How to Utilize AI in Wankel Engine Diagnostics?

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine AI Diagnostics Background and Objectives

The Wankel rotary engine, developed by German engineer Felix Wankel in the 1950s, represents a significant departure from conventional reciprocating piston engines. Its unique design featuring a triangular rotor moving within an epitrochoid housing has garnered attention for its compact size, smooth operation, and high power-to-weight ratio. Despite these advantages, Wankel engines have faced persistent challenges including sealing issues, fuel efficiency concerns, and emissions compliance difficulties, which have limited their widespread adoption in the automotive industry.

Recent technological advancements in artificial intelligence present unprecedented opportunities to address these longstanding challenges through enhanced diagnostics capabilities. The integration of AI with Wankel engine systems aims to revolutionize how these engines are monitored, maintained, and optimized throughout their operational lifecycle. This technological convergence represents a promising frontier for revitalizing interest in rotary engine technology.

The primary objective of this research is to explore comprehensive AI-driven diagnostic solutions specifically tailored for Wankel rotary engines. We seek to develop frameworks that can accurately detect, predict, and diagnose performance issues before they manifest as critical failures. By leveraging machine learning algorithms, sensor fusion techniques, and advanced data analytics, we aim to establish real-time monitoring systems capable of identifying subtle anomalies in rotary engine operation.

Historical attempts at Wankel engine diagnostics have relied predominantly on conventional methods such as periodic maintenance schedules and reactive troubleshooting. These approaches have proven inadequate for addressing the unique wear patterns, combustion characteristics, and thermal management challenges inherent to rotary engine design. The evolution toward predictive maintenance represents a significant paradigm shift with potential to overcome these limitations.

Current technological trends indicate growing momentum toward edge computing, Internet of Things (IoT) integration, and advanced sensor technologies in automotive diagnostics. These developments create a fertile environment for implementing sophisticated AI solutions in Wankel engine applications. The convergence of these technologies enables more granular data collection and analysis than previously possible.

This research aims to establish a technological foundation that not only improves the reliability and longevity of existing Wankel engine applications but also potentially revitalizes interest in rotary engine technology for future mobility solutions. By addressing the historical challenges through cutting-edge AI implementations, we envision creating diagnostic systems that transform the operational viability of Wankel engines in contemporary applications.

Recent technological advancements in artificial intelligence present unprecedented opportunities to address these longstanding challenges through enhanced diagnostics capabilities. The integration of AI with Wankel engine systems aims to revolutionize how these engines are monitored, maintained, and optimized throughout their operational lifecycle. This technological convergence represents a promising frontier for revitalizing interest in rotary engine technology.

The primary objective of this research is to explore comprehensive AI-driven diagnostic solutions specifically tailored for Wankel rotary engines. We seek to develop frameworks that can accurately detect, predict, and diagnose performance issues before they manifest as critical failures. By leveraging machine learning algorithms, sensor fusion techniques, and advanced data analytics, we aim to establish real-time monitoring systems capable of identifying subtle anomalies in rotary engine operation.

Historical attempts at Wankel engine diagnostics have relied predominantly on conventional methods such as periodic maintenance schedules and reactive troubleshooting. These approaches have proven inadequate for addressing the unique wear patterns, combustion characteristics, and thermal management challenges inherent to rotary engine design. The evolution toward predictive maintenance represents a significant paradigm shift with potential to overcome these limitations.

Current technological trends indicate growing momentum toward edge computing, Internet of Things (IoT) integration, and advanced sensor technologies in automotive diagnostics. These developments create a fertile environment for implementing sophisticated AI solutions in Wankel engine applications. The convergence of these technologies enables more granular data collection and analysis than previously possible.

This research aims to establish a technological foundation that not only improves the reliability and longevity of existing Wankel engine applications but also potentially revitalizes interest in rotary engine technology for future mobility solutions. By addressing the historical challenges through cutting-edge AI implementations, we envision creating diagnostic systems that transform the operational viability of Wankel engines in contemporary applications.

