How to Design Efficient Systems for Hydrochloric Acid Usage?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl System Background

Hydrochloric acid (HCl) is a crucial chemical compound widely used in various industrial processes and applications. Its efficient usage and management are essential for both economic and environmental reasons. The design of efficient systems for HCl usage has become increasingly important as industries strive to optimize their processes and reduce their environmental footprint.

HCl is primarily produced as a byproduct of chlorine production through the chloralkali process. It is also generated during the production of organic compounds such as polyurethane foams, PVC, and other chlorinated hydrocarbons. The global production of HCl is estimated to be around 20 million tonnes annually, with demand expected to grow steadily in the coming years.

In industrial settings, HCl is commonly used in steel pickling, oil well acidizing, food processing, and the production of various chemicals. Its corrosive nature and potential environmental impact necessitate careful handling and efficient usage systems. The concentration of HCl used in these applications typically ranges from 30% to 37% by weight.

The design of efficient HCl usage systems must consider several key factors. These include material compatibility, as HCl is highly corrosive to many metals and alloys. Specialized materials such as high-silicon iron, tantalum, or certain plastics are often required for equipment that comes into contact with HCl. Safety considerations are paramount, given the hazardous nature of HCl, requiring robust containment, ventilation, and personal protective equipment.

Efficient HCl systems also incorporate advanced process control and monitoring technologies. These may include real-time concentration sensors, flow meters, and automated dosing systems to ensure precise control of HCl usage. Such systems help minimize waste, optimize process efficiency, and reduce the risk of accidents or environmental releases.

Recovery and recycling of HCl have become increasingly important aspects of efficient usage systems. Technologies such as azeotropic distillation, membrane separation, and adsorption processes are employed to recover and purify HCl from waste streams, reducing overall consumption and environmental impact.

The regulatory landscape surrounding HCl usage has evolved significantly in recent years. Stringent environmental regulations, such as the Clean Air Act in the United States and REACH in the European Union, have driven the development of more efficient and environmentally friendly HCl usage systems. These regulations often require industries to implement best available techniques (BAT) for HCl management and emissions control.

As industries continue to seek ways to improve their HCl usage efficiency, emerging technologies and innovative approaches are being explored. These include the development of novel catalysts for HCl synthesis and recovery, advanced materials for corrosion resistance, and integrated process intensification techniques that combine multiple unit operations to reduce HCl consumption and improve overall process efficiency.

HCl is primarily produced as a byproduct of chlorine production through the chloralkali process. It is also generated during the production of organic compounds such as polyurethane foams, PVC, and other chlorinated hydrocarbons. The global production of HCl is estimated to be around 20 million tonnes annually, with demand expected to grow steadily in the coming years.

In industrial settings, HCl is commonly used in steel pickling, oil well acidizing, food processing, and the production of various chemicals. Its corrosive nature and potential environmental impact necessitate careful handling and efficient usage systems. The concentration of HCl used in these applications typically ranges from 30% to 37% by weight.

The design of efficient HCl usage systems must consider several key factors. These include material compatibility, as HCl is highly corrosive to many metals and alloys. Specialized materials such as high-silicon iron, tantalum, or certain plastics are often required for equipment that comes into contact with HCl. Safety considerations are paramount, given the hazardous nature of HCl, requiring robust containment, ventilation, and personal protective equipment.

Efficient HCl systems also incorporate advanced process control and monitoring technologies. These may include real-time concentration sensors, flow meters, and automated dosing systems to ensure precise control of HCl usage. Such systems help minimize waste, optimize process efficiency, and reduce the risk of accidents or environmental releases.

Recovery and recycling of HCl have become increasingly important aspects of efficient usage systems. Technologies such as azeotropic distillation, membrane separation, and adsorption processes are employed to recover and purify HCl from waste streams, reducing overall consumption and environmental impact.

