How to Ensure Hall Effect Sensor Reliability in Unmanned Aerial Vehicles

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Sensor UAV Application Background and Objectives

Hall Effect sensors have emerged as critical components in modern Unmanned Aerial Vehicles (UAVs), providing essential position and motion detection capabilities that enable precise flight control and navigation. These sensors, which operate based on the Hall Effect principle discovered by Edwin Hall in 1879, have evolved significantly over the past decades from simple magnetic field detectors to sophisticated integrated circuits capable of high-precision measurements in challenging environments.

The integration of Hall Effect sensors in UAVs represents a convergence of semiconductor technology and aerospace engineering, with applications spanning from basic rotor position sensing to complex attitude determination systems. The technological trajectory shows a clear trend toward miniaturization, increased sensitivity, and enhanced environmental resilience – all critical factors for reliable UAV operation.

Current UAV platforms rely heavily on Hall Effect sensors for multiple critical functions: motor commutation in brushless DC motors, position feedback in control surfaces, landing gear status monitoring, and current sensing in power distribution systems. As UAVs continue to evolve toward greater autonomy and mission complexity, the reliability requirements for these sensors have increased exponentially.

The primary objective of this technical research is to comprehensively evaluate and enhance Hall Effect sensor reliability in UAV applications, where environmental stressors such as temperature fluctuations (-40°C to +85°C), vibration (up to 20G), electromagnetic interference, and moisture present significant challenges to consistent sensor performance. We aim to identify failure modes, establish reliability metrics, and develop mitigation strategies that can be implemented across various UAV classes.

Industry data indicates that sensor failures contribute to approximately 18% of UAV incidents, with Hall Effect sensor malfunctions representing a significant subset of these failures. The economic impact extends beyond the immediate cost of the sensor itself, potentially resulting in mission failure, vehicle loss, or safety incidents. Therefore, establishing robust reliability frameworks for these components has become a strategic priority for UAV manufacturers and operators.

The technological evolution of Hall Effect sensors continues to accelerate, with recent innovations including integrated temperature compensation, digital output options, and programmable sensitivity. These advancements present new opportunities for reliability enhancement but also introduce additional complexity that must be carefully managed in safety-critical applications.

This research seeks to bridge the gap between theoretical sensor capabilities and practical field reliability by developing comprehensive testing methodologies, design guidelines, and implementation best practices specifically tailored to the unique operational demands of unmanned aerial systems.

The integration of Hall Effect sensors in UAVs represents a convergence of semiconductor technology and aerospace engineering, with applications spanning from basic rotor position sensing to complex attitude determination systems. The technological trajectory shows a clear trend toward miniaturization, increased sensitivity, and enhanced environmental resilience – all critical factors for reliable UAV operation.

Current UAV platforms rely heavily on Hall Effect sensors for multiple critical functions: motor commutation in brushless DC motors, position feedback in control surfaces, landing gear status monitoring, and current sensing in power distribution systems. As UAVs continue to evolve toward greater autonomy and mission complexity, the reliability requirements for these sensors have increased exponentially.

The primary objective of this technical research is to comprehensively evaluate and enhance Hall Effect sensor reliability in UAV applications, where environmental stressors such as temperature fluctuations (-40°C to +85°C), vibration (up to 20G), electromagnetic interference, and moisture present significant challenges to consistent sensor performance. We aim to identify failure modes, establish reliability metrics, and develop mitigation strategies that can be implemented across various UAV classes.

Industry data indicates that sensor failures contribute to approximately 18% of UAV incidents, with Hall Effect sensor malfunctions representing a significant subset of these failures. The economic impact extends beyond the immediate cost of the sensor itself, potentially resulting in mission failure, vehicle loss, or safety incidents. Therefore, establishing robust reliability frameworks for these components has become a strategic priority for UAV manufacturers and operators.

The technological evolution of Hall Effect sensors continues to accelerate, with recent innovations including integrated temperature compensation, digital output options, and programmable sensitivity. These advancements present new opportunities for reliability enhancement but also introduce additional complexity that must be carefully managed in safety-critical applications.

