HPLC vs PrepLC: Scale and Throughput Comparison

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chromatography Evolution and Objectives

Chromatography has undergone significant evolution since its inception in the early 20th century. Initially developed as a simple separation technique, it has transformed into a sophisticated analytical and preparative methodology essential across various scientific disciplines. The journey began with Mikhail Tsvet's pioneering work in 1903, using liquid-solid column chromatography to separate plant pigments. This fundamental discovery laid the groundwork for decades of innovation.

The 1940s and 1950s marked crucial advancements with the development of paper chromatography and thin-layer chromatography (TLC), offering simpler alternatives for analytical separations. However, the true revolution came in the 1960s with the introduction of High-Performance Liquid Chromatography (HPLC), which dramatically improved separation efficiency, speed, and reproducibility compared to traditional column chromatography.

Preparative Liquid Chromatography (PrepLC) emerged as a parallel development, focusing on larger-scale separations for isolation and purification purposes rather than analysis. While HPLC prioritized resolution and sensitivity for analytical applications, PrepLC emphasized throughput and loading capacity for production environments. This divergence in objectives has shaped their respective technological trajectories.

Recent decades have witnessed remarkable technological refinements in both HPLC and PrepLC systems. Improvements in stationary phase materials, pump technology, detection methods, and automation have continuously enhanced performance parameters. Ultra-High Performance Liquid Chromatography (UHPLC) emerged as an extension of HPLC, utilizing sub-2μm particles and higher pressures to achieve unprecedented separation efficiency and speed.

The primary objective in comparing HPLC and PrepLC systems is to establish a comprehensive understanding of their respective capabilities regarding scale and throughput. This comparison aims to identify optimal applications for each technology based on sample volume, purification requirements, time constraints, and economic considerations. Additionally, it seeks to explore the scalability between analytical HPLC methods and preparative processes.

Another critical objective is evaluating the technological trade-offs inherent in scaling chromatographic processes. This includes examining how resolution, efficiency, and selectivity are affected when transitioning between analytical and preparative scales. Understanding these relationships is essential for effective method transfer and scale-up strategies in pharmaceutical development, natural product isolation, and other separation-intensive industries.

The ultimate goal is to provide a framework for decision-making regarding chromatographic technology selection based on specific separation requirements, helping organizations optimize their analytical and purification workflows for maximum efficiency and cost-effectiveness.

The 1940s and 1950s marked crucial advancements with the development of paper chromatography and thin-layer chromatography (TLC), offering simpler alternatives for analytical separations. However, the true revolution came in the 1960s with the introduction of High-Performance Liquid Chromatography (HPLC), which dramatically improved separation efficiency, speed, and reproducibility compared to traditional column chromatography.

Preparative Liquid Chromatography (PrepLC) emerged as a parallel development, focusing on larger-scale separations for isolation and purification purposes rather than analysis. While HPLC prioritized resolution and sensitivity for analytical applications, PrepLC emphasized throughput and loading capacity for production environments. This divergence in objectives has shaped their respective technological trajectories.

Recent decades have witnessed remarkable technological refinements in both HPLC and PrepLC systems. Improvements in stationary phase materials, pump technology, detection methods, and automation have continuously enhanced performance parameters. Ultra-High Performance Liquid Chromatography (UHPLC) emerged as an extension of HPLC, utilizing sub-2μm particles and higher pressures to achieve unprecedented separation efficiency and speed.

The primary objective in comparing HPLC and PrepLC systems is to establish a comprehensive understanding of their respective capabilities regarding scale and throughput. This comparison aims to identify optimal applications for each technology based on sample volume, purification requirements, time constraints, and economic considerations. Additionally, it seeks to explore the scalability between analytical HPLC methods and preparative processes.

Another critical objective is evaluating the technological trade-offs inherent in scaling chromatographic processes. This includes examining how resolution, efficiency, and selectivity are affected when transitioning between analytical and preparative scales. Understanding these relationships is essential for effective method transfer and scale-up strategies in pharmaceutical development, natural product isolation, and other separation-intensive industries.

The ultimate goal is to provide a framework for decision-making regarding chromatographic technology selection based on specific separation requirements, helping organizations optimize their analytical and purification workflows for maximum efficiency and cost-effectiveness.

