Key Techniques for Hydrochloric Acid Emissions Control

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl Emissions Control Background and Objectives

Hydrochloric acid (HCl) emissions have been a significant environmental concern in various industries for decades. The control of these emissions has become increasingly critical due to their potential harmful effects on human health and the environment. HCl is a highly corrosive gas that can cause severe respiratory issues, damage to ecosystems, and contribute to acid rain formation. The primary sources of HCl emissions include waste incineration, coal-fired power plants, chemical manufacturing, and metal processing industries.

The evolution of HCl emissions control technologies has been driven by increasingly stringent environmental regulations and a growing awareness of the need for sustainable industrial practices. Early control methods focused on simple scrubbing techniques, but as understanding of the problem grew, more sophisticated approaches were developed. The technological progression has moved from basic wet scrubbers to advanced dry sorbent injection systems and membrane-based separation technologies.

The main objective of HCl emissions control is to reduce the concentration of HCl in flue gases to levels that comply with regulatory standards while maintaining operational efficiency and cost-effectiveness. This goal encompasses not only the removal of HCl but also the management of byproducts and the integration of control systems into existing industrial processes.

Current technological trends in HCl emissions control are focused on improving removal efficiency, reducing energy consumption, and minimizing waste generation. Emerging technologies include advanced catalytic processes, novel sorbent materials, and hybrid systems that combine multiple control techniques. There is also a growing emphasis on developing solutions that can simultaneously address multiple pollutants, including HCl, sulfur dioxide, and particulate matter.

The future direction of HCl emissions control is likely to involve the integration of smart monitoring systems, predictive maintenance, and real-time optimization algorithms. These advancements aim to enhance the adaptability and performance of control systems under varying operational conditions. Additionally, there is increasing interest in developing circular economy approaches, where captured HCl can be recovered and reused in industrial processes, turning a waste product into a valuable resource.

As industries continue to evolve and new processes emerge, the field of HCl emissions control must adapt to address novel challenges. This includes developing solutions for industries that were previously not significant sources of HCl emissions but are becoming more relevant due to changing production methods or increased scale of operations. The ongoing research and development in this field are crucial for ensuring that industrial growth can be sustained without compromising environmental integrity and public health.

The evolution of HCl emissions control technologies has been driven by increasingly stringent environmental regulations and a growing awareness of the need for sustainable industrial practices. Early control methods focused on simple scrubbing techniques, but as understanding of the problem grew, more sophisticated approaches were developed. The technological progression has moved from basic wet scrubbers to advanced dry sorbent injection systems and membrane-based separation technologies.

The main objective of HCl emissions control is to reduce the concentration of HCl in flue gases to levels that comply with regulatory standards while maintaining operational efficiency and cost-effectiveness. This goal encompasses not only the removal of HCl but also the management of byproducts and the integration of control systems into existing industrial processes.

Current technological trends in HCl emissions control are focused on improving removal efficiency, reducing energy consumption, and minimizing waste generation. Emerging technologies include advanced catalytic processes, novel sorbent materials, and hybrid systems that combine multiple control techniques. There is also a growing emphasis on developing solutions that can simultaneously address multiple pollutants, including HCl, sulfur dioxide, and particulate matter.

The future direction of HCl emissions control is likely to involve the integration of smart monitoring systems, predictive maintenance, and real-time optimization algorithms. These advancements aim to enhance the adaptability and performance of control systems under varying operational conditions. Additionally, there is increasing interest in developing circular economy approaches, where captured HCl can be recovered and reused in industrial processes, turning a waste product into a valuable resource.

As industries continue to evolve and new processes emerge, the field of HCl emissions control must adapt to address novel challenges. This includes developing solutions for industries that were previously not significant sources of HCl emissions but are becoming more relevant due to changing production methods or increased scale of operations. The ongoing research and development in this field are crucial for ensuring that industrial growth can be sustained without compromising environmental integrity and public health.

Market Demand for HCl Emissions Control Technologies

The market demand for hydrochloric acid (HCl) emissions control technologies has been steadily increasing due to stricter environmental regulations and growing awareness of the harmful effects of HCl emissions on human health and the environment. Industries such as chemical manufacturing, metal processing, and waste incineration are the primary sources of HCl emissions, driving the need for effective control technologies.

The global market for air pollution control systems, including HCl emissions control, is projected to grow significantly in the coming years. This growth is primarily attributed to the implementation of stringent air quality standards by governments worldwide and the increasing industrialization in developing countries. The Asia-Pacific region, particularly China and India, is expected to witness the highest growth rate in the market due to rapid industrialization and increasing environmental concerns.

