Optimize Solvent Use in HPLC for Environmental Safety

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HPLC Solvent Evolution and Optimization Goals

High-performance liquid chromatography (HPLC) has evolved significantly since its inception in the 1960s, with solvent usage representing one of the most critical aspects of this analytical technique. The evolution of HPLC solvents reflects broader trends in analytical chemistry, moving from purely performance-focused approaches toward environmentally conscious methodologies that maintain analytical integrity while reducing ecological impact.

Early HPLC systems relied heavily on traditional organic solvents such as acetonitrile, methanol, and tetrahydrofuran, selected primarily for their excellent chromatographic properties with little consideration for environmental consequences. The 1990s marked a turning point as awareness of the environmental and health impacts of these solvents began to influence research directions, coinciding with the emergence of green chemistry principles.

The development trajectory has since focused on three primary optimization paths: reduction of conventional solvent volumes, replacement with greener alternatives, and recycling/recovery systems. Miniaturization technologies like micro-HPLC and nano-HPLC have enabled dramatic reductions in solvent consumption while maintaining separation efficiency. Simultaneously, research into alternative mobile phases has yielded promising results with ionic liquids, supercritical CO2, and water-based systems under specific conditions.

Current optimization goals center on achieving a delicate balance between analytical performance and environmental responsibility. Key objectives include reducing the volume of hazardous solvents per analysis, developing effective recycling systems for recovered solvents, and identifying green alternatives that maintain or enhance separation efficiency. The industry aims to decrease waste generation by 50% within the next five years while maintaining or improving analytical precision.

Another significant goal involves standardizing green HPLC methodologies across regulatory frameworks to facilitate wider adoption in quality control laboratories, particularly in pharmaceutical and food safety sectors where regulatory compliance is paramount. This includes developing validated methods that use environmentally friendly solvents while meeting strict regulatory requirements.

The technological roadmap also emphasizes automation and intelligent solvent management systems that optimize usage in real-time based on separation requirements. Machine learning algorithms are being developed to predict optimal green solvent combinations for specific analytes, potentially revolutionizing method development processes.

Long-term objectives include the complete elimination of chlorinated solvents from HPLC applications and significant reduction of acetonitrile dependency through novel stationary phase developments that enable efficient separations with greener mobile phases. These goals align with broader sustainability initiatives in analytical chemistry and represent the industry's commitment to environmental stewardship without compromising scientific integrity.

Early HPLC systems relied heavily on traditional organic solvents such as acetonitrile, methanol, and tetrahydrofuran, selected primarily for their excellent chromatographic properties with little consideration for environmental consequences. The 1990s marked a turning point as awareness of the environmental and health impacts of these solvents began to influence research directions, coinciding with the emergence of green chemistry principles.

The development trajectory has since focused on three primary optimization paths: reduction of conventional solvent volumes, replacement with greener alternatives, and recycling/recovery systems. Miniaturization technologies like micro-HPLC and nano-HPLC have enabled dramatic reductions in solvent consumption while maintaining separation efficiency. Simultaneously, research into alternative mobile phases has yielded promising results with ionic liquids, supercritical CO2, and water-based systems under specific conditions.

Current optimization goals center on achieving a delicate balance between analytical performance and environmental responsibility. Key objectives include reducing the volume of hazardous solvents per analysis, developing effective recycling systems for recovered solvents, and identifying green alternatives that maintain or enhance separation efficiency. The industry aims to decrease waste generation by 50% within the next five years while maintaining or improving analytical precision.

Another significant goal involves standardizing green HPLC methodologies across regulatory frameworks to facilitate wider adoption in quality control laboratories, particularly in pharmaceutical and food safety sectors where regulatory compliance is paramount. This includes developing validated methods that use environmentally friendly solvents while meeting strict regulatory requirements.

The technological roadmap also emphasizes automation and intelligent solvent management systems that optimize usage in real-time based on separation requirements. Machine learning algorithms are being developed to predict optimal green solvent combinations for specific analytes, potentially revolutionizing method development processes.

