How to Compare Direct Lithium Extraction Techniques for Yield

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction Background and Objectives

Lithium has emerged as a critical element in the global transition towards renewable energy and electrification, primarily due to its essential role in rechargeable batteries. Traditional lithium extraction methods have predominantly relied on evaporative processes in salt flats or hard rock mining, both of which present significant environmental challenges and operational inefficiencies. The evolution of Direct Lithium Extraction (DLE) technologies represents a paradigm shift in the industry, offering potentially more sustainable and efficient alternatives.

The historical development of lithium extraction began in the early 20th century, initially focused on mineral sources. By the 1950s, extraction from brine resources gained prominence, establishing the foundation for today's conventional methods. The technological trajectory has been characterized by incremental improvements until the recent acceleration of DLE innovation, driven by the exponential growth in demand for lithium-ion batteries.

Current global lithium production is dominated by Australia, Chile, China, and Argentina, with extraction methodologies varying significantly by region based on available resources. The industry faces mounting pressure to increase production capacity while simultaneously reducing environmental impact, particularly water consumption and land disturbance associated with traditional extraction methods.

The primary objective of comparing DLE techniques for yield is to establish standardized evaluation frameworks that enable accurate assessment of different technologies' efficiency in extracting lithium from various source materials. This comparison must account for multiple performance indicators beyond simple recovery rates, including selectivity, processing time, energy requirements, and operational stability across diverse geological conditions.

Technical goals include developing comprehensive benchmarking methodologies that incorporate both laboratory and field-scale performance data, identifying key yield-limiting factors in current DLE implementations, and establishing predictive models for technology optimization. Additionally, the comparison aims to quantify the relationship between operational parameters and extraction yields to facilitate process engineering improvements.

The strategic importance of this technical investigation extends beyond immediate commercial applications. As global lithium demand is projected to increase by 40-fold by 2040, according to the International Energy Agency, developing high-yield extraction technologies has become critical to energy security and climate change mitigation efforts. Consequently, this technical research serves both immediate industrial needs and broader societal objectives in the transition to sustainable energy systems.

The historical development of lithium extraction began in the early 20th century, initially focused on mineral sources. By the 1950s, extraction from brine resources gained prominence, establishing the foundation for today's conventional methods. The technological trajectory has been characterized by incremental improvements until the recent acceleration of DLE innovation, driven by the exponential growth in demand for lithium-ion batteries.

Current global lithium production is dominated by Australia, Chile, China, and Argentina, with extraction methodologies varying significantly by region based on available resources. The industry faces mounting pressure to increase production capacity while simultaneously reducing environmental impact, particularly water consumption and land disturbance associated with traditional extraction methods.

The primary objective of comparing DLE techniques for yield is to establish standardized evaluation frameworks that enable accurate assessment of different technologies' efficiency in extracting lithium from various source materials. This comparison must account for multiple performance indicators beyond simple recovery rates, including selectivity, processing time, energy requirements, and operational stability across diverse geological conditions.

Technical goals include developing comprehensive benchmarking methodologies that incorporate both laboratory and field-scale performance data, identifying key yield-limiting factors in current DLE implementations, and establishing predictive models for technology optimization. Additionally, the comparison aims to quantify the relationship between operational parameters and extraction yields to facilitate process engineering improvements.

The strategic importance of this technical investigation extends beyond immediate commercial applications. As global lithium demand is projected to increase by 40-fold by 2040, according to the International Energy Agency, developing high-yield extraction technologies has become critical to energy security and climate change mitigation efforts. Consequently, this technical research serves both immediate industrial needs and broader societal objectives in the transition to sustainable energy systems.

Market Demand Analysis for Direct Lithium Extraction

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Direct Lithium Extraction (DLE) technologies have emerged as critical solutions to meet this surging demand, offering potentially higher yields and lower environmental impacts compared to traditional extraction methods.

