How to Improve HPLC Column Lifetime—Best Practices

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HPLC Column Lifetime Background and Objectives

High-performance liquid chromatography (HPLC) has evolved significantly since its introduction in the 1960s, becoming an indispensable analytical technique in pharmaceutical, environmental, food safety, and clinical research. The development of HPLC columns has progressed from large particle silica-based materials to modern sub-2-micron particles and monolithic structures, enabling enhanced separation efficiency and analytical precision.

Column lifetime represents a critical economic and performance factor in HPLC operations. Historically, early columns suffered from rapid degradation due to mechanical stress, chemical instability, and contamination. Modern columns, while more robust, still face significant longevity challenges that impact laboratory productivity, analytical consistency, and operational costs.

The evolution of column technology has been marked by several key innovations: the transition from irregular to spherical particles, the development of bonded phases with enhanced pH stability, the introduction of hybrid organic-inorganic materials, and the emergence of core-shell particle technology. Each advancement has contributed incrementally to improved column durability, yet column lifetime remains a persistent concern for analytical laboratories worldwide.

Current industry benchmarks suggest that properly maintained HPLC columns should deliver between 500-2000 injections, depending on application complexity and sample matrix. However, many laboratories report significantly shorter lifespans, indicating a substantial gap between theoretical and practical column performance. This discrepancy represents both a technical challenge and an opportunity for optimization.

The primary objective of this technical investigation is to comprehensively evaluate best practices for maximizing HPLC column lifetime across diverse analytical applications. Specifically, we aim to identify critical factors affecting column degradation, establish evidence-based maintenance protocols, and develop predictive models for column performance deterioration.

Secondary objectives include quantifying the economic impact of extended column lifetimes, assessing the relationship between column care practices and separation quality maintenance, and exploring emerging technologies that may fundamentally alter column durability paradigms. These objectives align with broader industry trends toward sustainable laboratory practices and reduced analytical costs.

The technical landscape surrounding HPLC column lifetime extends beyond simple mechanical considerations to encompass advances in surface chemistry, biomimetic materials, and intelligent system monitoring. Recent developments in machine learning applications for predictive maintenance and novel stationary phase designs suggest promising directions for future innovation in this critical aspect of chromatographic performance.

Column lifetime represents a critical economic and performance factor in HPLC operations. Historically, early columns suffered from rapid degradation due to mechanical stress, chemical instability, and contamination. Modern columns, while more robust, still face significant longevity challenges that impact laboratory productivity, analytical consistency, and operational costs.

The evolution of column technology has been marked by several key innovations: the transition from irregular to spherical particles, the development of bonded phases with enhanced pH stability, the introduction of hybrid organic-inorganic materials, and the emergence of core-shell particle technology. Each advancement has contributed incrementally to improved column durability, yet column lifetime remains a persistent concern for analytical laboratories worldwide.

Current industry benchmarks suggest that properly maintained HPLC columns should deliver between 500-2000 injections, depending on application complexity and sample matrix. However, many laboratories report significantly shorter lifespans, indicating a substantial gap between theoretical and practical column performance. This discrepancy represents both a technical challenge and an opportunity for optimization.

The primary objective of this technical investigation is to comprehensively evaluate best practices for maximizing HPLC column lifetime across diverse analytical applications. Specifically, we aim to identify critical factors affecting column degradation, establish evidence-based maintenance protocols, and develop predictive models for column performance deterioration.

Secondary objectives include quantifying the economic impact of extended column lifetimes, assessing the relationship between column care practices and separation quality maintenance, and exploring emerging technologies that may fundamentally alter column durability paradigms. These objectives align with broader industry trends toward sustainable laboratory practices and reduced analytical costs.

The technical landscape surrounding HPLC column lifetime extends beyond simple mechanical considerations to encompass advances in surface chemistry, biomimetic materials, and intelligent system monitoring. Recent developments in machine learning applications for predictive maintenance and novel stationary phase designs suggest promising directions for future innovation in this critical aspect of chromatographic performance.

Market Analysis of HPLC Column Durability Demands

The global HPLC column market demonstrates robust demand for increased column durability, with the market valued at approximately $2.5 billion in 2022 and projected to grow at a CAGR of 5.8% through 2028. This growth is primarily driven by expanding applications in pharmaceutical research, clinical diagnostics, and food safety testing, where column longevity directly impacts operational efficiency and cost-effectiveness.

