How to Conduct Direct Lithium Extraction in Hard-to-Reach Areas

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Direct Lithium Extraction Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a revolutionary approach to lithium production, offering significant advantages over traditional extraction methods such as evaporation ponds and hard-rock mining. The technology has evolved considerably since its conceptual development in the 1990s, with major breakthroughs occurring in the past decade as global demand for lithium has surged due to the electric vehicle revolution and renewable energy storage requirements.

The historical trajectory of DLE technology shows a shift from laboratory-scale experiments to commercial implementations, with several companies now operating pilot plants and small-scale commercial facilities. This evolution has been driven by the increasing recognition of lithium as a critical mineral for the clean energy transition, coupled with growing environmental concerns about conventional extraction methods.

Current DLE technologies encompass a diverse range of approaches, including adsorption, ion exchange, solvent extraction, and membrane processes. Each method offers distinct advantages in terms of efficiency, selectivity, and environmental impact, though all share the common goal of extracting lithium directly from brine resources with minimal environmental footprint and water consumption.

The technical objectives for implementing DLE in hard-to-reach areas present unique challenges that extend beyond those of conventional settings. These objectives include developing modular and scalable systems that can operate in remote locations with limited infrastructure, designing energy-efficient processes that can function with renewable or limited energy sources, and creating robust systems capable of withstanding extreme environmental conditions.

Additionally, DLE in challenging environments must address specific technical hurdles such as handling brines with complex chemical compositions, operating with limited water resources for processing, and minimizing the physical footprint of extraction facilities. These constraints necessitate innovative approaches to system design, materials selection, and process optimization.

The ultimate goal of advancing DLE technology for hard-to-reach areas is to unlock previously inaccessible lithium resources, thereby expanding global supply chains and reducing dependency on geographically concentrated conventional resources. This aligns with broader strategic objectives of resource diversification, supply chain resilience, and meeting the exponentially growing demand for lithium in the clean energy transition.

Furthermore, successful implementation of DLE in challenging environments could potentially transform the geopolitical landscape of lithium production, enabling countries with previously unexploited resources to become significant players in the global market, while simultaneously addressing environmental and social concerns associated with traditional extraction methods.

The historical trajectory of DLE technology shows a shift from laboratory-scale experiments to commercial implementations, with several companies now operating pilot plants and small-scale commercial facilities. This evolution has been driven by the increasing recognition of lithium as a critical mineral for the clean energy transition, coupled with growing environmental concerns about conventional extraction methods.

Current DLE technologies encompass a diverse range of approaches, including adsorption, ion exchange, solvent extraction, and membrane processes. Each method offers distinct advantages in terms of efficiency, selectivity, and environmental impact, though all share the common goal of extracting lithium directly from brine resources with minimal environmental footprint and water consumption.

The technical objectives for implementing DLE in hard-to-reach areas present unique challenges that extend beyond those of conventional settings. These objectives include developing modular and scalable systems that can operate in remote locations with limited infrastructure, designing energy-efficient processes that can function with renewable or limited energy sources, and creating robust systems capable of withstanding extreme environmental conditions.

Additionally, DLE in challenging environments must address specific technical hurdles such as handling brines with complex chemical compositions, operating with limited water resources for processing, and minimizing the physical footprint of extraction facilities. These constraints necessitate innovative approaches to system design, materials selection, and process optimization.

The ultimate goal of advancing DLE technology for hard-to-reach areas is to unlock previously inaccessible lithium resources, thereby expanding global supply chains and reducing dependency on geographically concentrated conventional resources. This aligns with broader strategic objectives of resource diversification, supply chain resilience, and meeting the exponentially growing demand for lithium in the clean energy transition.

Furthermore, successful implementation of DLE in challenging environments could potentially transform the geopolitical landscape of lithium production, enabling countries with previously unexploited resources to become significant players in the global market, while simultaneously addressing environmental and social concerns associated with traditional extraction methods.

Market Analysis for Remote Lithium Resources

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle production and renewable energy storage systems. Remote lithium resources, particularly those in hard-to-reach areas such as high-altitude salt flats, deep underground brines, and isolated desert regions, represent a significant untapped portion of global lithium reserves. Current estimates suggest that approximately 30% of the world's lithium resources are located in areas considered logistically challenging for traditional extraction methods.

