How to Calibrate HPLC for Accurate Quantitative Analysis

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HPLC Calibration Background and Objectives

High-Performance Liquid Chromatography (HPLC) has evolved significantly since its inception in the late 1960s, becoming an indispensable analytical technique in pharmaceutical, environmental, food safety, and clinical laboratories. The development trajectory of HPLC technology has been characterized by continuous improvements in column technology, detection methods, and data processing capabilities, all contributing to enhanced separation efficiency and analytical precision.

The evolution of HPLC calibration methodologies has paralleled these technological advancements. Early calibration approaches relied on simple external standardization, while modern methods incorporate sophisticated algorithms and automated systems to ensure analytical accuracy. This progression reflects the growing demand for more precise quantitative analysis across various industries.

Current trends in HPLC calibration technology emphasize automation, method validation, and compliance with increasingly stringent regulatory requirements. The integration of artificial intelligence and machine learning algorithms for calibration optimization represents the cutting edge of this field, promising to further enhance analytical reliability and efficiency.

The primary objective of HPLC calibration is to establish a reliable relationship between detector response and analyte concentration, ensuring accurate quantification across the analytical range. This involves determining system suitability, establishing calibration curves, validating analytical methods, and implementing robust quality control measures.

Secondary objectives include minimizing systematic errors, enhancing method reproducibility, and ensuring compliance with regulatory standards such as those established by the International Conference on Harmonisation (ICH), the United States Pharmacopeia (USP), and the Food and Drug Administration (FDA).

The technical goals of effective HPLC calibration encompass achieving linearity across the concentration range of interest, maintaining acceptable precision (typically RSD < 2%), ensuring accuracy within ±2% of the true value, and establishing appropriate detection and quantification limits. Additionally, modern calibration protocols aim to address matrix effects, instrument drift, and potential interferences that could compromise analytical results.

Looking forward, the field is moving toward real-time calibration verification, predictive maintenance systems, and cross-platform calibration standardization. These developments are expected to further enhance the reliability and efficiency of quantitative HPLC analysis, supporting critical applications in drug development, environmental monitoring, and clinical diagnostics.

The evolution of HPLC calibration methodologies has paralleled these technological advancements. Early calibration approaches relied on simple external standardization, while modern methods incorporate sophisticated algorithms and automated systems to ensure analytical accuracy. This progression reflects the growing demand for more precise quantitative analysis across various industries.

Current trends in HPLC calibration technology emphasize automation, method validation, and compliance with increasingly stringent regulatory requirements. The integration of artificial intelligence and machine learning algorithms for calibration optimization represents the cutting edge of this field, promising to further enhance analytical reliability and efficiency.

The primary objective of HPLC calibration is to establish a reliable relationship between detector response and analyte concentration, ensuring accurate quantification across the analytical range. This involves determining system suitability, establishing calibration curves, validating analytical methods, and implementing robust quality control measures.

Secondary objectives include minimizing systematic errors, enhancing method reproducibility, and ensuring compliance with regulatory standards such as those established by the International Conference on Harmonisation (ICH), the United States Pharmacopeia (USP), and the Food and Drug Administration (FDA).

The technical goals of effective HPLC calibration encompass achieving linearity across the concentration range of interest, maintaining acceptable precision (typically RSD < 2%), ensuring accuracy within ±2% of the true value, and establishing appropriate detection and quantification limits. Additionally, modern calibration protocols aim to address matrix effects, instrument drift, and potential interferences that could compromise analytical results.

Looking forward, the field is moving toward real-time calibration verification, predictive maintenance systems, and cross-platform calibration standardization. These developments are expected to further enhance the reliability and efficiency of quantitative HPLC analysis, supporting critical applications in drug development, environmental monitoring, and clinical diagnostics.

Market Demand for Precise Analytical Methods

The global analytical instrumentation market has witnessed substantial growth, with the HPLC segment emerging as a cornerstone technology for quantitative analysis across multiple industries. Current market assessments value the global HPLC market at approximately 4.5 billion USD, with projections indicating a compound annual growth rate of 5.2% through 2028. This growth is primarily driven by increasing demands for precise analytical methods in pharmaceutical development, clinical diagnostics, food safety testing, and environmental monitoring.