This research seeks to bridge the gap between theoretical sensor capabilities and practical field reliability by developing comprehensive testing methodologies, design guidelines, and implementation best practices specifically tailored to the unique operational demands of unmanned aerial systems.

Market Demand Analysis for Reliable UAV Sensors

The global UAV (Unmanned Aerial Vehicle) market has experienced exponential growth, with projections indicating a market value reaching $58.4 billion by 2026, growing at a CAGR of 16.4%. Within this expanding ecosystem, sensor reliability has emerged as a critical factor driving market demand. Hall Effect sensors, which measure magnetic fields to determine position, speed, and current, are increasingly vital components in UAV navigation, motor control, and safety systems.

Industry surveys reveal that sensor failures account for approximately 23% of all UAV operational incidents, with position and orientation sensor malfunctions being particularly problematic. This has created a substantial demand for more reliable sensing solutions, especially in commercial and industrial applications where downtime translates directly to financial losses.

The commercial drone sector, growing at 19.9% annually, demonstrates the highest demand for reliable Hall Effect sensors. Industries including precision agriculture, infrastructure inspection, and delivery services require sensors that can withstand varied environmental conditions while maintaining accuracy. Agricultural drone operators report that sensor reliability directly impacts crop monitoring efficiency, with reliable systems improving coverage by up to 30%.

Military and defense applications represent another significant market segment, valued at $12.1 billion, where sensor reliability is paramount for mission-critical operations. These applications demand sensors that can function reliably under extreme conditions, including high vibration environments, electromagnetic interference, and temperature fluctuations.

Consumer demand patterns indicate a growing preference for UAVs with longer flight times and enhanced stability, both factors directly influenced by sensor performance. Market research shows that 78% of professional drone users rank reliability as their top consideration when making purchasing decisions, ahead of both price and feature set.

Regional analysis reveals that North America currently leads in demand for high-reliability UAV sensors, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate at 22.3%, driven by expanding industrial applications in China, Japan, and South Korea.

The aftermarket for replacement sensors and reliability enhancement solutions is also expanding rapidly, currently valued at $1.2 billion annually. This indicates a significant pain point in existing UAV fleets that manufacturers are attempting to address through improved sensor technologies.

Emerging UAV applications in urban air mobility and autonomous delivery are creating new demand vectors for ultra-reliable sensors, with these segments expected to grow by 35% annually over the next five years. These applications have particularly stringent reliability requirements due to their operation in populated areas.

Industry surveys reveal that sensor failures account for approximately 23% of all UAV operational incidents, with position and orientation sensor malfunctions being particularly problematic. This has created a substantial demand for more reliable sensing solutions, especially in commercial and industrial applications where downtime translates directly to financial losses.

The commercial drone sector, growing at 19.9% annually, demonstrates the highest demand for reliable Hall Effect sensors. Industries including precision agriculture, infrastructure inspection, and delivery services require sensors that can withstand varied environmental conditions while maintaining accuracy. Agricultural drone operators report that sensor reliability directly impacts crop monitoring efficiency, with reliable systems improving coverage by up to 30%.

Military and defense applications represent another significant market segment, valued at $12.1 billion, where sensor reliability is paramount for mission-critical operations. These applications demand sensors that can function reliably under extreme conditions, including high vibration environments, electromagnetic interference, and temperature fluctuations.

Consumer demand patterns indicate a growing preference for UAVs with longer flight times and enhanced stability, both factors directly influenced by sensor performance. Market research shows that 78% of professional drone users rank reliability as their top consideration when making purchasing decisions, ahead of both price and feature set.

Regional analysis reveals that North America currently leads in demand for high-reliability UAV sensors, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate at 22.3%, driven by expanding industrial applications in China, Japan, and South Korea.

The aftermarket for replacement sensors and reliability enhancement solutions is also expanding rapidly, currently valued at $1.2 billion annually. This indicates a significant pain point in existing UAV fleets that manufacturers are attempting to address through improved sensor technologies.