Market Demand Analysis for AI-Enhanced Rotary Engine Diagnostics

The global market for AI-enhanced rotary engine diagnostics is experiencing significant growth, driven by the increasing adoption of Wankel engines in specialized applications and the broader trend toward predictive maintenance systems. While Wankel engines represent a niche segment compared to conventional piston engines, they maintain strong presence in specific sectors including aviation, racing, and certain automotive applications where their power-to-weight advantages are valued.

Market research indicates that the automotive diagnostics market is projected to grow at a compound annual growth rate of 5.7% through 2028, with AI-powered diagnostic solutions representing the fastest-growing segment. Within this broader trend, rotary engine diagnostics presents a specialized opportunity with unique value propositions for service providers and manufacturers.

The primary market drivers for AI-enhanced Wankel engine diagnostics include the aging fleet of rotary-powered vehicles requiring more sophisticated maintenance approaches, the complexity of rotary engine failure modes that benefit from AI pattern recognition, and the high cost of rotary engine repairs that creates demand for preventive solutions. Particularly notable is the enthusiast market surrounding vehicles like the Mazda RX series, where owners demonstrate willingness to invest in advanced diagnostic technologies to preserve these increasingly rare powerplants.

Commercial applications present another significant market segment, particularly in aviation where rotary engines are utilized in certain UAV and light aircraft applications. These use cases demand extremely high reliability and benefit substantially from predictive maintenance capabilities that AI can provide.

The market landscape reveals several distinct customer segments: professional service centers seeking efficiency improvements, enthusiast owners willing to pay premium prices for specialized diagnostic tools, fleet operators requiring system-wide monitoring solutions, and OEMs looking to integrate diagnostic capabilities into new designs or aftermarket support programs.

Geographically, the market shows concentration in Japan, North America, and parts of Europe where rotary engine adoption has historically been strongest. Japan represents a particularly important market due to the heritage of rotary technology and the concentration of technical expertise.

Competitive analysis reveals limited specialized offerings for rotary engine diagnostics, creating an opportunity gap for AI-enhanced solutions. Current market offerings typically consist of generic engine diagnostic tools with limited rotary-specific capabilities, presenting an underserved niche that AI solutions could effectively address through specialized algorithms trained on rotary engine failure patterns.

Market research indicates that the automotive diagnostics market is projected to grow at a compound annual growth rate of 5.7% through 2028, with AI-powered diagnostic solutions representing the fastest-growing segment. Within this broader trend, rotary engine diagnostics presents a specialized opportunity with unique value propositions for service providers and manufacturers.

The primary market drivers for AI-enhanced Wankel engine diagnostics include the aging fleet of rotary-powered vehicles requiring more sophisticated maintenance approaches, the complexity of rotary engine failure modes that benefit from AI pattern recognition, and the high cost of rotary engine repairs that creates demand for preventive solutions. Particularly notable is the enthusiast market surrounding vehicles like the Mazda RX series, where owners demonstrate willingness to invest in advanced diagnostic technologies to preserve these increasingly rare powerplants.

Commercial applications present another significant market segment, particularly in aviation where rotary engines are utilized in certain UAV and light aircraft applications. These use cases demand extremely high reliability and benefit substantially from predictive maintenance capabilities that AI can provide.

The market landscape reveals several distinct customer segments: professional service centers seeking efficiency improvements, enthusiast owners willing to pay premium prices for specialized diagnostic tools, fleet operators requiring system-wide monitoring solutions, and OEMs looking to integrate diagnostic capabilities into new designs or aftermarket support programs.

Geographically, the market shows concentration in Japan, North America, and parts of Europe where rotary engine adoption has historically been strongest. Japan represents a particularly important market due to the heritage of rotary technology and the concentration of technical expertise.

Competitive analysis reveals limited specialized offerings for rotary engine diagnostics, creating an opportunity gap for AI-enhanced solutions. Current market offerings typically consist of generic engine diagnostic tools with limited rotary-specific capabilities, presenting an underserved niche that AI solutions could effectively address through specialized algorithms trained on rotary engine failure patterns.