In the pharmaceutical sector, which accounts for nearly 60% of HPLC applications, regulatory requirements have become increasingly stringent, necessitating higher accuracy in drug development and quality control processes. The FDA and EMA have implemented more rigorous guidelines for analytical method validation, directly impacting the demand for advanced calibration techniques and standards. Companies are actively seeking solutions that can demonstrate consistent accuracy and precision in their analytical methods to ensure regulatory compliance.

The biopharmaceutical industry presents particularly robust demand growth, with the development of complex biologics requiring sophisticated analytical methods. The characterization of protein-based therapeutics, monoclonal antibodies, and gene therapy products demands highly calibrated HPLC systems capable of detecting minute variations in composition. Market research indicates that biopharmaceutical companies are willing to invest significantly in analytical technologies that can provide reliable quantitative data for these complex molecules.

Clinical diagnostics represents another rapidly expanding market segment, with hospitals and diagnostic laboratories increasingly adopting HPLC for therapeutic drug monitoring, vitamin D testing, hemoglobin A1c analysis, and neurotransmitter quantification. The demand for point-of-care testing solutions has further accelerated the need for simplified yet accurate calibration protocols that can be implemented in diverse clinical settings.

Food safety testing has emerged as a critical application area following numerous high-profile contamination incidents globally. Regulatory bodies worldwide have strengthened food safety standards, creating substantial demand for precise analytical methods to detect pesticides, mycotoxins, and other contaminants at increasingly lower detection limits. The food and beverage industry is actively seeking cost-effective calibration solutions that can be implemented across diverse product matrices.

Environmental monitoring applications continue to expand as awareness of pollution impacts grows and regulatory frameworks evolve. Water quality testing, soil contamination assessment, and air quality monitoring all require precisely calibrated HPLC methods to ensure accurate quantification of pollutants at environmentally relevant concentrations.

Market research indicates that end-users across all sectors are increasingly prioritizing calibration solutions that offer automation, reduced operator dependency, improved traceability, and integration with laboratory information management systems. This trend reflects the broader industry movement toward digitalization and data integrity assurance in analytical laboratories.

In the pharmaceutical sector, which accounts for nearly 60% of HPLC applications, regulatory requirements have become increasingly stringent, necessitating higher accuracy in drug development and quality control processes. The FDA and EMA have implemented more rigorous guidelines for analytical method validation, directly impacting the demand for advanced calibration techniques and standards. Companies are actively seeking solutions that can demonstrate consistent accuracy and precision in their analytical methods to ensure regulatory compliance.

The biopharmaceutical industry presents particularly robust demand growth, with the development of complex biologics requiring sophisticated analytical methods. The characterization of protein-based therapeutics, monoclonal antibodies, and gene therapy products demands highly calibrated HPLC systems capable of detecting minute variations in composition. Market research indicates that biopharmaceutical companies are willing to invest significantly in analytical technologies that can provide reliable quantitative data for these complex molecules.

Clinical diagnostics represents another rapidly expanding market segment, with hospitals and diagnostic laboratories increasingly adopting HPLC for therapeutic drug monitoring, vitamin D testing, hemoglobin A1c analysis, and neurotransmitter quantification. The demand for point-of-care testing solutions has further accelerated the need for simplified yet accurate calibration protocols that can be implemented in diverse clinical settings.

Food safety testing has emerged as a critical application area following numerous high-profile contamination incidents globally. Regulatory bodies worldwide have strengthened food safety standards, creating substantial demand for precise analytical methods to detect pesticides, mycotoxins, and other contaminants at increasingly lower detection limits. The food and beverage industry is actively seeking cost-effective calibration solutions that can be implemented across diverse product matrices.

Environmental monitoring applications continue to expand as awareness of pollution impacts grows and regulatory frameworks evolve. Water quality testing, soil contamination assessment, and air quality monitoring all require precisely calibrated HPLC methods to ensure accurate quantification of pollutants at environmentally relevant concentrations.

Market research indicates that end-users across all sectors are increasingly prioritizing calibration solutions that offer automation, reduced operator dependency, improved traceability, and integration with laboratory information management systems. This trend reflects the broader industry movement toward digitalization and data integrity assurance in analytical laboratories.

