HPLC Column Packing Material: Compare Silica vs Polymer

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HPLC Column Materials Evolution and Objectives

High-performance liquid chromatography (HPLC) has evolved significantly since its inception in the late 1960s, with column packing materials playing a pivotal role in this evolution. The journey began with large particle silica materials (40-50 μm), progressing through various generations to today's sub-2 μm particles and monolithic structures. This technological progression has consistently aimed to enhance separation efficiency, resolution, and analytical speed.

The development of silica-based materials represents a cornerstone in HPLC evolution. Early limitations of irregular silica particles gave way to spherical particles with controlled porosity in the 1970s. The 1980s witnessed the emergence of bonded phases, where silica surfaces were modified with various functional groups to control selectivity. By the 1990s, high-purity silica with reduced metal content addressed issues of peak tailing for basic compounds.

Parallel to silica development, polymer-based materials emerged as an alternative path. Initially introduced to overcome the pH limitations of silica, polymeric packings based on polystyrene-divinylbenzene (PS-DVB) and other polymers offered extended pH stability but suffered from lower efficiency. Recent decades have seen significant improvements in polymer technology, with cross-linked polymers and hybrid materials bridging the performance gap with silica.

The objectives of modern HPLC column material development focus on several key areas. First is the pursuit of higher efficiency through smaller particles, more uniform particle size distribution, and optimized pore structures. Second is enhanced selectivity through novel surface chemistries and mixed-mode functionalities. Third is improved robustness, with materials capable of withstanding extreme pH conditions, high temperatures, and high pressures to support increasingly demanding applications.

Another critical objective is the development of environmentally sustainable materials that reduce solvent consumption and enable greener chromatography practices. This includes materials compatible with aqueous mobile phases and those requiring lower backpressure, thus reducing energy requirements.

The evolution continues toward "smart" materials with stimuli-responsive properties, allowing dynamic control of selectivity during separation. Additionally, materials specifically designed for challenging biomolecule separations represent a frontier in HPLC column development, addressing the growing needs in biopharmaceutical analysis and proteomics research.

Understanding this technological trajectory provides crucial context for comparing silica and polymer-based materials, as both continue to evolve along parallel paths with distinct advantages in specific application domains.

The development of silica-based materials represents a cornerstone in HPLC evolution. Early limitations of irregular silica particles gave way to spherical particles with controlled porosity in the 1970s. The 1980s witnessed the emergence of bonded phases, where silica surfaces were modified with various functional groups to control selectivity. By the 1990s, high-purity silica with reduced metal content addressed issues of peak tailing for basic compounds.

Parallel to silica development, polymer-based materials emerged as an alternative path. Initially introduced to overcome the pH limitations of silica, polymeric packings based on polystyrene-divinylbenzene (PS-DVB) and other polymers offered extended pH stability but suffered from lower efficiency. Recent decades have seen significant improvements in polymer technology, with cross-linked polymers and hybrid materials bridging the performance gap with silica.

The objectives of modern HPLC column material development focus on several key areas. First is the pursuit of higher efficiency through smaller particles, more uniform particle size distribution, and optimized pore structures. Second is enhanced selectivity through novel surface chemistries and mixed-mode functionalities. Third is improved robustness, with materials capable of withstanding extreme pH conditions, high temperatures, and high pressures to support increasingly demanding applications.

Another critical objective is the development of environmentally sustainable materials that reduce solvent consumption and enable greener chromatography practices. This includes materials compatible with aqueous mobile phases and those requiring lower backpressure, thus reducing energy requirements.

The evolution continues toward "smart" materials with stimuli-responsive properties, allowing dynamic control of selectivity during separation. Additionally, materials specifically designed for challenging biomolecule separations represent a frontier in HPLC column development, addressing the growing needs in biopharmaceutical analysis and proteomics research.

Understanding this technological trajectory provides crucial context for comparing silica and polymer-based materials, as both continue to evolve along parallel paths with distinct advantages in specific application domains.

Market Analysis of HPLC Column Technologies

The global HPLC column market continues to experience robust growth, valued at approximately $2.5 billion in 2022 with projections to reach $3.8 billion by 2028, representing a compound annual growth rate (CAGR) of 7.2%. This growth is primarily driven by increasing applications in pharmaceutical research, biotechnology, food safety testing, and environmental analysis. The pharmaceutical and biopharmaceutical sectors remain the largest consumers, accounting for over 60% of the total market share.