Market demand for lithium is projected to increase fourfold by 2030, creating a substantial supply gap that remote resources could help fill. The current market value of lithium carbonate equivalent (LCE) has shown significant volatility, with prices reaching historic highs in recent years, making previously uneconomical remote deposits increasingly attractive from an investment perspective.

The geographical distribution of these remote lithium resources presents interesting market dynamics. South America's "Lithium Triangle" (Argentina, Bolivia, and Chile) contains substantial high-altitude brine deposits, while Australia harbors remote hard-rock lithium resources. North America, particularly the western United States and Canada, possesses significant untapped geothermal brine resources in isolated regions.

Market barriers for remote lithium extraction include high capital expenditure requirements for specialized equipment, transportation infrastructure limitations, and often complex regulatory frameworks in underdeveloped regions. These factors have historically deterred investment, creating a market opportunity for innovative extraction technologies specifically designed for remote deployment.

Consumer segments driving demand include major battery manufacturers, automotive companies with vertical integration strategies, and energy storage system developers. These end-users increasingly value supply chain security and are willing to pay premium prices for lithium sourced through environmentally sustainable methods, which many direct lithium extraction (DLE) technologies can provide compared to traditional evaporation ponds.

Competitive analysis reveals that early movers in remote lithium extraction technology are primarily specialized mining technology companies and well-funded startups rather than traditional mining conglomerates. This indicates a market in transition, with significant opportunities for technological innovation and strategic partnerships.

The economic viability threshold for remote lithium resources continues to improve as extraction technologies advance. Current break-even analysis suggests that DLE methods can be economically viable at sites with lithium concentrations as low as 50-100 mg/L, substantially lower than required for traditional methods, thus expanding the addressable market for previously overlooked remote resources.

Market demand for lithium is projected to increase fourfold by 2030, creating a substantial supply gap that remote resources could help fill. The current market value of lithium carbonate equivalent (LCE) has shown significant volatility, with prices reaching historic highs in recent years, making previously uneconomical remote deposits increasingly attractive from an investment perspective.

The geographical distribution of these remote lithium resources presents interesting market dynamics. South America's "Lithium Triangle" (Argentina, Bolivia, and Chile) contains substantial high-altitude brine deposits, while Australia harbors remote hard-rock lithium resources. North America, particularly the western United States and Canada, possesses significant untapped geothermal brine resources in isolated regions.

Market barriers for remote lithium extraction include high capital expenditure requirements for specialized equipment, transportation infrastructure limitations, and often complex regulatory frameworks in underdeveloped regions. These factors have historically deterred investment, creating a market opportunity for innovative extraction technologies specifically designed for remote deployment.

Consumer segments driving demand include major battery manufacturers, automotive companies with vertical integration strategies, and energy storage system developers. These end-users increasingly value supply chain security and are willing to pay premium prices for lithium sourced through environmentally sustainable methods, which many direct lithium extraction (DLE) technologies can provide compared to traditional evaporation ponds.

Competitive analysis reveals that early movers in remote lithium extraction technology are primarily specialized mining technology companies and well-funded startups rather than traditional mining conglomerates. This indicates a market in transition, with significant opportunities for technological innovation and strategic partnerships.

The economic viability threshold for remote lithium resources continues to improve as extraction technologies advance. Current break-even analysis suggests that DLE methods can be economically viable at sites with lithium concentrations as low as 50-100 mg/L, substantially lower than required for traditional methods, thus expanding the addressable market for previously overlooked remote resources.

Technical Barriers in Hard-to-Reach Lithium Extraction

Direct lithium extraction (DLE) in hard-to-reach areas faces significant technical barriers that impede efficient resource utilization. The geographical complexity of these regions presents formidable challenges, including extreme terrain variations, limited infrastructure, and harsh environmental conditions. Remote lithium-rich locations often lack basic utilities such as reliable electricity, water supply systems, and transportation networks essential for conventional extraction operations.

