How to Detect Water Content Using FTIR Techniques

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Water Detection Background and Objectives

Fourier Transform Infrared Spectroscopy (FTIR) has evolved significantly since its inception in the mid-20th century, becoming a cornerstone analytical technique for molecular characterization across numerous industries. The technology's development trajectory has been marked by continuous improvements in sensitivity, resolution, and application versatility, particularly in water content detection capabilities.

Water detection using FTIR leverages the fundamental principle that water molecules exhibit characteristic absorption bands in the infrared spectrum, primarily at approximately 3400 cm⁻¹ (O-H stretching) and 1640 cm⁻¹ (H-O-H bending). These distinctive spectral signatures enable both qualitative identification and quantitative measurement of water content in various matrices, from pharmaceutical products to petroleum derivatives.

The evolution of FTIR water detection methodologies has been driven by increasing regulatory requirements across industries, particularly in pharmaceuticals where water content critically affects product stability, efficacy, and shelf life. Similarly, in the petrochemical sector, water contamination can significantly impact product quality and equipment integrity, necessitating precise detection methods.

Recent technological advancements have expanded FTIR capabilities through the integration of advanced sampling techniques such as Attenuated Total Reflection (ATR), diffuse reflectance, and transmission methodologies. These innovations have substantially improved the technique's applicability to diverse sample types, including liquids, solids, powders, and gases, while minimizing sample preparation requirements.

The primary objective of this technical research is to comprehensively evaluate current FTIR-based water detection methodologies, identifying their respective strengths, limitations, and optimal application scenarios. We aim to establish a systematic framework for selecting appropriate FTIR techniques based on specific industry requirements, sample characteristics, and detection sensitivity needs.

Additionally, this research seeks to explore emerging trends in FTIR technology, including miniaturization for portable applications, integration with artificial intelligence for automated interpretation, and coupling with complementary analytical techniques for enhanced detection capabilities. These developments represent significant opportunities for expanding the utility of FTIR in water content analysis across diverse operational environments.

Furthermore, this investigation aims to identify potential innovation pathways that could address existing technical challenges, such as interference from overlapping spectral bands, matrix effects in complex samples, and quantification accuracy at trace moisture levels. By mapping these technological gaps against emerging solutions, we intend to outline strategic research directions that could yield substantial improvements in FTIR-based water detection methodologies.

Water detection using FTIR leverages the fundamental principle that water molecules exhibit characteristic absorption bands in the infrared spectrum, primarily at approximately 3400 cm⁻¹ (O-H stretching) and 1640 cm⁻¹ (H-O-H bending). These distinctive spectral signatures enable both qualitative identification and quantitative measurement of water content in various matrices, from pharmaceutical products to petroleum derivatives.

The evolution of FTIR water detection methodologies has been driven by increasing regulatory requirements across industries, particularly in pharmaceuticals where water content critically affects product stability, efficacy, and shelf life. Similarly, in the petrochemical sector, water contamination can significantly impact product quality and equipment integrity, necessitating precise detection methods.

Recent technological advancements have expanded FTIR capabilities through the integration of advanced sampling techniques such as Attenuated Total Reflection (ATR), diffuse reflectance, and transmission methodologies. These innovations have substantially improved the technique's applicability to diverse sample types, including liquids, solids, powders, and gases, while minimizing sample preparation requirements.

The primary objective of this technical research is to comprehensively evaluate current FTIR-based water detection methodologies, identifying their respective strengths, limitations, and optimal application scenarios. We aim to establish a systematic framework for selecting appropriate FTIR techniques based on specific industry requirements, sample characteristics, and detection sensitivity needs.

Additionally, this research seeks to explore emerging trends in FTIR technology, including miniaturization for portable applications, integration with artificial intelligence for automated interpretation, and coupling with complementary analytical techniques for enhanced detection capabilities. These developments represent significant opportunities for expanding the utility of FTIR in water content analysis across diverse operational environments.

Furthermore, this investigation aims to identify potential innovation pathways that could address existing technical challenges, such as interference from overlapping spectral bands, matrix effects in complex samples, and quantification accuracy at trace moisture levels. By mapping these technological gaps against emerging solutions, we intend to outline strategic research directions that could yield substantial improvements in FTIR-based water detection methodologies.