Within this expanding market, silica-based columns currently dominate with approximately 75% market share, while polymer-based columns hold roughly 20%, with the remaining 5% distributed among other materials. However, polymer-based columns are growing at a faster rate (9.5% CAGR) compared to silica-based columns (6.3% CAGR), indicating a gradual shift in market preferences.

Regional analysis reveals North America as the leading market with 38% share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (7%). The Asia-Pacific region, particularly China and India, demonstrates the highest growth rate at 10.2% annually, driven by expanding pharmaceutical manufacturing capabilities and increasing research activities.

Key market trends include growing demand for ultra-high-performance liquid chromatography (UHPLC) columns, which offer faster analysis times and higher resolution. This segment is growing at 12% annually, outpacing traditional HPLC columns. Additionally, there is increasing interest in specialized columns for biomolecule analysis, reflecting the growing importance of biopharmaceuticals.

The competitive landscape features both established players and innovative startups. Major companies like Waters Corporation, Agilent Technologies, and Thermo Fisher Scientific collectively control approximately 65% of the market. These companies offer comprehensive portfolios of both silica and polymer-based columns. Meanwhile, specialized manufacturers like Phenomenex and YMC are gaining market share through innovation in hybrid materials and application-specific columns.

Customer segmentation reveals distinct preferences: academic and research institutions typically prioritize cost-effectiveness, pharmaceutical quality control laboratories demand reproducibility and longevity, while discovery research teams value selectivity and specialized separations. This segmentation has led to increasingly tailored product offerings from manufacturers, with specialized columns for specific applications commanding premium prices up to 40% higher than general-purpose columns.

Within this expanding market, silica-based columns currently dominate with approximately 75% market share, while polymer-based columns hold roughly 20%, with the remaining 5% distributed among other materials. However, polymer-based columns are growing at a faster rate (9.5% CAGR) compared to silica-based columns (6.3% CAGR), indicating a gradual shift in market preferences.

Regional analysis reveals North America as the leading market with 38% share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (7%). The Asia-Pacific region, particularly China and India, demonstrates the highest growth rate at 10.2% annually, driven by expanding pharmaceutical manufacturing capabilities and increasing research activities.

Key market trends include growing demand for ultra-high-performance liquid chromatography (UHPLC) columns, which offer faster analysis times and higher resolution. This segment is growing at 12% annually, outpacing traditional HPLC columns. Additionally, there is increasing interest in specialized columns for biomolecule analysis, reflecting the growing importance of biopharmaceuticals.

The competitive landscape features both established players and innovative startups. Major companies like Waters Corporation, Agilent Technologies, and Thermo Fisher Scientific collectively control approximately 65% of the market. These companies offer comprehensive portfolios of both silica and polymer-based columns. Meanwhile, specialized manufacturers like Phenomenex and YMC are gaining market share through innovation in hybrid materials and application-specific columns.

Customer segmentation reveals distinct preferences: academic and research institutions typically prioritize cost-effectiveness, pharmaceutical quality control laboratories demand reproducibility and longevity, while discovery research teams value selectivity and specialized separations. This segmentation has led to increasingly tailored product offerings from manufacturers, with specialized columns for specific applications commanding premium prices up to 40% higher than general-purpose columns.

Silica vs Polymer Matrices: Current Status and Challenges

The current landscape of HPLC column packing materials presents a dichotomy between silica-based and polymer-based matrices, each with distinct advantages and limitations. Silica-based materials continue to dominate the market, accounting for approximately 70% of commercial HPLC columns due to their excellent mechanical stability, high efficiency, and reproducible manufacturing processes. These materials typically offer pressure tolerance up to 600 bar in standard applications and can reach 1200 bar in ultra-high-performance systems. However, silica matrices face significant limitations in pH stability, generally restricted to pH ranges of 2-8, with specialized end-capped silica extending only slightly to pH 1.5-10.

Polymer-based matrices have emerged as viable alternatives, particularly in applications requiring extreme pH conditions. These materials demonstrate remarkable chemical stability across the entire pH range (0-14), addressing a critical limitation of silica-based columns. Recent advancements in polymer cross-linking technology have significantly improved the mechanical stability of these materials, though they still generally underperform compared to silica in terms of pressure tolerance, typically limited to 200-350 bar.

A significant challenge for silica-based materials remains the presence of residual silanol groups that can cause peak tailing for basic compounds, despite advances in end-capping technologies. Conversely, polymer-based materials struggle with lower efficiency due to slower mass transfer kinetics and reduced plate counts compared to silica counterparts. This efficiency gap becomes particularly pronounced when separating small molecules, though polymers often excel with larger biomolecules.