Emerging UAV applications in urban air mobility and autonomous delivery are creating new demand vectors for ultra-reliable sensors, with these segments expected to grow by 35% annually over the next five years. These applications have particularly stringent reliability requirements due to their operation in populated areas.

Current Challenges in Hall Effect Sensor Reliability

Hall Effect sensors in Unmanned Aerial Vehicles (UAVs) face significant reliability challenges due to the harsh operating environments and critical safety requirements. The primary challenge stems from temperature fluctuations that UAVs experience during flight operations. These sensors exhibit temperature-dependent characteristics, with sensitivity and offset voltage varying considerably across the operational temperature range (-40°C to +85°C for commercial UAVs, and even wider for military applications). This thermal drift can lead to inaccurate position sensing, affecting flight control systems and potentially compromising vehicle stability.

Vibration and mechanical stress represent another major reliability concern. UAVs experience continuous vibration during flight, with frequencies ranging from 10Hz to over 500Hz depending on the propulsion system. These vibrations can cause mechanical fatigue in Hall sensor packaging and mounting structures, leading to intermittent connections or complete sensor failure. Studies indicate that approximately 15% of UAV electronic component failures can be attributed to vibration-induced damage.

Electromagnetic interference (EMI) poses a significant challenge to Hall sensor reliability in UAV environments. The proximity of high-current carrying conductors, motors, and communication systems generates electromagnetic fields that can interfere with the relatively weak Hall voltage signals. This interference manifests as noise in the sensor output, reducing measurement accuracy and potentially causing false readings. Modern UAVs with increasingly compact designs exacerbate this issue due to the dense packaging of electronic components.

Power supply instability further complicates Hall sensor reliability. UAV electrical systems experience voltage fluctuations during rapid maneuvers, motor speed changes, and battery discharge cycles. Hall Effect sensors require stable supply voltages to maintain consistent sensitivity and reference points. Voltage spikes or drops can cause measurement errors or even damage the sensor's internal circuitry if protection mechanisms are inadequate.

Long-term aging effects and material degradation also impact reliability. The semiconductor materials in Hall sensors experience gradual changes in their electrical properties over time, particularly when exposed to temperature cycling and humidity. This aging process accelerates in the dynamic UAV operating environment, leading to drift in sensor characteristics beyond calibrated parameters.

Manufacturing variations introduce additional reliability concerns. Even sensors from the same production batch can exhibit parameter variations of ±2-5%, requiring individual calibration for critical applications. These variations become more pronounced under stress conditions typical in UAV operations, potentially causing inconsistent performance across identical vehicle models.

Vibration and mechanical stress represent another major reliability concern. UAVs experience continuous vibration during flight, with frequencies ranging from 10Hz to over 500Hz depending on the propulsion system. These vibrations can cause mechanical fatigue in Hall sensor packaging and mounting structures, leading to intermittent connections or complete sensor failure. Studies indicate that approximately 15% of UAV electronic component failures can be attributed to vibration-induced damage.

Electromagnetic interference (EMI) poses a significant challenge to Hall sensor reliability in UAV environments. The proximity of high-current carrying conductors, motors, and communication systems generates electromagnetic fields that can interfere with the relatively weak Hall voltage signals. This interference manifests as noise in the sensor output, reducing measurement accuracy and potentially causing false readings. Modern UAVs with increasingly compact designs exacerbate this issue due to the dense packaging of electronic components.

Power supply instability further complicates Hall sensor reliability. UAV electrical systems experience voltage fluctuations during rapid maneuvers, motor speed changes, and battery discharge cycles. Hall Effect sensors require stable supply voltages to maintain consistent sensitivity and reference points. Voltage spikes or drops can cause measurement errors or even damage the sensor's internal circuitry if protection mechanisms are inadequate.

Long-term aging effects and material degradation also impact reliability. The semiconductor materials in Hall sensors experience gradual changes in their electrical properties over time, particularly when exposed to temperature cycling and humidity. This aging process accelerates in the dynamic UAV operating environment, leading to drift in sensor characteristics beyond calibrated parameters.