Market projections indicate that lithium demand will increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030, representing a compound annual growth rate exceeding 20%. This explosive growth trajectory has created an urgent need for more efficient extraction technologies that can deliver higher yields while maintaining economic viability.

The EV sector remains the primary demand driver, accounting for nearly 80% of lithium consumption. Major automotive manufacturers have announced ambitious electrification targets, with several committing to all-electric fleets by 2035. This transition alone is expected to require lithium production capacity to increase by at least five-fold within the next decade.

Energy storage systems represent the second-largest market segment, with grid-scale applications growing at over 30% annually. As renewable energy penetration increases globally, the need for efficient energy storage solutions will further accelerate lithium demand, particularly for high-yield extraction technologies that can scale rapidly.

Regional market analysis reveals significant geographical variations in demand patterns. Asia-Pacific, led by China, currently dominates lithium consumption, accounting for approximately 65% of global demand. However, Europe and North America are experiencing the fastest growth rates as their EV markets mature and manufacturing capacity expands.

Industry stakeholders are increasingly prioritizing extraction yield as a critical performance metric when evaluating DLE technologies. Market research indicates that technologies demonstrating consistent yields above 85% attract premium valuations and strategic partnerships. This yield-focused market dynamic is reshaping investment patterns, with venture capital and corporate funding increasingly flowing toward high-yield extraction innovations.

End-users across the battery supply chain are willing to pay premium prices for lithium produced through high-yield extraction methods, particularly when these methods also demonstrate reduced environmental impacts. This price premium ranges from 10-15% for technologies that can consistently deliver superior yields while maintaining product purity specifications.

The market is also witnessing growing demand for standardized yield comparison methodologies that enable objective evaluation across different DLE technologies. This trend reflects the maturing nature of the DLE sector and highlights the need for transparent performance metrics to guide investment decisions and technology adoption strategies.

Market projections indicate that lithium demand will increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030, representing a compound annual growth rate exceeding 20%. This explosive growth trajectory has created an urgent need for more efficient extraction technologies that can deliver higher yields while maintaining economic viability.

The EV sector remains the primary demand driver, accounting for nearly 80% of lithium consumption. Major automotive manufacturers have announced ambitious electrification targets, with several committing to all-electric fleets by 2035. This transition alone is expected to require lithium production capacity to increase by at least five-fold within the next decade.

Energy storage systems represent the second-largest market segment, with grid-scale applications growing at over 30% annually. As renewable energy penetration increases globally, the need for efficient energy storage solutions will further accelerate lithium demand, particularly for high-yield extraction technologies that can scale rapidly.

Regional market analysis reveals significant geographical variations in demand patterns. Asia-Pacific, led by China, currently dominates lithium consumption, accounting for approximately 65% of global demand. However, Europe and North America are experiencing the fastest growth rates as their EV markets mature and manufacturing capacity expands.

Industry stakeholders are increasingly prioritizing extraction yield as a critical performance metric when evaluating DLE technologies. Market research indicates that technologies demonstrating consistent yields above 85% attract premium valuations and strategic partnerships. This yield-focused market dynamic is reshaping investment patterns, with venture capital and corporate funding increasingly flowing toward high-yield extraction innovations.

End-users across the battery supply chain are willing to pay premium prices for lithium produced through high-yield extraction methods, particularly when these methods also demonstrate reduced environmental impacts. This price premium ranges from 10-15% for technologies that can consistently deliver superior yields while maintaining product purity specifications.

The market is also witnessing growing demand for standardized yield comparison methodologies that enable objective evaluation across different DLE technologies. This trend reflects the maturing nature of the DLE sector and highlights the need for transparent performance metrics to guide investment decisions and technology adoption strategies.

Current DLE Technologies and Technical Barriers

Direct Lithium Extraction (DLE) technologies represent a paradigm shift in lithium production, offering alternatives to traditional evaporation ponds and hard-rock mining. Currently, several DLE technologies dominate the landscape, each with distinct operational principles and performance characteristics.

