Hydrochloric Acid: Pioneering Biodegradable Material Production

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl in Biodegradable Materials: Background and Objectives

The development of biodegradable materials has gained significant attention in recent years due to growing environmental concerns and the need for sustainable alternatives to traditional plastics. Hydrochloric acid (HCl) has emerged as a potential key component in the production of these eco-friendly materials, offering unique properties and advantages in the manufacturing process.

Historically, the use of HCl in material science has been primarily focused on its role as a strong acid in various chemical reactions. However, recent advancements in polymer chemistry and materials engineering have opened up new possibilities for utilizing HCl in the synthesis of biodegradable polymers and composites. This shift in focus represents a paradigm change in how we approach the development of sustainable materials.

The primary objective of researching HCl for biodegradable material production is to harness its chemical properties to create materials that can decompose naturally in the environment without leaving harmful residues. This aligns with the global push towards circular economy principles and the reduction of plastic waste accumulation in ecosystems.

One of the key areas of interest is the potential of HCl to catalyze the polymerization of bio-based monomers, such as those derived from agricultural waste or renewable resources. By controlling the acid-catalyzed reactions, researchers aim to develop biodegradable polymers with tailored properties, including strength, flexibility, and degradation rates.

Another promising avenue is the use of HCl in the modification of natural polymers like cellulose, chitin, and starch. These abundant biopolymers can be chemically altered using HCl to enhance their processability and expand their range of applications while maintaining their inherent biodegradability.

The integration of HCl in biodegradable material production also presents opportunities for improving the efficiency and cost-effectiveness of manufacturing processes. By optimizing reaction conditions and developing novel synthesis routes, researchers aim to make biodegradable materials more competitive with conventional plastics in terms of production costs and scalability.

As the field progresses, there is a growing focus on understanding the environmental impact of HCl-based processes and ensuring that the entire lifecycle of the resulting materials aligns with sustainability goals. This includes investigating the potential for recycling or recovering HCl used in production, as well as assessing the degradation products and their effects on various ecosystems.

The research on using HCl for pioneering biodegradable material production is part of a broader technological evolution towards more sustainable and environmentally responsible manufacturing practices. By exploring innovative applications of this common chemical, scientists and engineers are paving the way for a new generation of materials that can meet the functional requirements of modern products while addressing urgent environmental challenges.

Historically, the use of HCl in material science has been primarily focused on its role as a strong acid in various chemical reactions. However, recent advancements in polymer chemistry and materials engineering have opened up new possibilities for utilizing HCl in the synthesis of biodegradable polymers and composites. This shift in focus represents a paradigm change in how we approach the development of sustainable materials.

The primary objective of researching HCl for biodegradable material production is to harness its chemical properties to create materials that can decompose naturally in the environment without leaving harmful residues. This aligns with the global push towards circular economy principles and the reduction of plastic waste accumulation in ecosystems.

One of the key areas of interest is the potential of HCl to catalyze the polymerization of bio-based monomers, such as those derived from agricultural waste or renewable resources. By controlling the acid-catalyzed reactions, researchers aim to develop biodegradable polymers with tailored properties, including strength, flexibility, and degradation rates.

Another promising avenue is the use of HCl in the modification of natural polymers like cellulose, chitin, and starch. These abundant biopolymers can be chemically altered using HCl to enhance their processability and expand their range of applications while maintaining their inherent biodegradability.

The integration of HCl in biodegradable material production also presents opportunities for improving the efficiency and cost-effectiveness of manufacturing processes. By optimizing reaction conditions and developing novel synthesis routes, researchers aim to make biodegradable materials more competitive with conventional plastics in terms of production costs and scalability.

As the field progresses, there is a growing focus on understanding the environmental impact of HCl-based processes and ensuring that the entire lifecycle of the resulting materials aligns with sustainability goals. This includes investigating the potential for recycling or recovering HCl used in production, as well as assessing the degradation products and their effects on various ecosystems.

The research on using HCl for pioneering biodegradable material production is part of a broader technological evolution towards more sustainable and environmentally responsible manufacturing practices. By exploring innovative applications of this common chemical, scientists and engineers are paving the way for a new generation of materials that can meet the functional requirements of modern products while addressing urgent environmental challenges.

Market Analysis for Eco-friendly Materials

The market for eco-friendly materials has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. The global biodegradable plastics market, which includes materials potentially produced using hydrochloric acid, is projected to reach $6.12 billion by 2025, growing at a CAGR of 21.3% from 2020 to 2025.