Market Applications and Demand Analysis

The global chromatography market has witnessed substantial growth in recent years, with HPLC and Preparative LC systems forming critical segments within this space. Market research indicates that the overall chromatography market is projected to reach approximately $13.3 billion by 2025, with liquid chromatography technologies accounting for nearly 60% of this value. This growth is primarily driven by increasing demand across pharmaceutical, biotechnology, food safety, and environmental monitoring sectors.

In the pharmaceutical and biotechnology industries, which represent the largest application segments, the demand for both HPLC and Preparative LC systems continues to rise due to stringent regulatory requirements for drug development and quality control. Pharmaceutical companies require high-throughput analytical HPLC for routine quality testing, while simultaneously needing preparative capabilities for drug discovery and development processes. This dual requirement has created a market where laboratories often need both technologies rather than choosing between them.

The academic research sector demonstrates growing demand for versatile chromatography solutions that can transition between analytical and small-scale preparative applications. This has led to the development of hybrid systems that can function in both modes, addressing budget constraints while maintaining necessary capabilities for diverse research projects.

Contract research organizations (CROs) and contract manufacturing organizations (CMOs) represent another significant market segment with specific throughput requirements. These organizations typically process large sample volumes and require systems that maximize efficiency. The ability to scale from analytical HPLC to preparative LC without significant method development overhead represents a substantial value proposition for these entities.

Regional market analysis reveals that North America dominates the chromatography market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate due to expanding pharmaceutical manufacturing, increasing research activities, and growing food safety concerns. China and India, in particular, are emerging as significant markets for both HPLC and preparative chromatography systems.

The environmental testing sector presents an expanding application area, particularly for HPLC systems, driven by increasing regulatory requirements for monitoring pollutants in water, soil, and air. This sector typically prioritizes analytical capabilities over preparative functions, though there are niche applications where preparative techniques are employed for isolating environmental compounds for further study.

Food and beverage safety testing represents another growth area, with increasing regulations requiring more sophisticated analytical capabilities. This sector predominantly utilizes analytical HPLC for routine testing but may employ preparative techniques for specific research applications or standard development.

In the pharmaceutical and biotechnology industries, which represent the largest application segments, the demand for both HPLC and Preparative LC systems continues to rise due to stringent regulatory requirements for drug development and quality control. Pharmaceutical companies require high-throughput analytical HPLC for routine quality testing, while simultaneously needing preparative capabilities for drug discovery and development processes. This dual requirement has created a market where laboratories often need both technologies rather than choosing between them.

The academic research sector demonstrates growing demand for versatile chromatography solutions that can transition between analytical and small-scale preparative applications. This has led to the development of hybrid systems that can function in both modes, addressing budget constraints while maintaining necessary capabilities for diverse research projects.

Contract research organizations (CROs) and contract manufacturing organizations (CMOs) represent another significant market segment with specific throughput requirements. These organizations typically process large sample volumes and require systems that maximize efficiency. The ability to scale from analytical HPLC to preparative LC without significant method development overhead represents a substantial value proposition for these entities.

Regional market analysis reveals that North America dominates the chromatography market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate due to expanding pharmaceutical manufacturing, increasing research activities, and growing food safety concerns. China and India, in particular, are emerging as significant markets for both HPLC and preparative chromatography systems.

The environmental testing sector presents an expanding application area, particularly for HPLC systems, driven by increasing regulatory requirements for monitoring pollutants in water, soil, and air. This sector typically prioritizes analytical capabilities over preparative functions, though there are niche applications where preparative techniques are employed for isolating environmental compounds for further study.

Food and beverage safety testing represents another growth area, with increasing regulations requiring more sophisticated analytical capabilities. This sector predominantly utilizes analytical HPLC for routine testing but may employ preparative techniques for specific research applications or standard development.

HPLC and PrepLC Technical Challenges

High-performance liquid chromatography (HPLC) and preparative liquid chromatography (PrepLC) face several significant technical challenges that impact their performance, efficiency, and applicability in various analytical and purification scenarios. Despite their widespread use in pharmaceutical, biotechnology, and chemical industries, both technologies encounter limitations that researchers and engineers continuously strive to overcome.

For HPLC systems, one of the primary challenges is achieving higher resolution while maintaining reasonable analysis times. As analytical demands increase for complex mixtures, conventional HPLC systems often struggle with closely eluting compounds, particularly when dealing with structural isomers or compounds with similar physicochemical properties. This challenge becomes more pronounced when analyzing biological samples containing thousands of components.

