Hydrochloric Acid's Role in Enhancing Material Durability

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl in Durability: Background and Objectives

Hydrochloric acid (HCl) has emerged as a significant player in the field of material durability enhancement. This powerful inorganic acid has been utilized across various industries for decades, primarily known for its corrosive properties. However, recent advancements in materials science and chemical engineering have unveiled its potential to improve the longevity and resilience of certain materials when applied under controlled conditions.

The evolution of HCl's role in material durability can be traced back to the early 20th century when industrial processes began to explore its applications beyond simple acid-base reactions. As manufacturing techniques advanced, researchers discovered that controlled exposure to HCl could alter the surface properties of metals, ceramics, and even some polymers, leading to enhanced resistance against environmental factors and wear.

The primary objective of utilizing HCl in durability enhancement is to create materials that can withstand harsh conditions, prolonged use, and aggressive environments without compromising their structural integrity or functional properties. This goal aligns with the growing demand for sustainable and long-lasting products across various sectors, including construction, automotive, aerospace, and consumer goods.

One of the key mechanisms by which HCl contributes to material durability is through surface modification. When applied in precise concentrations and under specific conditions, HCl can initiate chemical reactions that alter the outermost layer of materials. This process can lead to the formation of protective coatings, increased hardness, or improved bonding with other substances, all of which contribute to enhanced durability.

In the realm of metallic materials, HCl treatment has shown promising results in improving corrosion resistance. By carefully controlling the acid concentration and exposure time, a thin, stable oxide layer can be formed on the metal surface, acting as a barrier against further corrosion. This technique has found applications in the protection of structural steel, automotive components, and marine equipment.

For ceramic materials, HCl treatment has been explored as a means to enhance surface properties and increase resistance to thermal shock and mechanical stress. The acid etching process can create micro-textures on ceramic surfaces, improving their adhesion to other materials and potentially increasing their overall strength and durability.

As research in this field progresses, the objectives for HCl in durability enhancement continue to expand. Current goals include developing more efficient and environmentally friendly treatment processes, exploring new material combinations that can benefit from HCl modification, and pushing the boundaries of material performance in extreme conditions.

The evolution of HCl's role in material durability can be traced back to the early 20th century when industrial processes began to explore its applications beyond simple acid-base reactions. As manufacturing techniques advanced, researchers discovered that controlled exposure to HCl could alter the surface properties of metals, ceramics, and even some polymers, leading to enhanced resistance against environmental factors and wear.

The primary objective of utilizing HCl in durability enhancement is to create materials that can withstand harsh conditions, prolonged use, and aggressive environments without compromising their structural integrity or functional properties. This goal aligns with the growing demand for sustainable and long-lasting products across various sectors, including construction, automotive, aerospace, and consumer goods.

One of the key mechanisms by which HCl contributes to material durability is through surface modification. When applied in precise concentrations and under specific conditions, HCl can initiate chemical reactions that alter the outermost layer of materials. This process can lead to the formation of protective coatings, increased hardness, or improved bonding with other substances, all of which contribute to enhanced durability.

In the realm of metallic materials, HCl treatment has shown promising results in improving corrosion resistance. By carefully controlling the acid concentration and exposure time, a thin, stable oxide layer can be formed on the metal surface, acting as a barrier against further corrosion. This technique has found applications in the protection of structural steel, automotive components, and marine equipment.

For ceramic materials, HCl treatment has been explored as a means to enhance surface properties and increase resistance to thermal shock and mechanical stress. The acid etching process can create micro-textures on ceramic surfaces, improving their adhesion to other materials and potentially increasing their overall strength and durability.

As research in this field progresses, the objectives for HCl in durability enhancement continue to expand. Current goals include developing more efficient and environmentally friendly treatment processes, exploring new material combinations that can benefit from HCl modification, and pushing the boundaries of material performance in extreme conditions.

Market Analysis for HCl-Enhanced Materials

The market for HCl-enhanced materials has shown significant growth in recent years, driven by increasing demand for durable and corrosion-resistant products across various industries. The global market for these materials is expected to continue its upward trajectory, with a compound annual growth rate projected to remain strong over the next five years.

Key sectors driving this market growth include construction, automotive, aerospace, and industrial manufacturing. In the construction industry, HCl-enhanced materials are gaining traction for their ability to withstand harsh environmental conditions and extend the lifespan of structures. The automotive sector is increasingly adopting these materials for components that require high durability and resistance to chemical exposure.