Consumer demand for sustainable packaging solutions has been a key driver in this market expansion. Major retailers and consumer goods companies have made commitments to increase their use of recyclable, reusable, or compostable packaging, creating a substantial market opportunity for innovative biodegradable materials. The food and beverage industry, in particular, has shown strong interest in eco-friendly packaging alternatives, accounting for over 40% of the biodegradable plastics market share.

The automotive and electronics sectors are also emerging as significant consumers of biodegradable materials. These industries are exploring ways to incorporate eco-friendly components into their products to meet sustainability goals and comply with evolving environmental regulations. The automotive sector's demand for biodegradable materials is expected to grow at a CAGR of 18.7% from 2020 to 2025.

Geographically, Europe leads the market for eco-friendly materials, followed by North America and Asia-Pacific. European countries have implemented strict regulations on single-use plastics, driving the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization and increasing environmental concerns in countries like China and India.

The use of hydrochloric acid in biodegradable material production could potentially address some of the challenges faced by current biodegradable plastics, such as durability and cost-effectiveness. If successful, this innovative approach could disrupt the existing market dynamics and create new opportunities for growth.

However, the market for eco-friendly materials also faces challenges. The higher cost of production compared to traditional plastics remains a significant barrier to widespread adoption. Additionally, there is a need for improved waste management infrastructure to properly handle and process biodegradable materials at their end-of-life stage.

Despite these challenges, the overall market outlook for eco-friendly materials remains positive. Government initiatives, such as bans on single-use plastics and incentives for sustainable practices, are expected to further boost market growth. As research and development efforts continue to improve the performance and reduce the cost of biodegradable materials, their market penetration is likely to increase across various industries.

Consumer demand for sustainable packaging solutions has been a key driver in this market expansion. Major retailers and consumer goods companies have made commitments to increase their use of recyclable, reusable, or compostable packaging, creating a substantial market opportunity for innovative biodegradable materials. The food and beverage industry, in particular, has shown strong interest in eco-friendly packaging alternatives, accounting for over 40% of the biodegradable plastics market share.

The automotive and electronics sectors are also emerging as significant consumers of biodegradable materials. These industries are exploring ways to incorporate eco-friendly components into their products to meet sustainability goals and comply with evolving environmental regulations. The automotive sector's demand for biodegradable materials is expected to grow at a CAGR of 18.7% from 2020 to 2025.

Geographically, Europe leads the market for eco-friendly materials, followed by North America and Asia-Pacific. European countries have implemented strict regulations on single-use plastics, driving the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization and increasing environmental concerns in countries like China and India.

The use of hydrochloric acid in biodegradable material production could potentially address some of the challenges faced by current biodegradable plastics, such as durability and cost-effectiveness. If successful, this innovative approach could disrupt the existing market dynamics and create new opportunities for growth.

However, the market for eco-friendly materials also faces challenges. The higher cost of production compared to traditional plastics remains a significant barrier to widespread adoption. Additionally, there is a need for improved waste management infrastructure to properly handle and process biodegradable materials at their end-of-life stage.

Despite these challenges, the overall market outlook for eco-friendly materials remains positive. Government initiatives, such as bans on single-use plastics and incentives for sustainable practices, are expected to further boost market growth. As research and development efforts continue to improve the performance and reduce the cost of biodegradable materials, their market penetration is likely to increase across various industries.

Current Challenges in HCl-based Biodegradable Production

The production of biodegradable materials using hydrochloric acid (HCl) faces several significant challenges that hinder its widespread adoption and commercial viability. One of the primary obstacles is the corrosive nature of HCl, which poses safety risks and requires specialized equipment and handling procedures. This necessitates substantial investments in infrastructure and safety measures, increasing production costs and complexity.

Another major challenge lies in controlling the reaction kinetics when using HCl in biodegradable material synthesis. The high reactivity of HCl can lead to rapid and sometimes unpredictable reactions, making it difficult to maintain consistent product quality and properties. This variability can result in materials with inconsistent degradation rates or mechanical properties, limiting their applicability in various industries.

The environmental impact of HCl-based production processes also presents a significant hurdle. Despite the end product being biodegradable, the use of HCl in manufacturing can generate harmful byproducts and emissions. Addressing these environmental concerns requires the development of efficient waste treatment and neutralization systems, further adding to the complexity and cost of production.