Long-term objectives include the complete elimination of chlorinated solvents from HPLC applications and significant reduction of acetonitrile dependency through novel stationary phase developments that enable efficient separations with greener mobile phases. These goals align with broader sustainability initiatives in analytical chemistry and represent the industry's commitment to environmental stewardship without compromising scientific integrity.

Green Chromatography Market Analysis

The green chromatography market is experiencing significant growth driven by increasing environmental regulations and sustainability initiatives across industries. Currently valued at approximately 3.2 billion USD in 2023, the market is projected to reach 5.7 billion USD by 2028, representing a compound annual growth rate of 12.3%. This growth trajectory is primarily fueled by stringent environmental policies in developed regions, particularly in Europe and North America, where regulatory bodies have established clear guidelines for reducing hazardous waste in analytical procedures.

The pharmaceutical sector dominates the green chromatography market, accounting for nearly 40% of the total market share. This is attributed to the industry's high volume of analytical testing and increasing pressure to adopt sustainable practices. The food and beverage industry follows closely, representing approximately 25% of the market, with environmental testing and academic research constituting the remaining significant segments.

Geographically, North America leads the market with a 38% share, followed by Europe at 35%. The Asia-Pacific region, while currently holding a smaller market share of approximately 20%, is expected to witness the fastest growth rate of 15.4% annually, driven by rapid industrialization and increasing adoption of green technologies in countries like China, India, and Japan.

Key market trends include the rising demand for bio-based solvents as alternatives to traditional organic solvents, with ethanol and acetone derivatives gaining particular traction. The development of solvent recycling systems specifically designed for HPLC applications has emerged as a high-growth segment, expected to expand by 18% annually over the next five years.

Consumer preferences are increasingly favoring products manufactured using environmentally friendly processes, creating market pull for green chromatography adoption. Additionally, cost considerations are becoming more favorable as the price gap between conventional and green solvents narrows due to economies of scale and technological advancements in production methods.

Market challenges include the higher initial investment required for green chromatography systems and the technical expertise needed for method development. However, the long-term cost savings from reduced solvent consumption and waste disposal are creating a compelling return on investment case for many organizations, particularly those with high-volume analytical needs.

The pharmaceutical sector dominates the green chromatography market, accounting for nearly 40% of the total market share. This is attributed to the industry's high volume of analytical testing and increasing pressure to adopt sustainable practices. The food and beverage industry follows closely, representing approximately 25% of the market, with environmental testing and academic research constituting the remaining significant segments.

Geographically, North America leads the market with a 38% share, followed by Europe at 35%. The Asia-Pacific region, while currently holding a smaller market share of approximately 20%, is expected to witness the fastest growth rate of 15.4% annually, driven by rapid industrialization and increasing adoption of green technologies in countries like China, India, and Japan.

Key market trends include the rising demand for bio-based solvents as alternatives to traditional organic solvents, with ethanol and acetone derivatives gaining particular traction. The development of solvent recycling systems specifically designed for HPLC applications has emerged as a high-growth segment, expected to expand by 18% annually over the next five years.

Consumer preferences are increasingly favoring products manufactured using environmentally friendly processes, creating market pull for green chromatography adoption. Additionally, cost considerations are becoming more favorable as the price gap between conventional and green solvents narrows due to economies of scale and technological advancements in production methods.

Market challenges include the higher initial investment required for green chromatography systems and the technical expertise needed for method development. However, the long-term cost savings from reduced solvent consumption and waste disposal are creating a compelling return on investment case for many organizations, particularly those with high-volume analytical needs.

Current Challenges in Eco-friendly HPLC Solvents

The environmental impact of High-Performance Liquid Chromatography (HPLC) has become increasingly concerning as the technique continues to dominate analytical chemistry applications worldwide. Traditional HPLC methods rely heavily on organic solvents such as acetonitrile, methanol, and tetrahydrofuran, which pose significant environmental and health risks. These solvents contribute to air pollution through volatile organic compound (VOC) emissions, contaminate water systems when improperly disposed, and present occupational hazards to laboratory personnel through inhalation and dermal exposure.

A primary challenge in developing eco-friendly HPLC methodologies is maintaining analytical performance while reducing environmental impact. Current green alternatives often demonstrate reduced separation efficiency, decreased sensitivity, or limited applicability across diverse analyte classes. This performance gap represents a significant barrier to widespread adoption of greener practices in analytical laboratories.