The aerospace industry represents another significant market for HCl-enhanced materials, particularly in the manufacturing of aircraft components that must withstand extreme temperatures and corrosive environments. Industrial manufacturing, including chemical processing and oil and gas extraction, also contributes substantially to the demand for these materials due to their superior resistance to aggressive chemicals and harsh operating conditions.

Geographically, North America and Europe currently lead the market for HCl-enhanced materials, owing to their advanced manufacturing capabilities and stringent regulations promoting the use of durable and environmentally friendly materials. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, infrastructure development, and automotive production in countries like China and India.

Market trends indicate a growing preference for sustainable and eco-friendly HCl-enhanced materials, as environmental regulations become more stringent globally. This shift is prompting manufacturers to invest in research and development to create materials that offer enhanced durability while minimizing environmental impact.

The competitive landscape of the HCl-enhanced materials market is characterized by the presence of several major players and a number of smaller, specialized manufacturers. Key market players are focusing on product innovation and strategic partnerships to maintain their competitive edge and expand their market share.

Despite the positive growth outlook, the market faces challenges such as fluctuating raw material prices and the need for significant initial investments in research and development. However, the long-term benefits of HCl-enhanced materials, including reduced maintenance costs and extended product lifecycles, continue to drive market expansion and technological advancements in this field.

Key sectors driving this market growth include construction, automotive, aerospace, and industrial manufacturing. In the construction industry, HCl-enhanced materials are gaining traction for their ability to withstand harsh environmental conditions and extend the lifespan of structures. The automotive sector is increasingly adopting these materials for components that require high durability and resistance to chemical exposure.

The aerospace industry represents another significant market for HCl-enhanced materials, particularly in the manufacturing of aircraft components that must withstand extreme temperatures and corrosive environments. Industrial manufacturing, including chemical processing and oil and gas extraction, also contributes substantially to the demand for these materials due to their superior resistance to aggressive chemicals and harsh operating conditions.

Geographically, North America and Europe currently lead the market for HCl-enhanced materials, owing to their advanced manufacturing capabilities and stringent regulations promoting the use of durable and environmentally friendly materials. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, infrastructure development, and automotive production in countries like China and India.

Market trends indicate a growing preference for sustainable and eco-friendly HCl-enhanced materials, as environmental regulations become more stringent globally. This shift is prompting manufacturers to invest in research and development to create materials that offer enhanced durability while minimizing environmental impact.

The competitive landscape of the HCl-enhanced materials market is characterized by the presence of several major players and a number of smaller, specialized manufacturers. Key market players are focusing on product innovation and strategic partnerships to maintain their competitive edge and expand their market share.

Despite the positive growth outlook, the market faces challenges such as fluctuating raw material prices and the need for significant initial investments in research and development. However, the long-term benefits of HCl-enhanced materials, including reduced maintenance costs and extended product lifecycles, continue to drive market expansion and technological advancements in this field.

Current Challenges in HCl Application

Despite the widespread use of hydrochloric acid (HCl) in enhancing material durability, several challenges persist in its application. One of the primary concerns is the corrosive nature of HCl, which can potentially damage the very materials it aims to protect if not applied correctly. This necessitates precise control over concentration levels and exposure times, which can be difficult to maintain consistently in industrial settings.

Another significant challenge lies in the environmental impact of HCl usage. The production, transportation, and disposal of HCl can lead to air and water pollution if not managed properly. Stringent regulations surrounding its use and disposal add complexity to industrial processes and increase operational costs for companies.

Worker safety is a paramount concern when dealing with HCl. The acid's corrosive properties pose serious health risks, including respiratory issues and chemical burns. Implementing robust safety protocols and providing adequate personal protective equipment (PPE) are essential but can be challenging to enforce consistently across large-scale operations.

The variability in material composition presents another hurdle in HCl application. Different materials react differently to HCl treatment, requiring tailored approaches for each type of substrate. This variability makes it difficult to develop standardized treatment protocols, leading to potential inefficiencies and inconsistencies in material enhancement processes.

Furthermore, the long-term effects of HCl treatment on material properties are not always fully understood. While immediate improvements in durability may be observed, the potential for unforeseen degradation or changes in material characteristics over time remains a concern. This uncertainty complicates lifecycle assessments and long-term performance guarantees for treated materials.