Pressure limitations represent another significant hurdle for HPLC technology. Traditional HPLC systems typically operate at pressures below 6,000 psi, which restricts the use of smaller particle size columns that could otherwise provide enhanced separation efficiency. While UHPLC (Ultra-High Performance Liquid Chromatography) addresses this issue by operating at higher pressures, it introduces additional challenges related to system durability and maintenance requirements.

Sample capacity constraints in HPLC systems limit throughput capabilities, particularly when dealing with concentrated samples that can overload columns and compromise separation quality. This limitation becomes especially problematic when transitioning methods from analytical to preparative scale.

PrepLC systems face their own set of distinct challenges. Scaling up from analytical to preparative scale is not a straightforward process and often requires significant method redevelopment. Parameters that work effectively at analytical scale frequently do not translate directly to preparative applications due to differences in column dimensions, flow rates, and sample loading capacities.

Heat dissipation presents a substantial challenge in PrepLC operations. The higher flow rates and larger column diameters generate considerable heat through friction, which can lead to band broadening, reduced resolution, and potential sample degradation if not properly managed. Effective temperature control systems are essential but add complexity and cost to PrepLC instrumentation.

Sample recovery and solvent consumption represent economic and environmental challenges for PrepLC. The technology typically requires large volumes of often expensive and environmentally problematic solvents. Developing more efficient separation methods that minimize solvent usage while maintaining separation quality remains an ongoing challenge.

Both technologies also face challenges related to automation and integration with other analytical techniques. While significant progress has been made in developing automated systems, achieving seamless integration with mass spectrometry, spectroscopic techniques, and sample preparation workflows continues to present technical difficulties that impact overall laboratory efficiency.

For HPLC systems, one of the primary challenges is achieving higher resolution while maintaining reasonable analysis times. As analytical demands increase for complex mixtures, conventional HPLC systems often struggle with closely eluting compounds, particularly when dealing with structural isomers or compounds with similar physicochemical properties. This challenge becomes more pronounced when analyzing biological samples containing thousands of components.

Pressure limitations represent another significant hurdle for HPLC technology. Traditional HPLC systems typically operate at pressures below 6,000 psi, which restricts the use of smaller particle size columns that could otherwise provide enhanced separation efficiency. While UHPLC (Ultra-High Performance Liquid Chromatography) addresses this issue by operating at higher pressures, it introduces additional challenges related to system durability and maintenance requirements.

Sample capacity constraints in HPLC systems limit throughput capabilities, particularly when dealing with concentrated samples that can overload columns and compromise separation quality. This limitation becomes especially problematic when transitioning methods from analytical to preparative scale.

PrepLC systems face their own set of distinct challenges. Scaling up from analytical to preparative scale is not a straightforward process and often requires significant method redevelopment. Parameters that work effectively at analytical scale frequently do not translate directly to preparative applications due to differences in column dimensions, flow rates, and sample loading capacities.

Heat dissipation presents a substantial challenge in PrepLC operations. The higher flow rates and larger column diameters generate considerable heat through friction, which can lead to band broadening, reduced resolution, and potential sample degradation if not properly managed. Effective temperature control systems are essential but add complexity and cost to PrepLC instrumentation.

Sample recovery and solvent consumption represent economic and environmental challenges for PrepLC. The technology typically requires large volumes of often expensive and environmentally problematic solvents. Developing more efficient separation methods that minimize solvent usage while maintaining separation quality remains an ongoing challenge.

Both technologies also face challenges related to automation and integration with other analytical techniques. While significant progress has been made in developing automated systems, achieving seamless integration with mass spectrometry, spectroscopic techniques, and sample preparation workflows continues to present technical difficulties that impact overall laboratory efficiency.

Current Scale and Throughput Solutions

01 Scale-up strategies for preparative chromatography

Scale-up from analytical HPLC to preparative LC requires specific strategies to maintain separation efficiency while increasing throughput. These strategies include column dimension optimization, particle size selection, and flow rate adjustments. Proper scaling calculations ensure that separation parameters achieved at analytical scale can be successfully transferred to preparative scale, maximizing productivity while maintaining resolution and purity requirements.- Scale-up strategies for preparative chromatography: Scaling up from analytical HPLC to preparative LC requires specific strategies to maintain separation efficiency while increasing throughput. These strategies include adjusting column dimensions, optimizing flow rates, and modifying mobile phase compositions. The transition from analytical to preparative scale often involves considerations of particle size, column diameter, and loading capacity to ensure efficient separation at larger scales while maintaining resolution.