Manufacturing consistency presents another contrast between these materials. Silica production benefits from decades of refinement, resulting in highly reproducible batches with consistent particle size distribution and pore architecture. Polymer-based materials face greater batch-to-batch variability, presenting challenges for method transfer and validation in regulated environments.

Recent technological developments have focused on hybrid materials that combine silica cores with polymer coatings or organic-inorganic hybrid structures. These innovations aim to leverage the mechanical strength of silica while incorporating the chemical stability of polymers. Similarly, monolithic columns based on both silica and polymer matrices represent an emerging trend, offering reduced backpressure and improved mass transfer for high-speed separations.

The geographical distribution of technology development shows concentration in North America, Europe, and Japan for advanced silica technologies, while polymer innovation clusters in Europe and emerging Asian markets. This regional specialization reflects different approaches to addressing the fundamental challenges in HPLC column technology.

Polymer-based matrices have emerged as viable alternatives, particularly in applications requiring extreme pH conditions. These materials demonstrate remarkable chemical stability across the entire pH range (0-14), addressing a critical limitation of silica-based columns. Recent advancements in polymer cross-linking technology have significantly improved the mechanical stability of these materials, though they still generally underperform compared to silica in terms of pressure tolerance, typically limited to 200-350 bar.

A significant challenge for silica-based materials remains the presence of residual silanol groups that can cause peak tailing for basic compounds, despite advances in end-capping technologies. Conversely, polymer-based materials struggle with lower efficiency due to slower mass transfer kinetics and reduced plate counts compared to silica counterparts. This efficiency gap becomes particularly pronounced when separating small molecules, though polymers often excel with larger biomolecules.

Manufacturing consistency presents another contrast between these materials. Silica production benefits from decades of refinement, resulting in highly reproducible batches with consistent particle size distribution and pore architecture. Polymer-based materials face greater batch-to-batch variability, presenting challenges for method transfer and validation in regulated environments.

Recent technological developments have focused on hybrid materials that combine silica cores with polymer coatings or organic-inorganic hybrid structures. These innovations aim to leverage the mechanical strength of silica while incorporating the chemical stability of polymers. Similarly, monolithic columns based on both silica and polymer matrices represent an emerging trend, offering reduced backpressure and improved mass transfer for high-speed separations.

The geographical distribution of technology development shows concentration in North America, Europe, and Japan for advanced silica technologies, while polymer innovation clusters in Europe and emerging Asian markets. This regional specialization reflects different approaches to addressing the fundamental challenges in HPLC column technology.

Contemporary Silica and Polymer-Based Column Solutions

01 Silica-based HPLC column packing materials

Silica-based materials are widely used as HPLC column packing due to their mechanical stability and high surface area. These materials can be modified with various functional groups to achieve different separation mechanisms. Silica particles can be synthesized with controlled pore size and particle diameter to optimize chromatographic performance. Surface modifications include bonding with C18, C8, phenyl, or amino groups to create reversed-phase, normal-phase, or ion-exchange columns.- Silica-based HPLC column packing materials: Silica-based materials are widely used as HPLC column packing due to their mechanical stability and high surface area. These materials can be modified with various functional groups to achieve different separation mechanisms. Silica particles can be synthesized with controlled pore size and particle diameter to optimize chromatographic performance. Surface modifications include bonding with C18, C8, phenyl, or amino groups to create reversed-phase, normal-phase, or ion-exchange columns.

- Polymer-based HPLC column packing materials: Polymer-based packing materials offer advantages such as wider pH stability compared to silica. These materials include polystyrene-divinylbenzene copolymers, polymethacrylates, and other synthetic polymers. Polymer-based columns are particularly useful for separations requiring extreme pH conditions or when sample components might interact unfavorably with silica. These materials can be functionalized with various groups to achieve different selectivity profiles for specific analytical applications.

- Hybrid silica-polymer HPLC packing materials: Hybrid materials combining silica and organic polymers offer improved performance characteristics over traditional silica or polymer packings. These materials typically incorporate organic bridges within the silica structure or coat silica particles with polymer layers. The hybrid approach provides enhanced pH stability, reduced peak tailing, and improved mechanical strength. These materials can withstand higher pressures and offer unique selectivity for challenging separations in pharmaceutical, environmental, and biological analyses.