Market research indicates that laboratories typically spend between 15-20% of their analytical budgets on column replacement, representing a significant operational expense. A survey of 500 analytical laboratories revealed that 78% of respondents identified column lifetime as a "very important" or "critical" factor in purchasing decisions, ranking it above initial acquisition cost.

The pharmaceutical sector constitutes the largest market segment, accounting for approximately 45% of HPLC column demand. Within this segment, quality control applications generate the highest replacement frequency due to high sample throughput and diverse sample matrices. Academic and research institutions, while price-sensitive, increasingly prioritize column durability to maximize research budgets and ensure experimental reproducibility.

Geographically, North America leads the market with 38% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region demonstrates the fastest growth rate at 7.2% annually, driven by expanding pharmaceutical manufacturing and contract research operations in China and India.

Market analysis reveals a clear price premium for columns with demonstrated longevity advantages. Columns marketed specifically for extended lifetime command 15-30% higher prices than standard offerings, yet market data suggests these premium products maintain strong sales growth, indicating favorable return-on-investment calculations by end-users.

Customer satisfaction surveys highlight that laboratories are willing to invest in preventive maintenance practices and higher-quality columns when vendors can demonstrate tangible lifetime improvements. The average laboratory reports that doubling column lifetime would justify a 40-60% price premium, creating significant market opportunities for manufacturers who can deliver verifiable durability enhancements.

Emerging market trends include growing demand for application-specific columns with optimized durability profiles for challenging sample types, subscription-based column replacement programs that guarantee minimum lifetime performance, and increased interest in predictive maintenance solutions that can forecast column failure before performance degradation impacts analytical results.

Market research indicates that laboratories typically spend between 15-20% of their analytical budgets on column replacement, representing a significant operational expense. A survey of 500 analytical laboratories revealed that 78% of respondents identified column lifetime as a "very important" or "critical" factor in purchasing decisions, ranking it above initial acquisition cost.

The pharmaceutical sector constitutes the largest market segment, accounting for approximately 45% of HPLC column demand. Within this segment, quality control applications generate the highest replacement frequency due to high sample throughput and diverse sample matrices. Academic and research institutions, while price-sensitive, increasingly prioritize column durability to maximize research budgets and ensure experimental reproducibility.

Geographically, North America leads the market with 38% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region demonstrates the fastest growth rate at 7.2% annually, driven by expanding pharmaceutical manufacturing and contract research operations in China and India.

Market analysis reveals a clear price premium for columns with demonstrated longevity advantages. Columns marketed specifically for extended lifetime command 15-30% higher prices than standard offerings, yet market data suggests these premium products maintain strong sales growth, indicating favorable return-on-investment calculations by end-users.

Customer satisfaction surveys highlight that laboratories are willing to invest in preventive maintenance practices and higher-quality columns when vendors can demonstrate tangible lifetime improvements. The average laboratory reports that doubling column lifetime would justify a 40-60% price premium, creating significant market opportunities for manufacturers who can deliver verifiable durability enhancements.

Emerging market trends include growing demand for application-specific columns with optimized durability profiles for challenging sample types, subscription-based column replacement programs that guarantee minimum lifetime performance, and increased interest in predictive maintenance solutions that can forecast column failure before performance degradation impacts analytical results.

Current Challenges in HPLC Column Longevity

Despite significant advancements in HPLC technology, column longevity remains a persistent challenge for analytical laboratories. Current HPLC columns face several critical issues that limit their operational lifespan, increasing costs and reducing analytical efficiency. The primary challenge stems from chemical degradation of stationary phases, particularly in reversed-phase columns where silica-based materials are susceptible to hydrolysis at extreme pH conditions. This degradation accelerates at pH values below 2 or above 8, causing irreversible damage to the column structure.

Physical degradation represents another significant challenge, manifesting as bed collapse, void formation, and channeling within the column. These issues typically result from pressure fluctuations, improper handling, or operation beyond recommended pressure limits. Modern UHPLC systems, while offering enhanced resolution, exacerbate this problem by subjecting columns to extreme pressures that accelerate mechanical wear.

Contamination from sample matrices presents a growing concern, especially as HPLC applications expand into complex biological samples, environmental specimens, and pharmaceutical formulations. Proteins, lipids, and particulate matter can irreversibly bind to stationary phases, gradually reducing column efficiency and increasing backpressure. Current filtration and guard column technologies provide only partial protection against these contaminants.