Scaling up HCl-based biodegradable material production from laboratory to industrial levels presents its own set of challenges. The process optimization required for large-scale production often involves overcoming issues related to heat management, mixing efficiency, and maintaining uniform reaction conditions across larger volumes. These factors can significantly impact the quality and consistency of the final product.

Moreover, the sourcing and transportation of HCl in large quantities for industrial-scale production pose logistical and safety challenges. The hazardous nature of HCl requires specialized transportation and storage facilities, adding to the overall operational complexity and costs.

The regulatory landscape surrounding the use of HCl in biodegradable material production is another area of concern. Stringent safety and environmental regulations may impose additional requirements on manufacturers, necessitating extensive documentation, monitoring, and compliance measures. These regulatory hurdles can slow down innovation and increase the time-to-market for new biodegradable products.

Lastly, the economic viability of HCl-based biodegradable materials remains a significant challenge. The high production costs associated with specialized equipment, safety measures, and environmental controls can make these materials less competitive compared to traditional non-biodegradable alternatives or other biodegradable options. Overcoming this economic barrier requires further research into cost-effective production methods and the development of high-value applications that can justify the increased production expenses.

Another major challenge lies in controlling the reaction kinetics when using HCl in biodegradable material synthesis. The high reactivity of HCl can lead to rapid and sometimes unpredictable reactions, making it difficult to maintain consistent product quality and properties. This variability can result in materials with inconsistent degradation rates or mechanical properties, limiting their applicability in various industries.

The environmental impact of HCl-based production processes also presents a significant hurdle. Despite the end product being biodegradable, the use of HCl in manufacturing can generate harmful byproducts and emissions. Addressing these environmental concerns requires the development of efficient waste treatment and neutralization systems, further adding to the complexity and cost of production.

Scaling up HCl-based biodegradable material production from laboratory to industrial levels presents its own set of challenges. The process optimization required for large-scale production often involves overcoming issues related to heat management, mixing efficiency, and maintaining uniform reaction conditions across larger volumes. These factors can significantly impact the quality and consistency of the final product.

Moreover, the sourcing and transportation of HCl in large quantities for industrial-scale production pose logistical and safety challenges. The hazardous nature of HCl requires specialized transportation and storage facilities, adding to the overall operational complexity and costs.

The regulatory landscape surrounding the use of HCl in biodegradable material production is another area of concern. Stringent safety and environmental regulations may impose additional requirements on manufacturers, necessitating extensive documentation, monitoring, and compliance measures. These regulatory hurdles can slow down innovation and increase the time-to-market for new biodegradable products.

Lastly, the economic viability of HCl-based biodegradable materials remains a significant challenge. The high production costs associated with specialized equipment, safety measures, and environmental controls can make these materials less competitive compared to traditional non-biodegradable alternatives or other biodegradable options. Overcoming this economic barrier requires further research into cost-effective production methods and the development of high-value applications that can justify the increased production expenses.

Existing HCl-based Biodegradable Production Methods

01 Biodegradation of hydrochloric acid in wastewater treatment

Hydrochloric acid can be biodegraded in wastewater treatment processes. Certain microorganisms are capable of neutralizing or metabolizing the acid, converting it into less harmful substances. This biological treatment approach is often used in conjunction with other methods to effectively manage hydrochloric acid-containing wastewater.- Biodegradation of hydrochloric acid in wastewater treatment: Hydrochloric acid can be biodegraded in wastewater treatment processes. Certain microorganisms are capable of neutralizing or metabolizing the acid, contributing to its removal from wastewater. This biological treatment approach is often used in conjunction with other methods to effectively manage hydrochloric acid-containing effluents.

- Neutralization and conversion of hydrochloric acid: Hydrochloric acid can be neutralized or converted into less harmful compounds through various chemical processes. These methods often involve the use of alkaline substances or specific reagents to transform the acid into salts or other biodegradable compounds, facilitating its breakdown in the environment.

- Environmental impact and degradation of hydrochloric acid: While hydrochloric acid itself is not biodegradable, it can be naturally neutralized in the environment over time. The acid's environmental impact depends on factors such as concentration, pH of the receiving environment, and the presence of buffering substances. In aquatic ecosystems, dilution and reaction with minerals can contribute to its degradation.