- Surface modification techniques for HPLC packing materials: Various surface modification techniques are employed to enhance the performance of HPLC column packing materials. These include end-capping of residual silanol groups, bonding of specialized ligands, and surface coating with polymeric layers. Modified surfaces can provide improved peak shape, reduced tailing, enhanced selectivity, and better column longevity. Techniques such as hydrophilic interaction liquid chromatography (HILIC) rely on specific surface modifications to achieve unique separation mechanisms for polar compounds.

- Novel and specialized HPLC packing materials: Novel HPLC packing materials include monolithic columns, core-shell particles, and materials with specialized functionalities. Monolithic columns feature a continuous bed structure rather than discrete particles. Core-shell particles have a solid core with a porous outer layer, offering improved efficiency. Specialized materials include chiral stationary phases for enantiomer separation, affinity chromatography media for biomolecule purification, and materials designed for specific applications such as size exclusion chromatography or ion chromatography.

02 Polymer-based HPLC column packing materials

Polymer-based packing materials offer advantages such as wider pH stability compared to silica. These materials include polystyrene-divinylbenzene copolymers, polymethacrylates, and other organic polymers that can withstand extreme pH conditions. Polymer-based columns are particularly useful for biomolecule separations and applications requiring high pH stability. The polymeric structure can be modified with various functional groups to achieve different separation selectivities.Expand Specific Solutions03 Hybrid silica-polymer HPLC packing materials

Hybrid materials combine the advantages of both silica and polymeric materials. These materials typically consist of silica particles with organic groups incorporated into the silica matrix or polymeric layers grafted onto silica surfaces. Hybrid materials offer improved pH stability compared to pure silica while maintaining good mechanical strength. They can be further modified with various functional groups to achieve specific separation selectivities.Expand Specific Solutions04 Surface modification techniques for HPLC packing materials

Various surface modification techniques are employed to functionalize silica and polymer packing materials. These include end-capping to reduce unwanted interactions with residual silanol groups, bonding with specific ligands to achieve desired selectivity, and hydrophilic surface coatings to improve compatibility with aqueous mobile phases. Surface modifications can significantly impact column performance characteristics such as selectivity, efficiency, and peak symmetry.Expand Specific Solutions05 Specialized HPLC packing materials for specific applications

Specialized packing materials are designed for specific analytical challenges. These include chiral stationary phases for enantiomer separation, affinity chromatography materials for biomolecule purification, and mixed-mode materials combining multiple separation mechanisms. Other specialized materials include monolithic columns with continuous bed structure, core-shell particles with solid core and porous shell, and materials designed for high-temperature or high-pressure applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in HPLC Technology

The HPLC column packing material market is in a mature growth phase with an estimated global market size of $1.5-2 billion annually, showing steady 5-7% growth. The competition between silica and polymer-based materials reflects evolving industry needs, with silica dominating approximately 70% of applications due to its established performance and cost-effectiveness. Leading players like Waters Technology, Agilent Technologies, and Dionex (Thermo Fisher) control significant market share through extensive product portfolios. Regional competitors such as Tianjin Bonna-Agela, Welch Materials, and GL Sciences are gaining traction through specialized offerings. Academic institutions including Beijing University of Chemical Technology and Dalian Institute of Chemical Physics contribute to technological advancement, particularly in polymer-based materials which offer improved pH stability and biocompatibility for specialized applications.

Waters Technology Corp.

Technical Solution: Waters Technology has developed proprietary BEH (Bridged Ethyl Hybrid) silica particle technology that combines the mechanical strength of polymers with the efficiency of silica. Their ACQUITY UPLC columns utilize sub-2μm particles with hybrid organic-inorganic structure, providing enhanced pH stability (pH 1-12) compared to conventional silica (pH 2-8). Waters' XBridge and XSelect columns feature their patented trifunctional bonding chemistry that reduces silanol activity while maintaining high efficiency. For polymer-based materials, Waters offers OASIS HLB (Hydrophilic-Lipophilic Balance) technology that combines N-vinylpyrrolidone and divinylbenzene polymers to achieve both hydrophilic and lipophilic retention characteristics, enabling superior separation of polar and non-polar compounds simultaneously.

Strengths: Superior pH stability across wider ranges than conventional materials; hybrid technology combines advantages of both silica and polymers; excellent mechanical strength allowing higher pressures and faster analyses. Weaknesses: Higher cost compared to conventional materials; proprietary technology creates vendor lock-in; some specialized applications may still require dedicated silica or polymer phases.

Dionex Corp.