Market Applications and Demand Analysis

The global market for water content detection using FTIR techniques has witnessed substantial growth in recent years, driven by increasing regulatory requirements for quality control across multiple industries. The pharmaceutical sector represents one of the largest markets, where precise water content determination is critical for drug stability, formulation, and shelf-life. According to industry reports, the pharmaceutical quality control market utilizing spectroscopic techniques has been growing at a compound annual rate of 7.8%, with water content analysis being a significant component.

Food and beverage industries constitute another major market segment, where water content directly impacts product quality, safety, and compliance with labeling regulations. The demand for rapid, non-destructive testing methods has intensified as manufacturers seek to optimize production processes and ensure consistent product quality. This sector's adoption of FTIR-based moisture analysis solutions has increased by approximately 12% annually over the past five years.

The petrochemical industry represents a substantial market for water detection technologies, particularly in lubricants, fuels, and hydraulic fluids where water contamination can cause significant equipment damage and operational failures. The economic impact of water-related equipment failures in this sector exceeds billions annually, creating a strong incentive for implementing reliable detection methods.

Agricultural and environmental monitoring applications have emerged as rapidly growing markets for FTIR water content detection. Soil moisture analysis, crop quality assessment, and environmental compliance monitoring all require accurate water content determination. This segment is projected to experience the fastest growth rate among all applications, driven by increasing focus on sustainable farming practices and environmental regulations.

The semiconductor and electronics manufacturing industry demands extremely precise water content analysis, as even trace amounts of moisture can compromise product integrity. With the global semiconductor market expanding rapidly, the demand for advanced analytical techniques like FTIR for quality control has correspondingly increased.

Regional market analysis indicates that North America and Europe currently dominate the FTIR water detection market due to stringent regulatory frameworks and high technology adoption rates. However, the Asia-Pacific region is experiencing the fastest growth, driven by rapid industrialization, expanding pharmaceutical and food processing sectors, and increasing quality control standards.

Consumer demand trends show increasing preference for portable and field-deployable FTIR solutions that enable real-time analysis, reducing dependence on laboratory testing and accelerating decision-making processes. This shift is particularly evident in agricultural applications and on-site industrial quality control.

Food and beverage industries constitute another major market segment, where water content directly impacts product quality, safety, and compliance with labeling regulations. The demand for rapid, non-destructive testing methods has intensified as manufacturers seek to optimize production processes and ensure consistent product quality. This sector's adoption of FTIR-based moisture analysis solutions has increased by approximately 12% annually over the past five years.

The petrochemical industry represents a substantial market for water detection technologies, particularly in lubricants, fuels, and hydraulic fluids where water contamination can cause significant equipment damage and operational failures. The economic impact of water-related equipment failures in this sector exceeds billions annually, creating a strong incentive for implementing reliable detection methods.

Agricultural and environmental monitoring applications have emerged as rapidly growing markets for FTIR water content detection. Soil moisture analysis, crop quality assessment, and environmental compliance monitoring all require accurate water content determination. This segment is projected to experience the fastest growth rate among all applications, driven by increasing focus on sustainable farming practices and environmental regulations.

The semiconductor and electronics manufacturing industry demands extremely precise water content analysis, as even trace amounts of moisture can compromise product integrity. With the global semiconductor market expanding rapidly, the demand for advanced analytical techniques like FTIR for quality control has correspondingly increased.

Regional market analysis indicates that North America and Europe currently dominate the FTIR water detection market due to stringent regulatory frameworks and high technology adoption rates. However, the Asia-Pacific region is experiencing the fastest growth, driven by rapid industrialization, expanding pharmaceutical and food processing sectors, and increasing quality control standards.

Consumer demand trends show increasing preference for portable and field-deployable FTIR solutions that enable real-time analysis, reducing dependence on laboratory testing and accelerating decision-making processes. This shift is particularly evident in agricultural applications and on-site industrial quality control.