In the chemical industry, the demand for HCl emissions control technologies is particularly strong. As the production of chlorine-based chemicals continues to rise, the need for efficient HCl capture and treatment systems becomes more critical. The metal processing industry, especially steel manufacturing, also contributes significantly to the market demand as HCl is often used in pickling processes.

The waste incineration sector is another key driver of market demand. As municipalities and industries increasingly turn to incineration for waste management, the need for effective HCl emissions control becomes paramount. This is especially true in regions with strict regulations on incineration emissions, such as the European Union and North America.

Emerging technologies in HCl emissions control are also shaping market demand. Dry sorbent injection (DSI) systems, wet scrubbers, and advanced membrane technologies are gaining traction due to their improved efficiency and cost-effectiveness. The market is seeing a shift towards integrated systems that can handle multiple pollutants, including HCl, simultaneously.

The demand for retrofit solutions is also on the rise as existing industrial facilities seek to comply with updated emissions standards. This presents a significant opportunity for technology providers to offer upgrades and replacements for older, less efficient HCl control systems.

Sustainability trends are further influencing market demand. There is growing interest in technologies that not only capture HCl emissions but also allow for the recovery and reuse of the captured acid. This circular economy approach is becoming increasingly attractive to industries looking to improve their environmental footprint while potentially recovering valuable resources.

The global market for air pollution control systems, including HCl emissions control, is projected to grow significantly in the coming years. This growth is primarily attributed to the implementation of stringent air quality standards by governments worldwide and the increasing industrialization in developing countries. The Asia-Pacific region, particularly China and India, is expected to witness the highest growth rate in the market due to rapid industrialization and increasing environmental concerns.

In the chemical industry, the demand for HCl emissions control technologies is particularly strong. As the production of chlorine-based chemicals continues to rise, the need for efficient HCl capture and treatment systems becomes more critical. The metal processing industry, especially steel manufacturing, also contributes significantly to the market demand as HCl is often used in pickling processes.

The waste incineration sector is another key driver of market demand. As municipalities and industries increasingly turn to incineration for waste management, the need for effective HCl emissions control becomes paramount. This is especially true in regions with strict regulations on incineration emissions, such as the European Union and North America.

Emerging technologies in HCl emissions control are also shaping market demand. Dry sorbent injection (DSI) systems, wet scrubbers, and advanced membrane technologies are gaining traction due to their improved efficiency and cost-effectiveness. The market is seeing a shift towards integrated systems that can handle multiple pollutants, including HCl, simultaneously.

The demand for retrofit solutions is also on the rise as existing industrial facilities seek to comply with updated emissions standards. This presents a significant opportunity for technology providers to offer upgrades and replacements for older, less efficient HCl control systems.

Sustainability trends are further influencing market demand. There is growing interest in technologies that not only capture HCl emissions but also allow for the recovery and reuse of the captured acid. This circular economy approach is becoming increasingly attractive to industries looking to improve their environmental footprint while potentially recovering valuable resources.

Current Challenges in HCl Emissions Control

Hydrochloric acid (HCl) emissions control remains a significant challenge in various industrial processes, particularly in sectors such as chemical manufacturing, metal processing, and waste incineration. Despite advancements in emission control technologies, several obstacles persist in achieving optimal HCl abatement.

One of the primary challenges is the corrosive nature of HCl, which can severely damage control equipment and infrastructure. This corrosivity necessitates the use of specialized materials and coatings, significantly increasing the cost of emission control systems. Moreover, the long-term durability of these materials under continuous exposure to HCl remains a concern, leading to frequent maintenance and replacement requirements.

The efficiency of HCl removal techniques is another critical issue. While wet scrubbing is widely used, it often struggles to achieve consistently high removal rates, especially when dealing with fluctuating HCl concentrations. This variability in emission levels poses difficulties in meeting increasingly stringent environmental regulations across different jurisdictions.

Energy consumption presents a further challenge in HCl emissions control. Many existing technologies, particularly those involving thermal treatment or regeneration processes, are energy-intensive. This high energy demand not only increases operational costs but also contributes to the overall carbon footprint of industrial facilities, creating a conflict between air quality improvement and climate change mitigation efforts.

The generation of secondary waste streams is an additional concern in HCl control. Wet scrubbing systems, for instance, produce large volumes of acidic wastewater that require further treatment before disposal. This not only adds to the complexity of the overall emission control process but also raises environmental concerns regarding water pollution and resource management.