Temperature fluctuations pose another significant challenge to column stability. Inconsistent temperature control during analysis can lead to retention time shifts and accelerated stationary phase degradation. Many laboratories lack precise temperature control systems, particularly for columns operating at or near ambient conditions, leading to seasonal variations in column performance and lifetime.

Mobile phase-related issues further complicate column longevity. Buffer precipitation, microbial growth in aqueous mobile phases, and oxidation of stationary phases by dissolved oxygen all contribute to premature column failure. The increasing use of MS-compatible mobile phases, which often lack traditional stabilizers, has inadvertently created new challenges for column stability.

Manufacturing inconsistencies between column batches represent a persistent industry-wide challenge. Variations in silica substrate quality, bonding chemistry efficiency, and end-capping procedures result in unpredictable column lifetimes even within the same product line. This inconsistency complicates method transfer and validation processes in regulated environments.

The emergence of new column technologies, such as core-shell particles and monolithic columns, has introduced unique stability challenges distinct from traditional fully porous particle columns. These materials often exhibit different degradation mechanisms and require specialized handling protocols that are not yet widely understood or implemented in analytical laboratories.

Physical degradation represents another significant challenge, manifesting as bed collapse, void formation, and channeling within the column. These issues typically result from pressure fluctuations, improper handling, or operation beyond recommended pressure limits. Modern UHPLC systems, while offering enhanced resolution, exacerbate this problem by subjecting columns to extreme pressures that accelerate mechanical wear.

Contamination from sample matrices presents a growing concern, especially as HPLC applications expand into complex biological samples, environmental specimens, and pharmaceutical formulations. Proteins, lipids, and particulate matter can irreversibly bind to stationary phases, gradually reducing column efficiency and increasing backpressure. Current filtration and guard column technologies provide only partial protection against these contaminants.

Temperature fluctuations pose another significant challenge to column stability. Inconsistent temperature control during analysis can lead to retention time shifts and accelerated stationary phase degradation. Many laboratories lack precise temperature control systems, particularly for columns operating at or near ambient conditions, leading to seasonal variations in column performance and lifetime.

Mobile phase-related issues further complicate column longevity. Buffer precipitation, microbial growth in aqueous mobile phases, and oxidation of stationary phases by dissolved oxygen all contribute to premature column failure. The increasing use of MS-compatible mobile phases, which often lack traditional stabilizers, has inadvertently created new challenges for column stability.

Manufacturing inconsistencies between column batches represent a persistent industry-wide challenge. Variations in silica substrate quality, bonding chemistry efficiency, and end-capping procedures result in unpredictable column lifetimes even within the same product line. This inconsistency complicates method transfer and validation processes in regulated environments.

The emergence of new column technologies, such as core-shell particles and monolithic columns, has introduced unique stability challenges distinct from traditional fully porous particle columns. These materials often exhibit different degradation mechanisms and require specialized handling protocols that are not yet widely understood or implemented in analytical laboratories.

Best Practices for HPLC Column Maintenance

01 Column protection and maintenance techniques

Various techniques can be employed to protect and maintain HPLC columns, thereby extending their lifetime. These include using guard columns to prevent contaminants from reaching the main column, regular cleaning procedures to remove accumulated impurities, proper storage conditions when not in use, and controlled operating parameters such as flow rate and pressure. Implementing these maintenance practices can significantly increase column longevity and maintain separation efficiency over time.- Column protection and maintenance techniques: Various techniques can be employed to protect and maintain HPLC columns, thereby extending their lifetime. These include using guard columns to prevent contaminants from reaching the main column, regular cleaning procedures to remove accumulated impurities, proper storage conditions when not in use, and controlled operational parameters such as flow rate and pressure. Implementing these maintenance practices can significantly increase column longevity and maintain separation efficiency over time.

- Mobile phase composition and optimization: The composition of the mobile phase significantly impacts HPLC column lifetime. Optimizing pH levels, buffer concentration, organic solvent ratios, and ionic strength can minimize column degradation. Avoiding extreme pH conditions that can damage stationary phases and using high-purity solvents free from particulates are essential practices. Proper degassing of mobile phases also prevents air bubble formation that can disrupt flow and damage column packing materials.

- Sample preparation and injection techniques: Proper sample preparation is crucial for extending HPLC column lifetime. This includes filtration to remove particulates, appropriate dilution to prevent column overloading, and selection of compatible solvents for sample dissolution. Advanced injection techniques that minimize sample exposure to the stationary phase and reduce peak broadening can also contribute to column longevity. Implementing these practices helps prevent irreversible adsorption of contaminants to the column packing material.