Current Challenges in Wankel Engine Diagnostic Technologies

Despite significant advancements in automotive diagnostics, Wankel engine diagnostic technologies face several persistent challenges that impede efficient maintenance and performance optimization. The unique rotary design of Wankel engines creates distinctive failure modes and wear patterns that conventional diagnostic tools struggle to accurately identify and analyze. Traditional OBD-II systems, while effective for reciprocating engines, lack specialized parameters for monitoring the health of rotor seals, apex seals, and eccentric shaft bearings—critical components in rotary engines.

Vibration analysis, a common diagnostic technique, presents particular difficulties when applied to Wankel engines due to their inherently different vibration signatures compared to piston engines. Current accelerometer-based systems often misinterpret normal rotary operation as potential faults, leading to false positives and unnecessary maintenance interventions. This diagnostic uncertainty increases operational costs and reduces confidence in predictive maintenance schedules.

Thermal management diagnostics represent another significant challenge. Wankel engines' distinctive combustion chamber geometry creates unique heat distribution patterns that conventional temperature sensors fail to monitor effectively. The resulting incomplete thermal profile data prevents accurate assessment of combustion efficiency and potential cooling system failures, which are common issues in rotary engines.

Emissions analysis tools also demonstrate limitations when applied to Wankel engines. The continuous combustion process and distinctive exhaust gas composition require specialized interpretation algorithms that most current diagnostic systems lack. This deficiency hampers both environmental compliance efforts and performance tuning capabilities, particularly as emissions regulations become increasingly stringent worldwide.

Data integration presents perhaps the most significant obstacle to effective Wankel diagnostics. Current systems typically operate in isolation, with minimal cross-parameter analysis capabilities. This siloed approach prevents the identification of subtle correlations between different engine metrics that could indicate emerging problems before they cause catastrophic failures.

Resource constraints further complicate the diagnostic landscape. The relatively small market share of Wankel engines has limited investment in specialized diagnostic technologies, creating a self-reinforcing cycle where inadequate tools reduce adoption rates, which in turn reduces incentives for further diagnostic development. This has left Wankel engine operators with a fragmented ecosystem of partial solutions rather than comprehensive diagnostic platforms.

These challenges collectively create significant opportunities for AI-based solutions that can overcome the limitations of traditional diagnostic approaches through advanced pattern recognition, multi-parameter correlation analysis, and adaptive learning capabilities tailored to the unique characteristics of rotary engine operation.

Vibration analysis, a common diagnostic technique, presents particular difficulties when applied to Wankel engines due to their inherently different vibration signatures compared to piston engines. Current accelerometer-based systems often misinterpret normal rotary operation as potential faults, leading to false positives and unnecessary maintenance interventions. This diagnostic uncertainty increases operational costs and reduces confidence in predictive maintenance schedules.

Thermal management diagnostics represent another significant challenge. Wankel engines' distinctive combustion chamber geometry creates unique heat distribution patterns that conventional temperature sensors fail to monitor effectively. The resulting incomplete thermal profile data prevents accurate assessment of combustion efficiency and potential cooling system failures, which are common issues in rotary engines.

Emissions analysis tools also demonstrate limitations when applied to Wankel engines. The continuous combustion process and distinctive exhaust gas composition require specialized interpretation algorithms that most current diagnostic systems lack. This deficiency hampers both environmental compliance efforts and performance tuning capabilities, particularly as emissions regulations become increasingly stringent worldwide.

Data integration presents perhaps the most significant obstacle to effective Wankel diagnostics. Current systems typically operate in isolation, with minimal cross-parameter analysis capabilities. This siloed approach prevents the identification of subtle correlations between different engine metrics that could indicate emerging problems before they cause catastrophic failures.

Resource constraints further complicate the diagnostic landscape. The relatively small market share of Wankel engines has limited investment in specialized diagnostic technologies, creating a self-reinforcing cycle where inadequate tools reduce adoption rates, which in turn reduces incentives for further diagnostic development. This has left Wankel engine operators with a fragmented ecosystem of partial solutions rather than comprehensive diagnostic platforms.

