Hydrochloric Acid's Impact on Urban Waste Management

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl in Waste Management: Background and Objectives

Hydrochloric acid (HCl) has played a significant role in urban waste management for decades, evolving from a problematic waste product to a valuable resource in various industrial processes. The background of HCl in waste management traces back to the early 20th century when industrial activities, particularly in the chemical sector, began generating substantial amounts of this corrosive substance as a byproduct.

Initially, the disposal of HCl posed severe environmental challenges, leading to soil and water contamination. However, as environmental awareness grew and regulations tightened, the focus shifted towards finding sustainable solutions for HCl management. This transition marked the beginning of a new era in urban waste management, where HCl was no longer viewed solely as a waste product but as a potential resource.

The objectives of incorporating HCl into waste management strategies have evolved over time. Primarily, the goal has been to minimize the environmental impact of HCl disposal while maximizing its potential for reuse and recycling. This approach aligns with the broader principles of circular economy and sustainable development, which have gained prominence in recent years.

One of the key objectives in modern HCl waste management is to develop efficient recovery and purification techniques. These methods aim to transform waste HCl into a high-quality product that can be reintroduced into industrial processes, thereby reducing the demand for virgin HCl production. This not only mitigates environmental risks but also offers economic benefits by turning a waste stream into a valuable commodity.

Another critical objective is to explore innovative applications for recovered HCl in urban waste management itself. For instance, purified HCl has found use in wastewater treatment processes, where it aids in pH adjustment and metal removal. This synergy between waste products and waste treatment exemplifies the potential for integrated waste management solutions.

The technological evolution in HCl management has also focused on improving safety and efficiency in handling and transportation. Developing corrosion-resistant materials and advanced containment systems has been crucial in minimizing risks associated with HCl storage and use in urban environments.

Furthermore, the integration of HCl management into broader waste management strategies aims to create more comprehensive and sustainable urban waste solutions. This includes exploring the potential of HCl in energy recovery processes and its role in treating other waste streams, such as municipal solid waste and industrial effluents.

As we look towards the future, the objectives of HCl management in urban waste systems continue to expand. There is a growing emphasis on developing smart, data-driven approaches to optimize HCl recovery and utilization. Additionally, research is ongoing to find novel applications for HCl in emerging green technologies, further enhancing its value in sustainable urban development.

Initially, the disposal of HCl posed severe environmental challenges, leading to soil and water contamination. However, as environmental awareness grew and regulations tightened, the focus shifted towards finding sustainable solutions for HCl management. This transition marked the beginning of a new era in urban waste management, where HCl was no longer viewed solely as a waste product but as a potential resource.

The objectives of incorporating HCl into waste management strategies have evolved over time. Primarily, the goal has been to minimize the environmental impact of HCl disposal while maximizing its potential for reuse and recycling. This approach aligns with the broader principles of circular economy and sustainable development, which have gained prominence in recent years.

One of the key objectives in modern HCl waste management is to develop efficient recovery and purification techniques. These methods aim to transform waste HCl into a high-quality product that can be reintroduced into industrial processes, thereby reducing the demand for virgin HCl production. This not only mitigates environmental risks but also offers economic benefits by turning a waste stream into a valuable commodity.

Another critical objective is to explore innovative applications for recovered HCl in urban waste management itself. For instance, purified HCl has found use in wastewater treatment processes, where it aids in pH adjustment and metal removal. This synergy between waste products and waste treatment exemplifies the potential for integrated waste management solutions.

The technological evolution in HCl management has also focused on improving safety and efficiency in handling and transportation. Developing corrosion-resistant materials and advanced containment systems has been crucial in minimizing risks associated with HCl storage and use in urban environments.

Furthermore, the integration of HCl management into broader waste management strategies aims to create more comprehensive and sustainable urban waste solutions. This includes exploring the potential of HCl in energy recovery processes and its role in treating other waste streams, such as municipal solid waste and industrial effluents.