The physical characteristics of lithium deposits in these areas further complicate extraction efforts. Hard-to-reach deposits frequently exhibit complex mineralogical compositions with lithium tightly bound to various minerals, requiring specialized separation techniques. The heterogeneity of these deposits demands customized extraction approaches rather than standardized methods, significantly increasing technical complexity and operational costs.

Energy requirements pose another substantial barrier. Traditional lithium extraction methods are energy-intensive, consuming approximately 500,000 gallons of water per metric ton of lithium produced. In remote locations, establishing reliable energy sources becomes prohibitively expensive and logistically challenging, limiting the viability of conventional extraction technologies.

Water management represents a critical constraint, particularly in arid regions where many lithium deposits are located. The substantial water requirements for traditional brine evaporation methods create significant sustainability concerns and operational challenges in water-scarce environments. Additionally, the environmental sensitivity of many remote areas necessitates extraction methods with minimal ecological footprint.

Equipment mobility and durability present technical hurdles unique to hard-to-reach areas. Conventional lithium extraction equipment is typically designed for permanent installation in accessible locations, not for deployment in remote, challenging environments. The need for portable, robust, and self-sufficient extraction systems requires fundamental redesign of existing technologies.

Data acquisition and real-time monitoring capabilities are severely limited in remote locations. The absence of reliable communication infrastructure hampers the implementation of advanced process control systems, predictive maintenance, and optimization algorithms that could enhance extraction efficiency and reduce operational risks.

Waste management poses significant technical challenges in isolated areas. The disposal or treatment of extraction byproducts becomes problematic without access to appropriate facilities, potentially leading to environmental contamination if not properly addressed. Developing closed-loop systems that minimize waste generation becomes essential but adds layers of technical complexity.

Scaling challenges further complicate extraction efforts. Technologies that work effectively in laboratory settings or small-scale operations often encounter unforeseen difficulties when deployed at commercial scale in remote environments, necessitating substantial engineering modifications and on-site adaptations.

The physical characteristics of lithium deposits in these areas further complicate extraction efforts. Hard-to-reach deposits frequently exhibit complex mineralogical compositions with lithium tightly bound to various minerals, requiring specialized separation techniques. The heterogeneity of these deposits demands customized extraction approaches rather than standardized methods, significantly increasing technical complexity and operational costs.

Energy requirements pose another substantial barrier. Traditional lithium extraction methods are energy-intensive, consuming approximately 500,000 gallons of water per metric ton of lithium produced. In remote locations, establishing reliable energy sources becomes prohibitively expensive and logistically challenging, limiting the viability of conventional extraction technologies.

Water management represents a critical constraint, particularly in arid regions where many lithium deposits are located. The substantial water requirements for traditional brine evaporation methods create significant sustainability concerns and operational challenges in water-scarce environments. Additionally, the environmental sensitivity of many remote areas necessitates extraction methods with minimal ecological footprint.

Equipment mobility and durability present technical hurdles unique to hard-to-reach areas. Conventional lithium extraction equipment is typically designed for permanent installation in accessible locations, not for deployment in remote, challenging environments. The need for portable, robust, and self-sufficient extraction systems requires fundamental redesign of existing technologies.

Data acquisition and real-time monitoring capabilities are severely limited in remote locations. The absence of reliable communication infrastructure hampers the implementation of advanced process control systems, predictive maintenance, and optimization algorithms that could enhance extraction efficiency and reduce operational risks.

Waste management poses significant technical challenges in isolated areas. The disposal or treatment of extraction byproducts becomes problematic without access to appropriate facilities, potentially leading to environmental contamination if not properly addressed. Developing closed-loop systems that minimize waste generation becomes essential but adds layers of technical complexity.

Scaling challenges further complicate extraction efforts. Technologies that work effectively in laboratory settings or small-scale operations often encounter unforeseen difficulties when deployed at commercial scale in remote environments, necessitating substantial engineering modifications and on-site adaptations.