Monitoring and measurement of HCl emissions pose technical challenges as well. Accurate, real-time monitoring of HCl levels in flue gases is crucial for optimizing control strategies and ensuring regulatory compliance. However, existing monitoring technologies often struggle with interference from other gases, sensor drift, and the harsh conditions typical in industrial exhaust streams.

The integration of HCl control systems with other emission reduction technologies presents another hurdle. Many industrial processes require simultaneous control of multiple pollutants, such as particulate matter, sulfur oxides, and nitrogen oxides. Designing and operating integrated systems that effectively address all these pollutants without compromising the efficiency of HCl removal remains a complex engineering challenge.

Lastly, the economic feasibility of advanced HCl control technologies is a significant barrier to their widespread adoption. Many emerging technologies, while promising in terms of efficiency and environmental performance, are cost-prohibitive for smaller industrial operations. This economic constraint limits the industry-wide implementation of state-of-the-art HCl emission control solutions, particularly in developing economies where environmental regulations may be less stringent.

One of the primary challenges is the corrosive nature of HCl, which can severely damage control equipment and infrastructure. This corrosivity necessitates the use of specialized materials and coatings, significantly increasing the cost of emission control systems. Moreover, the long-term durability of these materials under continuous exposure to HCl remains a concern, leading to frequent maintenance and replacement requirements.

The efficiency of HCl removal techniques is another critical issue. While wet scrubbing is widely used, it often struggles to achieve consistently high removal rates, especially when dealing with fluctuating HCl concentrations. This variability in emission levels poses difficulties in meeting increasingly stringent environmental regulations across different jurisdictions.

Energy consumption presents a further challenge in HCl emissions control. Many existing technologies, particularly those involving thermal treatment or regeneration processes, are energy-intensive. This high energy demand not only increases operational costs but also contributes to the overall carbon footprint of industrial facilities, creating a conflict between air quality improvement and climate change mitigation efforts.

The generation of secondary waste streams is an additional concern in HCl control. Wet scrubbing systems, for instance, produce large volumes of acidic wastewater that require further treatment before disposal. This not only adds to the complexity of the overall emission control process but also raises environmental concerns regarding water pollution and resource management.

Monitoring and measurement of HCl emissions pose technical challenges as well. Accurate, real-time monitoring of HCl levels in flue gases is crucial for optimizing control strategies and ensuring regulatory compliance. However, existing monitoring technologies often struggle with interference from other gases, sensor drift, and the harsh conditions typical in industrial exhaust streams.

The integration of HCl control systems with other emission reduction technologies presents another hurdle. Many industrial processes require simultaneous control of multiple pollutants, such as particulate matter, sulfur oxides, and nitrogen oxides. Designing and operating integrated systems that effectively address all these pollutants without compromising the efficiency of HCl removal remains a complex engineering challenge.

Lastly, the economic feasibility of advanced HCl control technologies is a significant barrier to their widespread adoption. Many emerging technologies, while promising in terms of efficiency and environmental performance, are cost-prohibitive for smaller industrial operations. This economic constraint limits the industry-wide implementation of state-of-the-art HCl emission control solutions, particularly in developing economies where environmental regulations may be less stringent.

Existing HCl Emissions Control Solutions

01 Emission control systems for hydrochloric acid

Various systems and methods are employed to control and reduce hydrochloric acid emissions in industrial processes. These may include scrubbing systems, absorption towers, and other gas treatment technologies designed to capture and neutralize HCl before it is released into the atmosphere.- Absorption and neutralization of hydrochloric acid emissions: Various methods are employed to absorb and neutralize hydrochloric acid emissions in industrial processes. These techniques often involve the use of scrubbers or absorption towers where the acidic gases are brought into contact with alkaline solutions or materials. This process helps to reduce the concentration of hydrochloric acid in the exhaust gases, making them safer for release into the environment.

- Recycling and recovery of hydrochloric acid from emissions: Technologies have been developed to recycle and recover hydrochloric acid from industrial emissions. These systems often involve condensation, separation, and purification processes to extract the acid from waste gases. The recovered hydrochloric acid can then be reused in various industrial applications, reducing both emissions and the need for fresh acid production.