The regulatory landscape surrounding HCl usage has evolved significantly in recent years. Stringent environmental regulations, such as the Clean Air Act in the United States and REACH in the European Union, have driven the development of more efficient and environmentally friendly HCl usage systems. These regulations often require industries to implement best available techniques (BAT) for HCl management and emissions control.

As industries continue to seek ways to improve their HCl usage efficiency, emerging technologies and innovative approaches are being explored. These include the development of novel catalysts for HCl synthesis and recovery, advanced materials for corrosion resistance, and integrated process intensification techniques that combine multiple unit operations to reduce HCl consumption and improve overall process efficiency.

Market Analysis

The global market for hydrochloric acid has shown steady growth in recent years, driven by its widespread applications across various industries. The chemical sector remains the largest consumer of hydrochloric acid, utilizing it in the production of various chemicals and as a key reagent in numerous processes. The steel industry also represents a significant market segment, employing hydrochloric acid for pickling and descaling operations.

In the oil and gas sector, hydrochloric acid plays a crucial role in well acidizing and hydraulic fracturing processes, contributing to increased demand. The growing emphasis on water treatment and purification has further expanded the market, as hydrochloric acid is used in pH adjustment and chlorine production for water disinfection.

Geographically, Asia-Pacific dominates the hydrochloric acid market, with China being the largest producer and consumer. The region's rapid industrialization and expanding manufacturing sector continue to drive demand. North America and Europe follow, with mature markets characterized by stringent environmental regulations influencing consumption patterns.

The market is experiencing a shift towards higher-purity grades of hydrochloric acid, particularly in electronics and pharmaceutical industries. This trend is driving innovation in production and purification technologies to meet the stringent quality requirements of these sectors.

Environmental concerns and regulatory pressures are shaping the market dynamics. There is a growing focus on developing more sustainable production methods and implementing efficient recycling and recovery systems for hydrochloric acid. This has led to increased investment in closed-loop systems and technologies that minimize waste and emissions.

The construction industry's recovery in many regions has positively impacted the hydrochloric acid market, as it is used in the production of PVC and other construction materials. Additionally, the food industry's demand for hydrochloric acid in food processing and as a food additive has shown steady growth.

Market analysts project continued growth in the hydrochloric acid market, albeit at a moderate pace. Factors such as increasing industrial activities in emerging economies, growing demand from the water treatment sector, and ongoing technological advancements in production and application methods are expected to drive this growth. However, challenges such as price volatility of raw materials and environmental regulations may impact market dynamics, necessitating adaptive strategies from industry players.

In the oil and gas sector, hydrochloric acid plays a crucial role in well acidizing and hydraulic fracturing processes, contributing to increased demand. The growing emphasis on water treatment and purification has further expanded the market, as hydrochloric acid is used in pH adjustment and chlorine production for water disinfection.

Geographically, Asia-Pacific dominates the hydrochloric acid market, with China being the largest producer and consumer. The region's rapid industrialization and expanding manufacturing sector continue to drive demand. North America and Europe follow, with mature markets characterized by stringent environmental regulations influencing consumption patterns.

The market is experiencing a shift towards higher-purity grades of hydrochloric acid, particularly in electronics and pharmaceutical industries. This trend is driving innovation in production and purification technologies to meet the stringent quality requirements of these sectors.

Environmental concerns and regulatory pressures are shaping the market dynamics. There is a growing focus on developing more sustainable production methods and implementing efficient recycling and recovery systems for hydrochloric acid. This has led to increased investment in closed-loop systems and technologies that minimize waste and emissions.

The construction industry's recovery in many regions has positively impacted the hydrochloric acid market, as it is used in the production of PVC and other construction materials. Additionally, the food industry's demand for hydrochloric acid in food processing and as a food additive has shown steady growth.

Market analysts project continued growth in the hydrochloric acid market, albeit at a moderate pace. Factors such as increasing industrial activities in emerging economies, growing demand from the water treatment sector, and ongoing technological advancements in production and application methods are expected to drive this growth. However, challenges such as price volatility of raw materials and environmental regulations may impact market dynamics, necessitating adaptive strategies from industry players.