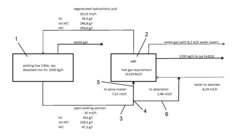

- Recovery and recycling of hydrochloric acid: Instead of biodegradation, hydrochloric acid can be recovered and recycled in industrial processes. Various technologies exist for the separation, purification, and reuse of hydrochloric acid from waste streams, reducing environmental impact and promoting circular economy principles in chemical manufacturing.

- Alternatives to hydrochloric acid with improved biodegradability: Research is ongoing to develop alternatives to hydrochloric acid with improved environmental profiles. These alternatives may include organic acids or other compounds that offer similar functional properties but demonstrate enhanced biodegradability or reduced ecological impact compared to traditional hydrochloric acid.

02 Neutralization and conversion of hydrochloric acid

Chemical processes can be employed to neutralize hydrochloric acid or convert it into less harmful compounds. This may involve the use of alkaline substances or specific chemical reactions that transform the acid into biodegradable or environmentally friendly products. Such methods are often applied in industrial settings to manage hydrochloric acid waste.Expand Specific Solutions03 Environmental impact and biodegradability assessment

Studies and assessments are conducted to evaluate the environmental impact and biodegradability of hydrochloric acid. These investigations consider factors such as concentration, pH, and the presence of other substances in the environment. The results help in developing appropriate disposal and treatment strategies for hydrochloric acid-containing waste.Expand Specific Solutions04 Hydrochloric acid recovery and recycling

Technologies and methods have been developed to recover and recycle hydrochloric acid from industrial processes. These approaches aim to reduce the environmental impact by minimizing the release of the acid into the environment. Recovered hydrochloric acid can be purified and reused in various applications, promoting a more sustainable use of resources.Expand Specific Solutions05 Biodegradable alternatives to hydrochloric acid

Research is being conducted to develop biodegradable alternatives that can replace hydrochloric acid in certain applications. These alternatives aim to provide similar functionality while being more environmentally friendly and easier to biodegrade. Such innovations can help reduce the environmental impact associated with the use and disposal of hydrochloric acid.Expand Specific Solutions

Key Players in Biodegradable Material Industry

The research on using Hydrochloric Acid for pioneering biodegradable material production is in an early developmental stage, with a growing market potential due to increasing environmental concerns. The technology's maturity is still evolving, with various companies and research institutions exploring its applications. Key players like LG Chem Ltd., Arkema France SA, and Novamont SpA are investing in this field, leveraging their expertise in chemical engineering and sustainable materials. Universities such as Xinjiang University and East China University of Science & Technology are contributing to academic research, while companies like Covestro Deutschland AG and CJ CheilJedang Corp. are exploring commercial applications. The competitive landscape is diverse, with both established chemical companies and innovative startups vying for market share in this emerging sector.

Arkema France SA

Technical Solution: Arkema France SA has developed a pioneering approach to biodegradable material production using hydrochloric acid (HCl) as a key component. Their process involves the controlled degradation of biopolymers through HCl-catalyzed hydrolysis, resulting in tailored biodegradable materials with specific degradation rates[1]. The company has optimized the reaction conditions to achieve a balance between material properties and biodegradability, utilizing a proprietary reactor design that allows for precise control of HCl concentration and reaction time[3]. This method enables the production of materials with a wide range of applications, from packaging to agricultural films, with degradation times ranging from weeks to months depending on the environmental conditions[5].

Strengths: Precise control over biodegradation rates, versatile application range, and ability to tailor material properties. Weaknesses: Potential environmental concerns related to HCl use and the need for specialized handling and disposal procedures.

Novamont SpA

Technical Solution: Novamont SpA has pioneered a novel approach to biodegradable material production incorporating hydrochloric acid (HCl) in their process. Their innovative technique involves the controlled depolymerization of renewable feedstocks using HCl as a catalyst, followed by a repolymerization step to create customized biodegradable polymers[2]. The company has developed a closed-loop system that efficiently recycles and neutralizes the HCl, minimizing environmental impact[4]. Novamont's process allows for the production of a diverse range of biodegradable materials with varying properties, suitable for applications in packaging, agriculture, and consumer goods[6]. Their materials have shown improved mechanical properties and controlled biodegradation rates compared to conventional biodegradable plastics[8].

Strengths: Efficient use of renewable resources, closed-loop HCl recycling system, and versatile material properties. Weaknesses: Potential higher production costs and the need for specialized equipment for HCl handling.