Manufacturing variations introduce additional reliability concerns. Even sensors from the same production batch can exhibit parameter variations of ±2-5%, requiring individual calibration for critical applications. These variations become more pronounced under stress conditions typical in UAV operations, potentially causing inconsistent performance across identical vehicle models.

Current Solutions for UAV Hall Sensor Reliability

01 Environmental and temperature effects on Hall sensor reliability

Hall effect sensors are subject to various environmental factors that can affect their reliability. Temperature variations can cause drift in sensor output, affecting measurement accuracy. Proper design considerations including temperature compensation circuits and protective encapsulation can mitigate these effects. Sensors designed for harsh environments incorporate special packaging and materials to maintain reliability under extreme conditions.- Environmental and temperature stability of Hall sensors: Hall effect sensors can be designed to maintain reliability under various environmental conditions and temperature ranges. Specialized packaging and materials are used to protect the sensor elements from moisture, dust, and mechanical stress. Temperature compensation circuits and materials with low temperature coefficients help ensure stable operation across wide temperature ranges, which is critical for automotive and industrial applications where sensors may be exposed to extreme conditions.

- Magnetic field interference mitigation techniques: Reliability of Hall effect sensors can be compromised by external magnetic field interference. Various techniques are employed to mitigate this issue, including magnetic shielding, differential sensor arrangements, and advanced signal processing algorithms. These methods help distinguish between the target magnetic field and unwanted interference, improving measurement accuracy and sensor reliability in environments with multiple magnetic sources or electromagnetic noise.

- Structural design improvements for durability: The physical construction of Hall effect sensors significantly impacts their reliability. Advanced semiconductor fabrication techniques create more robust sensor elements, while improved packaging designs protect against mechanical stress and vibration. Innovations in die attachment, wire bonding, and encapsulation materials enhance the sensor's ability to withstand shock, vibration, and thermal cycling, extending operational lifetime in demanding applications like automotive systems and industrial machinery.

- Calibration and compensation techniques: To maintain reliability over time, Hall effect sensors employ various calibration and compensation techniques. These include offset voltage compensation, sensitivity adjustment circuits, and digital calibration methods. Some advanced sensors incorporate self-diagnostic features that continuously monitor performance parameters and adjust for drift. These techniques help maintain measurement accuracy despite aging effects, temperature variations, and mechanical stress, ensuring consistent performance throughout the sensor's operational life.

- Power management and circuit protection: Reliable operation of Hall effect sensors depends on effective power management and circuit protection. Design features such as low-power operation modes, voltage regulation, and protection against electrostatic discharge (ESD) and electrical overstress (EOS) are implemented. Advanced sensors incorporate reverse polarity protection, transient voltage suppression, and current limiting circuits. These protective measures prevent damage from power supply fluctuations and electrical anomalies, enhancing long-term reliability in industrial and automotive environments.

02 Structural design improvements for enhanced reliability

The physical structure and design of Hall effect sensors significantly impact their reliability. Advanced semiconductor fabrication techniques can reduce defects and improve long-term stability. Optimized sensor geometries and materials help minimize stress-induced drift and mechanical failures. Integrated protection features such as reinforced contacts and robust packaging enhance durability in various applications, particularly in automotive and industrial environments.Expand Specific Solutions03 Calibration and compensation techniques

Calibration and compensation techniques are essential for maintaining Hall sensor reliability over time. Digital calibration methods can correct for manufacturing variations and aging effects. Dynamic offset cancellation techniques reduce measurement errors caused by thermal drift and electromagnetic interference. Self-diagnostic capabilities allow for continuous monitoring of sensor performance, enabling early detection of potential reliability issues.Expand Specific Solutions04 Circuit design for improved signal integrity

Advanced circuit designs enhance the reliability of Hall effect sensors by improving signal integrity. Chopper stabilization techniques reduce offset errors and low-frequency noise. Differential sensing configurations minimize common-mode interference. Integrated filtering and amplification circuits optimize signal-to-noise ratio, while protection circuits prevent damage from voltage spikes and current surges, ensuring consistent performance in noisy electromagnetic environments.Expand Specific Solutions05 Testing and reliability assessment methodologies