Current HPLC Calibration Challenges

Despite significant advancements in HPLC technology, several persistent challenges continue to impact calibration accuracy and reliability in quantitative analysis. One of the most prevalent issues is matrix interference, where components in complex samples interact with analytes, altering their chromatographic behavior compared to pure standards. This phenomenon often leads to suppression or enhancement effects that compromise quantification accuracy, particularly in biological, environmental, and food samples with complex matrices.

Instrument drift represents another significant challenge, manifesting as baseline shifts, retention time variations, and detector response changes over time. These fluctuations can occur due to temperature variations, mobile phase composition changes, column aging, or electronic instabilities. Without proper compensation strategies, drift can invalidate calibration curves established at the beginning of analytical sequences.

The selection of appropriate calibration models poses considerable difficulty for many analysts. While linear regression remains the default approach, many real-world analytical scenarios exhibit non-linear detector responses, especially at concentration extremes. Determining when to apply quadratic, weighted, or other advanced regression models requires statistical expertise that many laboratory personnel lack.

Carryover effects continue to plague HPLC calibration, particularly when analyzing compounds with strong affinity for stationary phases or when transitioning between samples with extreme concentration differences. This phenomenon can artificially inflate quantitative results for low-concentration samples analyzed after high-concentration standards.

Reference standard quality and stability issues represent another critical challenge. Many analytes are susceptible to degradation during storage or preparation, leading to inaccurate calibration curves. For certain compounds, certified reference materials may be unavailable, expensive, or of questionable purity, forcing laboratories to rely on in-house standards of uncertain quality.

Method transfer between different HPLC systems presents significant calibration hurdles. Variations in detector response factors, column performance, and system volumes between instruments often necessitate recalibration and revalidation, even for established methods. This challenge is particularly acute in multi-laboratory studies or when transitioning methods from development to routine analysis.

Finally, regulatory compliance requirements add complexity to HPLC calibration processes. Different industries and regulatory bodies mandate specific calibration approaches, documentation standards, and performance criteria. Navigating these requirements while maintaining scientific validity and operational efficiency represents a significant challenge for analytical laboratories across pharmaceutical, environmental, food safety, and clinical sectors.

Instrument drift represents another significant challenge, manifesting as baseline shifts, retention time variations, and detector response changes over time. These fluctuations can occur due to temperature variations, mobile phase composition changes, column aging, or electronic instabilities. Without proper compensation strategies, drift can invalidate calibration curves established at the beginning of analytical sequences.

The selection of appropriate calibration models poses considerable difficulty for many analysts. While linear regression remains the default approach, many real-world analytical scenarios exhibit non-linear detector responses, especially at concentration extremes. Determining when to apply quadratic, weighted, or other advanced regression models requires statistical expertise that many laboratory personnel lack.

Carryover effects continue to plague HPLC calibration, particularly when analyzing compounds with strong affinity for stationary phases or when transitioning between samples with extreme concentration differences. This phenomenon can artificially inflate quantitative results for low-concentration samples analyzed after high-concentration standards.

Reference standard quality and stability issues represent another critical challenge. Many analytes are susceptible to degradation during storage or preparation, leading to inaccurate calibration curves. For certain compounds, certified reference materials may be unavailable, expensive, or of questionable purity, forcing laboratories to rely on in-house standards of uncertain quality.

Method transfer between different HPLC systems presents significant calibration hurdles. Variations in detector response factors, column performance, and system volumes between instruments often necessitate recalibration and revalidation, even for established methods. This challenge is particularly acute in multi-laboratory studies or when transitioning methods from development to routine analysis.

Finally, regulatory compliance requirements add complexity to HPLC calibration processes. Different industries and regulatory bodies mandate specific calibration approaches, documentation standards, and performance criteria. Navigating these requirements while maintaining scientific validity and operational efficiency represents a significant challenge for analytical laboratories across pharmaceutical, environmental, food safety, and clinical sectors.