These challenges collectively create significant opportunities for AI-based solutions that can overcome the limitations of traditional diagnostic approaches through advanced pattern recognition, multi-parameter correlation analysis, and adaptive learning capabilities tailored to the unique characteristics of rotary engine operation.

Existing AI Diagnostic Approaches for Wankel Engines

01 AI-based diagnostic systems for Wankel engines

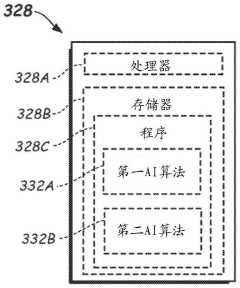

Artificial intelligence systems are being developed to diagnose issues in Wankel rotary engines. These systems use machine learning algorithms to analyze engine performance data, identify patterns associated with specific malfunctions, and provide accurate diagnostic results. The AI systems can detect abnormalities in engine operation before they lead to major failures, enabling preventive maintenance and reducing downtime.- AI-based diagnostic systems for Wankel engines: Artificial intelligence systems designed specifically for diagnosing issues in Wankel rotary engines. These systems use machine learning algorithms to analyze engine performance data, identify patterns associated with specific malfunctions, and provide accurate diagnostic recommendations. The AI systems can detect abnormalities in rotor movement, seal wear, and combustion efficiency that might be difficult to identify through conventional diagnostic methods.

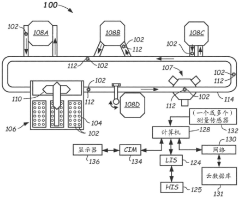

- Sensor integration for real-time monitoring: Implementation of advanced sensor networks within Wankel engines that collect real-time data for AI analysis. These sensors monitor critical parameters such as temperature, pressure, vibration, and exhaust composition. The integrated sensor systems provide continuous data streams that enable AI algorithms to detect early signs of potential failures, monitor engine efficiency, and recommend preventive maintenance actions before catastrophic failures occur.

- Predictive maintenance using machine learning: Machine learning algorithms that analyze historical and real-time data from Wankel engines to predict maintenance needs. These systems learn from past engine failures and performance patterns to forecast when components might fail or require service. By identifying potential issues before they cause engine failure, these predictive maintenance systems help optimize maintenance schedules, reduce downtime, and extend the operational life of Wankel engines.

- Combustion optimization through AI analysis: AI systems that analyze combustion processes within Wankel engines to optimize performance and efficiency. These systems monitor fuel injection timing, air-fuel mixture, and ignition parameters in real-time. By continuously adjusting these parameters based on operating conditions, the AI systems can maximize power output while minimizing fuel consumption and emissions, addressing some of the traditional efficiency challenges associated with Wankel engine designs.

- Digital twin technology for Wankel engine simulation: Implementation of digital twin technology that creates virtual models of physical Wankel engines for simulation and testing. These digital replicas allow engineers to simulate various operating conditions and potential failure scenarios without risking actual hardware. AI algorithms compare real-time data from the physical engine with the digital twin's predicted behavior to identify anomalies. This technology enables more accurate diagnostics, faster development cycles, and improved engine designs through virtual testing.

02 Sensor integration for real-time monitoring

Advanced sensor networks are integrated into Wankel engines to collect real-time operational data for AI diagnostic systems. These sensors monitor various parameters including temperature, pressure, vibration, and exhaust emissions. The comprehensive data collection enables AI algorithms to create a complete picture of engine health and performance, allowing for more accurate diagnostics and predictive maintenance recommendations.Expand Specific Solutions03 Predictive maintenance using AI algorithms

AI algorithms are employed to predict potential failures in Wankel engines before they occur. By analyzing historical data and current engine parameters, these systems can forecast when components might fail and recommend maintenance schedules. This predictive approach helps optimize maintenance timing, reduce unexpected breakdowns, and extend the overall lifespan of Wankel engines.Expand Specific Solutions04 Automated diagnostic procedures for rotary engines

Automated diagnostic systems specifically designed for Wankel rotary engines incorporate AI to streamline the troubleshooting process. These systems can automatically run diagnostic tests, interpret results, and suggest repair procedures without extensive human intervention. The automation reduces diagnostic time, minimizes human error, and ensures consistent evaluation of engine conditions across different service centers.Expand Specific Solutions05 Performance optimization through AI analysis