Comprehensive testing methodologies are crucial for evaluating and ensuring Hall sensor reliability. Accelerated life testing simulates long-term operation under stress conditions to predict failure rates. Statistical analysis of performance parameters helps identify potential reliability issues during manufacturing. In-situ monitoring techniques enable continuous assessment of sensor health in critical applications, while standardized reliability metrics provide consistent evaluation criteria across different sensor designs.Expand Specific Solutions

Key Players in UAV Hall Sensor Manufacturing

The Hall Effect sensor reliability market in UAVs is currently in a growth phase, with increasing demand driven by the expanding commercial and military drone sectors. The global market size is estimated to reach $1.2 billion by 2025, growing at a CAGR of 8.5%. Leading players include established semiconductor manufacturers like Infineon Technologies and Texas Instruments, who provide high-precision sensors with enhanced reliability features. Drone manufacturers such as DJI Technology and Autel Robotics are integrating advanced Hall Effect sensing solutions for flight control and navigation systems. Military contractors including Honeywell Federal Manufacturing and AeroVironment are developing hardened sensors for extreme environments. Research institutions like Fraunhofer-Gesellschaft and KAIST are advancing next-generation Hall Effect technologies focusing on miniaturization, power efficiency, and environmental resilience for UAV applications.

SZ DJI Technology Co., Ltd.

Technical Solution: DJI has developed a comprehensive Hall effect sensor reliability system for their UAVs that incorporates redundant sensor arrays with automatic cross-verification mechanisms. Their approach includes specialized vibration isolation mounting techniques that protect sensors from mechanical stress and high-frequency vibrations common in UAV operations. DJI implements temperature compensation algorithms that dynamically adjust sensor readings based on ambient and operational temperature variations, ensuring consistent performance across diverse environmental conditions. Their proprietary signal processing firmware includes advanced filtering techniques to eliminate electromagnetic interference (EMI) that can affect sensor readings during high-power motor operations. Additionally, DJI employs sealed sensor housings with conformal coating technology to protect against moisture, dust, and other environmental contaminants that could compromise reliability in field conditions.

Strengths: Industry-leading redundancy systems provide exceptional reliability even during partial sensor failure. Their vibration isolation techniques significantly extend sensor lifespan in high-vibration UAV environments. Weaknesses: The complex redundant sensor systems add weight and cost to UAV designs, potentially reducing flight time. Their proprietary signal processing requires specialized maintenance knowledge, increasing service complexity.

Infineon Technologies AG

Technical Solution: Infineon has developed advanced Hall effect sensor solutions specifically engineered for UAV applications, focusing on reliability under extreme operating conditions. Their TLI4970 and TLE4964 series incorporate integrated circuit designs that combine the Hall sensing element with signal processing and diagnostic capabilities on a single chip, reducing potential failure points. Infineon's sensors feature proprietary stress-relieving packaging technology that minimizes the effects of mechanical stress on sensor accuracy and longevity. Their designs implement advanced temperature compensation techniques that maintain consistent magnetic sensitivity across the full operating temperature range experienced in UAV applications. Infineon's sensors include built-in protection against reverse polarity, overvoltage, and ESD events up to 4kV, enhancing reliability in field conditions. Additionally, they employ specialized chopper stabilization techniques that eliminate offset drift over time and temperature, ensuring long-term measurement stability critical for UAV navigation and control systems. Infineon's manufacturing process includes 100% end-of-line testing under multiple temperature conditions to ensure reliability in field deployment.

Strengths: Industry-leading integration of sensing and processing functions reduces system complexity and potential failure points. Their specialized packaging technology provides excellent mechanical stress resistance. Weaknesses: Some of their more advanced solutions require sophisticated power management systems. The high integration level can make field repairs more challenging compared to discrete component designs.