The economic considerations further complicate the transition to environmentally safer HPLC practices. Many laboratories face budget constraints that make it difficult to justify the initial investment in alternative technologies or solvent systems, despite potential long-term cost savings. Additionally, the regulatory framework governing laboratory waste disposal varies significantly across regions, creating inconsistent incentives for adopting greener practices.

Technical limitations of current eco-friendly alternatives present another substantial challenge. Water-based mobile phases, while environmentally preferable, often struggle with the separation of hydrophobic compounds. Similarly, ionic liquids show promise as green solvents but face issues with detector compatibility and method transferability. Supercritical fluid chromatography offers environmental benefits but requires specialized equipment and expertise not readily available in many laboratories.

The development of universal green protocols represents perhaps the most significant hurdle. The diverse nature of analytical applications means that a one-size-fits-all approach is impractical. Method validation requirements further complicate matters, as regulatory bodies often require extensive documentation for any changes to established analytical procedures, creating resistance to adopting novel, greener approaches.

Waste management infrastructure limitations also impede progress toward more sustainable HPLC practices. Many facilities lack appropriate systems for solvent recovery, recycling, or safe disposal, resulting in environmentally harmful practices even when awareness of better alternatives exists. The absence of standardized metrics for evaluating the environmental impact of different HPLC methodologies further complicates decision-making processes for laboratories seeking to improve their environmental footprint.

A primary challenge in developing eco-friendly HPLC methodologies is maintaining analytical performance while reducing environmental impact. Current green alternatives often demonstrate reduced separation efficiency, decreased sensitivity, or limited applicability across diverse analyte classes. This performance gap represents a significant barrier to widespread adoption of greener practices in analytical laboratories.

The economic considerations further complicate the transition to environmentally safer HPLC practices. Many laboratories face budget constraints that make it difficult to justify the initial investment in alternative technologies or solvent systems, despite potential long-term cost savings. Additionally, the regulatory framework governing laboratory waste disposal varies significantly across regions, creating inconsistent incentives for adopting greener practices.

Technical limitations of current eco-friendly alternatives present another substantial challenge. Water-based mobile phases, while environmentally preferable, often struggle with the separation of hydrophobic compounds. Similarly, ionic liquids show promise as green solvents but face issues with detector compatibility and method transferability. Supercritical fluid chromatography offers environmental benefits but requires specialized equipment and expertise not readily available in many laboratories.

The development of universal green protocols represents perhaps the most significant hurdle. The diverse nature of analytical applications means that a one-size-fits-all approach is impractical. Method validation requirements further complicate matters, as regulatory bodies often require extensive documentation for any changes to established analytical procedures, creating resistance to adopting novel, greener approaches.

Waste management infrastructure limitations also impede progress toward more sustainable HPLC practices. Many facilities lack appropriate systems for solvent recovery, recycling, or safe disposal, resulting in environmentally harmful practices even when awareness of better alternatives exists. The absence of standardized metrics for evaluating the environmental impact of different HPLC methodologies further complicates decision-making processes for laboratories seeking to improve their environmental footprint.

Existing Green Solvent Alternatives and Approaches

01 Mobile phase composition for HPLC analysis

Various mobile phase compositions are used in HPLC analysis to optimize separation efficiency. These typically include combinations of water, organic solvents (like methanol, acetonitrile), and buffer solutions. The selection of appropriate mobile phase components affects resolution, retention time, and peak shape in chromatographic separations. Adjusting the ratio of these components allows for tailored separation of different analytes based on their chemical properties.- Mobile phase compositions for HPLC analysis: Various mobile phase compositions are used in HPLC analysis to optimize separation efficiency. These typically include combinations of water with organic solvents such as methanol, acetonitrile, or tetrahydrofuran. Buffer solutions may be added to control pH and improve peak shape. The selection of mobile phase composition depends on the nature of the analytes and the stationary phase used in the chromatographic system.