- Innovative column designs for improved throughput: Novel column designs enhance the efficiency and throughput of both HPLC and preparative LC systems. These designs include specialized packing materials, column geometries, and flow distribution systems that minimize back pressure while maximizing separation capacity. Advanced column technologies enable faster separations, higher loading capacities, and improved resolution, contributing to overall system performance and productivity.

- Automation and system integration for enhanced productivity: Automated systems integrate sample preparation, injection, collection, and analysis to increase throughput in chromatography workflows. These systems incorporate robotics, software control, and feedback mechanisms to optimize separation conditions in real-time. Automation reduces manual intervention, minimizes human error, and enables continuous operation, significantly improving laboratory efficiency and sample processing capacity.

- Advanced detection and fraction collection methods: Sophisticated detection systems coupled with intelligent fraction collection methods improve the efficiency of preparative chromatography. These systems utilize multiple detection parameters, peak recognition algorithms, and adaptive collection strategies to maximize purity and yield. Real-time monitoring of multiple wavelengths, mass detection, and other analytical signals allows for precise fraction collection even with complex sample mixtures.

- Continuous and multi-column chromatography techniques: Continuous chromatography and multi-column setups significantly increase throughput compared to traditional batch processes. These approaches include simulated moving bed (SMB) technology, sequential injection systems, and parallel processing configurations. By enabling continuous sample loading and processing, these techniques maximize column utilization, reduce solvent consumption, and increase overall productivity, particularly beneficial for large-scale purifications.

02 Advanced column technologies for improved throughput

Novel column technologies enhance preparative chromatography throughput and efficiency. These include monolithic columns, superficially porous particles, and specialized stationary phases designed specifically for preparative applications. These technologies allow for higher flow rates, reduced back pressure, improved mass transfer, and increased loading capacity, resulting in significantly higher throughput compared to conventional columns.Expand Specific Solutions03 Automated preparative chromatography systems

Automated systems for preparative liquid chromatography incorporate advanced features such as fraction collection, sample injection, and method development tools. These systems can operate continuously with minimal operator intervention, increasing laboratory efficiency. Integration of sensors, feedback control mechanisms, and software algorithms enables real-time monitoring and adjustment of separation parameters to optimize throughput and purity.Expand Specific Solutions04 Continuous and multi-column chromatography techniques

Continuous chromatography techniques, such as simulated moving bed (SMB) and multi-column countercurrent solvent gradient purification (MCSGP), significantly increase throughput compared to traditional batch processes. These approaches utilize multiple columns operating in sequence to create a continuous flow process, maximizing stationary phase utilization and reducing solvent consumption while maintaining or improving separation efficiency.Expand Specific Solutions05 Process intensification and optimization methods

Process intensification strategies for preparative chromatography include optimized gradient profiles, overloading techniques, and advanced detection methods. Mathematical modeling and design of experiments approaches help identify optimal operating conditions that maximize throughput without compromising purity. These methods consider factors such as mobile phase composition, temperature, pressure limitations, and sample characteristics to develop robust and efficient separation processes.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The HPLC vs PrepLC market is currently in a mature growth phase, with an estimated global chromatography market exceeding $10 billion and growing at 5-7% annually. The technology landscape shows high maturity with established protocols and standardized applications. Leading players include Waters Technology Corp. and Agilent Technologies dominating the high-end analytical HPLC segment, while Phenomenex and Interchim have strong positions in preparative chromatography solutions. The competitive landscape is characterized by differentiation through technological innovation, with companies like Hitachi High-Tech and DH Technologies focusing on throughput optimization and automation. Academic institutions such as California Institute of Technology and University of Twente contribute significantly to advancing separation science methodologies and applications.

Waters Technology Corp.

Technical Solution: Waters has developed a comprehensive technology solution that addresses the fundamental differences between HPLC and PrepLC systems. Their ACQUITY UPLC and prep LC systems feature patented column technology that optimizes particle size distribution - typically using sub-2μm particles for HPLC for analytical precision and larger particles (5-10μm) for PrepLC to handle higher sample loads. Waters' AutoPurification System integrates mass detection with optical detection for PrepLC, enabling throughput increases of up to 30-fold compared to traditional methods. Their systems implement dynamic flow adjustment technology that automatically optimizes flow rates based on column dimensions and separation requirements, allowing seamless method transfer between analytical and preparative scales. Waters' Prep Calculator software provides automated scaling calculations to translate HPLC methods to PrepLC parameters with minimal manual optimization.