Standard Calibration Methodologies

01 Method optimization for HPLC accuracy

Optimizing HPLC methods is crucial for achieving high accuracy in quantitative analysis. This includes careful selection of mobile phase composition, flow rate, column temperature, and detection parameters. Method validation procedures ensure that the analytical method consistently provides accurate and reliable results. Proper calibration curves with appropriate concentration ranges and internal standards can significantly improve quantitative accuracy.- Method optimization for HPLC accuracy: Optimizing HPLC methods is crucial for achieving high accuracy in quantitative analysis. This includes careful selection of mobile phase composition, flow rate, column temperature, and detection parameters. Method validation procedures ensure that the analytical method consistently provides accurate and reliable results. Proper calibration curves with appropriate concentration ranges and internal standards can significantly improve quantitative accuracy.

- Sample preparation techniques: Sample preparation plays a critical role in HPLC accuracy for quantitative analysis. Techniques such as filtration, extraction, concentration, and derivatization can remove interfering compounds and enhance detection sensitivity. Proper sample handling, storage conditions, and stability studies ensure sample integrity before analysis. Standardized sample preparation protocols minimize variability and improve reproducibility of quantitative results.

- Calibration and validation strategies: Robust calibration and validation strategies are essential for accurate HPLC quantitative analysis. This includes establishing linear calibration curves, determining limits of detection and quantification, and assessing precision through repeatability and intermediate precision studies. System suitability tests ensure that the chromatographic system performs consistently. Method validation parameters such as accuracy, specificity, and robustness must be thoroughly evaluated according to regulatory guidelines.

- Advanced detection techniques: Advanced detection techniques enhance HPLC accuracy in quantitative analysis. Mass spectrometry coupling (LC-MS/MS) provides superior selectivity and sensitivity for complex samples. Diode array detectors allow simultaneous monitoring at multiple wavelengths, improving compound identification and quantification. Fluorescence and electrochemical detectors offer enhanced sensitivity for specific analyte classes. These advanced detection methods can overcome matrix effects and improve quantification of trace components.

- Quality control and uncertainty measurement: Quality control procedures and uncertainty measurements are vital for ensuring HPLC accuracy in quantitative analysis. This includes regular system performance verification, use of certified reference materials, and participation in proficiency testing programs. Statistical approaches for evaluating measurement uncertainty consider factors such as sample preparation variability, instrument precision, and calibration errors. Implementation of quality management systems with proper documentation enhances the reliability of quantitative results.

02 Sample preparation techniques

Sample preparation plays a critical role in HPLC accuracy for quantitative analysis. Techniques such as filtration, extraction, concentration, and clean-up procedures help remove interfering compounds and matrix effects that could compromise accuracy. Proper homogenization and standardized sample handling protocols ensure consistent results. The use of appropriate solvents and extraction methods specific to the analyte of interest enhances recovery rates and quantitative precision.Expand Specific Solutions03 Instrument calibration and system suitability

Regular calibration of HPLC instruments is essential for maintaining quantitative accuracy. System suitability tests verify that the chromatographic system is performing adequately before and during analysis. Parameters such as retention time reproducibility, peak resolution, column efficiency, and detector response linearity must be monitored and maintained within acceptable limits. Proper qualification procedures for installation, operation, and performance ensure reliable quantitative results.Expand Specific Solutions04 Advanced detection techniques

The choice of detection technique significantly impacts HPLC quantitative accuracy. Advanced detectors such as diode array (DAD), fluorescence, mass spectrometry (MS), and evaporative light scattering (ELSD) offer improved sensitivity and selectivity compared to conventional UV detectors. Multiple detection methods can be combined to enhance compound identification and quantification accuracy. Detector-specific calibration procedures and signal processing algorithms help minimize noise and improve signal-to-noise ratios.Expand Specific Solutions05 Statistical approaches for accuracy assessment