- Monitoring and control systems for hydrochloric acid emissions: Advanced monitoring and control systems are utilized to manage hydrochloric acid emissions effectively. These systems may include real-time sensors, automated control mechanisms, and data analysis tools to detect and respond to changes in emission levels. By providing accurate and timely information, these systems help industries maintain compliance with environmental regulations and optimize their emission reduction processes.

- Treatment of hydrochloric acid-containing wastewater: Specialized treatment methods are employed for wastewater containing hydrochloric acid. These processes often involve neutralization, precipitation of dissolved metals, and separation of solid particles. Advanced techniques such as membrane filtration or ion exchange may also be used to further purify the water before discharge or reuse, thereby reducing the environmental impact of hydrochloric acid emissions in liquid form.

- Catalytic conversion of hydrochloric acid emissions: Catalytic processes are being developed to convert hydrochloric acid emissions into less harmful substances. These methods often involve the use of specific catalysts that can facilitate the transformation of hydrochloric acid into chlorine gas or other chlorine compounds. Such catalytic conversion techniques offer the potential for more efficient and environmentally friendly management of hydrochloric acid emissions in various industrial settings.

02 Recycling and recovery of hydrochloric acid

Technologies are developed to recycle and recover hydrochloric acid from waste streams and emissions. These processes aim to reduce overall emissions by reusing the acid in industrial processes, thereby minimizing the need for fresh acid production and associated emissions.Expand Specific Solutions03 Monitoring and detection of hydrochloric acid emissions

Advanced monitoring and detection systems are utilized to measure and track hydrochloric acid emissions in real-time. These systems help in early detection of leaks or excessive emissions, allowing for prompt corrective actions to minimize environmental impact.Expand Specific Solutions04 Treatment of hydrochloric acid-containing wastewater

Specialized treatment processes are developed for wastewater containing hydrochloric acid. These methods aim to neutralize the acid, remove contaminants, and ensure that the treated water meets environmental standards before discharge, thus reducing indirect HCl emissions to the environment.Expand Specific Solutions05 Process optimization to reduce hydrochloric acid formation

Industrial processes are optimized to minimize the formation of hydrochloric acid as a byproduct or waste stream. This includes modifying reaction conditions, using alternative raw materials, or implementing cleaner production technologies to reduce the overall generation of HCl and associated emissions.Expand Specific Solutions

Key Players in HCl Emissions Control Industry

The hydrochloric acid emissions control technology market is in a growth phase, driven by increasing environmental regulations and industrial demand. The market size is expanding, with a diverse range of players from chemical, automotive, and industrial sectors. Technological maturity varies, with established companies like Covestro Deutschland AG, Mitsubishi Heavy Industries, and ExxonMobil Upstream Research Co. leading in innovation. Emerging players such as Baowu Water Technology and Kanken Techno are also contributing to advancements. The competitive landscape is characterized by a mix of large multinational corporations and specialized firms, each bringing unique expertise to address the complex challenges of acid emissions control.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has pioneered an innovative dry sorbent injection (DSI) system for HCl emissions control, particularly in waste incineration and power generation applications. Their technique involves injecting a dry alkaline sorbent, such as sodium bicarbonate or hydrated lime, into the flue gas stream[2]. The sorbent reacts with HCl to form solid salts, which are then captured in particulate control devices. MHI has optimized the injection process through advanced computational fluid dynamics modeling, ensuring uniform distribution and maximum utilization of the sorbent[4]. They have also developed a novel sorbent recirculation system that significantly improves removal efficiency while reducing sorbent consumption by up to 30%[6].

Strengths: Low capital cost, easy retrofit to existing systems, and flexibility in operation. Weaknesses: Potential for increased particulate emissions, less effective for high HCl concentrations.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach for hydrochloric acid emissions control in petrochemical processes. Their technique involves a multi-stage scrubbing system using alkaline solutions, typically sodium hydroxide, to neutralize HCl emissions[1]. The process includes a primary absorption tower followed by secondary and tertiary scrubbers to ensure maximum removal efficiency. Sinopec has also implemented advanced process control systems to optimize the scrubbing process, reducing chemical consumption and improving overall efficiency[3]. Additionally, they have developed catalytic oxidation methods for treating low-concentration HCl streams, converting the acid into chlorine gas which can be recycled in the production process[5].

Strengths: High removal efficiency (>99%), ability to handle large volumes, and potential for resource recovery. Weaknesses: High capital and operating costs, potential for secondary pollution if not managed properly.