As we look towards the future, the objectives of HCl management in urban waste systems continue to expand. There is a growing emphasis on developing smart, data-driven approaches to optimize HCl recovery and utilization. Additionally, research is ongoing to find novel applications for HCl in emerging green technologies, further enhancing its value in sustainable urban development.

Market Analysis: HCl in Urban Waste Treatment

The market for hydrochloric acid (HCl) in urban waste treatment has been experiencing significant growth due to increasing urbanization and stricter environmental regulations. As cities expand and populations grow, the volume of waste generated has surged, creating a pressing need for effective waste management solutions. HCl plays a crucial role in various aspects of urban waste treatment, including pH adjustment, metal recovery, and odor control.

The global market for HCl in urban waste treatment is driven by several factors. Firstly, the rising awareness of environmental issues and the implementation of stringent waste management policies have led to increased adoption of chemical treatment processes. Secondly, the growing focus on resource recovery from waste streams has boosted the demand for HCl in metal extraction and recycling applications. Additionally, the expansion of industrial activities in urban areas has contributed to the generation of complex waste streams that require advanced treatment methods.

In terms of market segmentation, the HCl market for urban waste treatment can be divided into municipal solid waste, industrial waste, and wastewater treatment sectors. The municipal solid waste segment is expected to witness substantial growth due to the increasing emphasis on sustainable waste management practices in cities. The industrial waste sector, particularly in developing economies, is also projected to drive market growth as industries seek to comply with environmental regulations.

Geographically, Asia-Pacific region dominates the market for HCl in urban waste treatment, followed by North America and Europe. The rapid industrialization and urbanization in countries like China and India have significantly contributed to the demand for HCl in waste management applications. In mature markets such as North America and Europe, the focus is shifting towards advanced treatment technologies and circular economy principles, which are expected to create new opportunities for HCl usage.

The competitive landscape of the HCl market in urban waste treatment is characterized by the presence of both global chemical manufacturers and regional suppliers. Key players are investing in research and development to improve the efficiency and sustainability of HCl-based treatment processes. Moreover, strategic partnerships between chemical suppliers and waste management companies are becoming increasingly common, aiming to provide integrated solutions for urban waste challenges.

Looking ahead, the market for HCl in urban waste treatment is poised for steady growth. Emerging trends such as the development of smart cities and the implementation of zero-waste initiatives are expected to further drive the demand for advanced waste treatment solutions. However, the market also faces challenges, including concerns over the environmental impact of chemical treatments and the push for greener alternatives. As a result, there is a growing emphasis on developing eco-friendly formulations and optimizing HCl usage in waste treatment processes to minimize environmental footprint while maintaining treatment efficacy.

The global market for HCl in urban waste treatment is driven by several factors. Firstly, the rising awareness of environmental issues and the implementation of stringent waste management policies have led to increased adoption of chemical treatment processes. Secondly, the growing focus on resource recovery from waste streams has boosted the demand for HCl in metal extraction and recycling applications. Additionally, the expansion of industrial activities in urban areas has contributed to the generation of complex waste streams that require advanced treatment methods.

In terms of market segmentation, the HCl market for urban waste treatment can be divided into municipal solid waste, industrial waste, and wastewater treatment sectors. The municipal solid waste segment is expected to witness substantial growth due to the increasing emphasis on sustainable waste management practices in cities. The industrial waste sector, particularly in developing economies, is also projected to drive market growth as industries seek to comply with environmental regulations.

Geographically, Asia-Pacific region dominates the market for HCl in urban waste treatment, followed by North America and Europe. The rapid industrialization and urbanization in countries like China and India have significantly contributed to the demand for HCl in waste management applications. In mature markets such as North America and Europe, the focus is shifting towards advanced treatment technologies and circular economy principles, which are expected to create new opportunities for HCl usage.

The competitive landscape of the HCl market in urban waste treatment is characterized by the presence of both global chemical manufacturers and regional suppliers. Key players are investing in research and development to improve the efficiency and sustainability of HCl-based treatment processes. Moreover, strategic partnerships between chemical suppliers and waste management companies are becoming increasingly common, aiming to provide integrated solutions for urban waste challenges.