Statistical methods are essential for evaluating and improving HPLC quantitative accuracy. Techniques include calculation of relative standard deviation (RSD), limit of detection (LOD), limit of quantification (LOQ), and measurement uncertainty. Quality control samples, recovery studies, and proficiency testing help validate analytical results. Statistical process control charts monitor system performance over time, while robustness testing ensures method reliability under varying conditions. Advanced statistical approaches like Design of Experiments (DoE) optimize method parameters for maximum accuracy.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The HPLC calibration market is currently in a mature growth phase, with increasing demand driven by stringent regulatory requirements in pharmaceutical and biotechnology sectors. The global analytical instrumentation market, which includes HPLC systems, is valued at approximately $5-6 billion annually with steady growth projections. Leading players in this space include established pharmaceutical companies like F. Hoffmann-La Roche, AbbVie, and Janssen Pharmaceutica, alongside specialized instrumentation providers such as Hitachi High-Tech America. The technology has reached high maturity levels with standardized protocols, though innovation continues in automation and precision. Companies like Roche Diagnostics and Shimazu KK are advancing calibration technologies through integration with data analytics and AI, while academic institutions like Vrije Universiteit Brussel and University of Freiburg contribute to method development and validation techniques that enhance quantitative accuracy.

F. Hoffmann-La Roche Ltd.

Technical Solution: Roche has developed a comprehensive HPLC calibration approach that integrates automated system suitability testing (SST) with multi-point calibration curves. Their method employs certified reference standards with traceability to international standards, ensuring accuracy across their pharmaceutical analysis workflows. The company utilizes a bracketing calibration technique where standards are analyzed before and after sample batches to detect and compensate for potential instrument drift. Roche's calibration protocol includes validation of linearity across at least five concentration levels spanning 50-150% of the target analyte concentration, with r² values exceeding 0.999. Their system incorporates automated calibration verification using quality control samples at defined intervals, with real-time monitoring of system parameters including retention time stability, peak symmetry, and theoretical plate counts to ensure consistent chromatographic performance.

Strengths: Highly automated calibration processes reduce human error and increase throughput. Integration with laboratory information management systems enables comprehensive data tracking and compliance documentation. Weaknesses: The sophisticated calibration system requires significant initial investment in both equipment and training, potentially limiting accessibility for smaller laboratories.

Hitachi High-Tech America, Inc.

Technical Solution: Hitachi High-Tech has engineered a robust HPLC calibration system centered around their ChromasterUltra software platform. Their approach implements a multi-level calibration strategy with automatic bracketing of samples between calibration standards to compensate for instrumental drift during extended analytical runs. Hitachi's calibration methodology incorporates advanced peak integration algorithms that adapt to changing peak shapes and baseline conditions, ensuring consistent quantification across diverse sample types. Their system features automatic calibration verification using independently prepared quality control samples, with real-time monitoring of calibration performance metrics including correlation coefficient, residual analysis, and relative standard deviation of response factors. Hitachi's HPLC calibration protocol includes comprehensive system suitability testing that evaluates critical parameters such as retention time reproducibility (≤0.5% RSD), peak area precision (≤1.0% RSD), and column efficiency (>2000 theoretical plates) before accepting calibration results.

Strengths: Exceptional long-term calibration stability through intelligent drift compensation algorithms. Comprehensive system suitability testing ensures reliable quantitative performance. Weaknesses: The extensive system suitability requirements may increase analysis time and reduce sample throughput in high-volume laboratories.

Critical Parameters and Validation Protocols

High-performance liquid chromatography with a controllable transverse flow inducer

PatentActiveEP3322978A1

Innovation

- The use of a controllable transverse flow inducer, which generates micro-scale vortices through alternating current electrokinetics, allowing for orthogonal flow induction independent of axial velocity, reducing dispersion by combining pressure and electro-osmotic flow, and enabling retention modulation without permanent surface charges.

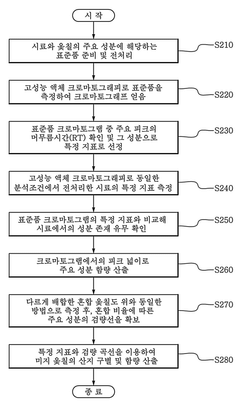

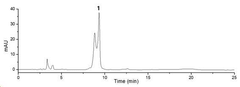

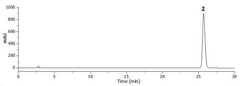

Method of identification and quantitative analysis of lacquers from different regions using high performance liquid chromatography

PatentActiveKR1020220022238A

Innovation

- A method using High Performance Liquid Chromatography (HPLC) to select a specific indicator (standard product) for each lacquer origin, measuring the main peak retention time, and generating calibration curves to determine the content of lacquer samples, enabling quick and accurate identification and quantification of lacquer origins.