Core Innovations in HCl Emissions Control

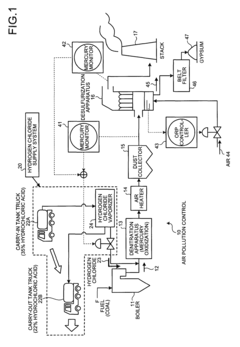

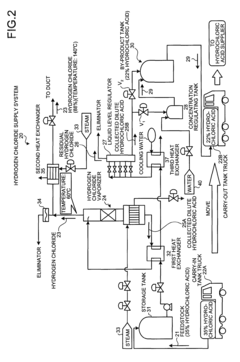

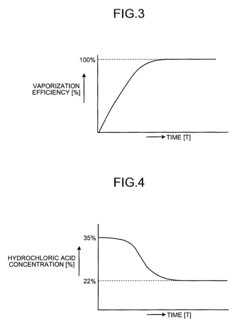

Hydrogen chloride supply system, air pollution control system, and hydrogen chloride supply control system

PatentInactiveUS8003068B2

Innovation

- A hydrogen chloride supply system that vaporizes concentrated hydrochloric acid, separates and regulates the residual hydrogen chloride from dilute hydrochloric acid, and recycles the dilute hydrochloric acid to a predetermined concentration for reutilization, incorporating a vaporizer, liquid level regulator, concentration regulating tank, and by-product tank, along with a network for inventory management and feedstock control.

Gas stream treatment process

PatentActiveUS20140084209A1

Innovation

- A sorbent composition comprising a compound with the formula (SiO2)x(OH)yMzSaF.B, where M is a metal or metalloid cation, S is a sulfur-based species, and B is a hygroscopic basic inorganic solid, which adsorbs both mercury and acid gases by maintaining a moist environment and utilizing a sulfur-based component for improved capture.

Environmental Regulations for HCl Emissions

Environmental regulations for hydrochloric acid (HCl) emissions have become increasingly stringent worldwide due to the harmful effects of HCl on human health and the environment. In the United States, the Environmental Protection Agency (EPA) has established National Emission Standards for Hazardous Air Pollutants (NESHAP) that specifically address HCl emissions from various industrial sources. These standards set limits on the amount of HCl that can be released into the atmosphere and require facilities to implement control technologies to reduce emissions.

The European Union has also implemented strict regulations through its Industrial Emissions Directive (IED), which sets emission limit values for HCl and other pollutants. The IED requires industrial facilities to use Best Available Techniques (BAT) to minimize emissions and environmental impact. In China, the Ministry of Ecology and Environment has issued standards for HCl emissions from different industrial sectors, with increasingly stringent limits being enforced in recent years.

Many countries have adopted a tiered approach to HCl emission regulations, with different limits applied based on the size and type of industrial facility. For example, larger facilities or those in sensitive areas may be subject to more stringent emission limits. Additionally, some regulations require continuous monitoring of HCl emissions to ensure compliance with set limits.

Regulatory frameworks often include provisions for periodic review and updates to emission standards, taking into account advancements in control technologies and new scientific evidence on the environmental and health impacts of HCl. This dynamic approach ensures that regulations remain effective and relevant over time.

Compliance with HCl emission regulations typically involves the implementation of various control technologies, such as wet scrubbers, dry scrubbers, and adsorption systems. Facilities are often required to demonstrate the effectiveness of their control measures through regular testing and reporting. Non-compliance can result in significant penalties, including fines and operational restrictions.

International agreements and conventions, such as the Stockholm Convention on Persistent Organic Pollutants, have also influenced national regulations on HCl emissions. These global efforts aim to reduce the overall environmental impact of industrial emissions and promote the adoption of cleaner production technologies across borders.

As awareness of air quality issues continues to grow, many jurisdictions are moving towards more comprehensive air quality management approaches that consider the cumulative impact of multiple pollutants, including HCl. This holistic approach may lead to even more stringent regulations and integrated control strategies in the future.

The European Union has also implemented strict regulations through its Industrial Emissions Directive (IED), which sets emission limit values for HCl and other pollutants. The IED requires industrial facilities to use Best Available Techniques (BAT) to minimize emissions and environmental impact. In China, the Ministry of Ecology and Environment has issued standards for HCl emissions from different industrial sectors, with increasingly stringent limits being enforced in recent years.

Many countries have adopted a tiered approach to HCl emission regulations, with different limits applied based on the size and type of industrial facility. For example, larger facilities or those in sensitive areas may be subject to more stringent emission limits. Additionally, some regulations require continuous monitoring of HCl emissions to ensure compliance with set limits.