Current FTIR Water Detection Challenges

Despite significant advancements in FTIR spectroscopy for water content detection, several technical challenges continue to impede optimal performance and widespread application. The primary challenge remains the strong absorption characteristics of water in the infrared region, which can easily saturate detectors and lead to non-linear responses when analyzing samples with high moisture content. This often necessitates complex sample preparation or dilution procedures that introduce additional variables and potential errors into the analytical process.

Quantitative accuracy presents another significant hurdle, particularly when dealing with heterogeneous samples where water distribution is not uniform. The Beer-Lambert law assumptions that underpin quantitative FTIR analysis become compromised in such scenarios, leading to systematic errors in water content determination. This is especially problematic in industrial applications where rapid, accurate measurements of diverse materials are required.

Environmental interference factors substantially impact measurement reliability. Ambient humidity variations can significantly alter baseline readings, while temperature fluctuations affect both the sample's physical properties and the instrument's performance characteristics. These environmental variables necessitate sophisticated compensation algorithms or strictly controlled measurement conditions that may be impractical in many industrial settings.

Resolution limitations create difficulties when distinguishing between different states of water (free, bound, or structural) within complex matrices. Current FTIR systems often lack the spectral resolution needed to differentiate these subtle variations, which is critical for applications in pharmaceutical stability studies, food quality assessment, and materials science. The overlapping absorption bands of water with other molecular components further complicates accurate identification and quantification.

Sample presentation inconsistencies introduce significant variability in measurements. Factors such as path length variations in liquid cells, uneven sample distribution in solid materials, and surface scattering effects in powders all contribute to measurement uncertainties. These physical sampling challenges often require specialized accessories and methodologies that increase analytical complexity and cost.

Data interpretation remains complex due to the multifaceted nature of water-matrix interactions. Current chemometric models struggle to account for all possible interactions between water molecules and various sample components, leading to model failures when analyzing novel or highly complex samples. The development of robust, universally applicable calibration models continues to be an elusive goal in FTIR water detection.

Miniaturization and field deployment of FTIR technology for water content analysis face substantial engineering challenges related to optical stability, energy requirements, and environmental robustness. While laboratory-grade instruments provide excellent performance, translating this capability to portable, field-ready devices without significant performance compromises remains difficult.

Quantitative accuracy presents another significant hurdle, particularly when dealing with heterogeneous samples where water distribution is not uniform. The Beer-Lambert law assumptions that underpin quantitative FTIR analysis become compromised in such scenarios, leading to systematic errors in water content determination. This is especially problematic in industrial applications where rapid, accurate measurements of diverse materials are required.

Environmental interference factors substantially impact measurement reliability. Ambient humidity variations can significantly alter baseline readings, while temperature fluctuations affect both the sample's physical properties and the instrument's performance characteristics. These environmental variables necessitate sophisticated compensation algorithms or strictly controlled measurement conditions that may be impractical in many industrial settings.

Resolution limitations create difficulties when distinguishing between different states of water (free, bound, or structural) within complex matrices. Current FTIR systems often lack the spectral resolution needed to differentiate these subtle variations, which is critical for applications in pharmaceutical stability studies, food quality assessment, and materials science. The overlapping absorption bands of water with other molecular components further complicates accurate identification and quantification.

Sample presentation inconsistencies introduce significant variability in measurements. Factors such as path length variations in liquid cells, uneven sample distribution in solid materials, and surface scattering effects in powders all contribute to measurement uncertainties. These physical sampling challenges often require specialized accessories and methodologies that increase analytical complexity and cost.

Data interpretation remains complex due to the multifaceted nature of water-matrix interactions. Current chemometric models struggle to account for all possible interactions between water molecules and various sample components, leading to model failures when analyzing novel or highly complex samples. The development of robust, universally applicable calibration models continues to be an elusive goal in FTIR water detection.

Miniaturization and field deployment of FTIR technology for water content analysis face substantial engineering challenges related to optical stability, energy requirements, and environmental robustness. While laboratory-grade instruments provide excellent performance, translating this capability to portable, field-ready devices without significant performance compromises remains difficult.

