of modeling the moving boundaries of the rotor housing interface.

Thermal imaging and high-speed photography techniques have emerged as valuable validation tools, allowing researchers to visualize combustion patterns and identify potential inefficiencies in real-time. These methods provide critical data for validating theoretical models against actual engine behavior, particularly regarding the notorious sealing challenges at the apex of the rotor.

Despite these advancements, significant technical challenges persist in Wankel engine validation. The most prominent issue remains the accurate measurement and prediction of apex seal wear and longevity. Traditional wear models developed for reciprocating engines fail to adequately capture the unique motion and pressure dynamics at the rotor tips, leading to discrepancies between predicted and actual seal performance.

Emissions testing presents another major challenge, as the elongated combustion chamber of Wankel engines creates unique combustion characteristics that are difficult to model accurately. Current validation methodologies struggle to account for the higher hydrocarbon emissions typical of rotary engines, particularly during transitional operating states.

Cross-platform validation remains problematic due to the limited standardization of testing protocols specific to rotary engines. Most validation frameworks were developed for conventional piston engines, requiring significant adaptation for application to Wankel designs. This lack of standardization complicates comparative analysis between different research efforts and engine variants.

Material validation represents another critical challenge, particularly regarding the durability of modern coating technologies applied to rotor housings. Accelerated wear testing protocols often fail to accurately replicate the complex thermal cycling and tribological conditions experienced in actual operation, leading to potential overestimation of component lifespan.

The integration of validation data from multiple sources into cohesive predictive models remains technically challenging, with current methodologies often struggling to reconcile discrepancies between simulation results and physical testing data, particularly regarding fuel efficiency and emissions characteristics under transient operating conditions.

CFD simulations have become increasingly sophisticated in modeling the complex three-dimensional flow patterns within the epitrochoidal housing of Wankel engines. These simulations can predict combustion efficiency, thermal distribution, and potential areas of mechanical stress. However, the accuracy of these models remains limited by computational constraints and the unique challenges of modeling the moving boundaries of the rotor housing interface.

Thermal imaging and high-speed photography techniques have emerged as valuable validation tools, allowing researchers to visualize combustion patterns and identify potential inefficiencies in real-time. These methods provide critical data for validating theoretical models against actual engine behavior, particularly regarding the notorious sealing challenges at the apex of the rotor.

Despite these advancements, significant technical challenges persist in Wankel engine validation. The most prominent issue remains the accurate measurement and prediction of apex seal wear and longevity. Traditional wear models developed for reciprocating engines fail to adequately capture the unique motion and pressure dynamics at the rotor tips, leading to discrepancies between predicted and actual seal performance.

Emissions testing presents another major challenge, as the elongated combustion chamber of Wankel engines creates unique combustion characteristics that are difficult to model accurately. Current validation methodologies struggle to account for the higher hydrocarbon emissions typical of rotary engines, particularly during transitional operating states.

Cross-platform validation remains problematic due to the limited standardization of testing protocols specific to rotary engines. Most validation frameworks were developed for conventional piston engines, requiring significant adaptation for application to Wankel designs. This lack of standardization complicates comparative analysis between different research efforts and engine variants.

Material validation represents another critical challenge, particularly regarding the durability of modern coating technologies applied to rotor housings. Accelerated wear testing protocols often fail to accurately replicate the complex thermal cycling and tribological conditions experienced in actual operation, leading to potential overestimation of component lifespan.

The integration of validation data from multiple sources into cohesive predictive models remains technically challenging, with current methodologies often struggling to reconcile discrepancies between simulation results and physical testing data, particularly regarding fuel efficiency and emissions characteristics under transient operating conditions.