Adsorption-based technologies utilize selective materials that preferentially bind lithium ions from brine solutions. These include ion-exchange resins, inorganic adsorbents, and metal oxide frameworks. While offering high selectivity, these systems often struggle with capacity degradation over multiple cycles and can be sensitive to brine impurities that compete for adsorption sites.

Membrane technologies, including nanofiltration and electrodialysis, leverage size exclusion and electrical charge to separate lithium from other constituents. These approaches offer continuous operation capabilities but face challenges with membrane fouling and scaling, particularly in high-TDS (Total Dissolved Solids) brines, necessitating extensive pre-treatment.

Solvent extraction methods employ specialized organic compounds that selectively complex with lithium ions. Though effective in laboratory settings, industrial implementation has been hindered by solvent loss, phase separation difficulties, and environmental concerns regarding chemical handling.

Electrochemical approaches, including electrochemical intercalation and capacitive deionization, utilize electrical potential to drive lithium separation. These technologies show promise for energy efficiency but currently face limitations in throughput capacity and electrode stability over extended operation periods.

A significant technical barrier across all DLE technologies is the trade-off between selectivity and recovery rate. Systems optimized for high lithium purity often sacrifice total recovery percentage, while those designed for maximum recovery may require additional purification steps, increasing process complexity and cost.

Scalability presents another universal challenge. Many DLE technologies demonstrate impressive performance in laboratory or pilot-scale operations but encounter unforeseen complications when scaled to commercial production volumes. These include flow distribution problems, increased energy requirements, and diminished efficiency at larger scales.

Brine chemistry variability constitutes a critical barrier to standardized DLE implementation. Technologies optimized for one brine source often perform suboptimally when applied to brines with different compositions, concentrations, and impurity profiles, necessitating customized process designs for each resource.

Energy consumption remains a persistent concern, with most current DLE technologies requiring significant electrical or thermal inputs that impact operational economics and sustainability metrics. Innovations in energy recovery and process integration are needed to address this limitation.

Adsorption-based technologies utilize selective materials that preferentially bind lithium ions from brine solutions. These include ion-exchange resins, inorganic adsorbents, and metal oxide frameworks. While offering high selectivity, these systems often struggle with capacity degradation over multiple cycles and can be sensitive to brine impurities that compete for adsorption sites.

Membrane technologies, including nanofiltration and electrodialysis, leverage size exclusion and electrical charge to separate lithium from other constituents. These approaches offer continuous operation capabilities but face challenges with membrane fouling and scaling, particularly in high-TDS (Total Dissolved Solids) brines, necessitating extensive pre-treatment.

Solvent extraction methods employ specialized organic compounds that selectively complex with lithium ions. Though effective in laboratory settings, industrial implementation has been hindered by solvent loss, phase separation difficulties, and environmental concerns regarding chemical handling.

Electrochemical approaches, including electrochemical intercalation and capacitive deionization, utilize electrical potential to drive lithium separation. These technologies show promise for energy efficiency but currently face limitations in throughput capacity and electrode stability over extended operation periods.

A significant technical barrier across all DLE technologies is the trade-off between selectivity and recovery rate. Systems optimized for high lithium purity often sacrifice total recovery percentage, while those designed for maximum recovery may require additional purification steps, increasing process complexity and cost.

Scalability presents another universal challenge. Many DLE technologies demonstrate impressive performance in laboratory or pilot-scale operations but encounter unforeseen complications when scaled to commercial production volumes. These include flow distribution problems, increased energy requirements, and diminished efficiency at larger scales.

Brine chemistry variability constitutes a critical barrier to standardized DLE implementation. Technologies optimized for one brine source often perform suboptimally when applied to brines with different compositions, concentrations, and impurity profiles, necessitating customized process designs for each resource.