Existing FTIR Water Content Measurement Methods

01 FTIR techniques for water content measurement in materials

Fourier Transform Infrared (FTIR) spectroscopy can be used to measure water content in various materials by analyzing the absorption bands associated with water molecules. This technique provides accurate and non-destructive analysis of moisture levels in samples. The method typically focuses on specific infrared absorption bands characteristic of water, allowing for quantitative determination of water content in solid, liquid, or gaseous samples.- FTIR techniques for water content measurement in materials: Fourier Transform Infrared (FTIR) spectroscopy can be used to measure water content in various materials by analyzing the absorption bands associated with water molecules. This technique provides accurate and non-destructive analysis of moisture levels by detecting the characteristic O-H stretching vibrations. The method can be applied to solid, liquid, and gaseous samples, making it versatile for different industries including pharmaceuticals, food, and materials science.

- Quantitative analysis of water content using FTIR calibration methods: Quantitative determination of water content using FTIR requires specific calibration methods to establish the relationship between spectral features and actual water concentration. These methods include developing calibration curves using reference standards with known water content, multivariate analysis techniques, and chemometric models. The calibration process enhances the accuracy and reliability of water content measurements across different sample matrices and concentration ranges.

- Real-time monitoring of water content using FTIR systems: Advanced FTIR systems enable real-time monitoring of water content in industrial processes and environmental applications. These systems incorporate automated sampling, continuous measurement capabilities, and data processing algorithms to provide immediate feedback on moisture levels. Real-time monitoring is particularly valuable in manufacturing processes where water content affects product quality, in environmental monitoring, and in quality control applications requiring rapid assessment of moisture levels.

- Portable and miniaturized FTIR devices for water content analysis: Recent advancements have led to the development of portable and miniaturized FTIR devices specifically designed for on-site water content analysis. These compact instruments maintain analytical performance while offering increased mobility and ease of use. They incorporate simplified user interfaces, reduced power requirements, and robust designs suitable for field applications. Portable FTIR analyzers enable water content measurements outside laboratory environments, supporting applications in agriculture, construction, and remote monitoring.

- Enhanced FTIR techniques for complex sample matrices: Enhanced FTIR methodologies have been developed to address challenges in measuring water content in complex sample matrices. These techniques include specialized sample preparation methods, advanced spectral processing algorithms, and combination with complementary analytical methods. Innovations such as attenuated total reflection (ATR), diffuse reflectance, and chemometric data analysis improve the accuracy of water content determination in heterogeneous materials, emulsions, and samples with interfering compounds.

02 Portable and in-line FTIR systems for water content monitoring

Portable and in-line FTIR systems have been developed for real-time monitoring of water content in industrial processes. These systems allow for continuous measurement without the need for sample extraction and laboratory analysis. The technology incorporates specialized sample interfaces and automated data processing algorithms to provide immediate feedback on moisture levels, enabling process control and quality assurance in manufacturing environments.Expand Specific Solutions03 Calibration methods for FTIR water content analysis

Specialized calibration methods have been developed to enhance the accuracy of water content determination using FTIR spectroscopy. These methods include multivariate statistical approaches, reference standard comparisons, and algorithmic corrections for matrix effects. Calibration techniques address challenges such as overlapping spectral bands, baseline shifts, and sample-to-sample variations, resulting in more reliable quantification of water in complex matrices.Expand Specific Solutions04 FTIR microspectroscopy for spatial mapping of water distribution

FTIR microspectroscopy techniques enable spatial mapping of water distribution within heterogeneous samples. By combining infrared spectroscopy with microscopy, researchers can visualize moisture gradients and water localization at microscopic scales. This approach is particularly valuable for studying water migration, hydration processes, and moisture-related degradation in materials science, pharmaceutical formulations, and biological samples.Expand Specific Solutions05 Advanced data processing for FTIR water content analysis

Advanced data processing methods enhance the sensitivity and specificity of water content determination by FTIR. These include spectral preprocessing techniques, chemometric analysis, artificial intelligence algorithms, and machine learning approaches for pattern recognition in complex spectra. Such computational methods improve the detection limits, reduce interference from other components, and enable automated analysis of large datasets, making FTIR water content analysis more robust and efficient.Expand Specific Solutions