- Column packing materials and manufacturing innovations: Advancements in column packing materials have led to increased HPLC column durability. Modern stationary phases with improved chemical stability, mechanical strength, and resistance to extreme pH conditions contribute to extended column lifetime. Innovations in bonding technologies, end-capping procedures, and particle design have resulted in columns that can withstand rigorous operating conditions while maintaining separation efficiency. These developments include hybrid organic-inorganic materials and monolithic columns with enhanced stability characteristics.

- Monitoring and predictive maintenance systems: Implementing monitoring systems and predictive maintenance approaches can significantly extend HPLC column lifetime. These include tracking column performance parameters such as back pressure, peak symmetry, and resolution to detect early signs of degradation. Advanced analytical software can predict column failure before critical performance loss occurs, allowing for timely intervention. Some systems incorporate machine learning algorithms to optimize maintenance schedules based on usage patterns and performance metrics.

02 Mobile phase optimization for column longevity

The composition and quality of mobile phases significantly impact HPLC column lifetime. Using high-purity solvents, proper pH buffers, and appropriate organic modifiers can prevent column degradation. Filtration of mobile phases to remove particulates, degassing to prevent air bubble formation, and gradual transitions between different mobile phase compositions help maintain column integrity. Optimizing these factors reduces chemical stress on the stationary phase and extends column usability.Expand Specific Solutions03 Advanced column materials and manufacturing

Innovations in column materials and manufacturing processes have led to more durable HPLC columns. These include improved silica-based materials with enhanced pH stability, polymer-based stationary phases resistant to chemical degradation, hybrid organic-inorganic materials combining the advantages of both, and monolithic columns with improved mechanical stability. These advanced materials can withstand harsh conditions, high pressures, and extended use cycles, significantly extending column lifetime.Expand Specific Solutions04 Sample preparation techniques to extend column life

Proper sample preparation is crucial for extending HPLC column lifetime. Techniques such as filtration to remove particulates, protein precipitation to prevent column fouling, solid-phase extraction to eliminate matrix interferences, and dilution of highly concentrated samples help protect the column. These preparation methods prevent contaminants from accumulating on the column, reducing the need for aggressive cleaning procedures that can shorten column life.Expand Specific Solutions05 Monitoring and predictive maintenance systems

Advanced monitoring systems and predictive maintenance approaches can help extend HPLC column lifetime. These include pressure monitoring to detect column blockages, retention time tracking to identify performance degradation, automated system suitability tests to verify column condition, and software-based predictive maintenance algorithms. By identifying early signs of column deterioration, corrective actions can be taken before complete failure occurs, maximizing column lifespan and ensuring consistent analytical results.Expand Specific Solutions

Leading Manufacturers and Research Institutions in HPLC

The HPLC column lifetime improvement market is in a mature growth phase, with an estimated global value exceeding $1 billion. The competitive landscape is dominated by established analytical instrumentation leaders including Agilent Technologies, Waters Technology Corp., and Hitachi High-Tech America, who have developed comprehensive column protection solutions. Technical maturity is high, with companies like Merck Patent GmbH and Cytiva offering advanced column protection technologies, guard columns, and specialized filtration systems. Pharmaceutical giants such as F. Hoffmann-La Roche and smaller specialized players like IDEX Health & Science contribute innovative approaches to extend column life through improved sample preparation and mobile phase optimization. Academic institutions including Xiamen University and University College Cork provide research support advancing fundamental understanding of column degradation mechanisms.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed a comprehensive approach to HPLC column lifetime extension through their InfinityLab column technology. Their solution incorporates advanced end-fitting designs that minimize dead volume and reduce peak dispersion, alongside proprietary packing techniques that ensure bed stability even under high pressure conditions. Agilent's columns feature ultra-high purity silica with minimal metal contamination, reducing catalytic activity that can lead to stationary phase degradation. Their A-Line Quick Connect fittings technology eliminates improper connections, a common cause of column damage. Additionally, Agilent has implemented intelligent column identification technology with embedded RFID tags that track usage history, injection counts, and maximum pressure exposure, allowing proactive maintenance before performance deteriorates. Their columns also incorporate advanced bonding chemistry that creates hydrolytically stable phases, particularly important for analyses at extreme pH conditions.