The development of alternative, less hazardous treatments is an ongoing challenge in the field. While HCl remains effective for many applications, there is a growing demand for safer, more environmentally friendly options. Balancing the proven efficacy of HCl with the need for sustainable alternatives presents a significant research and development challenge for the industry.

Lastly, the cost-effectiveness of HCl treatment in comparison to other durability enhancement methods is an ongoing consideration. While HCl can be relatively inexpensive, the associated costs of safety measures, environmental compliance, and specialized equipment can offset its economic advantages in some applications. Finding the right balance between cost, effectiveness, and safety remains a key challenge in the industrial use of HCl for material durability enhancement.

Another significant challenge lies in the environmental impact of HCl usage. The production, transportation, and disposal of HCl can lead to air and water pollution if not managed properly. Stringent regulations surrounding its use and disposal add complexity to industrial processes and increase operational costs for companies.

Worker safety is a paramount concern when dealing with HCl. The acid's corrosive properties pose serious health risks, including respiratory issues and chemical burns. Implementing robust safety protocols and providing adequate personal protective equipment (PPE) are essential but can be challenging to enforce consistently across large-scale operations.

The variability in material composition presents another hurdle in HCl application. Different materials react differently to HCl treatment, requiring tailored approaches for each type of substrate. This variability makes it difficult to develop standardized treatment protocols, leading to potential inefficiencies and inconsistencies in material enhancement processes.

Furthermore, the long-term effects of HCl treatment on material properties are not always fully understood. While immediate improvements in durability may be observed, the potential for unforeseen degradation or changes in material characteristics over time remains a concern. This uncertainty complicates lifecycle assessments and long-term performance guarantees for treated materials.

The development of alternative, less hazardous treatments is an ongoing challenge in the field. While HCl remains effective for many applications, there is a growing demand for safer, more environmentally friendly options. Balancing the proven efficacy of HCl with the need for sustainable alternatives presents a significant research and development challenge for the industry.

Lastly, the cost-effectiveness of HCl treatment in comparison to other durability enhancement methods is an ongoing consideration. While HCl can be relatively inexpensive, the associated costs of safety measures, environmental compliance, and specialized equipment can offset its economic advantages in some applications. Finding the right balance between cost, effectiveness, and safety remains a key challenge in the industrial use of HCl for material durability enhancement.

Existing HCl Treatment Solutions

01 Corrosion-resistant materials for hydrochloric acid environments

Various materials are developed to withstand the corrosive effects of hydrochloric acid. These include specialized alloys, coatings, and composite materials that offer improved durability in acidic conditions. Such materials are crucial for equipment and structures exposed to hydrochloric acid in industrial applications.- Corrosion-resistant materials for hydrochloric acid environments: Various materials are developed to withstand the corrosive effects of hydrochloric acid. These include specialized alloys, coatings, and composite materials that exhibit high resistance to chemical attack. Such materials are crucial for equipment and structures exposed to hydrochloric acid in industrial applications.

- Protective coatings for hydrochloric acid resistance: Protective coatings are applied to surfaces to enhance their durability against hydrochloric acid. These coatings can be made from polymers, ceramics, or other chemically resistant materials. They form a barrier between the substrate and the acid, significantly extending the lifespan of the protected components.

- Treatment processes to improve acid resistance: Various treatment processes are employed to enhance the hydrochloric acid resistance of materials. These may include heat treatments, chemical treatments, or surface modifications that alter the material's structure or composition to increase its durability in acidic environments.

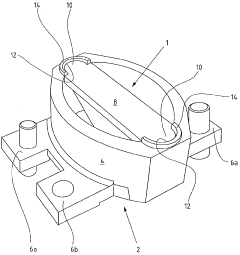

- Acid-resistant equipment design: Specialized equipment designs are developed to withstand hydrochloric acid exposure. These designs incorporate features such as optimized geometries, strategic material selection, and innovative sealing mechanisms to minimize acid contact and enhance overall durability in corrosive environments.

- Monitoring and maintenance techniques for acid-exposed systems: Advanced monitoring and maintenance techniques are implemented to ensure the longevity of systems exposed to hydrochloric acid. These may include real-time corrosion monitoring, predictive maintenance algorithms, and specialized inspection methods to detect and address potential issues before they lead to failure.