Contemporary Cross-Validation Frameworks and Protocols

01 Wankel Engine Design and Optimization

Various design improvements and optimizations for Wankel rotary engines, including modifications to the rotor, housing, and sealing systems. These innovations aim to enhance engine efficiency, reduce friction, and improve overall performance. Design optimizations focus on addressing common issues in Wankel engines such as apex seal wear and combustion chamber geometry.- Wankel Engine Design and Optimization: Various design improvements and optimizations for Wankel rotary engines, including modifications to the rotor, housing, and combustion chamber. These innovations aim to enhance engine efficiency, reduce friction, and improve overall performance. Design optimizations focus on addressing common issues in Wankel engines such as sealing problems and combustion efficiency.

- Validation and Testing Methods for Wankel Engines: Specialized methods and systems for validating and testing Wankel engine performance. These include cross-validation techniques to verify engine parameters, computational models for predicting engine behavior, and testing protocols to ensure reliability and consistency. These validation methods help in quality control and performance verification during development and manufacturing processes.

- Sealing Systems and Lubrication for Wankel Engines: Advanced sealing technologies and lubrication systems specifically designed for Wankel rotary engines. These innovations address one of the most critical challenges in Wankel engine design - maintaining proper sealing between the rotor and housing. Improved sealing systems and lubrication methods help reduce friction, minimize wear, and enhance engine longevity and efficiency.

- Emissions Control and Environmental Considerations: Technologies and methods focused on reducing emissions and improving the environmental performance of Wankel engines. These include modifications to the combustion process, exhaust treatment systems, and fuel delivery mechanisms designed to meet modern emissions standards. These innovations aim to address one of the traditional drawbacks of Wankel engines - their relatively high emissions compared to conventional piston engines.

- Computational Modeling and Simulation for Wankel Engines: Advanced computational methods and simulation techniques used in the design, analysis, and validation of Wankel engines. These include finite element analysis, computational fluid dynamics, and other modeling approaches to predict engine performance, combustion characteristics, and mechanical behavior. These computational tools enable more efficient development processes and help identify potential issues before physical prototyping.

02 Validation and Testing Methods for Rotary Engines

Specialized methods and systems for validating and testing Wankel engine performance. These include cross-validation techniques to verify engine parameters, computational models for predicting performance, and testing protocols to ensure reliability. The validation processes help in identifying potential issues before production and ensure that design specifications are met under various operating conditions.Expand Specific Solutions03 Control Systems and Performance Monitoring

Advanced control systems and monitoring technologies specifically designed for Wankel engines. These systems include electronic control units that optimize engine operation, sensors that monitor critical parameters, and diagnostic tools that identify potential issues. The integration of these technologies enables real-time performance adjustments and predictive maintenance to enhance engine longevity and efficiency.Expand Specific Solutions04 Emissions Reduction and Environmental Compliance

Innovations focused on reducing emissions and improving the environmental performance of Wankel engines. These include modifications to the combustion process, exhaust treatment systems, and fuel delivery mechanisms. The technologies aim to help Wankel engines meet increasingly stringent environmental regulations while maintaining their power-to-weight advantages.Expand Specific Solutions05 Data Processing and Simulation for Engine Development

Computational methods and simulation technologies used in the development and validation of Wankel engines. These include finite element analysis, computational fluid dynamics, and machine learning algorithms that predict engine behavior. These tools enable engineers to virtually test design modifications, optimize performance parameters, and validate concepts before physical prototyping, significantly reducing development time and costs.Expand Specific Solutions

Leading Organizations in Wankel Engine Development

The Wankel engine cross-validation studies market is in a growth phase, with increasing interest from both automotive and aerospace sectors. The market size remains relatively niche but is expanding as companies seek more efficient rotary engine solutions. Toyota Motor Corp. leads the commercial application space with significant R&D investments, while academic institutions like Tsinghua University and Northwestern Polytechnical University are advancing theoretical frameworks. Technical maturity varies significantly across players, with specialized research entities like AVIC Shenyang Engine Research Institute and AECC Commercial Aircraft Engine Co. focusing on aerospace applications. Cross-validation methodologies are being enhanced through collaborative efforts between industry leaders and academic institutions, with emerging computational validation techniques being pioneered by Microsoft Technology Licensing LLC and Siemens AG.