Regulatory Compliance Requirements

Regulatory compliance is a critical aspect of HPLC calibration for quantitative analysis, particularly in regulated industries such as pharmaceuticals, food safety, environmental monitoring, and clinical diagnostics. Organizations must adhere to various international, regional, and industry-specific standards that govern analytical method validation and instrument calibration procedures.

The most prominent regulatory frameworks include the International Conference on Harmonisation (ICH) guidelines, particularly ICH Q2(R1) for analytical method validation. This guideline specifies requirements for accuracy, precision, specificity, detection limit, quantitation limit, linearity, and range—all parameters directly impacted by proper HPLC calibration. Pharmaceutical laboratories must demonstrate compliance with these parameters through comprehensive documentation of calibration procedures.

In the United States, the Food and Drug Administration (FDA) enforces compliance through 21 CFR Part 11 for electronic records and signatures, and 21 CFR Part 211 for Good Manufacturing Practices (GMPs). These regulations mandate regular calibration, validation, and verification of analytical instruments, including HPLC systems. The FDA expects laboratories to maintain detailed records of calibration procedures, reference standards used, and personnel qualifications.

European regulatory bodies enforce compliance with European Medicines Agency (EMA) guidelines and the European Pharmacopoeia standards. These frameworks emphasize traceability of measurements to international standards and require comprehensive uncertainty calculations for analytical results derived from calibrated instruments.

ISO/IEC 17025 serves as the global standard for testing and calibration laboratories, requiring documented calibration procedures, regular performance verification, and traceability to SI units. Laboratories seeking accreditation must demonstrate robust calibration practices and participate in proficiency testing programs to verify the accuracy of their quantitative analyses.

The United States Pharmacopeia (USP) and European Pharmacopoeia (Ph. Eur.) provide specific guidance on system suitability tests and calibration requirements for chromatographic systems. These include specifications for resolution, tailing factor, theoretical plates, and signal-to-noise ratios that must be verified through proper calibration procedures.

Compliance documentation requirements typically include calibration protocols, standard operating procedures (SOPs), calibration certificates for reference standards, training records for personnel, instrument qualification documents (IQ/OQ/PQ), and calibration verification reports. Regulatory inspections often focus on the integrity and completeness of these records, with particular attention to data integrity principles outlined in the ALCOA+ framework (Attributable, Legible, Contemporaneous, Original, Accurate, plus Complete, Consistent, Enduring, and Available).

The most prominent regulatory frameworks include the International Conference on Harmonisation (ICH) guidelines, particularly ICH Q2(R1) for analytical method validation. This guideline specifies requirements for accuracy, precision, specificity, detection limit, quantitation limit, linearity, and range—all parameters directly impacted by proper HPLC calibration. Pharmaceutical laboratories must demonstrate compliance with these parameters through comprehensive documentation of calibration procedures.

In the United States, the Food and Drug Administration (FDA) enforces compliance through 21 CFR Part 11 for electronic records and signatures, and 21 CFR Part 211 for Good Manufacturing Practices (GMPs). These regulations mandate regular calibration, validation, and verification of analytical instruments, including HPLC systems. The FDA expects laboratories to maintain detailed records of calibration procedures, reference standards used, and personnel qualifications.

European regulatory bodies enforce compliance with European Medicines Agency (EMA) guidelines and the European Pharmacopoeia standards. These frameworks emphasize traceability of measurements to international standards and require comprehensive uncertainty calculations for analytical results derived from calibrated instruments.

ISO/IEC 17025 serves as the global standard for testing and calibration laboratories, requiring documented calibration procedures, regular performance verification, and traceability to SI units. Laboratories seeking accreditation must demonstrate robust calibration practices and participate in proficiency testing programs to verify the accuracy of their quantitative analyses.

The United States Pharmacopeia (USP) and European Pharmacopoeia (Ph. Eur.) provide specific guidance on system suitability tests and calibration requirements for chromatographic systems. These include specifications for resolution, tailing factor, theoretical plates, and signal-to-noise ratios that must be verified through proper calibration procedures.