02 Protective coatings for hydrochloric acid resistance

Protective coatings are applied to surfaces to enhance their resistance to hydrochloric acid. These coatings can be made from various materials such as polymers, ceramics, or specialized compounds that create a barrier between the acid and the underlying substrate, thereby increasing the durability of the protected surface.Expand Specific Solutions03 Treatment processes to improve acid resistance

Various treatment processes are employed to enhance the hydrochloric acid durability of materials. These may include heat treatments, chemical treatments, or surface modifications that alter the material's properties to better withstand acidic environments. Such treatments can significantly extend the lifespan of components exposed to hydrochloric acid.Expand Specific Solutions04 Acid-resistant equipment design

Specialized equipment designs are developed to withstand hydrochloric acid exposure. These designs incorporate features such as optimized geometries, strategic material selection, and innovative sealing mechanisms to minimize acid contact and enhance overall durability in acidic environments.Expand Specific Solutions05 Monitoring and maintenance techniques for acid-exposed systems

Advanced monitoring and maintenance techniques are implemented to ensure the longevity of systems exposed to hydrochloric acid. These may include real-time corrosion monitoring, predictive maintenance algorithms, and specialized inspection methods to detect and address potential issues before they lead to failure.Expand Specific Solutions

Key Industry Players and Competitors

The competitive landscape for hydrochloric acid's role in enhancing material durability is characterized by a mature market with established players and ongoing innovation. The industry is in a growth phase, driven by increasing demand for durable materials across various sectors. Major companies like Dow Global Technologies, POSCO Holdings, and Nippon Shokubai are at the forefront of research and development in this field. The market size is substantial, with applications spanning automotive, construction, and electronics industries. Technological advancements by companies such as FUJIFILM Corp. and Sony Group Corp. are pushing the boundaries of material durability, while specialized firms like Moulded Optics GmbH focus on niche applications.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has developed innovative solutions for enhancing material durability using hydrochloric acid. Their approach involves a surface treatment process that utilizes controlled exposure to hydrochloric acid to create a protective layer on various materials, particularly metals and alloys. This process, known as acid etching, removes surface impurities and creates a uniform, corrosion-resistant surface[1]. The company has also developed specialized polymer coatings that incorporate hydrochloric acid-resistant compounds, providing an additional layer of protection for materials exposed to harsh chemical environments[2]. These coatings are particularly effective in industrial applications where equipment is regularly exposed to acidic conditions.

Strengths: Improved corrosion resistance, enhanced surface properties, and increased material lifespan. Weaknesses: Potential environmental concerns related to acid handling and disposal, and the need for careful process control to avoid over-etching or material damage.

POSCO Holdings, Inc.

Technical Solution: POSCO Holdings, Inc. has implemented advanced techniques in steel production that leverage hydrochloric acid to enhance material durability. Their process involves a controlled pickling method using hydrochloric acid to remove surface oxides and impurities from steel sheets, resulting in improved surface quality and corrosion resistance[3]. Additionally, POSCO has developed a proprietary acid regeneration system that allows for the efficient recycling of hydrochloric acid used in the pickling process, reducing waste and environmental impact[4]. The company has also introduced a novel surface passivation technique that uses dilute hydrochloric acid solutions to create a thin, protective oxide layer on stainless steel products, further enhancing their durability and resistance to various environmental factors[5].

Strengths: Improved steel surface quality, enhanced corrosion resistance, and efficient acid recycling process. Weaknesses: High initial investment costs for acid regeneration systems and potential for acid-induced hydrogen embrittlement in certain steel grades if not properly controlled.

Innovative HCl Applications in Materials

Hybrid optic

PatentWO2010057489A1

Innovation

- Treating the glass element with hydrochloric acid to neutralize alkali and alkaline earth metals from the surface areas before overmoulding with plastic, or using borosilicate glass and resistant plastics like ABS or PPS to minimize diffusion, thereby enhancing the durability of the hybrid optics.

Hybrid optic

PatentInactiveEP2215509A1

Innovation

- Treating the glass elements with hydrochloric acid to neutralize alkali and alkaline earth metals from the surface areas before injection molding with plastic, or using borosilicate glass and resistant plastics like ABS or PPS to minimize diffusion, thereby enhancing the durability of the hybrid optics.

Environmental Impact of HCl Treatments

The environmental impact of hydrochloric acid (HCl) treatments in enhancing material durability is a critical consideration for industries employing this technique. While HCl treatments can significantly improve the longevity and performance of various materials, their potential environmental consequences must be carefully evaluated and managed.