Energy consumption remains a persistent concern, with most current DLE technologies requiring significant electrical or thermal inputs that impact operational economics and sustainability metrics. Innovations in energy recovery and process integration are needed to address this limitation.

Current Yield Comparison Methodologies for DLE

01 Adsorption-based lithium extraction methods

Adsorption-based techniques utilize specialized materials that selectively bind to lithium ions from brine solutions. These methods typically employ ion-exchange materials, lithium-selective adsorbents, or molecular sieves that can capture lithium while rejecting other ions. The process generally involves passing lithium-rich solutions through columns containing these adsorbents, followed by desorption steps to recover concentrated lithium. This approach offers advantages in selectivity and can be applied to low-concentration brines where traditional evaporation methods are inefficient.- Adsorption-based lithium extraction techniques: Adsorption-based methods utilize selective adsorbents to capture lithium ions from brine solutions. These techniques employ specialized materials such as lithium manganese oxide, lithium titanium oxide, or ion-exchange resins that preferentially bind to lithium ions over other elements present in the brine. The process typically involves passing the brine through columns containing these adsorbents, followed by desorption steps to recover concentrated lithium. This approach offers advantages in selectivity and can be applied to low-concentration brines where traditional evaporation methods are inefficient.

- Membrane and electrochemical extraction systems: Membrane and electrochemical systems employ selective membranes and electrical potential to separate lithium ions from brine solutions. These techniques include electrodialysis, membrane filtration, and electrochemical cells that leverage the different migration rates of ions under electrical fields. The systems can continuously process brine without large evaporation ponds, reducing water consumption and processing time. Advanced membrane technologies enhance selectivity for lithium over competing ions such as sodium, magnesium, and calcium, resulting in higher purity lithium products with fewer processing steps.

- Solvent extraction and chemical precipitation methods: Solvent extraction and chemical precipitation techniques involve the use of specific chemicals to selectively extract or precipitate lithium from brine solutions. These methods utilize specialized solvents, complexing agents, or precipitating reagents that interact preferentially with lithium ions. The process typically includes mixing the brine with the extraction medium, followed by separation and recovery steps. These techniques can achieve high lithium recovery rates and are particularly effective for brines with challenging compositions. The methods can be optimized for different brine chemistries by adjusting reagent formulations and process conditions.

- Integrated and hybrid extraction processes: Integrated and hybrid extraction processes combine multiple lithium extraction technologies to maximize yield and efficiency. These systems typically incorporate sequential or parallel processing steps that leverage the strengths of different extraction methods. For example, a hybrid process might use membrane pre-concentration followed by adsorption for final purification. These integrated approaches can overcome limitations of individual technologies, handle varying brine compositions, and optimize energy consumption. The combined processes often result in higher overall lithium recovery rates, improved product purity, and reduced environmental impact compared to single-technology approaches.

- Yield optimization and process efficiency improvements: Various techniques focus on optimizing the yield and efficiency of direct lithium extraction processes. These include advanced process control systems, regeneration methods for extraction media, and recovery of lithium from process waste streams. Innovations in this category address challenges such as adsorbent degradation, energy consumption, and water usage. Technologies include improved regeneration chemistries that extend the lifespan of extraction materials, energy recovery systems that reduce operational costs, and water recycling methods that minimize environmental impact. These optimizations can significantly increase the economic viability of direct lithium extraction operations while improving sustainability metrics.