- Solvent recycling and purification systems: Systems for recycling and purifying HPLC solvents help reduce operational costs and environmental impact. These systems typically include distillation units, filtration mechanisms, and quality monitoring components to ensure the recycled solvents meet the required purity standards for analytical applications. Recycling systems are particularly valuable for laboratories that consume large volumes of expensive HPLC-grade solvents.

- Green solvents and environmentally friendly alternatives: Environmentally friendly alternatives to traditional HPLC solvents are being developed to reduce toxicity and environmental impact. These include bio-based solvents, ionic liquids, and supercritical fluids. Green solvents aim to maintain separation efficiency while reducing hazardous waste generation and improving laboratory safety profiles. The development of these alternatives aligns with sustainable chemistry principles and regulatory trends.

- Gradient elution optimization techniques: Gradient elution techniques involve changing the mobile phase composition during the HPLC analysis to improve separation of complex mixtures. Optimization methods include adjusting gradient steepness, implementing step gradients, and using multi-solvent systems. Advanced algorithms and software tools help determine optimal gradient profiles based on sample characteristics and separation goals, reducing method development time.

- Specialized solvent systems for specific applications: Specialized solvent systems are developed for specific HPLC applications such as chiral separations, protein analysis, and pharmaceutical impurity profiling. These systems may include additives like ion-pairing reagents, chiral selectors, or metal complexing agents to enhance selectivity. The composition of these specialized solvent systems is tailored to the unique requirements of the target analytes and the separation mechanism employed.

02 Green solvents for sustainable HPLC applications

Environmentally friendly solvents are increasingly being used in HPLC to reduce ecological impact. These green alternatives include bio-derived solvents, ionic liquids, and water-based systems that minimize hazardous waste. Such sustainable approaches maintain analytical performance while reducing toxicity and environmental footprint. The development of green chromatography methods addresses growing concerns about laboratory waste and aligns with sustainable chemistry principles.Expand Specific Solutions03 Specialized solvent systems for complex sample matrices

Complex samples require specialized solvent systems to achieve effective separation. These systems may incorporate gradient elution techniques, ternary solvent mixtures, or additives like ion-pairing reagents to enhance selectivity. For biological samples, pharmaceutical compounds, or environmental contaminants, customized solvent compositions help overcome matrix interference and improve detection limits. These specialized approaches enable accurate analysis of challenging sample types.Expand Specific Solutions04 HPLC solvent recycling and purification systems

Solvent recycling and purification systems help reduce costs and waste in HPLC operations. These systems collect, filter, and purify used mobile phases for reuse in subsequent analyses. Technologies include distillation units, membrane filtration, and adsorption systems that restore solvent purity. Implementing solvent recycling practices significantly decreases laboratory operating expenses while maintaining analytical performance and addressing environmental concerns related to solvent disposal.Expand Specific Solutions05 Temperature-controlled solvent delivery for enhanced HPLC performance

Temperature control of solvents improves HPLC separation reproducibility and efficiency. Maintaining consistent mobile phase temperature prevents fluctuations in retention times and reduces baseline noise. Advanced systems incorporate pre-column heating, solvent pre-heaters, and thermostatic column compartments to ensure temperature stability throughout the analysis. This approach is particularly important for thermally sensitive compounds and when using highly viscous mobile phases.Expand Specific Solutions

Leading Companies in Sustainable Chromatography

The HPLC solvent optimization market is in a growth phase, driven by increasing environmental regulations and sustainability initiatives. The market is expanding as pharmaceutical, chemical, and research sectors seek greener alternatives to traditional solvents. Key players include major chemical manufacturers like BASF, Arkema, and Albemarle, who are developing eco-friendly solvent technologies. Academic institutions (Texas A&M, EPFL) and specialized companies (pH7 Technologies, TBF Environmental) are advancing research in this field. The technology is approaching maturity with companies like AGC and Chemours offering commercial green solvent solutions, while research organizations continue to develop next-generation alternatives with reduced environmental impact and improved performance characteristics.

BASF Corp.