AI systems analyze Wankel engine performance data to recommend optimizations for fuel efficiency, power output, and emissions control. By continuously learning from operational data, these systems can suggest adjustments to engine parameters that improve performance under various conditions. The AI-driven optimization helps maintain peak engine efficiency throughout its service life while adapting to changing environmental and operational factors.Expand Specific Solutions

Key Industry Players in AI-Powered Engine Diagnostic Solutions

The AI integration in Wankel engine diagnostics market is in its early growth phase, with increasing adoption driven by the need for more efficient rotary engine maintenance. Major automotive players like Hyundai Motor Co., Kia Corp., and Volkswagen AG are investing in this technology, while specialized companies such as Delphi Technology and MS Motorservice International are developing AI-powered diagnostic tools. Academic institutions including Northwestern Polytechnical University and Nanjing University of Aeronautics & Astronautics are contributing research advancements. The market shows promising growth potential as AI diagnostic capabilities mature, with automotive manufacturers and tech companies forming strategic partnerships to enhance Wankel engine performance monitoring and predictive maintenance solutions.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a comprehensive AI diagnostic system specifically for Wankel engines, leveraging their experience with rotary engine technology through past partnerships. Their solution employs a hybrid approach combining physics-based models with data-driven machine learning algorithms. The system utilizes acoustic emission sensors strategically placed around the engine to capture high-frequency sound waves generated during operation. These signals are processed through a custom neural network architecture that can identify specific failure modes unique to rotary engines, such as apex seal wear, side seal leakage, and rotor bearing deterioration. Hyundai's system also incorporates oil analysis through specialized sensors that detect metal particles indicative of specific component wear, with AI algorithms correlating particle composition to particular engine components.

Strengths: Specialized focus on rotary engine peculiarities; integration of multiple diagnostic approaches (acoustic, vibration, oil analysis) for comprehensive assessment. Weaknesses: System complexity requires specialized training for service technicians; higher initial implementation cost compared to conventional diagnostic tools.

Delphi Technology, Inc.

Technical Solution: Delphi has created an integrated AI diagnostic platform for Wankel engines that combines advanced sensor technology with sophisticated machine learning algorithms. Their system utilizes a distributed sensor network that monitors multiple engine parameters simultaneously, including exhaust gas composition, vibration signatures, temperature profiles, and fuel consumption patterns. The collected data is processed through a hierarchical neural network architecture that first identifies normal operating patterns and then detects deviations that may indicate developing problems. Delphi's solution incorporates reinforcement learning techniques that optimize diagnostic accuracy over time by correlating predicted issues with confirmed repair outcomes. The system features a modular design that can be adapted to different Wankel engine configurations while maintaining diagnostic consistency, making it suitable for both automotive and aviation applications of rotary engine technology.

Strengths: Extensive automotive diagnostic experience; highly adaptable system architecture that works across different rotary engine implementations. Weaknesses: Requires significant initial data collection period for optimal performance; higher complexity in implementation compared to conventional diagnostic systems.

Core AI Algorithms and Models for Rotary Engine Analysis

Method of AI-Based Vehicle Diagnosis Using CAN Data and Device thereof

PatentPendingKR1020220118801A

Innovation

- An AI-based method using CAN data preprocessing and deep learning to extract features with high correlation to irregular vibrations, followed by data filtering and dimensionality reduction techniques to improve diagnostic accuracy.

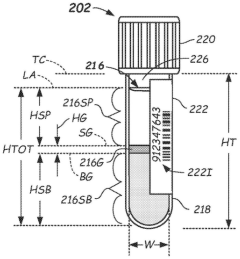

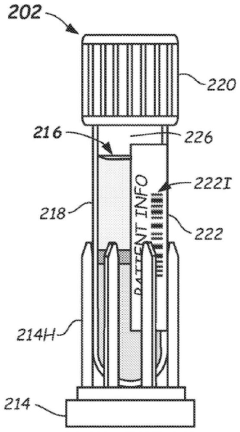

Site-specific adaptation of automated diagnostic analysis systems

PatentPendingCN117616508A

Innovation

- By capturing the image data of the sample container in the automatic diagnostic analysis system, the system controller is used to perform the AI algorithm characterization, and based on the characterization confidence level is lower than the pre-selected threshold, a retraining process is triggered to perform the AI algorithm using the characteristic data of the current location. Retrain to enhance its adaptability.