Strengths: Superior hardware engineering with zero-dead-volume connections and proprietary packing techniques that maintain bed stability under pressure fluctuations. Their integrated column tracking system provides usage analytics for preventive maintenance. Weaknesses: Premium pricing structure makes their solutions less accessible for budget-constrained laboratories, and some of their advanced features require compatible Agilent instrumentation to realize full benefits.

Waters Technology Corp.

Technical Solution: Waters Technology has pioneered the XBridge and ACQUITY column technologies specifically designed for extended column lifetime. Their approach centers on hybrid particle technology that combines the mechanical strength of polymers with the separation efficiency of silica. This proprietary Ethylene-Bridged Hybrid (BEH) particle technology creates pH-resistant particles (pH 1-12) that significantly outlast conventional silica columns in harsh mobile phase conditions. Waters' columns incorporate their patented High Strength Silica (HSS) technology, which maintains structural integrity under ultra-high pressures (up to 15,000 psi), preventing bed collapse that typically shortens column life. Their TruView LC Column Technology includes end-fitting designs that distribute sample across the entire column diameter, preventing channeling and uneven bed wear. Waters also developed Intelligent Column Management with electronic chips that store column history, method parameters, and performance data, enabling consistent method transfer and preventing column misuse.

Strengths: Industry-leading pH stability range (1-12) through hybrid particle technology allows use of aggressive mobile phases without column degradation. Their columns demonstrate exceptional mechanical stability under UHPLC conditions, maintaining performance after thousands of injections. Weaknesses: Higher initial investment compared to standard columns, and optimal performance requires adherence to Waters' recommended operating parameters which may require workflow adjustments for labs transitioning from other systems.

Key Innovations in Column Protection Technology

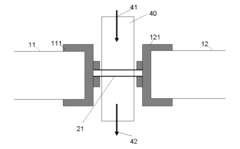

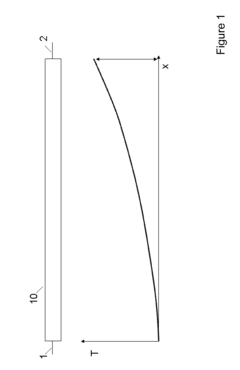

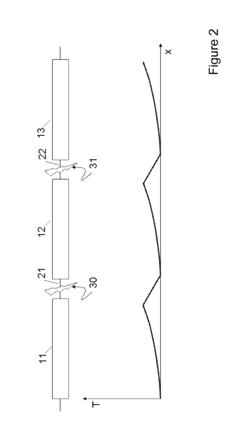

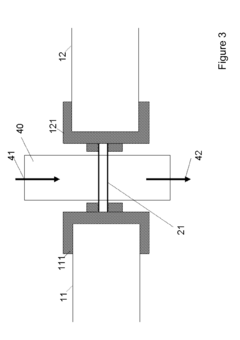

Method for improving the efficiency of high-pressure liquid chromatography

PatentInactiveUS20120011921A1

Innovation

- Dividing the HPLC column into shorter separation segments with actively cooled cooling segments in between, where the fluid flow is cooled to remove viscous friction heat efficiently, maintaining separation efficiency without significant band broadening.

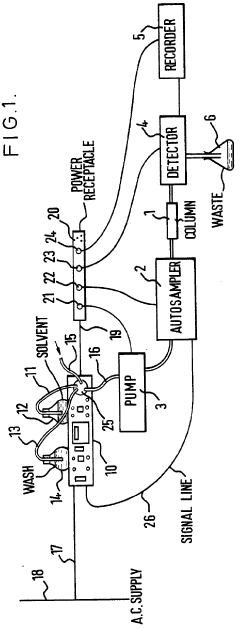

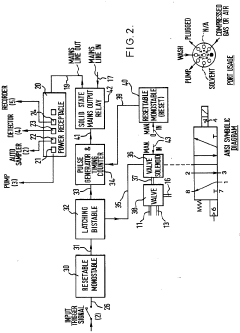

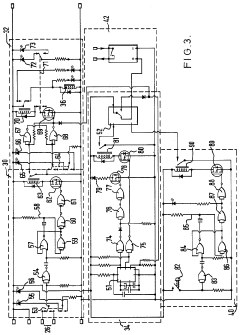

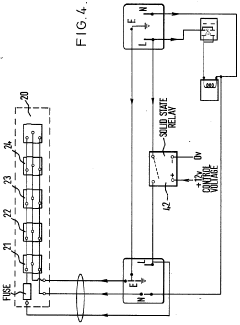

Improvements in or relating to high performance liquid chromatography systems

PatentInactiveGB2174016A

Innovation

- An ancillary apparatus that includes a valve system for selecting between mobile phase and wash liquid sources, a timing mechanism initiated by a trigger pulse from the HPLC system, and an electric switch to disconnect power to the HPLC system units after a predetermined wash liquid supply, ensuring a controlled shutdown and washout process.