02 Electrochemical lithium extraction processes

Electrochemical extraction techniques leverage electrical potential differences to selectively recover lithium from brines and other sources. These methods include electrochemical cells, capacitive deionization, and electrodialysis systems specifically designed for lithium separation. By applying controlled voltage, lithium ions can be directed through selective membranes or captured at electrodes, allowing for continuous extraction with reduced environmental impact compared to evaporation ponds. These processes can achieve higher recovery rates and operate with lower energy consumption than traditional methods.Expand Specific Solutions03 Membrane and solvent-based separation technologies

These extraction techniques utilize specialized membranes or solvent systems to selectively separate lithium from other elements in solution. Membrane processes may include nanofiltration, reverse osmosis, or supported liquid membranes that allow lithium ions to pass while blocking competing ions. Solvent extraction methods use specific organic compounds that preferentially bind to lithium, enabling its separation from the aqueous phase. These approaches can process brines continuously and often require less land area than traditional evaporation methods, while potentially offering higher recovery rates.Expand Specific Solutions04 Integrated hybrid extraction systems

Hybrid extraction systems combine multiple lithium recovery technologies to maximize yield and efficiency. These integrated approaches might combine adsorption with electrochemical methods, membrane filtration with selective precipitation, or other combinations tailored to specific brine compositions. By leveraging the strengths of different extraction mechanisms, these systems can overcome limitations of individual methods, achieving higher lithium recovery rates, greater purity, and improved economics. Such hybrid approaches are particularly valuable for processing complex brines with challenging impurity profiles.Expand Specific Solutions05 Direct extraction from geothermal and unconventional sources

These techniques focus on extracting lithium directly from geothermal brines, oilfield produced waters, and other unconventional sources. The methods are specifically designed to handle the unique challenges of these resources, including high temperatures, complex chemical compositions, and varying lithium concentrations. Technologies may include specialized adsorbents that function at elevated temperatures, pressure-driven separation systems, or chemical processes that can selectively recover lithium from these challenging matrices. These approaches expand the potential lithium resource base beyond traditional salt flats and mining operations.Expand Specific Solutions

Major Industry Players in DLE Technology

The direct lithium extraction (DLE) technology landscape is currently in an early growth phase, characterized by rapid innovation and increasing commercial interest. The market size is projected to expand significantly due to surging demand for lithium in battery applications, with estimates suggesting a multi-billion dollar opportunity by 2030. Technologically, the field shows varying maturity levels across different approaches. Leading players like Energy Exploration Technologies (EnergyX), Schlumberger, and International Battery Metals are advancing membrane-based solutions, while companies such as Evove, Watercycle Technologies, and Novalith Technologies are developing innovative adsorption and chemical processes. Academic institutions including Penn State Research Foundation and the Chinese Academy of Sciences are contributing fundamental research, creating a competitive ecosystem where yield optimization remains a critical differentiator as the industry moves toward commercial-scale implementation.

Energy Exploration Technologies, Inc.

Technical Solution: EnergyX has developed a proprietary LiTAS™ (Lithium Ionic Transport and Separation) platform based on mixed matrix membranes (MMMs) for direct lithium extraction. Their technology utilizes metal-organic framework (MOF) nanoparticles embedded in polymer membranes that selectively filter lithium ions from brine solutions. The process operates at ambient temperature and pressure, requiring minimal pre-treatment of brines. EnergyX's approach achieves lithium recovery rates of over 90% in laboratory conditions while rejecting over 99% of impurities like sodium, magnesium, and calcium. The system employs a continuous flow process rather than batch processing, allowing for higher throughput and efficiency. Their modular design enables scalability from pilot to commercial operations, with reported energy consumption of approximately 1 kWh per kg of lithium extracted - significantly lower than traditional evaporation methods that require 15-20 kWh/kg.