Leading Companies in FTIR Technology

The water content detection using FTIR techniques market is in a growth phase, with increasing applications across pharmaceutical, environmental monitoring, and industrial sectors. The market size is expanding due to rising demand for precise moisture analysis in quality control processes. Technologically, FTIR water detection has reached moderate maturity, with companies at different development stages. Industry leaders like Daylight Solutions and Orono Spectral Solutions offer specialized FTIR solutions, while research institutions such as Heriot-Watt University and Technical University of Denmark contribute significant innovations. Major corporations including Saudi Aramco, Boeing, and Philips incorporate these technologies into their quality control systems. The competitive landscape features specialized instrumentation providers alongside academic research centers, with emerging players from China like Hangzhou Puyu Technology increasingly entering the market.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed specialized FTIR-based water detection technologies optimized for petroleum industry applications. Their approach combines attenuated total reflectance (ATR) FTIR with advanced chemometric modeling specifically calibrated for crude oil, refined products, and petrochemical streams. The company's technology employs specialized sampling accessories designed to handle the unique challenges of high-viscosity and optically dense petroleum samples. Their systems feature automated sample preparation modules that can handle emulsified water in oil samples through controlled heating and homogenization protocols. Saudi Aramco's methodology incorporates multivariate statistical analysis to differentiate between water signals and hydrocarbon matrix interference, enabling accurate quantification across diverse petroleum compositions. The technology includes specialized calibration procedures that account for the varying optical properties of different crude oil types. Their systems support both laboratory analysis and field-deployable units for real-time monitoring at production sites, with ruggedized components designed to withstand harsh oilfield environments.

Strengths: Highly specialized for petroleum industry applications; robust performance with challenging sample types (heavy crude, emulsions); field-deployable options for remote operations; extensive calibration libraries for different petroleum compositions. Weaknesses: Less versatile for non-petroleum applications; may require frequent recalibration with changing crude sources; higher complexity systems requiring specialized maintenance.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed comprehensive FTIR-based solutions for water detection across multiple industrial applications. Their technology incorporates both transmission and attenuated total reflectance (ATR) FTIR methodologies optimized for different sample types and concentration ranges. For polymer applications, Dow has pioneered specialized sampling techniques that can detect water content as low as 10 ppm in hydrophobic matrices. Their approach employs chemometric modeling with multivariate analysis to overcome matrix interference issues, particularly in complex chemical environments. The company has developed industry-specific calibration libraries that account for the unique spectral characteristics of different material types. Dow's systems feature automated sampling handling capabilities for high-throughput industrial environments, with specialized flow cells for continuous online monitoring of water content in process streams. Their technology includes temperature-controlled sampling accessories to maintain measurement consistency across varying environmental conditions.

Strengths: Extensive application-specific expertise across multiple industries; robust systems designed for industrial environments; comprehensive calibration libraries for different material types; capability for online continuous monitoring. Weaknesses: Systems often require significant customization for specific applications; higher implementation complexity for full integration into production environments; may require regular recalibration for changing product formulations.

Key Spectral Analysis Techniques for Water Detection

System and process for detecting phosphonate

PatentInactiveUS20140264055A1

Innovation

- A system and process using optical and electronic technology with a side stream sampling subsystem, optical sources, and a processing subsystem that measures phosphonate concentrations by detecting absorption and photodegradation, allowing for on-site, real-time monitoring and dosing of chemicals to prevent scale, rust, and corrosion.

particle detection device and method and method of manufacture

PatentInactiveFR3104718A1

Innovation

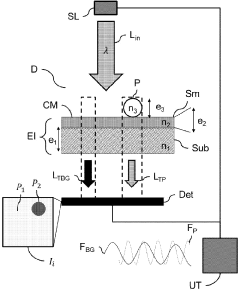

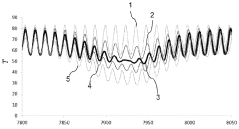

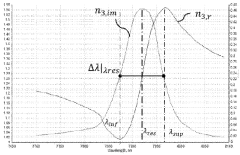

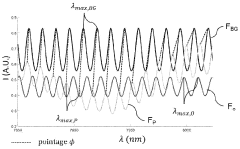

- A compact particle detection device using a Fabry-Pérot interferometric element with a thin layer and substrate forming a cavity, employing tunable coherent radiation to detect phase shifts in pixel intensity variations, allowing for rapid identification of particles through Fabry-Pérot cavity fringes inversion.