Cost-Benefit Analysis of Column Lifetime Extension Methods

Extending the lifetime of HPLC columns represents a significant economic consideration for laboratories conducting routine analyses. When evaluating various column lifetime extension methods, a comprehensive cost-benefit analysis reveals compelling financial advantages that justify the implementation of proper maintenance protocols.

Initial investment in preventive measures typically requires additional expenditure on guard columns, inline filters, and proper sample preparation equipment. These preventive hardware solutions range from $200-800 in upfront costs but can extend column life by 2-4 times, resulting in a positive return on investment within 3-6 months for high-throughput laboratories.

Regular maintenance procedures such as proper flushing and storage protocols require minimal additional materials (approximately $50-100 annually) but demand analyst time (estimated at 1-2 hours weekly). The labor cost must be weighed against the average 30-50% increase in column longevity, which translates to savings of $1,000-3,000 annually for laboratories running multiple analyses daily.

Advanced sample preparation techniques represent a more substantial investment, with automated systems costing $5,000-15,000. However, these systems not only extend column life by eliminating damaging contaminants but also improve overall analytical precision and reduce operator variability. The dual benefit creates a complex but favorable cost-benefit ratio, with typical payback periods of 12-24 months depending on analysis volume.

Mobile phase optimization and proper pH selection incur minimal additional costs while potentially doubling column lifetime. This represents perhaps the highest return on investment among all methods, requiring only analyst knowledge rather than significant financial outlay.

Temperature control systems ($1,500-4,000) demonstrate variable returns depending on application, with greatest benefits observed in analyses involving thermally sensitive compounds or matrices. For these applications, the extended column life combined with improved chromatographic performance justifies the investment with typical payback periods of 8-12 months.

When comparing replacement versus maintenance costs, laboratories running 20+ samples daily typically save $3,000-8,000 annually through comprehensive column care protocols. Even accounting for the time investment in maintenance procedures, the net financial benefit remains strongly positive, with ROI calculations showing 200-400% returns on maintenance investments over a two-year period.

For specialized columns with higher acquisition costs ($1,000+), the financial case for lifetime extension becomes even more compelling, with potential savings exceeding $10,000 annually for multi-instrument laboratories implementing comprehensive column care strategies.

Initial investment in preventive measures typically requires additional expenditure on guard columns, inline filters, and proper sample preparation equipment. These preventive hardware solutions range from $200-800 in upfront costs but can extend column life by 2-4 times, resulting in a positive return on investment within 3-6 months for high-throughput laboratories.

Regular maintenance procedures such as proper flushing and storage protocols require minimal additional materials (approximately $50-100 annually) but demand analyst time (estimated at 1-2 hours weekly). The labor cost must be weighed against the average 30-50% increase in column longevity, which translates to savings of $1,000-3,000 annually for laboratories running multiple analyses daily.

Advanced sample preparation techniques represent a more substantial investment, with automated systems costing $5,000-15,000. However, these systems not only extend column life by eliminating damaging contaminants but also improve overall analytical precision and reduce operator variability. The dual benefit creates a complex but favorable cost-benefit ratio, with typical payback periods of 12-24 months depending on analysis volume.

Mobile phase optimization and proper pH selection incur minimal additional costs while potentially doubling column lifetime. This represents perhaps the highest return on investment among all methods, requiring only analyst knowledge rather than significant financial outlay.

Temperature control systems ($1,500-4,000) demonstrate variable returns depending on application, with greatest benefits observed in analyses involving thermally sensitive compounds or matrices. For these applications, the extended column life combined with improved chromatographic performance justifies the investment with typical payback periods of 8-12 months.

When comparing replacement versus maintenance costs, laboratories running 20+ samples daily typically save $3,000-8,000 annually through comprehensive column care protocols. Even accounting for the time investment in maintenance procedures, the net financial benefit remains strongly positive, with ROI calculations showing 200-400% returns on maintenance investments over a two-year period.