Looking ahead, the market for HCl in urban waste treatment is poised for steady growth. Emerging trends such as the development of smart cities and the implementation of zero-waste initiatives are expected to further drive the demand for advanced waste treatment solutions. However, the market also faces challenges, including concerns over the environmental impact of chemical treatments and the push for greener alternatives. As a result, there is a growing emphasis on developing eco-friendly formulations and optimizing HCl usage in waste treatment processes to minimize environmental footprint while maintaining treatment efficacy.

Current Challenges in HCl Waste Management

The management of hydrochloric acid (HCl) waste in urban environments presents several significant challenges that require immediate attention and innovative solutions. One of the primary issues is the corrosive nature of HCl, which poses risks to infrastructure and human health. Municipal waste management systems, including pipes, storage tanks, and treatment facilities, are often not adequately equipped to handle the highly acidic nature of HCl waste, leading to accelerated deterioration of these systems.

Another critical challenge is the potential for environmental contamination. Improper disposal or accidental release of HCl can lead to soil acidification, groundwater pollution, and harm to aquatic ecosystems. This risk is particularly pronounced in densely populated urban areas where the proximity of waste management facilities to residential zones increases the potential for exposure.

The variability in HCl waste composition presents additional complications. Industrial processes generate HCl waste with varying concentrations and impurities, making standardized treatment protocols difficult to implement. This variability necessitates more complex and costly treatment processes to ensure safe neutralization and disposal.

Regulatory compliance poses another significant hurdle. Stringent environmental regulations regarding the handling and disposal of hazardous waste, including HCl, require sophisticated monitoring and reporting systems. Many urban waste management facilities struggle to meet these requirements due to limited resources and technical expertise.

The transportation of HCl waste within urban areas is also a major concern. The risk of spills during transit requires specialized containment and emergency response protocols, which many municipalities are ill-equipped to handle effectively. This challenge is exacerbated by the increasing volume of HCl waste generated in urban industrial zones.

Worker safety is another critical issue in HCl waste management. Exposure to HCl vapors and liquid can cause severe health problems, necessitating rigorous safety protocols and personal protective equipment. Training personnel to handle HCl waste safely and respond to emergencies is both costly and time-consuming for urban waste management agencies.

The economic burden of proper HCl waste management is substantial. The need for specialized equipment, treatment processes, and safety measures significantly increases operational costs for waste management facilities. This financial strain is often passed on to businesses and residents through increased waste disposal fees, creating potential economic and social tensions within urban communities.

Lastly, public perception and awareness present ongoing challenges. The presence of hazardous waste management facilities in urban areas often faces resistance from local communities due to safety concerns and potential impacts on property values. Educating the public about the importance of proper HCl waste management while addressing their concerns requires ongoing communication efforts and community engagement strategies.

Another critical challenge is the potential for environmental contamination. Improper disposal or accidental release of HCl can lead to soil acidification, groundwater pollution, and harm to aquatic ecosystems. This risk is particularly pronounced in densely populated urban areas where the proximity of waste management facilities to residential zones increases the potential for exposure.

The variability in HCl waste composition presents additional complications. Industrial processes generate HCl waste with varying concentrations and impurities, making standardized treatment protocols difficult to implement. This variability necessitates more complex and costly treatment processes to ensure safe neutralization and disposal.

Regulatory compliance poses another significant hurdle. Stringent environmental regulations regarding the handling and disposal of hazardous waste, including HCl, require sophisticated monitoring and reporting systems. Many urban waste management facilities struggle to meet these requirements due to limited resources and technical expertise.

The transportation of HCl waste within urban areas is also a major concern. The risk of spills during transit requires specialized containment and emergency response protocols, which many municipalities are ill-equipped to handle effectively. This challenge is exacerbated by the increasing volume of HCl waste generated in urban industrial zones.