Calibration Standards and Reference Materials

Accurate water content determination using FTIR techniques critically depends on the quality and appropriateness of calibration standards and reference materials. The selection of suitable calibration standards represents a fundamental step in developing reliable quantitative methods for water detection across various matrices.

Primary calibration standards for water content analysis typically include certified reference materials (CRMs) with precisely known water concentrations. These standards are produced by metrological institutes such as NIST (National Institute of Standards and Technology) and provide traceability to SI units, ensuring measurement accuracy. For FTIR applications, KF-titrated standards with verified water content serve as excellent calibration references, particularly when analyzing similar matrices to the samples of interest.

Matrix-matched reference materials deserve special consideration as they account for matrix effects that can significantly influence FTIR spectral responses. When analyzing water in complex organic solvents, for instance, calibration standards should contain similar chemical compositions to minimize spectral interferences. Commercial suppliers now offer industry-specific reference materials for pharmaceuticals, petrochemicals, and food products with certified water content levels spanning typical concentration ranges.

The preparation and handling of calibration standards require meticulous attention to prevent moisture contamination. Standards should be stored in hermetically sealed containers, preferably under inert gas atmospheres, and equilibrated to measurement temperature before use. For volatile matrices, specialized sealed cells with known path lengths help maintain sample integrity during measurement.

Multi-point calibration approaches using standards that bracket the expected concentration range yield superior quantitative results compared to single-point calibrations. Statistical validation of calibration curves through parameters like R² values, residual analysis, and prediction intervals provides confidence in measurement reliability. Regular verification using independent reference materials helps detect calibration drift and systematic errors.

For specialized applications, in-house preparation of calibration standards may be necessary. This involves precise gravimetric or volumetric addition of water to anhydrous matrices, followed by verification using established methods like Karl Fischer titration. Documentation of preparation procedures, uncertainty calculations, and stability testing ensures the long-term reliability of these standards.

Interlaboratory comparison programs offer valuable opportunities to validate calibration approaches against peer laboratories. Participation in proficiency testing schemes specifically designed for water content determination helps identify methodological biases and provides external quality assurance for FTIR-based water detection methods.

Primary calibration standards for water content analysis typically include certified reference materials (CRMs) with precisely known water concentrations. These standards are produced by metrological institutes such as NIST (National Institute of Standards and Technology) and provide traceability to SI units, ensuring measurement accuracy. For FTIR applications, KF-titrated standards with verified water content serve as excellent calibration references, particularly when analyzing similar matrices to the samples of interest.

Matrix-matched reference materials deserve special consideration as they account for matrix effects that can significantly influence FTIR spectral responses. When analyzing water in complex organic solvents, for instance, calibration standards should contain similar chemical compositions to minimize spectral interferences. Commercial suppliers now offer industry-specific reference materials for pharmaceuticals, petrochemicals, and food products with certified water content levels spanning typical concentration ranges.

The preparation and handling of calibration standards require meticulous attention to prevent moisture contamination. Standards should be stored in hermetically sealed containers, preferably under inert gas atmospheres, and equilibrated to measurement temperature before use. For volatile matrices, specialized sealed cells with known path lengths help maintain sample integrity during measurement.

Multi-point calibration approaches using standards that bracket the expected concentration range yield superior quantitative results compared to single-point calibrations. Statistical validation of calibration curves through parameters like R² values, residual analysis, and prediction intervals provides confidence in measurement reliability. Regular verification using independent reference materials helps detect calibration drift and systematic errors.

For specialized applications, in-house preparation of calibration standards may be necessary. This involves precise gravimetric or volumetric addition of water to anhydrous matrices, followed by verification using established methods like Karl Fischer titration. Documentation of preparation procedures, uncertainty calculations, and stability testing ensures the long-term reliability of these standards.