Strengths: High selectivity for lithium with minimal chemical consumption; energy-efficient process with lower water usage than evaporation ponds; rapid extraction timeframe (hours vs. months); modular and scalable design. Weaknesses: Technology still scaling from pilot to commercial implementation; membrane fouling may occur in high-impurity brines; performance in varied brine chemistries needs further validation; capital costs for initial setup may be higher than conventional methods.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has commercialized the Li-Pro™ direct lithium extraction technology, which utilizes a proprietary adsorbent-based system for selective lithium recovery from various brine sources. Their process employs specialized ion exchange materials that preferentially adsorb lithium ions while rejecting competing ions like sodium, calcium, and magnesium. The Li-Pro™ system operates in a continuous countercurrent mode, allowing for efficient mass transfer and higher lithium recovery rates. Koch's technology achieves lithium concentration factors of 50-100x from initial brine concentrations, with recovery efficiencies reported between 85-95% depending on brine chemistry. The process requires minimal pre-treatment and operates at near-ambient conditions, reducing energy requirements compared to traditional evaporation methods. Their system incorporates a regeneration cycle using dilute acid solutions to desorb lithium and prepare the adsorbent for reuse, with adsorbent lifespans estimated at 3-5 years before replacement is needed. Koch has demonstrated the technology at commercial scale with processing capacities of several thousand cubic meters of brine per day.

Strengths: High lithium selectivity with proven commercial-scale implementation; adaptable to various brine chemistries; significantly faster extraction times than evaporation ponds; reduced environmental footprint with lower land and water requirements. Weaknesses: Regeneration chemicals add to operational costs; potential for adsorbent degradation over multiple cycles; energy requirements for regeneration may be significant; performance may vary with different brine compositions and impurity profiles.

Key Technical Parameters Affecting DLE Yield

Method for improving lithium yield in a direct lithium extraction process

PatentPendingUS20250249465A1

Innovation

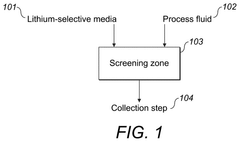

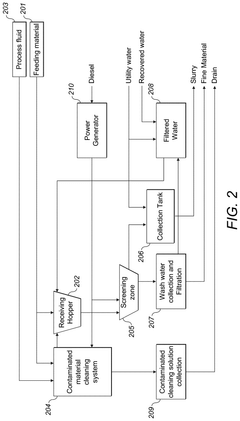

- A method involving a screening process using sieve elements with specific mesh sizes to separate lithium-selective media into desired particle sizes and remove contaminants, followed by dewatering and cleaning, to ensure optimal media performance in packed-bed columns.

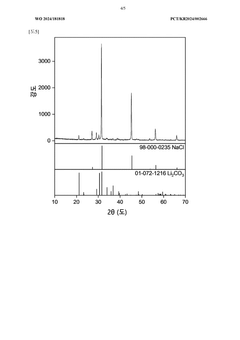

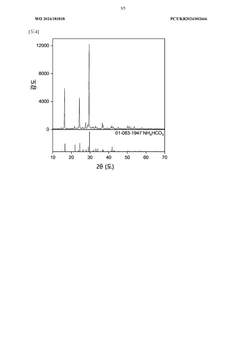

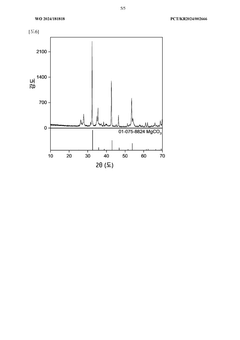

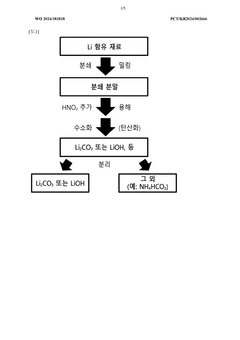

Method for extracting lithium from lithium-containing material

PatentWO2024181818A1

Innovation

- A lithium extraction method using a ruthenium oxide catalyst (HxRuO2) that catalyzes hydrogen, nitric acid, and carbon dioxide at high pressure to produce lithium carbonate or lithium hydroxide, reducing wastewater generation and allowing for the reuse of the catalyst, thereby minimizing chemical usage and environmental impact.

Environmental Impact Assessment of DLE Technologies

The environmental impact of Direct Lithium Extraction (DLE) technologies represents a critical dimension when comparing different extraction methods for yield optimization. Traditional lithium extraction methods, particularly evaporative ponds, have faced increasing scrutiny due to their substantial water consumption, land use requirements, and potential for contamination of local ecosystems.