Technical Challenges

The design of efficient systems for hydrochloric acid usage faces several significant technical challenges. One of the primary concerns is the highly corrosive nature of hydrochloric acid, which necessitates the use of specialized materials for containment and transport. Traditional metals like steel are quickly degraded by the acid, leading to potential leaks and system failures. This has driven the need for advanced corrosion-resistant materials such as high-grade stainless steel, tantalum, or specialized polymers like PTFE (Teflon).

Another major challenge lies in the precise control and monitoring of acid concentration and flow rates. Hydrochloric acid's reactivity can vary significantly with concentration, and maintaining the optimal concentration for specific industrial processes is crucial. This requires sophisticated sensors and control systems capable of withstanding the harsh acidic environment while providing accurate, real-time data.

The storage and handling of hydrochloric acid present additional complexities. The acid can release hydrogen chloride gas, which is both toxic and corrosive. Designing effective ventilation systems and implementing robust safety protocols are essential to prevent worker exposure and environmental contamination. Furthermore, the potential for acid mist formation during transfer operations necessitates the development of specialized equipment to minimize emissions and ensure worker safety.

Temperature control is another critical aspect of efficient hydrochloric acid systems. The acid's properties can change significantly with temperature variations, affecting its reactivity and handling characteristics. Designing heating or cooling systems that can operate reliably in an acidic environment while maintaining precise temperature control is a substantial engineering challenge.

The disposal and neutralization of waste hydrochloric acid also present technical hurdles. Efficient systems must incorporate methods for safely neutralizing the acid before disposal, often requiring the precise addition of alkaline substances. This process must be carefully controlled to prevent excessive heat generation or the release of harmful byproducts.

Lastly, the integration of these systems into existing industrial processes poses significant challenges. Retrofitting older facilities to accommodate new, more efficient hydrochloric acid systems often requires innovative solutions to space constraints and compatibility issues with existing equipment. Engineers must develop modular, flexible designs that can be adapted to various industrial settings while maintaining high efficiency and safety standards.

Another major challenge lies in the precise control and monitoring of acid concentration and flow rates. Hydrochloric acid's reactivity can vary significantly with concentration, and maintaining the optimal concentration for specific industrial processes is crucial. This requires sophisticated sensors and control systems capable of withstanding the harsh acidic environment while providing accurate, real-time data.

The storage and handling of hydrochloric acid present additional complexities. The acid can release hydrogen chloride gas, which is both toxic and corrosive. Designing effective ventilation systems and implementing robust safety protocols are essential to prevent worker exposure and environmental contamination. Furthermore, the potential for acid mist formation during transfer operations necessitates the development of specialized equipment to minimize emissions and ensure worker safety.

Temperature control is another critical aspect of efficient hydrochloric acid systems. The acid's properties can change significantly with temperature variations, affecting its reactivity and handling characteristics. Designing heating or cooling systems that can operate reliably in an acidic environment while maintaining precise temperature control is a substantial engineering challenge.

The disposal and neutralization of waste hydrochloric acid also present technical hurdles. Efficient systems must incorporate methods for safely neutralizing the acid before disposal, often requiring the precise addition of alkaline substances. This process must be carefully controlled to prevent excessive heat generation or the release of harmful byproducts.

Lastly, the integration of these systems into existing industrial processes poses significant challenges. Retrofitting older facilities to accommodate new, more efficient hydrochloric acid systems often requires innovative solutions to space constraints and compatibility issues with existing equipment. Engineers must develop modular, flexible designs that can be adapted to various industrial settings while maintaining high efficiency and safety standards.

Current HCl Solutions

01 Hydrochloric acid recovery systems

Systems designed to recover and recycle hydrochloric acid from industrial processes, improving overall efficiency and reducing waste. These systems often involve distillation, absorption, or membrane separation techniques to purify and concentrate the acid for reuse.- Hydrochloric acid recovery and recycling systems: These systems focus on recovering and recycling hydrochloric acid from industrial processes, improving overall usage efficiency. They typically involve separation techniques, purification methods, and reintroduction of the recovered acid into the production cycle, reducing waste and minimizing the need for fresh acid input.