Current DLE Solutions for Challenging Environments

01 Adsorption-based lithium extraction methods

Direct lithium extraction using adsorption techniques involves selective lithium capture from brine solutions using specialized adsorbent materials. These materials can selectively bind lithium ions while rejecting other ions present in the brine. The process typically includes adsorption, elution, and recovery steps, allowing for more efficient lithium recovery compared to traditional evaporation methods. This approach reduces water consumption and processing time while increasing lithium recovery rates.- Adsorption-based lithium extraction methods: Direct lithium extraction using adsorption techniques involves selective lithium capture from brines or other sources using specialized adsorbent materials. These materials are designed to preferentially bind lithium ions over other elements present in the solution. After adsorption, the lithium is typically recovered through desorption processes, often using acid or other eluents. This method offers advantages in terms of efficiency and selectivity compared to traditional evaporation pond methods.

- Membrane and electrochemical extraction technologies: Electrochemical methods for direct lithium extraction utilize ion-selective membranes and electrical potential to separate lithium from source solutions. These approaches include electrodialysis, electrochemical cells, and other membrane-based separation techniques that leverage the unique electrochemical properties of lithium ions. The technology allows for continuous processing and can achieve high recovery rates while minimizing water consumption and environmental impact compared to conventional methods.

- Solvent extraction and ion exchange processes: Solvent extraction and ion exchange technologies for direct lithium extraction involve the use of specialized chemical solutions or resins that selectively capture lithium ions from brines or other sources. These methods typically employ multiple stages of extraction and stripping to achieve high purity lithium compounds. The processes can be optimized for different brine compositions and offer advantages in terms of processing speed compared to traditional evaporation methods.

- Integrated lithium recovery systems: Integrated systems for direct lithium extraction combine multiple technologies and processes to optimize recovery efficiency and product quality. These systems often incorporate pre-treatment steps, primary extraction technologies, and downstream processing to produce battery-grade lithium compounds. The integrated approach addresses challenges such as impurity removal, process efficiency, and water management, creating comprehensive solutions for commercial lithium production from various sources.

- Geothermal brine and unconventional lithium source extraction: Specialized direct lithium extraction technologies have been developed for unconventional sources such as geothermal brines, oilfield produced water, and clay deposits. These methods address the unique challenges presented by these sources, including high temperatures, complex chemical compositions, and varying lithium concentrations. The technologies enable access to previously untapped lithium resources and often integrate with existing operations to provide economic and environmental benefits.

02 Membrane-based separation technologies

Membrane-based technologies for direct lithium extraction utilize specialized membranes that allow selective passage of lithium ions while blocking other elements. These systems may employ nanofiltration, electrodialysis, or ion-exchange membranes to achieve separation. The technology enables continuous processing of brine solutions with higher recovery rates and reduced environmental impact compared to conventional methods. Membrane systems can be designed for specific brine compositions and can operate effectively at various scales.Expand Specific Solutions03 Electrochemical lithium extraction processes

Electrochemical methods for direct lithium extraction utilize electrical potential differences to selectively recover lithium from brines and other sources. These processes may involve electrochemical cells with specialized electrodes that can capture lithium ions when current is applied. The captured lithium can then be released by reversing the electrical potential. This approach offers advantages including reduced chemical consumption, continuous operation capability, and the ability to process low-concentration lithium sources efficiently.Expand Specific Solutions04 Solvent extraction and chemical precipitation methods

Solvent extraction and chemical precipitation techniques for direct lithium extraction involve the use of specific chemicals or solvents that selectively react with or bind to lithium ions. These methods can include liquid-liquid extraction using specialized extractants or precipitation reactions that form lithium-containing solids. The processes typically include multiple stages for extraction, purification, and recovery of lithium compounds. These approaches can be tailored to specific brine compositions and can achieve high purity lithium products.Expand Specific Solutions05 Integrated lithium extraction systems and process optimization

Integrated systems for direct lithium extraction combine multiple technologies and process steps to optimize lithium recovery from various sources. These systems may incorporate pre-treatment steps, multiple extraction stages, and recovery processes designed to work together efficiently. Process optimization focuses on reducing energy consumption, minimizing waste generation, and maximizing lithium yield and purity. Advanced control systems and monitoring technologies are often employed to maintain optimal operating conditions throughout the extraction process.Expand Specific Solutions