DLE technologies generally demonstrate significant environmental advantages compared to conventional methods. Most notably, DLE processes typically reduce water consumption by 50-90% compared to evaporative techniques, addressing a major sustainability concern in water-stressed regions where lithium deposits are often found. This reduction is particularly important considering that traditional evaporative methods can consume up to 500,000 gallons of water per ton of lithium produced.

Land disturbance metrics also favor DLE approaches, with footprints often 90% smaller than evaporative ponds. This reduced spatial requirement minimizes habitat disruption and preserves biodiversity in sensitive ecological areas. The accelerated extraction timeframe of DLE (days versus months) further contributes to reduced cumulative environmental impact over project lifespans.

Chemical usage patterns vary significantly across DLE technologies. Ion-exchange methods typically employ regeneration chemicals that must be carefully managed, while adsorption-based techniques may require fewer reagents but different maintenance protocols. Proper assessment must include full lifecycle analysis of chemical inputs, including production, transportation, and disposal considerations.

Energy consumption represents another key environmental parameter. While DLE methods generally require more energy input than passive evaporation, this must be balanced against their higher efficiency and reduced resource consumption. Technologies utilizing renewable energy sources for powering extraction processes can significantly improve their overall environmental profile.

Waste stream management differs substantially between DLE variants. Some technologies produce concentrated brine that requires specialized disposal, while others generate solid waste byproducts with different environmental implications. Advanced DLE systems increasingly incorporate closed-loop designs that minimize discharge and maximize resource recovery, though implementation maturity varies across available technologies.

Carbon footprint calculations must account for both direct operational emissions and embodied carbon in infrastructure and chemicals. When properly implemented, certain DLE technologies can achieve carbon intensity reductions of 30-60% compared to conventional extraction methods, particularly when integrated with renewable energy systems.

DLE technologies generally demonstrate significant environmental advantages compared to conventional methods. Most notably, DLE processes typically reduce water consumption by 50-90% compared to evaporative techniques, addressing a major sustainability concern in water-stressed regions where lithium deposits are often found. This reduction is particularly important considering that traditional evaporative methods can consume up to 500,000 gallons of water per ton of lithium produced.

Land disturbance metrics also favor DLE approaches, with footprints often 90% smaller than evaporative ponds. This reduced spatial requirement minimizes habitat disruption and preserves biodiversity in sensitive ecological areas. The accelerated extraction timeframe of DLE (days versus months) further contributes to reduced cumulative environmental impact over project lifespans.

Chemical usage patterns vary significantly across DLE technologies. Ion-exchange methods typically employ regeneration chemicals that must be carefully managed, while adsorption-based techniques may require fewer reagents but different maintenance protocols. Proper assessment must include full lifecycle analysis of chemical inputs, including production, transportation, and disposal considerations.

Energy consumption represents another key environmental parameter. While DLE methods generally require more energy input than passive evaporation, this must be balanced against their higher efficiency and reduced resource consumption. Technologies utilizing renewable energy sources for powering extraction processes can significantly improve their overall environmental profile.

Waste stream management differs substantially between DLE variants. Some technologies produce concentrated brine that requires specialized disposal, while others generate solid waste byproducts with different environmental implications. Advanced DLE systems increasingly incorporate closed-loop designs that minimize discharge and maximize resource recovery, though implementation maturity varies across available technologies.

Carbon footprint calculations must account for both direct operational emissions and embodied carbon in infrastructure and chemicals. When properly implemented, certain DLE technologies can achieve carbon intensity reductions of 30-60% compared to conventional extraction methods, particularly when integrated with renewable energy systems.

Economic Feasibility Analysis of DLE Implementation

The economic viability of Direct Lithium Extraction (DLE) technologies represents a critical factor in determining their commercial adoption potential. Initial capital expenditure for DLE implementation varies significantly across different techniques, with adsorption-based systems typically requiring investments between $20-30 million for medium-scale operations, while ion exchange technologies may demand $25-40 million due to more complex material requirements and regeneration systems.