- Hydrochloric acid production optimization: This category includes methods and systems for optimizing the production of hydrochloric acid, focusing on improving yield, purity, and energy efficiency. These innovations may involve advanced reactor designs, catalytic processes, or novel synthesis routes to enhance the overall efficiency of hydrochloric acid production.

- Hydrochloric acid handling and storage improvements: These innovations focus on enhancing the handling, storage, and transportation of hydrochloric acid to minimize losses and improve safety. They may include specialized container designs, corrosion-resistant materials, and advanced monitoring systems to ensure efficient and safe management of hydrochloric acid throughout its lifecycle.

- Process integration for hydrochloric acid utilization: This category involves systems that integrate hydrochloric acid usage across multiple industrial processes or within a single complex process. By optimizing the flow and utilization of hydrochloric acid between different stages or units, these systems aim to maximize efficiency and minimize waste, often through heat integration, byproduct utilization, or cascading use strategies.

- Advanced control and monitoring systems for hydrochloric acid usage: These systems employ sophisticated control and monitoring technologies to optimize hydrochloric acid usage in real-time. They may include sensors, data analytics, and automated control systems that adjust acid dosing, concentration, or flow rates based on process conditions, ensuring maximum efficiency and minimizing overconsumption or waste.

02 Hydrochloric acid production optimization

Methods and systems for optimizing the production of hydrochloric acid, including improved reactor designs, catalysts, and process control strategies. These innovations aim to increase yield, reduce energy consumption, and minimize byproduct formation during acid production.Expand Specific Solutions03 Hydrochloric acid handling and storage solutions

Specialized equipment and systems for the safe and efficient handling, storage, and transportation of hydrochloric acid. This includes corrosion-resistant materials, advanced pumping systems, and innovative tank designs to minimize losses and ensure worker safety.Expand Specific Solutions04 Hydrochloric acid purification techniques

Advanced methods for purifying hydrochloric acid to remove contaminants and increase its quality for various industrial applications. These techniques may involve adsorption, ion exchange, or advanced filtration processes to achieve high-purity acid.Expand Specific Solutions05 Hydrochloric acid usage optimization in specific industries

Tailored systems and processes for optimizing hydrochloric acid usage in specific industries such as metal processing, chemical manufacturing, and water treatment. These solutions focus on reducing acid consumption, improving process efficiency, and minimizing environmental impact.Expand Specific Solutions

Industry Leaders

The hydrochloric acid usage systems market is in a mature stage, with established players and well-developed technologies. The global market size for hydrochloric acid is substantial, driven by diverse industrial applications. Technologically, the focus is on improving efficiency, safety, and environmental sustainability. Companies like Covestro Deutschland AG, Tokuyama Corp., and Wacker Chemie AG are at the forefront, leveraging their extensive chemical industry experience to develop advanced systems. Emerging players such as Jiangyin Jianghua Micro-electronics Materials Co., Ltd. and Runma Chemical are also making significant contributions, particularly in the electronics sector. The competitive landscape is characterized by ongoing innovation in process optimization, corrosion-resistant materials, and waste reduction techniques.

Covestro Deutschland AG

Technical Solution: Covestro has developed an innovative system for efficient hydrochloric acid usage in their polycarbonate production process. They employ a closed-loop recycling system that captures and purifies HCl byproduct for reuse in the production cycle. This system incorporates advanced membrane separation technology and thermal regeneration processes to recover high-purity HCl[1]. The company has also implemented real-time monitoring and control systems to optimize HCl consumption and minimize waste. Additionally, Covestro has invested in corrosion-resistant materials and equipment to enhance the longevity and safety of their HCl handling systems[2].