Leading Companies in Remote Lithium Extraction

Direct Lithium Extraction (DLE) in hard-to-reach areas is currently in an early growth phase, with the market expanding rapidly due to increasing demand for lithium in battery technologies. The global DLE market is projected to reach significant scale as traditional extraction methods face sustainability challenges. Technologically, the field shows varying maturity levels, with companies like Lilac Solutions, EnergyX, and Vulcan Energy pioneering innovative approaches for challenging environments. POSCO Holdings and Schlumberger have leveraged their industrial expertise to develop specialized DLE technologies for remote operations. Academic institutions including Central South University and The University of Manchester are advancing fundamental research, while companies like Watercycle Technologies and Pure Lithium are developing modular systems specifically designed for deployment in logistically challenging regions.

Koch Technology Solutions LLC

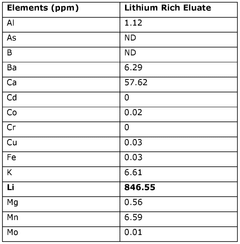

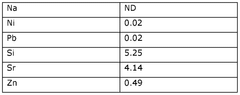

Technical Solution: Koch Technology Solutions has developed an advanced direct lithium extraction (DLE) platform specifically engineered for challenging and remote lithium resources. Their technology utilizes a proprietary selective adsorption process with customized adsorbent materials that can be tailored to specific brine chemistries. The system employs a continuous countercurrent extraction process that maximizes lithium recovery while minimizing reagent consumption. Koch's innovation lies in their modular, skid-mounted design that can be transported to remote locations with limited infrastructure. Each processing unit is engineered for minimal maintenance requirements, reducing the need for specialized personnel in isolated areas. The technology operates with significantly reduced water consumption compared to evaporation ponds, making it suitable for water-scarce regions. Koch has integrated advanced automation and remote monitoring capabilities, allowing for operation with minimal on-site personnel. Their system can process complex brines with high concentrations of interfering ions such as magnesium, calcium, and boron that would render traditional extraction methods uneconomical. The technology has been demonstrated in pilot operations in South America's lithium triangle, achieving lithium recovery rates exceeding 85% from challenging brine compositions.

Strengths: Highly customizable adsorption technology that can be optimized for specific brine chemistries; robust modular design suitable for remote deployment; advanced automation reducing on-site personnel requirements; significantly reduced water footprint. Weaknesses: Higher energy consumption compared to some competing DLE technologies; requires reliable chemical supply chains to remote locations; technology still being scaled to full commercial implementation; higher capital costs compared to traditional methods.

Lilac Solutions, Inc.

Technical Solution: Lilac Solutions has developed an ion exchange technology specifically designed for direct lithium extraction (DLE) in challenging environments. Their proprietary ion exchange beads selectively absorb lithium from brine solutions while rejecting other elements. The system operates as a continuous flow process where lithium-rich brine passes through modules containing these beads, which capture lithium ions and release them into a small volume of fresh solution, creating a concentrated lithium chloride product. This technology enables extraction from low-concentration, high-impurity brines that traditional evaporation ponds cannot economically process. Lilac's modular system can be deployed directly at remote wellheads, eliminating the need for large land areas and reducing water consumption by approximately 90% compared to evaporation methods. The company has demonstrated successful pilot operations in Argentina's lithium triangle, processing challenging brines with high magnesium content that would be uneconomical using conventional methods.

Strengths: Highly selective ion exchange technology that works with low-grade and high-impurity brines; modular design allows for deployment in remote locations; significantly reduced water footprint; faster extraction time (hours vs. months). Weaknesses: Requires reliable electricity supply in remote areas; higher upfront capital costs compared to traditional methods; technology still being scaled to commercial production levels.

Key Patents and Innovations in Remote Extraction Methods

Process and product

PatentPendingUS20250161879A1

Innovation

- The process involves contacting an aqueous lithium solution with a lithium sorbent to absorb lithium, followed by separation of the loaded sorbent and depleted solution, and subsequent treatment to regenerate the sorbent. This process utilizes pH control to maintain the lithium depleted solution at a pH of about 3 to 7 and employs ultrafiltration or nanofiltration membranes for separation.