Technical Solution: BASF has developed a comprehensive Green HPLC Solvent Selection Guide that evaluates solvents based on environmental, health, and safety (EHS) criteria. Their approach includes replacing traditional toxic solvents with bio-based alternatives derived from renewable resources. BASF's SupraSolv® and LiChrosolv® product lines feature ultra-pure solvents specifically designed for HPLC applications with reduced environmental impact. The company has pioneered solvent recovery systems that can recapture up to 90% of used HPLC solvents, significantly reducing waste and environmental contamination. Their technology incorporates automated solvent recycling units that integrate directly with HPLC systems, allowing for closed-loop operation that minimizes exposure and emissions.

Strengths: Comprehensive portfolio of green solvents with established performance metrics; integrated recycling solutions that provide both environmental and economic benefits. Weaknesses: Higher initial implementation costs; some bio-based alternatives may have different selectivity profiles requiring method revalidation.

Albemarle Corp.

Technical Solution: Albemarle has developed a proprietary solvent optimization platform called EcoSolv™ specifically for HPLC applications. This technology focuses on replacing conventional acetonitrile and methanol with more environmentally benign alternatives while maintaining chromatographic performance. Their approach includes custom-designed solvent blends that reduce toxicity by up to 65% while maintaining separation efficiency. Albemarle's system incorporates predictive modeling software that can recommend optimal green solvent compositions based on analyte properties, reducing method development time by approximately 40%. The company has also pioneered micro-volume HPLC techniques that reduce solvent consumption by up to 80% compared to conventional systems, while maintaining analytical precision and reproducibility.

Strengths: Specialized expertise in green chemistry for analytical applications; comprehensive approach combining alternative solvents with hardware optimization. Weaknesses: Some specialized solvent blends may be proprietary and more expensive than standard options; requires significant method development investment during transition.

Key Innovations in Environmentally Safe HPLC Technologies

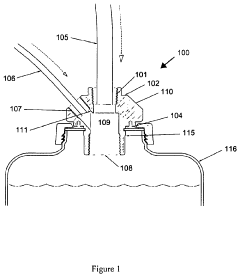

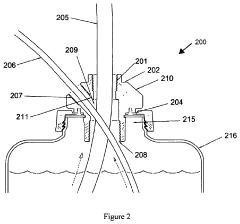

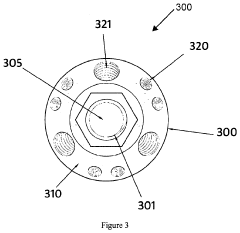

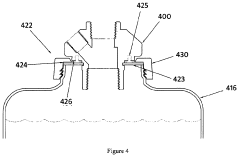

Universal manifold for delivering hazardous liquid

PatentActiveUS20210214210A1

Innovation

- A universal manifold with angled ports for easy attachment of supply tubes and an exchangeable washer system that accommodates variously sized storage containers, allowing for the use of a single manifold for both delivery and collection, and compatibility with non-standard aperture sizes.

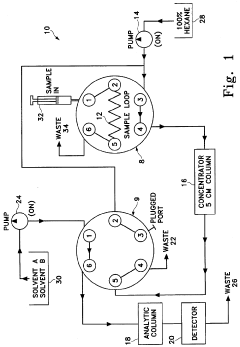

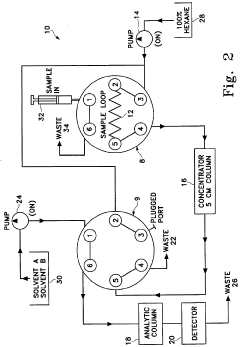

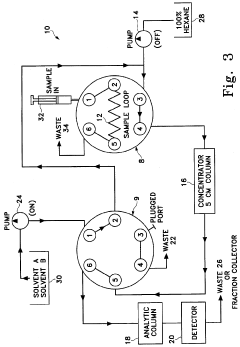

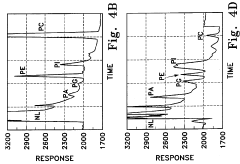

High performance liquid chromatography injection system for the simultaneous concentration and analysis of trace components

PatentInactiveUS5462660A

Innovation

- A novel HPLC injection system with two independently controlled six-port valves and two pumping means allows simultaneous concentration and analysis of trace components using a concentration column and an analysis column equilibrated with different solvent systems, enabling direct injection and online cleanup, while allowing the concentration column to be reloaded during analysis.