Operational expenses constitute another crucial economic consideration, with energy consumption emerging as a primary cost driver. Membrane-based DLE systems consume approximately 15-25 kWh per kilogram of lithium extracted, whereas electrochemical methods may require 30-40 kWh/kg. This energy differential translates to substantial cost variations when scaled to commercial production levels, particularly in regions with high electricity prices.

Chemical reagent costs represent another significant operational expense, with solvent-based extraction methods requiring continuous replenishment of expensive organic compounds at approximately $2,000-3,500 per ton of lithium produced. Conversely, adsorption-based techniques typically utilize more durable materials with longer replacement cycles, reducing recurring expenses to $1,000-1,800 per ton.

Return on investment timelines vary considerably based on technology selection. Analysis of current market implementations indicates that adsorption-based systems generally achieve ROI within 4-6 years, while more capital-intensive electrochemical approaches may require 6-8 years to reach profitability. These calculations assume lithium carbonate prices remaining above $15,000 per ton.

Scalability economics present another critical dimension, with certain technologies demonstrating more favorable cost curves at larger scales. Ion exchange systems exhibit economies of scale with approximately 15-20% cost reduction when doubling capacity, while membrane systems show more modest improvements of 8-12% due to the linear nature of membrane module expansion requirements.

Geographic considerations significantly impact economic feasibility, with brine chemistry variations necessitating different pre-treatment processes. Brines with high magnesium content may require additional processing steps costing $500-800 per ton of lithium in regions like Chile's Atacama, while lower-impurity brines in Argentina's salars may reduce these costs by 30-40%.

Market volatility represents a final economic consideration, with lithium price fluctuations directly impacting payback periods. Sensitivity analysis indicates that a 20% decrease in lithium prices extends ROI timelines by approximately 1.5-2 years across all DLE technologies, highlighting the importance of incorporating market risk factors into economic feasibility assessments.

Operational expenses constitute another crucial economic consideration, with energy consumption emerging as a primary cost driver. Membrane-based DLE systems consume approximately 15-25 kWh per kilogram of lithium extracted, whereas electrochemical methods may require 30-40 kWh/kg. This energy differential translates to substantial cost variations when scaled to commercial production levels, particularly in regions with high electricity prices.

Chemical reagent costs represent another significant operational expense, with solvent-based extraction methods requiring continuous replenishment of expensive organic compounds at approximately $2,000-3,500 per ton of lithium produced. Conversely, adsorption-based techniques typically utilize more durable materials with longer replacement cycles, reducing recurring expenses to $1,000-1,800 per ton.

Return on investment timelines vary considerably based on technology selection. Analysis of current market implementations indicates that adsorption-based systems generally achieve ROI within 4-6 years, while more capital-intensive electrochemical approaches may require 6-8 years to reach profitability. These calculations assume lithium carbonate prices remaining above $15,000 per ton.

Scalability economics present another critical dimension, with certain technologies demonstrating more favorable cost curves at larger scales. Ion exchange systems exhibit economies of scale with approximately 15-20% cost reduction when doubling capacity, while membrane systems show more modest improvements of 8-12% due to the linear nature of membrane module expansion requirements.

Geographic considerations significantly impact economic feasibility, with brine chemistry variations necessitating different pre-treatment processes. Brines with high magnesium content may require additional processing steps costing $500-800 per ton of lithium in regions like Chile's Atacama, while lower-impurity brines in Argentina's salars may reduce these costs by 30-40%.

Market volatility represents a final economic consideration, with lithium price fluctuations directly impacting payback periods. Sensitivity analysis indicates that a 20% decrease in lithium prices extends ROI timelines by approximately 1.5-2 years across all DLE technologies, highlighting the importance of incorporating market risk factors into economic feasibility assessments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!