Process and product

PatentWO2025105970A1

Innovation

- A DLE process using a lithium sorbent with a high specific surface area, combined with ultrafiltration or nanofiltration membranes for separation, and a pH-controlled upload step to optimize lithium absorption and reduce impurity carryover.

Environmental Impact Assessment of Remote DLE Operations

Direct Lithium Extraction (DLE) operations in remote and hard-to-reach areas present unique environmental challenges that require comprehensive assessment. The ecological footprint of these operations extends beyond the immediate extraction site, affecting surrounding ecosystems, water resources, and local communities in often sensitive environments.

Water usage represents one of the most significant environmental concerns for remote DLE operations. Unlike traditional evaporation methods, DLE technologies typically require less water overall but may still place substantial demands on local freshwater resources in areas where such resources are already scarce. Advanced DLE methods incorporating water recycling systems can reduce consumption by up to 90% compared to conventional extraction, though implementation in remote locations presents logistical challenges.

Land disturbance patterns differ markedly between remote DLE operations and traditional lithium extraction. While DLE facilities generally require smaller physical footprints than evaporation ponds, the infrastructure needed to access remote locations—including roads, power generation facilities, and transportation networks—can fragment habitats and disrupt wildlife migration patterns. Recent environmental impact studies indicate that careful site selection and infrastructure planning can mitigate these effects by up to 60%.

Emissions considerations for remote DLE operations must account for both direct operational emissions and those associated with power generation in off-grid locations. Diesel generators commonly used in remote areas produce significant carbon emissions—approximately 2.6 kg CO₂ per liter of fuel consumed. Integration of renewable energy sources, particularly solar and wind power, can substantially reduce this environmental burden, though initial implementation costs remain high.

Waste management presents particular challenges in hard-to-reach areas where disposal infrastructure is limited. DLE processes generate spent sorbents, filter materials, and chemical waste that require proper handling. Recent technological innovations have focused on developing biodegradable sorbents and closed-loop systems that minimize waste generation, though these solutions remain in early adoption phases for remote operations.

Ecosystem protection measures must be tailored to the specific environmental sensitivities of each extraction site. Remote areas often harbor unique or endangered species with limited ranges, making comprehensive baseline ecological surveys essential before operations commence. Continuous monitoring programs using remote sensing technologies and environmental DNA sampling can provide early warning of ecological impacts, allowing for adaptive management approaches.

Water usage represents one of the most significant environmental concerns for remote DLE operations. Unlike traditional evaporation methods, DLE technologies typically require less water overall but may still place substantial demands on local freshwater resources in areas where such resources are already scarce. Advanced DLE methods incorporating water recycling systems can reduce consumption by up to 90% compared to conventional extraction, though implementation in remote locations presents logistical challenges.

Land disturbance patterns differ markedly between remote DLE operations and traditional lithium extraction. While DLE facilities generally require smaller physical footprints than evaporation ponds, the infrastructure needed to access remote locations—including roads, power generation facilities, and transportation networks—can fragment habitats and disrupt wildlife migration patterns. Recent environmental impact studies indicate that careful site selection and infrastructure planning can mitigate these effects by up to 60%.

Emissions considerations for remote DLE operations must account for both direct operational emissions and those associated with power generation in off-grid locations. Diesel generators commonly used in remote areas produce significant carbon emissions—approximately 2.6 kg CO₂ per liter of fuel consumed. Integration of renewable energy sources, particularly solar and wind power, can substantially reduce this environmental burden, though initial implementation costs remain high.

Waste management presents particular challenges in hard-to-reach areas where disposal infrastructure is limited. DLE processes generate spent sorbents, filter materials, and chemical waste that require proper handling. Recent technological innovations have focused on developing biodegradable sorbents and closed-loop systems that minimize waste generation, though these solutions remain in early adoption phases for remote operations.

Ecosystem protection measures must be tailored to the specific environmental sensitivities of each extraction site. Remote areas often harbor unique or endangered species with limited ranges, making comprehensive baseline ecological surveys essential before operations commence. Continuous monitoring programs using remote sensing technologies and environmental DNA sampling can provide early warning of ecological impacts, allowing for adaptive management approaches.