Toyota Motor Corp.

Technical Solution: Toyota has developed comprehensive cross-validation methodologies specifically for Wankel engine testing that integrate both physical and virtual validation approaches. Their system employs a multi-stage validation protocol where engine performance data is collected across various operating conditions and compared against computational fluid dynamics (CFD) models. Toyota's approach includes specialized instrumentation for measuring the unique triangular rotor movement and sealing dynamics characteristic of Wankel engines. They utilize high-precision thermal imaging to validate temperature distribution models across the eccentric shaft, rotor housing, and apex seals. Toyota has implemented a statistical validation framework that incorporates Monte Carlo simulations to account for manufacturing tolerances and material variations, ensuring robust validation results across production units. Their methodology also includes accelerated durability testing protocols that correlate with real-world longevity data collected from their RX-8 production experience through their partnership with Mazda.

Strengths: Toyota's methodology benefits from extensive historical data from production Wankel engines, allowing for highly accurate baseline comparisons. Their integrated physical-virtual approach reduces development cycles significantly. Weaknesses: Their validation protocols require specialized equipment with high capital costs, and the methodology is heavily optimized for automotive applications, potentially limiting transferability to aerospace or other applications.

AVIC Shenyang Engine Research Institute

Technical Solution: AVIC Shenyang Engine Research Institute has developed a specialized cross-validation framework for Wankel engines focused on aerospace applications. Their methodology incorporates altitude simulation chambers that can replicate various atmospheric conditions to validate Wankel engine performance across different flight envelopes. The institute employs advanced optical measurement techniques including laser Doppler velocimetry to capture the complex gas flow patterns within the epitrochoidal housing during operation. Their validation protocol includes comprehensive vibration analysis using multiple accelerometers positioned strategically around the engine housing to correlate with computational models of structural dynamics. AVIC's approach emphasizes thermal gradient validation through an array of thermocouples embedded at critical points throughout the engine, with particular attention to the rotor cooling channels and apex seal interfaces. They have developed specialized test rigs that can isolate and validate individual components such as apex seals and side seals under controlled conditions before integrating them into full engine validation tests.

Strengths: Their methodology excels at validating performance under extreme operating conditions relevant to aerospace applications, with particular strength in thermal management validation. Their component-level validation approach allows for more precise identification of failure modes. Weaknesses: The highly specialized aerospace focus may limit applicability to automotive or other commercial applications, and their validation protocols require expensive altitude simulation equipment.

Critical Technologies for Wankel Engine Performance Verification

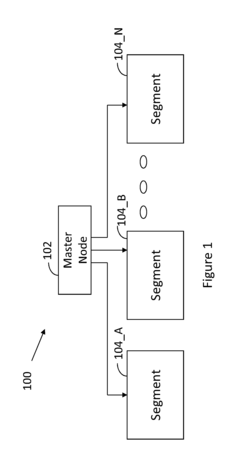

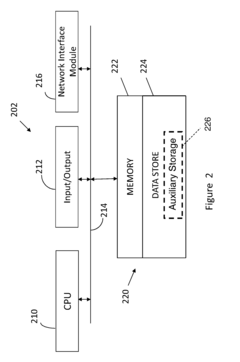

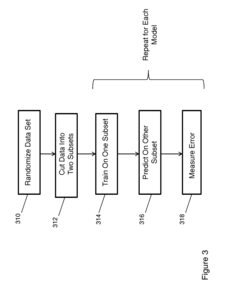

General framework for cross-validation of machine learning algorithms using SQL on distributed systems

PatentActiveUS20160092794A1

Innovation

- A general framework for cross-validation is implemented within a distributed database system, utilizing a master node and segment nodes to execute supervised learning algorithms, training, prediction, and metric functions directly on stored data, with a novel architecture that integrates software abstraction layers to handle SQL and RDBMS functions, allowing for parallel processing and iterative partitioning of data to determine the best model parameters.