Strengths: Reduced raw material costs, minimized environmental impact, and improved process efficiency. Weaknesses: High initial investment costs and complexity in system integration.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced systems for efficient hydrochloric acid usage in oil and gas well stimulation. Their technology includes a precise acid delivery system that optimizes the placement and concentration of HCl in the wellbore. They utilize real-time downhole sensors to monitor acid concentration and pH levels, allowing for dynamic adjustment of acid injection rates[3]. Schlumberger's system also incorporates a novel acid diversion technique using degradable particles, which ensures uniform distribution of acid across the target formation[4]. Furthermore, they have implemented a closed-loop acid management system that recycles and reuses spent acid, significantly reducing waste and environmental impact.

Strengths: Enhanced well productivity, reduced acid consumption, and improved environmental sustainability. Weaknesses: High operational costs and potential complexity in field implementation.

Key HCl Innovations

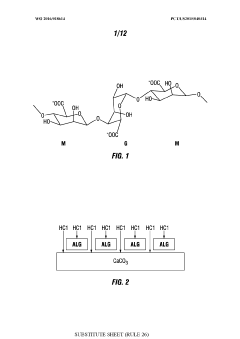

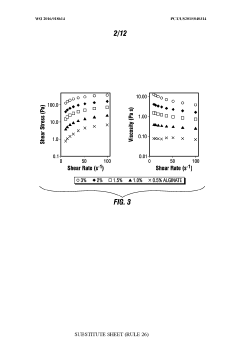

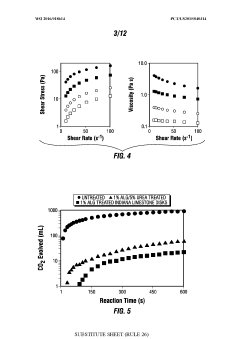

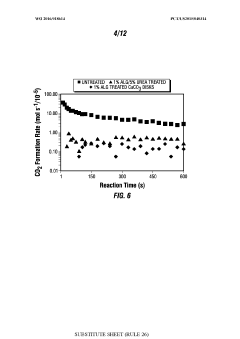

Fluid systems and methods for treating subterranean formations

PatentWO2016018614A1

Innovation

- The use of treatment fluids comprising multivalent-cation reacting polymers, fatty acids with ethanolamine, insoluble calcium salt compounds, urea derivatives, and polyvinylpyrrolidone (PVP) to form protective films on carbonate surfaces, allowing controlled acid penetration and stimulation, reducing acid consumption and equipment damage.

Mixing device

PatentActiveUS20180147548A1

Innovation

- A mixing device that produces fluidic vortices within a chamber with strategically placed apertures to stabilize HOCl, allowing for its production without electrolysis or chlorine gas, and using a weaker acid like acetic acid to control pH and proton concentration, enabling stable storage for several months.

Safety Regulations

Safety regulations play a crucial role in designing efficient systems for hydrochloric acid usage. These regulations are established to protect workers, the environment, and the general public from the potential hazards associated with this corrosive substance. Compliance with these regulations is not only a legal requirement but also essential for maintaining operational efficiency and minimizing risks.

One of the primary safety regulations for hydrochloric acid systems is the proper storage and handling of the chemical. Storage tanks and containers must be constructed of materials resistant to acid corrosion, such as high-density polyethylene or fiberglass-reinforced plastic. These containers should be equipped with secondary containment systems to prevent spills from spreading in case of a leak. Regular inspections and maintenance of storage facilities are mandatory to ensure their integrity and prevent potential accidents.

Personal protective equipment (PPE) is another critical aspect of safety regulations. Workers handling hydrochloric acid must wear appropriate PPE, including chemical-resistant gloves, goggles, face shields, and protective clothing. Respiratory protection may also be required in certain situations, especially when there is a risk of acid vapor inhalation. Employers are responsible for providing and maintaining this equipment, as well as training employees on its proper use.