Logistical Challenges and Infrastructure Requirements

Direct Lithium Extraction (DLE) in hard-to-reach areas presents significant logistical challenges that must be addressed through comprehensive infrastructure planning. The remote nature of many lithium-rich brine reservoirs, often located in mountainous regions, salt flats, or desert environments, creates fundamental access difficulties for equipment transportation and personnel deployment. These locations frequently lack basic infrastructure such as roads, reliable power sources, and water supply systems, which are essential for DLE operations.

Transportation infrastructure represents a primary concern, as heavy extraction equipment and processing machinery must be transported to sites with limited accessibility. This often necessitates the construction of temporary roads or the use of specialized vehicles capable of traversing difficult terrain. In some cases, helicopter transport may be required, significantly increasing operational costs and limiting the scale of equipment that can be deployed.

Energy requirements for DLE operations pose another substantial challenge. Most DLE technologies require consistent power supply for pumping, processing, and monitoring systems. In remote locations, this typically demands the establishment of independent power generation facilities, often utilizing diesel generators, solar arrays, or small-scale wind farms. The selection of appropriate energy solutions must balance operational requirements with environmental considerations and logistical feasibility.

Water management infrastructure presents a third critical challenge. While DLE processes are generally more water-efficient than traditional evaporation methods, they still require water for various operational aspects. In arid regions where many lithium deposits are found, water access is limited, necessitating either long-distance water transportation or the implementation of water recycling systems. The development of closed-loop water systems has become increasingly important to minimize environmental impact and operational costs.

Communication infrastructure is essential for remote monitoring, data collection, and safety protocols. Establishing reliable telecommunications in isolated areas often requires satellite systems or the construction of local communication networks, adding another layer of complexity to project planning and implementation.

Personnel accommodation and support facilities constitute another infrastructure requirement that is frequently overlooked. Extended operations in remote locations necessitate the construction of living quarters, medical facilities, and supply chain management systems to support the workforce. These facilities must be designed to withstand local environmental conditions while providing adequate comfort and safety for personnel.

The development of modular, scalable infrastructure solutions has emerged as a promising approach to addressing these challenges. Containerized processing units, portable power systems, and rapidly deployable camp facilities allow for more flexible operations and reduced initial capital expenditure. This approach enables companies to establish operations more quickly and adapt to changing conditions or extraction requirements.

Transportation infrastructure represents a primary concern, as heavy extraction equipment and processing machinery must be transported to sites with limited accessibility. This often necessitates the construction of temporary roads or the use of specialized vehicles capable of traversing difficult terrain. In some cases, helicopter transport may be required, significantly increasing operational costs and limiting the scale of equipment that can be deployed.

Energy requirements for DLE operations pose another substantial challenge. Most DLE technologies require consistent power supply for pumping, processing, and monitoring systems. In remote locations, this typically demands the establishment of independent power generation facilities, often utilizing diesel generators, solar arrays, or small-scale wind farms. The selection of appropriate energy solutions must balance operational requirements with environmental considerations and logistical feasibility.

Water management infrastructure presents a third critical challenge. While DLE processes are generally more water-efficient than traditional evaporation methods, they still require water for various operational aspects. In arid regions where many lithium deposits are found, water access is limited, necessitating either long-distance water transportation or the implementation of water recycling systems. The development of closed-loop water systems has become increasingly important to minimize environmental impact and operational costs.

Communication infrastructure is essential for remote monitoring, data collection, and safety protocols. Establishing reliable telecommunications in isolated areas often requires satellite systems or the construction of local communication networks, adding another layer of complexity to project planning and implementation.

Personnel accommodation and support facilities constitute another infrastructure requirement that is frequently overlooked. Extended operations in remote locations necessitate the construction of living quarters, medical facilities, and supply chain management systems to support the workforce. These facilities must be designed to withstand local environmental conditions while providing adequate comfort and safety for personnel.

The development of modular, scalable infrastructure solutions has emerged as a promising approach to addressing these challenges. Containerized processing units, portable power systems, and rapidly deployable camp facilities allow for more flexible operations and reduced initial capital expenditure. This approach enables companies to establish operations more quickly and adapt to changing conditions or extraction requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!