Strengths: Industry-leading column technology with optimized particle morphology for both scales; proprietary software for automated method transfer between analytical and preparative scales; integrated detection systems. Weaknesses: Higher initial investment cost compared to competitors; proprietary consumables can increase operational expenses; complex systems may require specialized training.

Agilent Technologies, Inc.

Technical Solution: Agilent has developed an integrated approach to bridging HPLC and PrepLC applications through their InfinityLab platform. Their technology solution focuses on scalable column chemistry that maintains separation selectivity across different scales. The InfinityLab Prep LC systems feature dynamic flow range capabilities spanning from analytical (0.05-5 mL/min) to preparative scales (up to 100 mL/min) within a single instrument architecture. Agilent's Intelligent System Emulation Technology (ISET) enables method transfer between different systems while maintaining chromatographic results. Their PrepLC systems incorporate active solvent and waste monitoring with predictive maintenance algorithms that reduce downtime by up to 25%. Agilent's OpenLab CDS software platform provides unified control across both HPLC and PrepLC operations with automated method scaling tools that account for differences in column dimensions, particle size, and flow dynamics.

Strengths: Exceptional method transferability between analytical and preparative scales; modular design allows customization for specific applications; comprehensive software integration. Weaknesses: Higher complexity in system configuration may present steeper learning curve; premium pricing structure; some advanced features require additional software modules.

Key Innovations in Column Technology

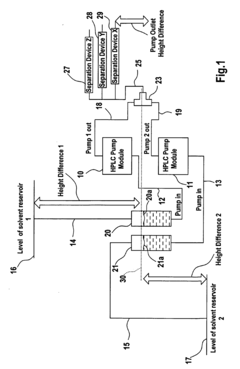

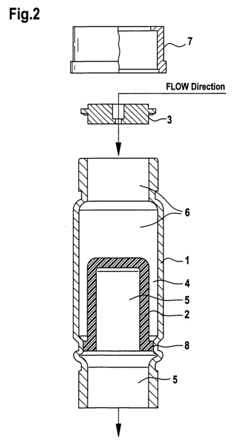

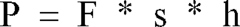

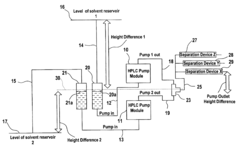

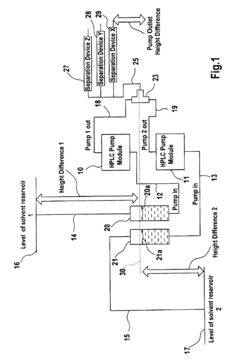

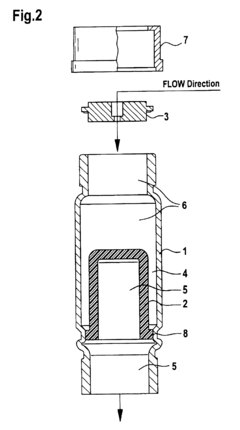

Pumping arrangement

PatentInactiveEP1376121A1

Innovation

- A pumping arrangement with filtration devices comprising a porous inner member within a borosilicate glass outer chamber, allowing two-phase systems to handle non-degassed solvents and prevent backflow, featuring reusable and sterilizable design to manage high flow rates and level differences between reservoirs.

Pumping arrangement

PatentInactiveUS6793815B2

Innovation

- A pumping arrangement with filtration devices comprising a porous inner member within a borosilicate glass outer chamber, designed to prevent backflow and corrosion, allowing a two-phase system for efficient solvent handling and priming, and featuring a reusable design for easy cleaning and sterilization.

Cost-Benefit Analysis of HPLC vs PrepLC

When evaluating the economic viability of chromatography systems, a comprehensive cost-benefit analysis between HPLC (High-Performance Liquid Chromatography) and PrepLC (Preparative Liquid Chromatography) reveals significant differences that impact laboratory operations and research outcomes.

Initial capital investment represents a primary consideration, with HPLC systems typically ranging from $30,000 to $100,000 depending on detector configurations and automation features. In contrast, PrepLC systems command substantially higher prices, often between $100,000 and $500,000, reflecting their industrial-scale capabilities and robust construction requirements for handling larger sample volumes.