Innovative HCl Applications in Material Science

Method And Device For Regenerating Hydrochloric Acid

PatentActiveUS20160244330A1

Innovation

- A method where the hydrochloric acid solution is split into two partial flows, with only one partial flow undergoing pyrohydrolytic treatment and the other fed directly to an absorption column, allowing for increased metal concentration and reduced energy consumption by minimizing water evaporation and fuel usage.

HYDROCHLORIC ACID RECOVERY AND REGENERATION PROCESS WITH SULFATE PRODUCTION

PatentInactiveBR102022004827A2

Innovation

- A process that regenerates hydrochloric acid by reacting exhausted acid with sulfuric acid, producing zinc sulfate and iron sulfate, utilizing a reactor with heating and agitation, followed by concentration and absorption, allowing the acid to be reused and the sulfates to be used in various industries.

Environmental Impact Assessment

The use of hydrochloric acid in biodegradable material production presents both opportunities and challenges from an environmental perspective. This assessment examines the potential impacts on ecosystems, human health, and overall environmental sustainability.

Hydrochloric acid, when used in controlled industrial processes, can contribute to the development of innovative biodegradable materials. These materials have the potential to reduce long-term environmental pollution by replacing conventional plastics and other non-biodegradable products. The biodegradation process of these materials typically results in less harmful residues compared to traditional plastics, potentially reducing the accumulation of microplastics in marine and terrestrial ecosystems.

However, the production and handling of hydrochloric acid pose significant environmental risks. Accidental spills or improper disposal can lead to soil and water acidification, causing severe damage to local ecosystems. Aquatic life is particularly vulnerable to pH changes, and even small releases of hydrochloric acid can have devastating effects on fish populations and other water-dwelling organisms.

Air quality is another concern, as hydrochloric acid can vaporize and form acidic mists. These emissions can contribute to acid rain formation, impacting vegetation and infrastructure over wide areas. Proper ventilation and emission control systems are crucial to mitigate these risks in production facilities.

The manufacturing process itself may have a substantial carbon footprint, depending on the energy sources used. The production of hydrochloric acid is energy-intensive, and if fossil fuels are the primary energy source, this could offset some of the environmental benefits of the resulting biodegradable materials.

From a resource perspective, hydrochloric acid is typically produced as a byproduct of other chemical processes. Utilizing this byproduct for biodegradable material production could be seen as a form of industrial symbiosis, potentially reducing waste and improving overall resource efficiency.

The end-of-life management of products made from these biodegradable materials also requires consideration. While they may degrade more readily than conventional plastics, the breakdown products and their potential environmental impacts need thorough investigation. There is a risk of introducing new types of pollutants or altering soil and water chemistry in ways that could have unforeseen consequences for ecosystems.

In conclusion, while the use of hydrochloric acid in biodegradable material production offers promising environmental benefits, it also presents significant challenges. Careful management, stringent safety protocols, and ongoing environmental monitoring are essential to ensure that the potential benefits outweigh the risks. Further research into the long-term ecological impacts of both the production process and the resulting materials is crucial for a comprehensive environmental assessment.

Hydrochloric acid, when used in controlled industrial processes, can contribute to the development of innovative biodegradable materials. These materials have the potential to reduce long-term environmental pollution by replacing conventional plastics and other non-biodegradable products. The biodegradation process of these materials typically results in less harmful residues compared to traditional plastics, potentially reducing the accumulation of microplastics in marine and terrestrial ecosystems.

However, the production and handling of hydrochloric acid pose significant environmental risks. Accidental spills or improper disposal can lead to soil and water acidification, causing severe damage to local ecosystems. Aquatic life is particularly vulnerable to pH changes, and even small releases of hydrochloric acid can have devastating effects on fish populations and other water-dwelling organisms.

Air quality is another concern, as hydrochloric acid can vaporize and form acidic mists. These emissions can contribute to acid rain formation, impacting vegetation and infrastructure over wide areas. Proper ventilation and emission control systems are crucial to mitigate these risks in production facilities.

The manufacturing process itself may have a substantial carbon footprint, depending on the energy sources used. The production of hydrochloric acid is energy-intensive, and if fossil fuels are the primary energy source, this could offset some of the environmental benefits of the resulting biodegradable materials.

From a resource perspective, hydrochloric acid is typically produced as a byproduct of other chemical processes. Utilizing this byproduct for biodegradable material production could be seen as a form of industrial symbiosis, potentially reducing waste and improving overall resource efficiency.