Worker safety is another critical issue in HCl waste management. Exposure to HCl vapors and liquid can cause severe health problems, necessitating rigorous safety protocols and personal protective equipment. Training personnel to handle HCl waste safely and respond to emergencies is both costly and time-consuming for urban waste management agencies.

The economic burden of proper HCl waste management is substantial. The need for specialized equipment, treatment processes, and safety measures significantly increases operational costs for waste management facilities. This financial strain is often passed on to businesses and residents through increased waste disposal fees, creating potential economic and social tensions within urban communities.

Lastly, public perception and awareness present ongoing challenges. The presence of hazardous waste management facilities in urban areas often faces resistance from local communities due to safety concerns and potential impacts on property values. Educating the public about the importance of proper HCl waste management while addressing their concerns requires ongoing communication efforts and community engagement strategies.

Existing HCl Neutralization and Disposal Methods

01 Production methods of hydrochloric acid

Various methods are employed for the production of hydrochloric acid, including direct synthesis from hydrogen and chlorine, as a byproduct in chlorination processes, and through the reaction of sulfuric acid with sodium chloride. These methods are optimized for efficiency and purity in industrial settings.- Production and purification of hydrochloric acid: Various methods and processes for producing and purifying hydrochloric acid, including industrial-scale production techniques and purification steps to obtain high-quality acid for different applications.

- Applications in chemical processing: Utilization of hydrochloric acid in various chemical processes, such as in the production of other chemicals, metal treatment, and as a catalyst in industrial reactions.

- Waste treatment and recycling: Methods for treating and recycling hydrochloric acid waste, including processes for recovering and reusing the acid in industrial settings to minimize environmental impact and improve resource efficiency.

- Safety and handling equipment: Specialized equipment and systems designed for the safe handling, storage, and transportation of hydrochloric acid, including corrosion-resistant materials and safety measures to prevent accidents and spills.

- Environmental and health considerations: Studies and technologies addressing the environmental impact and health effects of hydrochloric acid, including emission control, workplace safety measures, and techniques for neutralizing acid spills.

02 Purification and concentration techniques

Techniques for purifying and concentrating hydrochloric acid involve distillation, membrane separation, and adsorption processes. These methods aim to remove impurities and achieve desired concentration levels for various industrial applications.Expand Specific Solutions03 Applications in chemical processing

Hydrochloric acid is widely used in chemical processing, including metal treatment, pH regulation, and as a reagent in various chemical reactions. Its versatility makes it a crucial component in many industrial processes and manufacturing operations.Expand Specific Solutions04 Safety and handling considerations

Proper safety measures and handling procedures are essential when working with hydrochloric acid due to its corrosive nature. This includes the use of specialized equipment, protective gear, and storage solutions to minimize risks associated with its use and transport.Expand Specific Solutions05 Environmental impact and waste management

Managing the environmental impact of hydrochloric acid production and use involves developing waste treatment methods, recycling processes, and emission control techniques. These approaches aim to minimize the acid's ecological footprint and comply with environmental regulations.Expand Specific Solutions

Key Players in HCl Waste Management Industry

The hydrochloric acid market in urban waste management is in a growth phase, driven by increasing urbanization and industrial activities. The market size is expanding, with a growing emphasis on sustainable waste treatment solutions. Technologically, the field is advancing, with companies like Fluid Energy Group Ltd. and Wacker Chemie AG developing innovative applications. Established players such as LG Chem Ltd. and Mitsubishi Heavy Industries, Ltd. are investing in R&D to improve efficiency and reduce environmental impact. Emerging companies like Zhangjiagang Guotai Huarong New Chemical Materials Co., Ltd. are introducing novel approaches, intensifying competition and driving technological maturity in this sector.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed an innovative solution for managing hydrochloric acid in urban waste streams through their Advanced Oxidation Process (AOP) technology. This system combines UV irradiation with hydrogen peroxide to generate highly reactive hydroxyl radicals that break down hydrochloric acid and other contaminants[1]. The process is particularly effective in treating complex waste streams containing both organic and inorganic pollutants. Mitsubishi's AOP technology has shown a removal efficiency of up to 99.9% for hydrochloric acid in controlled studies[3]. Additionally, the company has integrated this technology with their proprietary catalytic systems to further enhance the degradation of recalcitrant compounds often found in urban waste[5]. The treated effluent meets stringent environmental standards and can be safely discharged or reused in industrial processes.