Regulatory Framework for Laboratory Chemical Waste

The regulatory landscape governing laboratory chemical waste management has become increasingly stringent, particularly concerning HPLC solvent disposal. The Environmental Protection Agency (EPA) in the United States classifies most HPLC waste solvents as hazardous under the Resource Conservation and Recovery Act (RCRA), requiring specific handling, storage, and disposal procedures. Laboratories must adhere to strict documentation requirements, including maintaining accurate waste manifests and conducting regular staff training on proper waste management protocols.

European regulations, notably the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, impose additional requirements on laboratories operating within EU member states. These regulations emphasize the "polluter pays" principle and extended producer responsibility, placing greater accountability on laboratories for the entire lifecycle of chemical solvents used in analytical processes such as HPLC.

International standards like ISO 14001 provide guidelines for environmental management systems that laboratories can implement to ensure regulatory compliance while optimizing their environmental performance. These standards encourage a systematic approach to waste reduction and management, aligning with the broader goal of optimizing solvent use in HPLC applications.

Local regulations often impose additional requirements beyond federal mandates. Many municipalities have implemented stricter discharge limits for laboratory effluents entering public sewer systems, directly impacting how HPLC waste must be managed. Some jurisdictions require permits for certain volumes or types of waste generation, creating another layer of compliance complexity for analytical laboratories.

Regulatory trends indicate a movement toward more comprehensive chemical management approaches. The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has standardized hazard communication requirements across borders, facilitating better understanding of chemical risks and appropriate disposal methods for HPLC solvents.

Penalties for non-compliance with these regulations can be severe, including substantial fines, facility closures, and even criminal charges for egregious violations. The financial implications extend beyond direct penalties to include remediation costs, legal expenses, and potential reputational damage that can impact business operations.

Staying current with evolving regulations presents a significant challenge for laboratories. Many organizations have implemented dedicated compliance teams or utilize specialized software solutions to track regulatory changes and ensure ongoing adherence to applicable requirements. Professional organizations such as the American Chemical Society offer resources to help laboratories navigate the complex regulatory landscape surrounding HPLC solvent management and disposal.

European regulations, notably the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, impose additional requirements on laboratories operating within EU member states. These regulations emphasize the "polluter pays" principle and extended producer responsibility, placing greater accountability on laboratories for the entire lifecycle of chemical solvents used in analytical processes such as HPLC.

International standards like ISO 14001 provide guidelines for environmental management systems that laboratories can implement to ensure regulatory compliance while optimizing their environmental performance. These standards encourage a systematic approach to waste reduction and management, aligning with the broader goal of optimizing solvent use in HPLC applications.

Local regulations often impose additional requirements beyond federal mandates. Many municipalities have implemented stricter discharge limits for laboratory effluents entering public sewer systems, directly impacting how HPLC waste must be managed. Some jurisdictions require permits for certain volumes or types of waste generation, creating another layer of compliance complexity for analytical laboratories.

Regulatory trends indicate a movement toward more comprehensive chemical management approaches. The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has standardized hazard communication requirements across borders, facilitating better understanding of chemical risks and appropriate disposal methods for HPLC solvents.

Penalties for non-compliance with these regulations can be severe, including substantial fines, facility closures, and even criminal charges for egregious violations. The financial implications extend beyond direct penalties to include remediation costs, legal expenses, and potential reputational damage that can impact business operations.

Staying current with evolving regulations presents a significant challenge for laboratories. Many organizations have implemented dedicated compliance teams or utilize specialized software solutions to track regulatory changes and ensure ongoing adherence to applicable requirements. Professional organizations such as the American Chemical Society offer resources to help laboratories navigate the complex regulatory landscape surrounding HPLC solvent management and disposal.

Economic Impact of Green HPLC Implementation

The implementation of green HPLC methodologies presents significant economic implications for laboratories and organizations across various sectors. Initial investment in green HPLC technologies typically requires capital expenditure for equipment modifications or replacements, with costs ranging from $10,000 to $50,000 depending on the scale of operations. However, this investment demonstrates compelling return potential through multiple economic channels.