Operational expenses further differentiate these technologies. HPLC systems consume relatively modest volumes of mobile phase solvents (typically 0.5-2 mL/min), resulting in annual solvent costs of approximately $5,000-$15,000 for a laboratory running regular analyses. PrepLC operations demand significantly higher solvent volumes (often 20-100 mL/min), potentially increasing annual solvent expenses to $30,000-$100,000 depending on separation complexity and throughput requirements.

Maintenance costs follow similar patterns. HPLC systems typically require $3,000-$8,000 annually for routine maintenance, while PrepLC systems necessitate $10,000-$30,000 due to more complex pumping systems, larger columns, and industrial-grade components subject to greater mechanical stress.

Return on investment calculations reveal complementary advantages. HPLC systems deliver exceptional value for analytical work, method development, and quality control applications, with typical ROI periods of 2-3 years in active laboratories. PrepLC systems, while requiring larger initial investments, demonstrate compelling ROI for production environments where purified compound value exceeds $500,000 annually, with typical payback periods of 3-5 years.

Labor efficiency metrics further illuminate operational differences. HPLC protocols typically require 1-2 hours of hands-on time per day for sample preparation and system operation. PrepLC operations demand more intensive oversight, often requiring dedicated personnel for continuous operation, representing 4-8 hours of daily technical labor.

Throughput economics reveal PrepLC's fundamental advantage: while costing 3-5 times more than HPLC systems, they can process 20-100 times the sample volume, yielding substantial economies of scale for purification campaigns. This translates to per-gram purification costs of $50-200 for PrepLC versus $500-2,000 for HPLC when scaled to production levels.

Facility impact assessments complete the economic picture. HPLC systems occupy minimal laboratory space (approximately 2-3 square feet) with standard electrical requirements. PrepLC installations demand dedicated facilities with reinforced benching, enhanced ventilation, and potentially specialized electrical and waste handling systems, adding 15-30% to total implementation costs beyond the equipment itself.

Initial capital investment represents a primary consideration, with HPLC systems typically ranging from $30,000 to $100,000 depending on detector configurations and automation features. In contrast, PrepLC systems command substantially higher prices, often between $100,000 and $500,000, reflecting their industrial-scale capabilities and robust construction requirements for handling larger sample volumes.

Operational expenses further differentiate these technologies. HPLC systems consume relatively modest volumes of mobile phase solvents (typically 0.5-2 mL/min), resulting in annual solvent costs of approximately $5,000-$15,000 for a laboratory running regular analyses. PrepLC operations demand significantly higher solvent volumes (often 20-100 mL/min), potentially increasing annual solvent expenses to $30,000-$100,000 depending on separation complexity and throughput requirements.

Maintenance costs follow similar patterns. HPLC systems typically require $3,000-$8,000 annually for routine maintenance, while PrepLC systems necessitate $10,000-$30,000 due to more complex pumping systems, larger columns, and industrial-grade components subject to greater mechanical stress.

Return on investment calculations reveal complementary advantages. HPLC systems deliver exceptional value for analytical work, method development, and quality control applications, with typical ROI periods of 2-3 years in active laboratories. PrepLC systems, while requiring larger initial investments, demonstrate compelling ROI for production environments where purified compound value exceeds $500,000 annually, with typical payback periods of 3-5 years.

Labor efficiency metrics further illuminate operational differences. HPLC protocols typically require 1-2 hours of hands-on time per day for sample preparation and system operation. PrepLC operations demand more intensive oversight, often requiring dedicated personnel for continuous operation, representing 4-8 hours of daily technical labor.

Throughput economics reveal PrepLC's fundamental advantage: while costing 3-5 times more than HPLC systems, they can process 20-100 times the sample volume, yielding substantial economies of scale for purification campaigns. This translates to per-gram purification costs of $50-200 for PrepLC versus $500-2,000 for HPLC when scaled to production levels.

Facility impact assessments complete the economic picture. HPLC systems occupy minimal laboratory space (approximately 2-3 square feet) with standard electrical requirements. PrepLC installations demand dedicated facilities with reinforced benching, enhanced ventilation, and potentially specialized electrical and waste handling systems, adding 15-30% to total implementation costs beyond the equipment itself.