Implementation Roadmap for AI Diagnostic Integration

The successful integration of AI into Wankel engine diagnostic systems requires a carefully structured implementation approach. Organizations should begin with a comprehensive assessment of their current diagnostic infrastructure, identifying key integration points where AI can deliver maximum value. This initial phase should include cataloging existing sensor networks, data collection mechanisms, and diagnostic protocols currently in use for rotary engine monitoring.

Following the assessment, a phased implementation strategy is recommended, starting with pilot deployments focused on specific high-value diagnostic areas such as rotor seal wear detection or combustion efficiency analysis. These controlled implementations allow for validation of AI models in real-world conditions while minimizing operational disruption. Each pilot should include clear success metrics and evaluation protocols to measure performance improvements against traditional diagnostic methods.

Data infrastructure development represents a critical parallel workstream. Organizations must establish robust data pipelines capable of handling the volume and velocity of sensor data from Wankel engines. This includes implementing edge computing solutions for real-time processing of critical parameters and cloud infrastructure for deeper analytical capabilities and model training. Standardized data formats and governance protocols should be established early to ensure consistency across the diagnostic ecosystem.

Technical team preparation constitutes another essential implementation component. Cross-functional teams comprising engine specialists, data scientists, and software engineers should be formed and upskilled on both rotary engine mechanics and AI methodologies. These teams will be responsible for model development, validation, and continuous improvement cycles as operational data accumulates.

The implementation roadmap should incorporate progressive expansion of AI capabilities, moving from basic anomaly detection to predictive maintenance and eventually to prescriptive maintenance recommendations. Each expansion phase should be triggered by performance thresholds achieved in previous phases rather than fixed timelines, ensuring system reliability before additional complexity is introduced.

Integration with existing enterprise systems represents the final implementation consideration. AI diagnostic outputs must be seamlessly incorporated into maintenance management systems, parts inventory controls, and operational dashboards to deliver actionable intelligence to technicians and managers. API development and standardized communication protocols between the AI diagnostic system and enterprise applications should be prioritized to ensure information flows efficiently across the organization's technology ecosystem.

Following the assessment, a phased implementation strategy is recommended, starting with pilot deployments focused on specific high-value diagnostic areas such as rotor seal wear detection or combustion efficiency analysis. These controlled implementations allow for validation of AI models in real-world conditions while minimizing operational disruption. Each pilot should include clear success metrics and evaluation protocols to measure performance improvements against traditional diagnostic methods.

Data infrastructure development represents a critical parallel workstream. Organizations must establish robust data pipelines capable of handling the volume and velocity of sensor data from Wankel engines. This includes implementing edge computing solutions for real-time processing of critical parameters and cloud infrastructure for deeper analytical capabilities and model training. Standardized data formats and governance protocols should be established early to ensure consistency across the diagnostic ecosystem.

Technical team preparation constitutes another essential implementation component. Cross-functional teams comprising engine specialists, data scientists, and software engineers should be formed and upskilled on both rotary engine mechanics and AI methodologies. These teams will be responsible for model development, validation, and continuous improvement cycles as operational data accumulates.

The implementation roadmap should incorporate progressive expansion of AI capabilities, moving from basic anomaly detection to predictive maintenance and eventually to prescriptive maintenance recommendations. Each expansion phase should be triggered by performance thresholds achieved in previous phases rather than fixed timelines, ensuring system reliability before additional complexity is introduced.

Integration with existing enterprise systems represents the final implementation consideration. AI diagnostic outputs must be seamlessly incorporated into maintenance management systems, parts inventory controls, and operational dashboards to deliver actionable intelligence to technicians and managers. API development and standardized communication protocols between the AI diagnostic system and enterprise applications should be prioritized to ensure information flows efficiently across the organization's technology ecosystem.