Emergency response procedures are an integral part of safety regulations for hydrochloric acid systems. Facilities must have clearly defined protocols for handling spills, leaks, and other emergencies. This includes the installation of emergency showers and eyewash stations in easily accessible locations. Workers should be trained in emergency response procedures, including the proper use of neutralizing agents and spill containment materials.

Ventilation requirements are another crucial aspect of safety regulations. Adequate ventilation systems must be in place to prevent the accumulation of acid vapors, which can be harmful if inhaled. This may include the use of local exhaust ventilation systems near areas where acid is handled or processed. Regular air quality monitoring should be conducted to ensure that exposure levels remain within safe limits.

Transportation of hydrochloric acid is subject to strict regulations to prevent accidents during transit. This includes proper labeling of containers, use of appropriate transport vehicles, and adherence to specific routing requirements. Drivers transporting hydrochloric acid must be trained in handling hazardous materials and equipped with necessary emergency response equipment.

Safety regulations also mandate the implementation of comprehensive risk assessment and management programs. This involves identifying potential hazards associated with hydrochloric acid usage, evaluating the likelihood and severity of potential incidents, and implementing appropriate control measures. Regular safety audits and reviews should be conducted to ensure ongoing compliance and identify areas for improvement.

In conclusion, designing efficient systems for hydrochloric acid usage requires a thorough understanding and implementation of safety regulations. These regulations encompass various aspects, from proper storage and handling to emergency response procedures and risk management. By adhering to these regulations, companies can ensure the safety of their workers and the environment while maintaining operational efficiency.

One of the primary safety regulations for hydrochloric acid systems is the proper storage and handling of the chemical. Storage tanks and containers must be constructed of materials resistant to acid corrosion, such as high-density polyethylene or fiberglass-reinforced plastic. These containers should be equipped with secondary containment systems to prevent spills from spreading in case of a leak. Regular inspections and maintenance of storage facilities are mandatory to ensure their integrity and prevent potential accidents.

Personal protective equipment (PPE) is another critical aspect of safety regulations. Workers handling hydrochloric acid must wear appropriate PPE, including chemical-resistant gloves, goggles, face shields, and protective clothing. Respiratory protection may also be required in certain situations, especially when there is a risk of acid vapor inhalation. Employers are responsible for providing and maintaining this equipment, as well as training employees on its proper use.

Emergency response procedures are an integral part of safety regulations for hydrochloric acid systems. Facilities must have clearly defined protocols for handling spills, leaks, and other emergencies. This includes the installation of emergency showers and eyewash stations in easily accessible locations. Workers should be trained in emergency response procedures, including the proper use of neutralizing agents and spill containment materials.

Ventilation requirements are another crucial aspect of safety regulations. Adequate ventilation systems must be in place to prevent the accumulation of acid vapors, which can be harmful if inhaled. This may include the use of local exhaust ventilation systems near areas where acid is handled or processed. Regular air quality monitoring should be conducted to ensure that exposure levels remain within safe limits.

Transportation of hydrochloric acid is subject to strict regulations to prevent accidents during transit. This includes proper labeling of containers, use of appropriate transport vehicles, and adherence to specific routing requirements. Drivers transporting hydrochloric acid must be trained in handling hazardous materials and equipped with necessary emergency response equipment.

Safety regulations also mandate the implementation of comprehensive risk assessment and management programs. This involves identifying potential hazards associated with hydrochloric acid usage, evaluating the likelihood and severity of potential incidents, and implementing appropriate control measures. Regular safety audits and reviews should be conducted to ensure ongoing compliance and identify areas for improvement.

In conclusion, designing efficient systems for hydrochloric acid usage requires a thorough understanding and implementation of safety regulations. These regulations encompass various aspects, from proper storage and handling to emergency response procedures and risk management. By adhering to these regulations, companies can ensure the safety of their workers and the environment while maintaining operational efficiency.