Environmental Impact and Green Chemistry Considerations

The environmental impact of chromatographic techniques has become increasingly important as laboratories worldwide strive to adopt more sustainable practices. When comparing HPLC (High-Performance Liquid Chromatography) and PrepLC (Preparative Liquid Chromatography), significant differences emerge in their environmental footprints, primarily due to their scale and throughput characteristics.

HPLC systems typically consume smaller volumes of mobile phase solvents—generally in the milliliter range per analysis—compared to PrepLC systems that may use liters of solvent for a single purification run. This substantial difference in solvent consumption directly translates to increased waste generation, energy requirements for solvent evaporation, and higher disposal costs for PrepLC operations. However, when evaluated on a per-compound basis, PrepLC may demonstrate greater efficiency by processing larger quantities in a single run.

The environmental impact extends beyond solvent usage to energy consumption. PrepLC systems require more powerful pumps to maintain flow rates that can be 100-1000 times higher than analytical HPLC, resulting in significantly higher electricity consumption. Additionally, the larger columns and instruments in PrepLC demand more resources for manufacturing and eventually create more waste at end-of-life disposal.

Recent advances in green chemistry have introduced several innovations to mitigate these environmental concerns. Supercritical fluid chromatography (SFC) using CO2 as the primary mobile phase represents a promising alternative, reducing organic solvent usage by up to 90% in both analytical and preparative applications. Similarly, the development of more efficient stationary phases has enabled faster separations with reduced solvent consumption across both platforms.

Recycling solvent systems have gained traction particularly in PrepLC applications, where the economic and environmental benefits are most pronounced. These systems can recover and purify used solvents, reducing fresh solvent requirements by 60-80% in optimized setups. Additionally, miniaturization trends in HPLC (micro and nano-LC) have dramatically reduced solvent consumption while maintaining analytical performance.

The pharmaceutical industry has been at the forefront of implementing green metrics for chromatographic processes, developing comprehensive environmental impact assessments that consider solvent toxicity, energy usage, and waste generation. These metrics increasingly influence decision-making when choosing between HPLC and PrepLC approaches for specific applications, with some organizations adopting hybrid workflows that optimize the use of both techniques to minimize overall environmental impact.

Regulatory pressures and corporate sustainability initiatives continue to drive innovation in this space, with equipment manufacturers now offering eco-friendly options such as low-flow PrepLC systems and energy-efficient HPLC instruments designed to reduce environmental footprint while maintaining separation performance.

HPLC systems typically consume smaller volumes of mobile phase solvents—generally in the milliliter range per analysis—compared to PrepLC systems that may use liters of solvent for a single purification run. This substantial difference in solvent consumption directly translates to increased waste generation, energy requirements for solvent evaporation, and higher disposal costs for PrepLC operations. However, when evaluated on a per-compound basis, PrepLC may demonstrate greater efficiency by processing larger quantities in a single run.

The environmental impact extends beyond solvent usage to energy consumption. PrepLC systems require more powerful pumps to maintain flow rates that can be 100-1000 times higher than analytical HPLC, resulting in significantly higher electricity consumption. Additionally, the larger columns and instruments in PrepLC demand more resources for manufacturing and eventually create more waste at end-of-life disposal.

Recent advances in green chemistry have introduced several innovations to mitigate these environmental concerns. Supercritical fluid chromatography (SFC) using CO2 as the primary mobile phase represents a promising alternative, reducing organic solvent usage by up to 90% in both analytical and preparative applications. Similarly, the development of more efficient stationary phases has enabled faster separations with reduced solvent consumption across both platforms.

Recycling solvent systems have gained traction particularly in PrepLC applications, where the economic and environmental benefits are most pronounced. These systems can recover and purify used solvents, reducing fresh solvent requirements by 60-80% in optimized setups. Additionally, miniaturization trends in HPLC (micro and nano-LC) have dramatically reduced solvent consumption while maintaining analytical performance.

The pharmaceutical industry has been at the forefront of implementing green metrics for chromatographic processes, developing comprehensive environmental impact assessments that consider solvent toxicity, energy usage, and waste generation. These metrics increasingly influence decision-making when choosing between HPLC and PrepLC approaches for specific applications, with some organizations adopting hybrid workflows that optimize the use of both techniques to minimize overall environmental impact.

Regulatory pressures and corporate sustainability initiatives continue to drive innovation in this space, with equipment manufacturers now offering eco-friendly options such as low-flow PrepLC systems and energy-efficient HPLC instruments designed to reduce environmental footprint while maintaining separation performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!