Interlaboratory comparison programs offer valuable opportunities to validate calibration approaches against peer laboratories. Participation in proficiency testing schemes specifically designed for water content determination helps identify methodological biases and provides external quality assurance for FTIR-based water detection methods.

Environmental Factors Affecting Measurement Accuracy

Environmental conditions play a critical role in determining the accuracy and reliability of water content measurements using Fourier Transform Infrared (FTIR) spectroscopy. Temperature variations represent one of the most significant environmental factors affecting FTIR measurements. When ambient temperature fluctuates, it can cause thermal expansion or contraction of optical components within the FTIR instrument, potentially leading to wavelength shifts and baseline drifts. Research indicates that even minor temperature changes of ±2°C can result in measurement deviations exceeding 5% for certain water content applications.

Humidity levels in the testing environment constitute another crucial factor impacting measurement accuracy. Atmospheric water vapor can interfere directly with sample analysis by contributing absorption bands that overlap with those of the target water content being measured. This interference becomes particularly problematic when analyzing samples with low water concentrations, where the signal-to-noise ratio is already challenging. Controlled environments maintaining relative humidity below 30% are often recommended for high-precision measurements.

Atmospheric CO2 concentrations represent a third significant environmental variable affecting FTIR water content measurements. Carbon dioxide exhibits strong absorption bands in regions that may overlap with water's spectroscopic signature, particularly around 2350 cm⁻¹ and 667 cm⁻¹. These overlaps can complicate spectral interpretation and quantification if not properly accounted for in calibration models.

Vibration and mechanical stability issues can severely compromise measurement accuracy in industrial settings. Even minor vibrations transmitted through floors or nearby equipment can disrupt the precise optical alignment necessary for FTIR measurements. Studies have demonstrated that vibration-induced errors can contribute up to 8% uncertainty in water content determinations, particularly in portable or field-deployed FTIR systems.

Dust and particulate contamination represent an often-overlooked environmental factor affecting FTIR performance. Airborne particles can gradually accumulate on optical surfaces, reducing light throughput and introducing scattering effects that distort spectral features. This degradation typically manifests as a progressive decline in signal-to-noise ratio and measurement precision over time.

Electromagnetic interference (EMI) from nearby electronic equipment can introduce noise artifacts in FTIR measurements, particularly affecting the detector and signal processing components. This interference becomes especially problematic in industrial environments with multiple high-power devices operating simultaneously. Proper shielding and grounding protocols are essential to maintain measurement integrity under such conditions.

Humidity levels in the testing environment constitute another crucial factor impacting measurement accuracy. Atmospheric water vapor can interfere directly with sample analysis by contributing absorption bands that overlap with those of the target water content being measured. This interference becomes particularly problematic when analyzing samples with low water concentrations, where the signal-to-noise ratio is already challenging. Controlled environments maintaining relative humidity below 30% are often recommended for high-precision measurements.

Atmospheric CO2 concentrations represent a third significant environmental variable affecting FTIR water content measurements. Carbon dioxide exhibits strong absorption bands in regions that may overlap with water's spectroscopic signature, particularly around 2350 cm⁻¹ and 667 cm⁻¹. These overlaps can complicate spectral interpretation and quantification if not properly accounted for in calibration models.

Vibration and mechanical stability issues can severely compromise measurement accuracy in industrial settings. Even minor vibrations transmitted through floors or nearby equipment can disrupt the precise optical alignment necessary for FTIR measurements. Studies have demonstrated that vibration-induced errors can contribute up to 8% uncertainty in water content determinations, particularly in portable or field-deployed FTIR systems.

Dust and particulate contamination represent an often-overlooked environmental factor affecting FTIR performance. Airborne particles can gradually accumulate on optical surfaces, reducing light throughput and introducing scattering effects that distort spectral features. This degradation typically manifests as a progressive decline in signal-to-noise ratio and measurement precision over time.

Electromagnetic interference (EMI) from nearby electronic equipment can introduce noise artifacts in FTIR measurements, particularly affecting the detector and signal processing components. This interference becomes especially problematic in industrial environments with multiple high-power devices operating simultaneously. Proper shielding and grounding protocols are essential to maintain measurement integrity under such conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!