Regulatory frameworks often include provisions for periodic review and updates to emission standards, taking into account advancements in control technologies and new scientific evidence on the environmental and health impacts of HCl. This dynamic approach ensures that regulations remain effective and relevant over time.

Compliance with HCl emission regulations typically involves the implementation of various control technologies, such as wet scrubbers, dry scrubbers, and adsorption systems. Facilities are often required to demonstrate the effectiveness of their control measures through regular testing and reporting. Non-compliance can result in significant penalties, including fines and operational restrictions.

International agreements and conventions, such as the Stockholm Convention on Persistent Organic Pollutants, have also influenced national regulations on HCl emissions. These global efforts aim to reduce the overall environmental impact of industrial emissions and promote the adoption of cleaner production technologies across borders.

As awareness of air quality issues continues to grow, many jurisdictions are moving towards more comprehensive air quality management approaches that consider the cumulative impact of multiple pollutants, including HCl. This holistic approach may lead to even more stringent regulations and integrated control strategies in the future.

Economic Impact of HCl Emissions Control

The economic impact of hydrochloric acid (HCl) emissions control is significant and multifaceted, affecting various sectors of the economy. Implementing effective control measures requires substantial investments from industries, particularly those in chemical manufacturing, metal processing, and waste incineration. These investments often lead to increased operational costs, which can potentially be passed on to consumers, affecting product pricing and market competitiveness.

However, the long-term economic benefits of HCl emissions control are considerable. Reduced emissions contribute to improved air quality, leading to decreased healthcare costs associated with respiratory illnesses and other health issues caused by HCl exposure. This improvement in public health can result in increased productivity and reduced absenteeism in the workforce, positively impacting overall economic output.

The implementation of HCl emissions control technologies also stimulates innovation and growth in the environmental technology sector. Companies specializing in emissions control equipment and services experience increased demand, creating job opportunities and driving technological advancements. This can lead to the development of more efficient and cost-effective control methods, potentially reducing implementation costs for industries over time.

Furthermore, stringent emissions control regulations can enhance a country's global competitiveness in environmental standards. Nations with robust HCl emissions control measures may gain advantages in international trade agreements and attract environmentally conscious investments. This can lead to the creation of "green" jobs and foster the growth of sustainable industries.

The economic impact extends to agriculture as well. Reduced HCl emissions result in decreased acid rain, which can improve soil quality and crop yields. This can lead to increased agricultural productivity and reduced costs for soil treatment and crop protection measures.

However, it is important to note that the economic impact varies across different regions and industries. Smaller businesses may face greater challenges in implementing costly control measures, potentially leading to consolidation within certain sectors. Policymakers must carefully balance environmental protection with economic considerations to ensure sustainable growth and development.

In conclusion, while the initial economic impact of HCl emissions control may involve significant costs, the long-term benefits to public health, environmental quality, and technological innovation can outweigh these expenses, contributing to sustainable economic growth and improved quality of life.

However, the long-term economic benefits of HCl emissions control are considerable. Reduced emissions contribute to improved air quality, leading to decreased healthcare costs associated with respiratory illnesses and other health issues caused by HCl exposure. This improvement in public health can result in increased productivity and reduced absenteeism in the workforce, positively impacting overall economic output.

The implementation of HCl emissions control technologies also stimulates innovation and growth in the environmental technology sector. Companies specializing in emissions control equipment and services experience increased demand, creating job opportunities and driving technological advancements. This can lead to the development of more efficient and cost-effective control methods, potentially reducing implementation costs for industries over time.

Furthermore, stringent emissions control regulations can enhance a country's global competitiveness in environmental standards. Nations with robust HCl emissions control measures may gain advantages in international trade agreements and attract environmentally conscious investments. This can lead to the creation of "green" jobs and foster the growth of sustainable industries.

The economic impact extends to agriculture as well. Reduced HCl emissions result in decreased acid rain, which can improve soil quality and crop yields. This can lead to increased agricultural productivity and reduced costs for soil treatment and crop protection measures.

However, it is important to note that the economic impact varies across different regions and industries. Smaller businesses may face greater challenges in implementing costly control measures, potentially leading to consolidation within certain sectors. Policymakers must carefully balance environmental protection with economic considerations to ensure sustainable growth and development.

In conclusion, while the initial economic impact of HCl emissions control may involve significant costs, the long-term benefits to public health, environmental quality, and technological innovation can outweigh these expenses, contributing to sustainable economic growth and improved quality of life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!