The end-of-life management of products made from these biodegradable materials also requires consideration. While they may degrade more readily than conventional plastics, the breakdown products and their potential environmental impacts need thorough investigation. There is a risk of introducing new types of pollutants or altering soil and water chemistry in ways that could have unforeseen consequences for ecosystems.

In conclusion, while the use of hydrochloric acid in biodegradable material production offers promising environmental benefits, it also presents significant challenges. Careful management, stringent safety protocols, and ongoing environmental monitoring are essential to ensure that the potential benefits outweigh the risks. Further research into the long-term ecological impacts of both the production process and the resulting materials is crucial for a comprehensive environmental assessment.

Regulatory Framework for Chemical Use in Materials

The regulatory framework for chemical use in materials production is a critical aspect of the research on using hydrochloric acid for pioneering biodegradable material production. This framework encompasses a complex set of laws, regulations, and guidelines that govern the use, handling, and disposal of chemicals in manufacturing processes.

At the international level, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to chemical hazard classification and communication. This system is widely adopted and influences national regulations worldwide, including those pertaining to hydrochloric acid use in biodegradable material production.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating chemical use through the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices for new chemical substances, which would apply to novel biodegradable materials produced using hydrochloric acid. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, including the handling of hazardous chemicals like hydrochloric acid.

The European Union's regulatory framework is particularly stringent, with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation being a cornerstone of chemical management. REACH requires companies to register chemical substances and provide safety data, which would be applicable to the use of hydrochloric acid in biodegradable material production. The EU also has specific regulations on biodegradable materials, such as the Packaging and Packaging Waste Directive, which sets targets for the biodegradability of packaging materials.

In Asia, countries like China and Japan have their own regulatory systems. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both require notification and risk assessment for new chemical uses, which would be relevant to innovative biodegradable material production methods.

Specific to biodegradable materials, many countries have implemented standards and certifications. For instance, the American Society for Testing and Materials (ASTM) and the European Committee for Standardization (CEN) have developed standards for biodegradability testing. These standards would likely need to be considered when developing new biodegradable materials using hydrochloric acid.

Compliance with these regulatory frameworks is essential for the successful development and commercialization of biodegradable materials produced using hydrochloric acid. Manufacturers must navigate these complex regulations, ensuring that their production processes and final products meet all safety and environmental requirements. This often involves extensive testing, documentation, and potentially seeking approvals or exemptions from regulatory bodies.

As research in this field progresses, it is crucial to maintain ongoing dialogue with regulatory agencies to ensure that innovative production methods align with current regulations or to advocate for appropriate regulatory adaptations that support sustainable material development while maintaining safety and environmental standards.

At the international level, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to chemical hazard classification and communication. This system is widely adopted and influences national regulations worldwide, including those pertaining to hydrochloric acid use in biodegradable material production.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating chemical use through the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices for new chemical substances, which would apply to novel biodegradable materials produced using hydrochloric acid. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, including the handling of hazardous chemicals like hydrochloric acid.

The European Union's regulatory framework is particularly stringent, with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation being a cornerstone of chemical management. REACH requires companies to register chemical substances and provide safety data, which would be applicable to the use of hydrochloric acid in biodegradable material production. The EU also has specific regulations on biodegradable materials, such as the Packaging and Packaging Waste Directive, which sets targets for the biodegradability of packaging materials.

In Asia, countries like China and Japan have their own regulatory systems. China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law both require notification and risk assessment for new chemical uses, which would be relevant to innovative biodegradable material production methods.

Specific to biodegradable materials, many countries have implemented standards and certifications. For instance, the American Society for Testing and Materials (ASTM) and the European Committee for Standardization (CEN) have developed standards for biodegradability testing. These standards would likely need to be considered when developing new biodegradable materials using hydrochloric acid.

Compliance with these regulatory frameworks is essential for the successful development and commercialization of biodegradable materials produced using hydrochloric acid. Manufacturers must navigate these complex regulations, ensuring that their production processes and final products meet all safety and environmental requirements. This often involves extensive testing, documentation, and potentially seeking approvals or exemptions from regulatory bodies.

As research in this field progresses, it is crucial to maintain ongoing dialogue with regulatory agencies to ensure that innovative production methods align with current regulations or to advocate for appropriate regulatory adaptations that support sustainable material development while maintaining safety and environmental standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!