One of the primary environmental concerns associated with HCl treatments is the release of acidic waste into water systems. If not properly neutralized or contained, the discharge of HCl-containing effluents can lead to the acidification of aquatic ecosystems, potentially harming flora and fauna. This impact can be particularly severe in freshwater environments, where even small changes in pH can disrupt the delicate balance of aquatic life.

Air pollution is another significant environmental issue related to HCl treatments. During the treatment process, volatile HCl vapors may be released into the atmosphere. These emissions can contribute to the formation of acid rain, which has far-reaching effects on terrestrial and aquatic ecosystems, as well as human-made structures. Additionally, HCl vapors can pose respiratory risks to workers and nearby communities if not properly controlled.

The production and transportation of HCl for treatment purposes also carry environmental implications. The manufacturing process of HCl often involves energy-intensive methods and may result in greenhouse gas emissions. Furthermore, the transportation of this corrosive substance presents risks of accidental spills or leaks, which can have immediate and severe impacts on local environments.

Land contamination is a potential long-term consequence of HCl treatments, particularly in cases where treated materials or waste products are improperly disposed of. Soil acidification can occur, leading to changes in soil chemistry that affect plant growth and microbial communities. This, in turn, can have cascading effects on local ecosystems and potentially enter the food chain.

However, it is important to note that the environmental impact of HCl treatments can be significantly mitigated through proper management and technological innovations. Advanced treatment systems can neutralize acidic waste before discharge, while closed-loop processes can minimize emissions and reduce the overall consumption of HCl. Additionally, the development of less hazardous alternatives and more efficient application methods can further reduce the environmental footprint of durability-enhancing treatments.

The regulatory landscape surrounding HCl treatments has evolved to address these environmental concerns. Many countries have implemented strict guidelines for the handling, use, and disposal of HCl and related waste products. Compliance with these regulations often necessitates investment in environmental protection measures, which can drive innovation in cleaner technologies and practices within the industry.

In conclusion, while HCl treatments offer significant benefits in terms of material durability, their environmental impact must be carefully managed. Balancing the advantages of enhanced material performance with environmental stewardship requires ongoing research, technological advancement, and regulatory oversight to ensure sustainable practices in the application of HCl treatments.

One of the primary environmental concerns associated with HCl treatments is the release of acidic waste into water systems. If not properly neutralized or contained, the discharge of HCl-containing effluents can lead to the acidification of aquatic ecosystems, potentially harming flora and fauna. This impact can be particularly severe in freshwater environments, where even small changes in pH can disrupt the delicate balance of aquatic life.

Air pollution is another significant environmental issue related to HCl treatments. During the treatment process, volatile HCl vapors may be released into the atmosphere. These emissions can contribute to the formation of acid rain, which has far-reaching effects on terrestrial and aquatic ecosystems, as well as human-made structures. Additionally, HCl vapors can pose respiratory risks to workers and nearby communities if not properly controlled.

The production and transportation of HCl for treatment purposes also carry environmental implications. The manufacturing process of HCl often involves energy-intensive methods and may result in greenhouse gas emissions. Furthermore, the transportation of this corrosive substance presents risks of accidental spills or leaks, which can have immediate and severe impacts on local environments.

Land contamination is a potential long-term consequence of HCl treatments, particularly in cases where treated materials or waste products are improperly disposed of. Soil acidification can occur, leading to changes in soil chemistry that affect plant growth and microbial communities. This, in turn, can have cascading effects on local ecosystems and potentially enter the food chain.

However, it is important to note that the environmental impact of HCl treatments can be significantly mitigated through proper management and technological innovations. Advanced treatment systems can neutralize acidic waste before discharge, while closed-loop processes can minimize emissions and reduce the overall consumption of HCl. Additionally, the development of less hazardous alternatives and more efficient application methods can further reduce the environmental footprint of durability-enhancing treatments.

The regulatory landscape surrounding HCl treatments has evolved to address these environmental concerns. Many countries have implemented strict guidelines for the handling, use, and disposal of HCl and related waste products. Compliance with these regulations often necessitates investment in environmental protection measures, which can drive innovation in cleaner technologies and practices within the industry.

In conclusion, while HCl treatments offer significant benefits in terms of material durability, their environmental impact must be carefully managed. Balancing the advantages of enhanced material performance with environmental stewardship requires ongoing research, technological advancement, and regulatory oversight to ensure sustainable practices in the application of HCl treatments.