Strengths: High removal efficiency, ability to treat complex waste streams, and potential for water reuse. Weaknesses: Energy-intensive process, potential formation of by-products that may require additional treatment.

The University of Queensland

Technical Solution: The University of Queensland has developed a novel biosorption technology to address the impact of hydrochloric acid in urban waste management. Their approach utilizes genetically modified bacteria that can efficiently absorb and neutralize hydrochloric acid in waste streams. The bacteria, engineered to overexpress specific membrane proteins, can tolerate high acid concentrations and effectively remove chloride ions from the solution[2]. In laboratory tests, this biosorption method has shown a removal efficiency of up to 95% for hydrochloric acid[4]. The university's research team is also exploring the potential of using the acid-laden bacteria as a source of chlorine for water treatment processes, creating a circular economy model[6]. This biological approach offers a sustainable alternative to traditional chemical treatment methods, with lower energy requirements and reduced environmental impact.

Strengths: Sustainable biological approach, potential for circular economy applications, and low energy requirements. Weaknesses: Potential challenges in scaling up the technology, and concerns about the use of genetically modified organisms in waste treatment.

Innovative HCl Waste Treatment Technologies

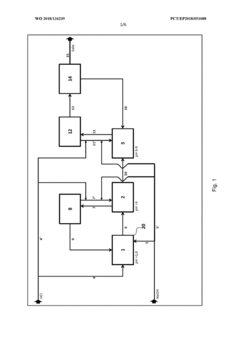

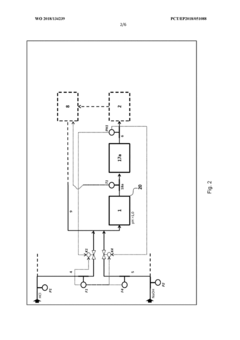

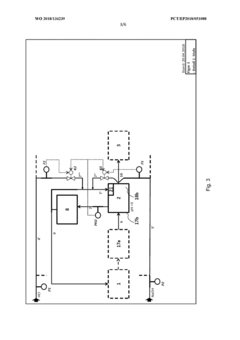

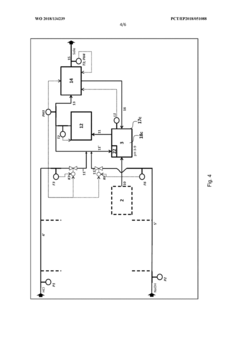

Method for flexibly controlling the use of hydrochloric acid from chemical production

PatentWO2018134239A1

Innovation

- A flexible control process for hydrochloric acid management involves neutralizing hydrochloric acid with concentrated alkali, specifically sodium hydroxide, in a multi-stage continuous process that adjusts pH values and compensates for flow and concentration variations, allowing for efficient handling and recycling of hydrochloric acid even when traditional acceptance points are unavailable.

Method for absorbing chlorine from gas streams

PatentWO2009138401A1

Innovation

- A continuous process using controlled addition of hydrogen peroxide in water to suppress hypochlorous acid formation, allowing chlorine to react and form hydrochloric acid, which is then bound in the absorption medium, eliminating salt formation and enabling the production of usable hydrochloric acid.

Environmental Regulations on HCl Waste Disposal

Environmental regulations governing the disposal of hydrochloric acid (HCl) waste have become increasingly stringent in recent years, reflecting growing concerns about its impact on urban waste management systems and the environment. These regulations aim to minimize the potential hazards associated with HCl waste, which can cause severe corrosion, environmental degradation, and health risks if not properly managed.