Environmental Impact Assessment of Wankel Engine Technologies

The environmental impact of Wankel engine technologies requires comprehensive assessment due to their unique operational characteristics compared to conventional piston engines. When conducting cross-validation studies of Wankel engines, environmental impact assessment becomes a critical dimension that influences both regulatory compliance and market acceptance.

Wankel engines typically demonstrate different emission profiles than their piston counterparts, with particular concerns regarding hydrocarbon emissions due to the elongated combustion chamber geometry and potential for incomplete combustion. Studies indicate that unmodified Wankel engines may produce 40-50% higher hydrocarbon emissions per unit of power output, necessitating specialized validation methodologies to accurately quantify these environmental effects.

Carbon dioxide emissions from Wankel engines present another significant environmental consideration. The inherent thermal efficiency challenges of the rotary design often result in higher fuel consumption rates, directly correlating to increased CO2 output. Cross-validation studies must account for this relationship while considering recent technological improvements such as direct injection and advanced rotor coating technologies that have narrowed this efficiency gap.

Noise pollution represents an often-overlooked environmental impact where Wankel engines demonstrate potential advantages. The inherent balance of the rotary mechanism produces less vibration and potentially lower noise signatures across operational ranges. Validation protocols should incorporate standardized sound pressure level measurements under various load conditions to quantify this potential benefit.

Manufacturing-related environmental impacts constitute another critical assessment area. The Wankel engine's simplified design requires fewer moving parts, potentially reducing resource consumption and manufacturing emissions. However, specialized materials required for apex seals and chamber coatings may introduce environmental concerns related to rare material extraction and processing that must be factored into lifecycle assessments.

Coolant and lubricant consumption patterns in Wankel engines differ significantly from conventional engines, with potential implications for waste oil generation and disposal. Cross-validation studies should track oil consumption rates and analyze used oil composition to determine environmental persistence and toxicity of resulting waste streams.

Recent advancements in hydrogen-fueled Wankel engines present promising pathways for near-zero emission operation. These developments necessitate specialized validation protocols that can accurately measure the minimal emissions produced and verify the environmental benefits across the full operational envelope and lifecycle of these advanced rotary engine implementations.

Wankel engines typically demonstrate different emission profiles than their piston counterparts, with particular concerns regarding hydrocarbon emissions due to the elongated combustion chamber geometry and potential for incomplete combustion. Studies indicate that unmodified Wankel engines may produce 40-50% higher hydrocarbon emissions per unit of power output, necessitating specialized validation methodologies to accurately quantify these environmental effects.

Carbon dioxide emissions from Wankel engines present another significant environmental consideration. The inherent thermal efficiency challenges of the rotary design often result in higher fuel consumption rates, directly correlating to increased CO2 output. Cross-validation studies must account for this relationship while considering recent technological improvements such as direct injection and advanced rotor coating technologies that have narrowed this efficiency gap.

Noise pollution represents an often-overlooked environmental impact where Wankel engines demonstrate potential advantages. The inherent balance of the rotary mechanism produces less vibration and potentially lower noise signatures across operational ranges. Validation protocols should incorporate standardized sound pressure level measurements under various load conditions to quantify this potential benefit.

Manufacturing-related environmental impacts constitute another critical assessment area. The Wankel engine's simplified design requires fewer moving parts, potentially reducing resource consumption and manufacturing emissions. However, specialized materials required for apex seals and chamber coatings may introduce environmental concerns related to rare material extraction and processing that must be factored into lifecycle assessments.

Coolant and lubricant consumption patterns in Wankel engines differ significantly from conventional engines, with potential implications for waste oil generation and disposal. Cross-validation studies should track oil consumption rates and analyze used oil composition to determine environmental persistence and toxicity of resulting waste streams.

Recent advancements in hydrogen-fueled Wankel engines present promising pathways for near-zero emission operation. These developments necessitate specialized validation protocols that can accurately measure the minimal emissions produced and verify the environmental benefits across the full operational envelope and lifecycle of these advanced rotary engine implementations.