Technical Solution: Dionex (now part of Thermo Fisher Scientific) has pioneered polymer-based HPLC column technology with their IonPac columns utilizing ethylvinylbenzene cross-linked with divinylbenzene (EVB-DVB) polymer particles. Their proprietary hyperbranched condensation polymer coating technology creates highly stable ion-exchange surfaces that maintain performance across extreme pH ranges (0-14). For silica-based materials, Dionex offers Acclaim mixed-mode columns with embedded polar groups within hydrophobic ligands, providing unique selectivity for complex separations. Their Acclaim RSLC columns feature 2.2μm silica particles with advanced end-capping technology that reduces secondary interactions. Dionex's polymer monolith columns (ProSwift) provide high-throughput separations of large biomolecules with minimal backpressure due to their unique macroporous structure allowing convective mass transfer rather than diffusion-limited processes seen in traditional packed columns.

Strengths: Industry-leading polymer technology for ion chromatography; exceptional pH stability across entire range; specialized selectivity options for complex matrices; lower operating pressures for polymer monoliths. Weaknesses: Lower efficiency for some polymer phases compared to silica; higher cost for specialized ion chromatography columns; some polymer phases show limited compatibility with certain organic solvents.

Critical Patents and Innovations in Column Packing Materials

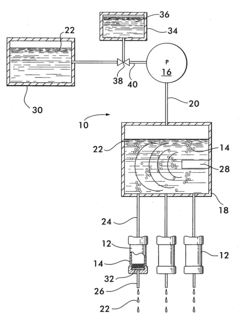

Method and apparatus for packing chromatography column

PatentInactiveUS20070181501A1

Innovation

- An apparatus and method involving a chamber with a vibrator to agitate a mixture of packing medium and liquid, ensuring uniform distribution and retention of packing medium within the column, using a pump to force the mixture through, and a porous element to retain the medium, facilitating a stable and homogeneous packing bed.

Sustainability and Green Chemistry Considerations in HPLC Materials

The environmental impact of HPLC column materials has become increasingly important as analytical laboratories worldwide seek to align with sustainability goals. Traditional silica-based materials present several environmental challenges throughout their lifecycle. The manufacturing process of silica materials requires high energy consumption and generates significant waste, including hazardous byproducts from silane chemistry used in surface modifications. Additionally, the short lifespan of silica columns under extreme pH conditions necessitates frequent replacements, contributing to laboratory waste.

Polymer-based materials offer several sustainability advantages in comparison. These materials generally require lower energy inputs during manufacturing and avoid the use of certain toxic reagents associated with silica derivatization. The extended pH stability of polymeric columns (typically pH 1-14) significantly extends their operational lifespan, reducing the frequency of column replacement and associated waste generation. Furthermore, many polymer-based materials can be produced from renewable resources, presenting opportunities for reducing reliance on petroleum-based starting materials.

Recent innovations in green chemistry approaches have focused on developing more sustainable HPLC materials. Bio-based polymers derived from agricultural waste products represent a promising direction, with research demonstrating comparable separation performance to traditional materials while reducing environmental footprint. Additionally, manufacturers have begun implementing solvent recovery systems and closed-loop manufacturing processes to minimize waste generation during production of both silica and polymer materials.

The disposal considerations between these materials also differ significantly. End-of-life silica materials may contain residual metal contaminants and modified surface chemistries that complicate disposal. In contrast, certain polymer-based materials can be more readily recycled or safely disposed of through conventional waste streams, though this varies considerably depending on specific polymer chemistry and modifications.

Water consumption represents another important sustainability metric. The production of high-purity silica typically requires substantial water usage for washing and purification steps. Some newer polymer manufacturing processes have been designed specifically to reduce water requirements, though comprehensive lifecycle analyses comparing total water footprints remain limited in the scientific literature.

Energy efficiency during HPLC operation also favors polymer columns in many applications. Their tolerance for faster flow rates and lower backpressure can reduce instrument runtime and energy consumption. However, this advantage must be balanced against separation performance requirements specific to each analytical method.

Polymer-based materials offer several sustainability advantages in comparison. These materials generally require lower energy inputs during manufacturing and avoid the use of certain toxic reagents associated with silica derivatization. The extended pH stability of polymeric columns (typically pH 1-14) significantly extends their operational lifespan, reducing the frequency of column replacement and associated waste generation. Furthermore, many polymer-based materials can be produced from renewable resources, presenting opportunities for reducing reliance on petroleum-based starting materials.