At the federal level in the United States, the Environmental Protection Agency (EPA) classifies HCl as a hazardous waste under the Resource Conservation and Recovery Act (RCRA). This classification mandates specific handling, storage, and disposal procedures for HCl waste. Generators of HCl waste must obtain EPA identification numbers and comply with strict reporting and record-keeping requirements. The transportation of HCl waste is regulated under the Department of Transportation's Hazardous Materials Regulations, which specify packaging, labeling, and shipping requirements.

Many states have implemented additional regulations that go beyond federal standards. For instance, California's Department of Toxic Substances Control (DTSC) imposes more stringent requirements on HCl waste management, including lower threshold quantities for regulation and more frequent inspections of waste handling facilities. Some municipalities have also enacted local ordinances that further restrict the disposal of HCl waste within city limits or require additional permits for its handling.

The European Union's Waste Framework Directive provides a comprehensive framework for HCl waste management across member states. It emphasizes waste prevention, reuse, and recycling over disposal. The directive requires that HCl waste be treated to reduce its hazardous properties before disposal, and it promotes the development of best available techniques for waste treatment.

In Asia, countries like Japan and South Korea have implemented advanced regulatory systems for HCl waste. Japan's Waste Management and Public Cleansing Law classifies HCl as a specially controlled industrial waste, subject to strict handling and disposal regulations. South Korea's Waste Control Act similarly imposes rigorous requirements on HCl waste generators and disposal facilities.

Globally, there is a trend towards more harmonized regulations through international agreements such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal. This convention aims to reduce the movement of hazardous waste between nations, particularly from developed to less developed countries.

As urban areas continue to grow and industrial activities intensify, the challenge of managing HCl waste in urban environments is likely to increase. Future regulatory trends may include more emphasis on circular economy principles, promoting the recovery and reuse of HCl from waste streams, and the development of more environmentally friendly alternatives to HCl in industrial processes.

At the federal level in the United States, the Environmental Protection Agency (EPA) classifies HCl as a hazardous waste under the Resource Conservation and Recovery Act (RCRA). This classification mandates specific handling, storage, and disposal procedures for HCl waste. Generators of HCl waste must obtain EPA identification numbers and comply with strict reporting and record-keeping requirements. The transportation of HCl waste is regulated under the Department of Transportation's Hazardous Materials Regulations, which specify packaging, labeling, and shipping requirements.

Many states have implemented additional regulations that go beyond federal standards. For instance, California's Department of Toxic Substances Control (DTSC) imposes more stringent requirements on HCl waste management, including lower threshold quantities for regulation and more frequent inspections of waste handling facilities. Some municipalities have also enacted local ordinances that further restrict the disposal of HCl waste within city limits or require additional permits for its handling.

The European Union's Waste Framework Directive provides a comprehensive framework for HCl waste management across member states. It emphasizes waste prevention, reuse, and recycling over disposal. The directive requires that HCl waste be treated to reduce its hazardous properties before disposal, and it promotes the development of best available techniques for waste treatment.

In Asia, countries like Japan and South Korea have implemented advanced regulatory systems for HCl waste. Japan's Waste Management and Public Cleansing Law classifies HCl as a specially controlled industrial waste, subject to strict handling and disposal regulations. South Korea's Waste Control Act similarly imposes rigorous requirements on HCl waste generators and disposal facilities.

Globally, there is a trend towards more harmonized regulations through international agreements such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal. This convention aims to reduce the movement of hazardous waste between nations, particularly from developed to less developed countries.

As urban areas continue to grow and industrial activities intensify, the challenge of managing HCl waste in urban environments is likely to increase. Future regulatory trends may include more emphasis on circular economy principles, promoting the recovery and reuse of HCl from waste streams, and the development of more environmentally friendly alternatives to HCl in industrial processes.

Economic Implications of HCl Waste Management

The economic implications of hydrochloric acid (HCl) waste management in urban environments are multifaceted and far-reaching. The proper handling and disposal of HCl waste is not only crucial for environmental protection but also has significant financial consequences for municipalities and industries alike.