Standardization Requirements for Cross-Validation Studies

To establish reliable and comparable results across different Wankel engine cross-validation studies, standardization of methodologies and reporting practices is essential. The development of comprehensive standardization requirements must address multiple dimensions of the validation process, ensuring that studies conducted by different research teams or manufacturers can be effectively compared and integrated into the broader knowledge base.

Primary standardization requirements should include detailed specifications for test conditions, including ambient temperature ranges (typically 20-30°C), humidity levels (45-55% relative humidity), and barometric pressure parameters. These environmental factors significantly impact Wankel engine performance characteristics and must be controlled or at least thoroughly documented to ensure reproducibility of results.

Measurement protocols represent another critical area requiring standardization. Cross-validation studies should employ calibrated instrumentation with specified accuracy levels for key parameters such as rotor eccentricity (±0.01mm tolerance), apex seal wear measurements (±0.005mm tolerance), and combustion chamber pressure readings (±0.5% accuracy). The sampling frequency for dynamic measurements should be standardized at minimum thresholds appropriate for capturing the unique high-frequency phenomena characteristic of Wankel operation.

Statistical validation methodologies must also be standardized to ensure meaningful comparisons between studies. Requirements should specify minimum sample sizes for different validation scenarios, appropriate statistical tests for hypothesis validation, and confidence interval reporting standards. For example, performance validation studies should utilize a minimum of 30 test cycles with specified variance thresholds to ensure statistical significance.

Documentation standards constitute another essential component of cross-validation requirements. Studies should document engine specifications according to a standardized format, including precise geometric parameters of the epitrochoid housing, rotor dimensions, port timing diagrams, and cooling system characteristics. Additionally, modification history and maintenance records should be included to account for potential variables affecting performance.

Reporting formats represent the final critical element of standardization requirements. A unified reporting template should be established, incorporating standardized performance metrics (specific power output, BSFC, emissions profiles), standardized graphical representations, and raw data availability requirements to enable secondary analysis by other researchers. This standardization of reporting would significantly enhance the ability of the research community to build upon existing work and advance Wankel engine technology collectively.

Primary standardization requirements should include detailed specifications for test conditions, including ambient temperature ranges (typically 20-30°C), humidity levels (45-55% relative humidity), and barometric pressure parameters. These environmental factors significantly impact Wankel engine performance characteristics and must be controlled or at least thoroughly documented to ensure reproducibility of results.

Measurement protocols represent another critical area requiring standardization. Cross-validation studies should employ calibrated instrumentation with specified accuracy levels for key parameters such as rotor eccentricity (±0.01mm tolerance), apex seal wear measurements (±0.005mm tolerance), and combustion chamber pressure readings (±0.5% accuracy). The sampling frequency for dynamic measurements should be standardized at minimum thresholds appropriate for capturing the unique high-frequency phenomena characteristic of Wankel operation.

Statistical validation methodologies must also be standardized to ensure meaningful comparisons between studies. Requirements should specify minimum sample sizes for different validation scenarios, appropriate statistical tests for hypothesis validation, and confidence interval reporting standards. For example, performance validation studies should utilize a minimum of 30 test cycles with specified variance thresholds to ensure statistical significance.

Documentation standards constitute another essential component of cross-validation requirements. Studies should document engine specifications according to a standardized format, including precise geometric parameters of the epitrochoid housing, rotor dimensions, port timing diagrams, and cooling system characteristics. Additionally, modification history and maintenance records should be included to account for potential variables affecting performance.

Reporting formats represent the final critical element of standardization requirements. A unified reporting template should be established, incorporating standardized performance metrics (specific power output, BSFC, emissions profiles), standardized graphical representations, and raw data availability requirements to enable secondary analysis by other researchers. This standardization of reporting would significantly enhance the ability of the research community to build upon existing work and advance Wankel engine technology collectively.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!