Environmental Impact and Sustainability Considerations

The integration of AI in Wankel engine diagnostics presents significant environmental and sustainability implications that extend beyond mere technical efficiency. Rotary engines have historically faced criticism for their higher fuel consumption and emissions compared to conventional piston engines. AI-powered diagnostic systems can directly address these environmental concerns by optimizing engine performance and reducing ecological impact.

Advanced AI algorithms can continuously monitor and adjust combustion parameters in real-time, significantly reducing hydrocarbon emissions and improving fuel efficiency. Studies indicate that AI-optimized Wankel engines can achieve up to 15% reduction in carbon emissions through precise control of the combustion process and early detection of inefficiencies that lead to increased pollution.

The predictive maintenance capabilities of AI systems further contribute to sustainability by extending engine lifespan. By identifying potential failures before they occur, these systems reduce the need for replacement parts and minimize waste generation. This approach aligns with circular economy principles, where resource utilization is optimized and product lifecycles are extended through intelligent management.

Energy consumption during diagnostic processes is another area where AI offers environmental benefits. Traditional diagnostic methods often require multiple test runs and physical inspections, consuming additional fuel and resources. AI-based systems can perform comprehensive diagnostics with minimal additional energy expenditure, analyzing existing operational data rather than requiring special test conditions.

From a lifecycle assessment perspective, AI-enhanced Wankel engines demonstrate improved environmental performance. The technology enables more precise manufacturing tolerances and operational parameters, reducing material waste during production and operation. Additionally, the data collected through AI diagnostics provides valuable insights for future engine designs with enhanced environmental credentials.

Regulatory compliance represents another dimension where AI diagnostics contribute to sustainability. As emission standards become increasingly stringent worldwide, AI systems can adapt engine performance to meet these requirements without sacrificing power output. This adaptability ensures Wankel engines remain viable in an evolving regulatory landscape focused on environmental protection.

The environmental benefits of AI in Wankel diagnostics also extend to noise pollution reduction. By optimizing rotational smoothness and identifying vibration issues early, AI systems help maintain the characteristic low-noise operation of rotary engines, contributing to reduced noise pollution in urban environments.

Advanced AI algorithms can continuously monitor and adjust combustion parameters in real-time, significantly reducing hydrocarbon emissions and improving fuel efficiency. Studies indicate that AI-optimized Wankel engines can achieve up to 15% reduction in carbon emissions through precise control of the combustion process and early detection of inefficiencies that lead to increased pollution.

The predictive maintenance capabilities of AI systems further contribute to sustainability by extending engine lifespan. By identifying potential failures before they occur, these systems reduce the need for replacement parts and minimize waste generation. This approach aligns with circular economy principles, where resource utilization is optimized and product lifecycles are extended through intelligent management.

Energy consumption during diagnostic processes is another area where AI offers environmental benefits. Traditional diagnostic methods often require multiple test runs and physical inspections, consuming additional fuel and resources. AI-based systems can perform comprehensive diagnostics with minimal additional energy expenditure, analyzing existing operational data rather than requiring special test conditions.

From a lifecycle assessment perspective, AI-enhanced Wankel engines demonstrate improved environmental performance. The technology enables more precise manufacturing tolerances and operational parameters, reducing material waste during production and operation. Additionally, the data collected through AI diagnostics provides valuable insights for future engine designs with enhanced environmental credentials.

Regulatory compliance represents another dimension where AI diagnostics contribute to sustainability. As emission standards become increasingly stringent worldwide, AI systems can adapt engine performance to meet these requirements without sacrificing power output. This adaptability ensures Wankel engines remain viable in an evolving regulatory landscape focused on environmental protection.

The environmental benefits of AI in Wankel diagnostics also extend to noise pollution reduction. By optimizing rotational smoothness and identifying vibration issues early, AI systems help maintain the characteristic low-noise operation of rotary engines, contributing to reduced noise pollution in urban environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!