One of the primary economic considerations is the cost of implementing and maintaining effective HCl waste management systems. This includes investments in specialized equipment, such as corrosion-resistant storage tanks, neutralization facilities, and treatment plants. These capital expenditures can be substantial, particularly for smaller municipalities or businesses that may struggle to allocate sufficient funds for such infrastructure.

Operational costs associated with HCl waste management are also considerable. Regular maintenance of equipment, procurement of neutralizing agents, and energy consumption for treatment processes contribute to ongoing expenses. Additionally, the training and employment of skilled personnel to handle hazardous materials safely add to the overall cost burden.

However, the economic impact of proper HCl waste management extends beyond direct costs. Effective management practices can lead to long-term savings by preventing environmental damage and associated cleanup costs. By mitigating the risk of accidental releases or improper disposal, municipalities and industries can avoid hefty fines and legal liabilities that could arise from non-compliance with environmental regulations.

Furthermore, the recycling and reuse of HCl waste present economic opportunities. Advanced recovery technologies can transform waste into valuable resources, creating new revenue streams and reducing disposal costs. For instance, recovered HCl can be repurposed in various industrial processes, contributing to a more circular economy and potentially offsetting some of the management costs.

The economic implications also extend to public health. Proper HCl waste management reduces the risk of exposure to harmful substances, potentially lowering healthcare costs associated with treating acid-related injuries or illnesses. This indirect economic benefit, while challenging to quantify, is nonetheless significant in the broader context of urban waste management.

Moreover, the adoption of efficient HCl waste management practices can enhance a city's or company's reputation, potentially attracting environmentally conscious investors and businesses. This positive image can translate into economic growth and increased property values in areas known for their commitment to sustainable waste management practices.

In conclusion, while the initial and ongoing costs of HCl waste management are substantial, the long-term economic benefits of proper handling and disposal practices are equally significant. Balancing these factors requires careful planning and investment, but ultimately contributes to the economic sustainability and resilience of urban areas facing the challenges of hazardous waste management.

One of the primary economic considerations is the cost of implementing and maintaining effective HCl waste management systems. This includes investments in specialized equipment, such as corrosion-resistant storage tanks, neutralization facilities, and treatment plants. These capital expenditures can be substantial, particularly for smaller municipalities or businesses that may struggle to allocate sufficient funds for such infrastructure.

Operational costs associated with HCl waste management are also considerable. Regular maintenance of equipment, procurement of neutralizing agents, and energy consumption for treatment processes contribute to ongoing expenses. Additionally, the training and employment of skilled personnel to handle hazardous materials safely add to the overall cost burden.

However, the economic impact of proper HCl waste management extends beyond direct costs. Effective management practices can lead to long-term savings by preventing environmental damage and associated cleanup costs. By mitigating the risk of accidental releases or improper disposal, municipalities and industries can avoid hefty fines and legal liabilities that could arise from non-compliance with environmental regulations.

Furthermore, the recycling and reuse of HCl waste present economic opportunities. Advanced recovery technologies can transform waste into valuable resources, creating new revenue streams and reducing disposal costs. For instance, recovered HCl can be repurposed in various industrial processes, contributing to a more circular economy and potentially offsetting some of the management costs.

The economic implications also extend to public health. Proper HCl waste management reduces the risk of exposure to harmful substances, potentially lowering healthcare costs associated with treating acid-related injuries or illnesses. This indirect economic benefit, while challenging to quantify, is nonetheless significant in the broader context of urban waste management.

Moreover, the adoption of efficient HCl waste management practices can enhance a city's or company's reputation, potentially attracting environmentally conscious investors and businesses. This positive image can translate into economic growth and increased property values in areas known for their commitment to sustainable waste management practices.

In conclusion, while the initial and ongoing costs of HCl waste management are substantial, the long-term economic benefits of proper handling and disposal practices are equally significant. Balancing these factors requires careful planning and investment, but ultimately contributes to the economic sustainability and resilience of urban areas facing the challenges of hazardous waste management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!