Safety Protocols in HCl Material Processing

The implementation of safety protocols in hydrochloric acid (HCl) material processing is crucial for ensuring the well-being of workers and the integrity of the materials being treated. When using HCl to enhance material durability, strict adherence to safety guidelines is paramount due to the corrosive and hazardous nature of the acid.

Personal protective equipment (PPE) forms the first line of defense in HCl handling. Workers must wear acid-resistant gloves, goggles, face shields, and protective clothing to prevent skin contact and inhalation of fumes. Respiratory protection, such as acid gas respirators, is essential in areas with potential HCl vapor exposure. Regular inspection and maintenance of PPE ensure its effectiveness over time.

Proper ventilation systems are critical in HCl processing areas. These systems should be designed to efficiently remove acid vapors and maintain air quality within safe limits. Local exhaust ventilation near HCl handling points and fume hoods for laboratory work are standard practices. Air quality monitoring devices should be installed to detect any leaks or sudden increases in HCl concentration.

Storage and handling protocols for HCl require special attention. Acid-resistant containers with proper labeling must be used, and storage areas should be well-ventilated, cool, and away from incompatible materials. Secondary containment systems are necessary to prevent spills from spreading. Transfer of HCl should be conducted using closed systems or in well-ventilated areas to minimize exposure risks.

Emergency response procedures are an integral part of safety protocols. Eyewash stations and safety showers must be readily accessible in HCl processing areas. Spill kits containing neutralizing agents should be available, and workers must be trained in their proper use. Clear evacuation routes and emergency communication systems should be established and regularly tested.

Training and education form the backbone of safety protocols. All personnel involved in HCl processing must undergo comprehensive training on the hazards of HCl, proper handling techniques, emergency procedures, and the use of safety equipment. Regular refresher courses and safety drills help maintain a high level of preparedness.

Documentation and record-keeping are essential for maintaining and improving safety standards. This includes keeping detailed logs of HCl usage, safety inspections, incident reports, and training records. Regular safety audits should be conducted to identify potential hazards and ensure compliance with established protocols.

By implementing these comprehensive safety protocols, organizations can significantly reduce the risks associated with HCl material processing while effectively harnessing its potential for enhancing material durability. Continuous improvement of these protocols based on industry best practices and lessons learned is key to maintaining a safe working environment in HCl-related operations.

Personal protective equipment (PPE) forms the first line of defense in HCl handling. Workers must wear acid-resistant gloves, goggles, face shields, and protective clothing to prevent skin contact and inhalation of fumes. Respiratory protection, such as acid gas respirators, is essential in areas with potential HCl vapor exposure. Regular inspection and maintenance of PPE ensure its effectiveness over time.

Proper ventilation systems are critical in HCl processing areas. These systems should be designed to efficiently remove acid vapors and maintain air quality within safe limits. Local exhaust ventilation near HCl handling points and fume hoods for laboratory work are standard practices. Air quality monitoring devices should be installed to detect any leaks or sudden increases in HCl concentration.

Storage and handling protocols for HCl require special attention. Acid-resistant containers with proper labeling must be used, and storage areas should be well-ventilated, cool, and away from incompatible materials. Secondary containment systems are necessary to prevent spills from spreading. Transfer of HCl should be conducted using closed systems or in well-ventilated areas to minimize exposure risks.

Emergency response procedures are an integral part of safety protocols. Eyewash stations and safety showers must be readily accessible in HCl processing areas. Spill kits containing neutralizing agents should be available, and workers must be trained in their proper use. Clear evacuation routes and emergency communication systems should be established and regularly tested.

Training and education form the backbone of safety protocols. All personnel involved in HCl processing must undergo comprehensive training on the hazards of HCl, proper handling techniques, emergency procedures, and the use of safety equipment. Regular refresher courses and safety drills help maintain a high level of preparedness.

Documentation and record-keeping are essential for maintaining and improving safety standards. This includes keeping detailed logs of HCl usage, safety inspections, incident reports, and training records. Regular safety audits should be conducted to identify potential hazards and ensure compliance with established protocols.

By implementing these comprehensive safety protocols, organizations can significantly reduce the risks associated with HCl material processing while effectively harnessing its potential for enhancing material durability. Continuous improvement of these protocols based on industry best practices and lessons learned is key to maintaining a safe working environment in HCl-related operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!