Environmental Impact

The environmental impact of hydrochloric acid usage in industrial systems is a critical consideration for efficient design. Hydrochloric acid, while essential in many processes, poses significant risks to ecosystems and human health if not properly managed. Efficient systems must incorporate robust containment measures to prevent accidental releases and spills. This includes corrosion-resistant materials for storage tanks, pipelines, and processing equipment, as well as secondary containment structures to capture potential leaks.

Emissions control is another crucial aspect of environmental protection in hydrochloric acid systems. Scrubbers and absorption towers are commonly employed to neutralize acid vapors before they are released into the atmosphere. These systems can be optimized for energy efficiency and effectiveness by carefully selecting packing materials and controlling liquid-to-gas ratios. Additionally, closed-loop systems that recycle and reuse hydrochloric acid can significantly reduce overall consumption and minimize waste generation.

Water pollution is a major concern in hydrochloric acid applications. Efficient systems should incorporate wastewater treatment facilities capable of neutralizing acidic effluents before discharge. This may involve pH adjustment, precipitation of heavy metals, and filtration processes. Advanced treatment technologies, such as ion exchange or membrane filtration, can further improve water quality and enable water reuse within the facility, reducing overall environmental impact.

Lifecycle assessment (LCA) is an invaluable tool for evaluating the environmental footprint of hydrochloric acid systems. By considering raw material extraction, production, transportation, use, and disposal, designers can identify opportunities for improvement across the entire value chain. This holistic approach may reveal unexpected environmental hotspots and guide decision-making towards more sustainable alternatives.

Energy efficiency is another key factor in reducing the environmental impact of hydrochloric acid systems. Heat recovery systems, such as heat exchangers and thermal insulation, can minimize energy losses and reduce the carbon footprint associated with acid production and use. Furthermore, the integration of renewable energy sources, like solar or wind power, can further decrease reliance on fossil fuels and associated greenhouse gas emissions.

Biodiversity protection must also be addressed in the design of efficient hydrochloric acid systems. This includes careful site selection to avoid sensitive ecosystems, implementation of buffer zones, and monitoring programs to detect and mitigate potential impacts on local flora and fauna. Emergency response plans should be developed to address accidental releases and minimize ecological damage in worst-case scenarios.

Emissions control is another crucial aspect of environmental protection in hydrochloric acid systems. Scrubbers and absorption towers are commonly employed to neutralize acid vapors before they are released into the atmosphere. These systems can be optimized for energy efficiency and effectiveness by carefully selecting packing materials and controlling liquid-to-gas ratios. Additionally, closed-loop systems that recycle and reuse hydrochloric acid can significantly reduce overall consumption and minimize waste generation.

Water pollution is a major concern in hydrochloric acid applications. Efficient systems should incorporate wastewater treatment facilities capable of neutralizing acidic effluents before discharge. This may involve pH adjustment, precipitation of heavy metals, and filtration processes. Advanced treatment technologies, such as ion exchange or membrane filtration, can further improve water quality and enable water reuse within the facility, reducing overall environmental impact.

Lifecycle assessment (LCA) is an invaluable tool for evaluating the environmental footprint of hydrochloric acid systems. By considering raw material extraction, production, transportation, use, and disposal, designers can identify opportunities for improvement across the entire value chain. This holistic approach may reveal unexpected environmental hotspots and guide decision-making towards more sustainable alternatives.

Energy efficiency is another key factor in reducing the environmental impact of hydrochloric acid systems. Heat recovery systems, such as heat exchangers and thermal insulation, can minimize energy losses and reduce the carbon footprint associated with acid production and use. Furthermore, the integration of renewable energy sources, like solar or wind power, can further decrease reliance on fossil fuels and associated greenhouse gas emissions.

Biodiversity protection must also be addressed in the design of efficient hydrochloric acid systems. This includes careful site selection to avoid sensitive ecosystems, implementation of buffer zones, and monitoring programs to detect and mitigate potential impacts on local flora and fauna. Emergency response plans should be developed to address accidental releases and minimize ecological damage in worst-case scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!