Solvent reduction represents the most immediate cost-saving opportunity, with traditional HPLC methods consuming approximately 500-1000 liters of organic solvents annually per instrument. Green HPLC techniques can reduce this consumption by 40-80%, translating to direct savings of $5,000-$15,000 per instrument annually based on current solvent pricing trends. These savings accelerate as petroleum-derived solvent costs continue to rise due to global supply chain pressures.

Waste management cost reduction constitutes another substantial economic benefit. Hazardous waste disposal costs average $5-$15 per liter in developed markets, creating significant ongoing operational expenses for laboratories. Green HPLC implementation can reduce waste volumes by 50-70%, delivering annual savings of $3,000-$10,000 per instrument while simultaneously reducing regulatory compliance burdens and associated administrative costs.

Energy efficiency improvements further enhance the economic case for green HPLC adoption. Modern green HPLC systems demonstrate 15-30% lower energy consumption compared to conventional systems, reducing utility costs and supporting organizational sustainability goals. This efficiency gain becomes increasingly valuable as energy prices rise and carbon pricing mechanisms expand globally.

Labor productivity also improves with green HPLC implementation. Reduced solvent handling time, decreased waste management requirements, and fewer system maintenance needs can save 2-5 hours of technician time weekly per instrument. At average laboratory technician compensation rates, this efficiency translates to $5,000-$12,000 in annual labor cost savings per instrument.

The market differentiation advantage cannot be overlooked in competitive sectors. Organizations implementing green HPLC can leverage their environmental commitment for brand enhancement, potentially commanding premium pricing or securing preferred supplier status with environmentally conscious clients. This advantage is particularly valuable in pharmaceutical, food safety, and consumer product testing markets where end-consumer environmental awareness continues to grow.

Return on investment calculations indicate that most green HPLC implementations achieve breakeven within 12-24 months, followed by sustained cost advantages throughout the equipment lifecycle. This favorable economic profile, combined with regulatory compliance benefits and corporate social responsibility alignment, presents a compelling business case for green HPLC adoption across laboratory operations.

Solvent reduction represents the most immediate cost-saving opportunity, with traditional HPLC methods consuming approximately 500-1000 liters of organic solvents annually per instrument. Green HPLC techniques can reduce this consumption by 40-80%, translating to direct savings of $5,000-$15,000 per instrument annually based on current solvent pricing trends. These savings accelerate as petroleum-derived solvent costs continue to rise due to global supply chain pressures.

Waste management cost reduction constitutes another substantial economic benefit. Hazardous waste disposal costs average $5-$15 per liter in developed markets, creating significant ongoing operational expenses for laboratories. Green HPLC implementation can reduce waste volumes by 50-70%, delivering annual savings of $3,000-$10,000 per instrument while simultaneously reducing regulatory compliance burdens and associated administrative costs.

Energy efficiency improvements further enhance the economic case for green HPLC adoption. Modern green HPLC systems demonstrate 15-30% lower energy consumption compared to conventional systems, reducing utility costs and supporting organizational sustainability goals. This efficiency gain becomes increasingly valuable as energy prices rise and carbon pricing mechanisms expand globally.

Labor productivity also improves with green HPLC implementation. Reduced solvent handling time, decreased waste management requirements, and fewer system maintenance needs can save 2-5 hours of technician time weekly per instrument. At average laboratory technician compensation rates, this efficiency translates to $5,000-$12,000 in annual labor cost savings per instrument.

The market differentiation advantage cannot be overlooked in competitive sectors. Organizations implementing green HPLC can leverage their environmental commitment for brand enhancement, potentially commanding premium pricing or securing preferred supplier status with environmentally conscious clients. This advantage is particularly valuable in pharmaceutical, food safety, and consumer product testing markets where end-consumer environmental awareness continues to grow.

Return on investment calculations indicate that most green HPLC implementations achieve breakeven within 12-24 months, followed by sustained cost advantages throughout the equipment lifecycle. This favorable economic profile, combined with regulatory compliance benefits and corporate social responsibility alignment, presents a compelling business case for green HPLC adoption across laboratory operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!