Compliance documentation requirements typically include calibration protocols, standard operating procedures (SOPs), calibration certificates for reference standards, training records for personnel, instrument qualification documents (IQ/OQ/PQ), and calibration verification reports. Regulatory inspections often focus on the integrity and completeness of these records, with particular attention to data integrity principles outlined in the ALCOA+ framework (Attributable, Legible, Contemporaneous, Original, Accurate, plus Complete, Consistent, Enduring, and Available).

Quality Assurance Best Practices

Quality assurance in HPLC calibration represents a critical foundation for reliable analytical results. Implementing standardized operating procedures (SOPs) is essential for maintaining consistency across different analysts and laboratory sessions. These SOPs should detail step-by-step calibration protocols, including preparation of calibration standards, system suitability requirements, and acceptance criteria for calibration curves.

Regular instrument performance verification forms another cornerstone of quality assurance. This includes daily, weekly, and monthly maintenance checks to ensure optimal chromatographic performance. Detector linearity tests, pump flow rate accuracy verification, and wavelength accuracy checks should be conducted according to a predetermined schedule and documented thoroughly.

Control charting represents a powerful statistical tool for monitoring calibration performance over time. By tracking parameters such as calibration curve slopes, correlation coefficients, and retention times of standard compounds, analysts can identify subtle shifts in system performance before they impact analytical results. Control limits should be established based on historical data, with appropriate corrective actions defined for out-of-specification results.

Reference standard management demands particular attention in quality assurance programs. Primary reference standards should be traceable to recognized authorities such as USP or NIST, with certificates of analysis maintained in a centralized documentation system. Working standards should be regularly compared against primary standards, with expiration dates clearly established and monitored.

Blind quality control samples provide an objective assessment of calibration effectiveness. These samples, with concentrations unknown to the analyst, should be inserted randomly within analytical batches to verify the accuracy of the calibration curve across its working range. Results from these samples should be tracked over time to identify any systematic biases.

Comprehensive documentation practices underpin all quality assurance efforts. Electronic or paper-based systems must capture all calibration data, including raw chromatograms, integration parameters, and calculation methodologies. Audit trails should track any changes to data processing, ensuring data integrity throughout the analytical workflow.

Proficiency testing through participation in interlaboratory comparison programs offers external validation of calibration accuracy. These programs allow laboratories to compare their quantitative results against peer organizations, providing valuable insights into systematic errors that might otherwise go undetected through internal quality controls alone.

Regular instrument performance verification forms another cornerstone of quality assurance. This includes daily, weekly, and monthly maintenance checks to ensure optimal chromatographic performance. Detector linearity tests, pump flow rate accuracy verification, and wavelength accuracy checks should be conducted according to a predetermined schedule and documented thoroughly.

Control charting represents a powerful statistical tool for monitoring calibration performance over time. By tracking parameters such as calibration curve slopes, correlation coefficients, and retention times of standard compounds, analysts can identify subtle shifts in system performance before they impact analytical results. Control limits should be established based on historical data, with appropriate corrective actions defined for out-of-specification results.

Reference standard management demands particular attention in quality assurance programs. Primary reference standards should be traceable to recognized authorities such as USP or NIST, with certificates of analysis maintained in a centralized documentation system. Working standards should be regularly compared against primary standards, with expiration dates clearly established and monitored.

Blind quality control samples provide an objective assessment of calibration effectiveness. These samples, with concentrations unknown to the analyst, should be inserted randomly within analytical batches to verify the accuracy of the calibration curve across its working range. Results from these samples should be tracked over time to identify any systematic biases.

Comprehensive documentation practices underpin all quality assurance efforts. Electronic or paper-based systems must capture all calibration data, including raw chromatograms, integration parameters, and calculation methodologies. Audit trails should track any changes to data processing, ensuring data integrity throughout the analytical workflow.

Proficiency testing through participation in interlaboratory comparison programs offers external validation of calibration accuracy. These programs allow laboratories to compare their quantitative results against peer organizations, providing valuable insights into systematic errors that might otherwise go undetected through internal quality controls alone.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!