For specialized columns with higher acquisition costs ($1,000+), the financial case for lifetime extension becomes even more compelling, with potential savings exceeding $10,000 annually for multi-instrument laboratories implementing comprehensive column care strategies.

Environmental Impact of HPLC Column Disposal and Recycling

The environmental implications of HPLC column disposal represent a growing concern in analytical laboratories worldwide. Traditional disposal methods often involve treating used columns as hazardous waste due to residual solvents and analytes, contributing significantly to laboratory waste streams. These columns typically contain silica-based or polymer-based materials that do not readily degrade in landfills, while their metal components (stainless steel housings) persist for decades or longer in the environment.

Recent studies indicate that a standard analytical laboratory may dispose of 20-50 HPLC columns annually, creating substantial cumulative environmental impact across the industry. The silica particles and bonded phases may contain potentially harmful substances that can leach into groundwater when improperly disposed of, while the manufacturing process itself carries a considerable carbon footprint.

Column recycling programs have emerged as a sustainable alternative, with several major manufacturers now offering take-back services. These programs typically involve collecting used columns, disassembling them, and recovering valuable materials such as stainless steel housings and frits. The recovery rate for metal components can exceed 95%, significantly reducing the need for virgin materials in new column production.

Advanced recycling technologies have been developed to address the challenges of separating and processing the various column components. Thermal treatment processes can safely eliminate residual organic compounds, while specialized mechanical separation techniques enable efficient recovery of different materials. Some innovative approaches even focus on reconditioning column packings through washing and chemical treatments.

The economic benefits of recycling programs are increasingly compelling. Analysis shows that recycling HPLC columns can reduce disposal costs by 30-40% compared to hazardous waste handling, while manufacturers benefit from reduced raw material costs. Several leading analytical laboratories have reported annual savings of $5,000-$10,000 through participation in column recycling initiatives.

Life cycle assessment (LCA) studies demonstrate that recycling HPLC columns can reduce their overall environmental impact by 40-60% compared to conventional disposal methods. This includes significant reductions in greenhouse gas emissions, energy consumption, and resource depletion. The environmental benefits are particularly pronounced when considering the cumulative impact across thousands of laboratories worldwide.

Regulatory frameworks are evolving to encourage more sustainable practices in laboratory waste management. In Europe, the Waste Electrical and Electronic Equipment (WEEE) directive increasingly influences how analytical instruments and components are handled at end-of-life, while similar regulations are emerging in North America and Asia. Forward-thinking laboratories are proactively adopting recycling practices to align with these evolving requirements.

Recent studies indicate that a standard analytical laboratory may dispose of 20-50 HPLC columns annually, creating substantial cumulative environmental impact across the industry. The silica particles and bonded phases may contain potentially harmful substances that can leach into groundwater when improperly disposed of, while the manufacturing process itself carries a considerable carbon footprint.

Column recycling programs have emerged as a sustainable alternative, with several major manufacturers now offering take-back services. These programs typically involve collecting used columns, disassembling them, and recovering valuable materials such as stainless steel housings and frits. The recovery rate for metal components can exceed 95%, significantly reducing the need for virgin materials in new column production.

Advanced recycling technologies have been developed to address the challenges of separating and processing the various column components. Thermal treatment processes can safely eliminate residual organic compounds, while specialized mechanical separation techniques enable efficient recovery of different materials. Some innovative approaches even focus on reconditioning column packings through washing and chemical treatments.

The economic benefits of recycling programs are increasingly compelling. Analysis shows that recycling HPLC columns can reduce disposal costs by 30-40% compared to hazardous waste handling, while manufacturers benefit from reduced raw material costs. Several leading analytical laboratories have reported annual savings of $5,000-$10,000 through participation in column recycling initiatives.

Life cycle assessment (LCA) studies demonstrate that recycling HPLC columns can reduce their overall environmental impact by 40-60% compared to conventional disposal methods. This includes significant reductions in greenhouse gas emissions, energy consumption, and resource depletion. The environmental benefits are particularly pronounced when considering the cumulative impact across thousands of laboratories worldwide.

Regulatory frameworks are evolving to encourage more sustainable practices in laboratory waste management. In Europe, the Waste Electrical and Electronic Equipment (WEEE) directive increasingly influences how analytical instruments and components are handled at end-of-life, while similar regulations are emerging in North America and Asia. Forward-thinking laboratories are proactively adopting recycling practices to align with these evolving requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!