Recent innovations in green chemistry approaches have focused on developing more sustainable HPLC materials. Bio-based polymers derived from agricultural waste products represent a promising direction, with research demonstrating comparable separation performance to traditional materials while reducing environmental footprint. Additionally, manufacturers have begun implementing solvent recovery systems and closed-loop manufacturing processes to minimize waste generation during production of both silica and polymer materials.

The disposal considerations between these materials also differ significantly. End-of-life silica materials may contain residual metal contaminants and modified surface chemistries that complicate disposal. In contrast, certain polymer-based materials can be more readily recycled or safely disposed of through conventional waste streams, though this varies considerably depending on specific polymer chemistry and modifications.

Water consumption represents another important sustainability metric. The production of high-purity silica typically requires substantial water usage for washing and purification steps. Some newer polymer manufacturing processes have been designed specifically to reduce water requirements, though comprehensive lifecycle analyses comparing total water footprints remain limited in the scientific literature.

Energy efficiency during HPLC operation also favors polymer columns in many applications. Their tolerance for faster flow rates and lower backpressure can reduce instrument runtime and energy consumption. However, this advantage must be balanced against separation performance requirements specific to each analytical method.

Application-Specific Performance Comparison Framework

To effectively evaluate HPLC column packing materials across different application domains, a structured performance comparison framework is essential. This framework must consider the diverse requirements of various analytical scenarios where silica and polymer-based materials demonstrate distinct advantages.

For pharmaceutical applications, the framework should assess separation efficiency at different pH ranges, particularly examining polymer-based materials' superior performance in alkaline conditions where silica typically degrades. Quantitative metrics should include resolution of closely related impurities, detection limits for trace components, and long-term stability under routine pharmaceutical quality control conditions.

Biomolecule analysis requires evaluation of non-specific adsorption characteristics, with polymer-based materials generally showing advantages for protein and peptide separations due to reduced secondary interactions. The framework should measure recovery rates of sensitive biomolecules, peak symmetry, and resolution maintenance across multiple injections of biological samples.

Environmental analysis comparison metrics must include resistance to complex matrices, focusing on polymer materials' superior chemical stability when analyzing soil extracts, wastewater, or samples with extreme pH. Performance indicators should track column lifetime under harsh conditions and consistency of retention times when processing dirty samples.

For food and beverage applications, the framework should evaluate selectivity for structurally similar compounds like isomers and homologs, where silica's higher theoretical plate counts often provide advantages. Temperature stability becomes critical for high-temperature separations of certain food components, with polymeric materials typically offering better thermal resistance.

Industrial quality control applications require assessment of batch-to-batch reproducibility and long-term cost effectiveness, comparing initial performance against sustained separation capability after thousands of injections. The framework should include total cost of ownership calculations incorporating column lifetime under application-specific conditions.

Method transferability metrics are essential for multi-site operations, evaluating how consistently methods developed on silica columns transfer to polymer columns and vice versa, particularly important for global organizations with diverse instrument platforms and regulatory requirements.

For pharmaceutical applications, the framework should assess separation efficiency at different pH ranges, particularly examining polymer-based materials' superior performance in alkaline conditions where silica typically degrades. Quantitative metrics should include resolution of closely related impurities, detection limits for trace components, and long-term stability under routine pharmaceutical quality control conditions.

Biomolecule analysis requires evaluation of non-specific adsorption characteristics, with polymer-based materials generally showing advantages for protein and peptide separations due to reduced secondary interactions. The framework should measure recovery rates of sensitive biomolecules, peak symmetry, and resolution maintenance across multiple injections of biological samples.

Environmental analysis comparison metrics must include resistance to complex matrices, focusing on polymer materials' superior chemical stability when analyzing soil extracts, wastewater, or samples with extreme pH. Performance indicators should track column lifetime under harsh conditions and consistency of retention times when processing dirty samples.

For food and beverage applications, the framework should evaluate selectivity for structurally similar compounds like isomers and homologs, where silica's higher theoretical plate counts often provide advantages. Temperature stability becomes critical for high-temperature separations of certain food components, with polymeric materials typically offering better thermal resistance.

Industrial quality control applications require assessment of batch-to-batch reproducibility and long-term cost effectiveness, comparing initial performance against sustained separation capability after thousands of injections. The framework should include total cost of ownership calculations incorporating column lifetime under application-specific conditions.

Method transferability metrics are essential for multi-site operations, evaluating how consistently methods developed on silica columns transfer to polymer columns and vice versa, particularly important for global organizations with diverse instrument platforms and regulatory requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!