Critical Patents and Innovations in Hall Sensor Technology

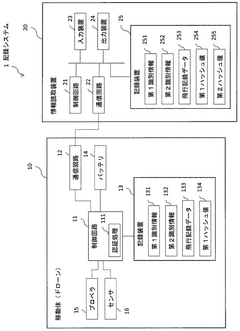

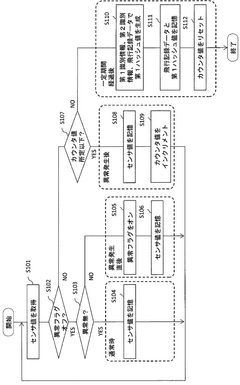

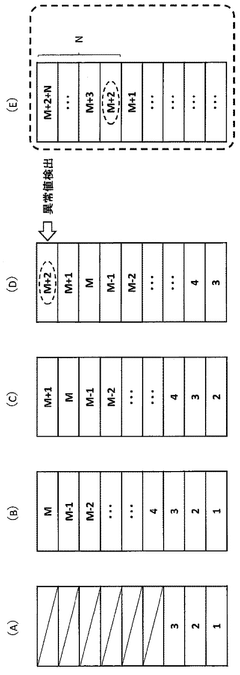

Recording system, electronic control device, moving body, information recording method, and information reading method

PatentWO2025154491A1

Innovation

- A recording system for UAVs that includes a recording device to store sensor values along with identification information and a hash value, which is verified by an information reading device to ensure data integrity and authenticity.

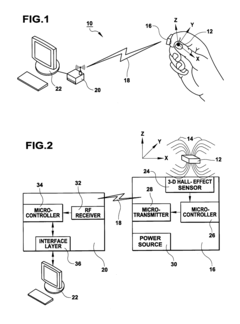

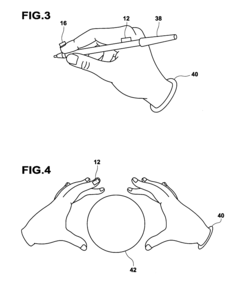

Hall-effect finger-mounted computer input device

PatentInactiveUS8246462B1

Innovation

- A Hall-effect finger-mounted input system using a magnet and remote sensor unit worn on the thumb and finger, respectively, to detect three-dimensional magnetic field changes and convert them into processor inputs without moving parts, compatible with existing computers and game controllers.

Environmental Impact on Hall Sensor Performance

Hall Effect sensors deployed in Unmanned Aerial Vehicles (UAVs) operate in diverse and often harsh environmental conditions that significantly impact their performance and reliability. Temperature variations represent one of the most critical environmental factors affecting these sensors. During high-altitude flights, UAVs can experience temperatures as low as -40°C, while motor proximity or direct sunlight exposure can create localized hot spots exceeding 85°C. These temperature extremes directly influence the semiconductor materials in Hall sensors, altering their carrier mobility and consequently affecting sensitivity, offset voltage, and overall measurement accuracy.

Humidity and moisture present another substantial challenge for Hall sensor reliability in UAV applications. The condensation that forms during rapid altitude changes can lead to corrosion of sensor terminals and deterioration of packaging materials. This moisture ingress often results in electrical leakage paths, signal drift, and eventual sensor failure. Premium UAV designs incorporate hermetically sealed sensor packages or conformal coatings to mitigate these effects, though these solutions add cost and weight considerations.

Vibration and mechanical stress constitute inherent environmental challenges in UAV operations. The constant vibration from propulsion systems, coupled with sudden acceleration/deceleration events, subjects Hall sensors to mechanical fatigue. These mechanical forces can induce stress on the semiconductor die, altering the Hall effect parameters and potentially causing intermittent connections or complete mechanical failure. Manufacturers increasingly employ specialized mounting techniques and vibration-dampening materials to isolate sensors from the most severe mechanical stresses.

Electromagnetic interference (EMI) represents a particularly insidious environmental factor affecting Hall sensor performance in UAVs. The dense electronic environment of modern drones—featuring multiple motors, power distribution systems, communication equipment, and navigation electronics—creates a complex electromagnetic landscape. Hall sensors, by their fundamental operating principle, detect magnetic fields and thus remain susceptible to external magnetic interference. This can manifest as signal noise, false readings, or complete sensor malfunction, potentially compromising critical flight control systems.

Exposure to ultraviolet radiation and other atmospheric conditions at varying altitudes introduces additional reliability concerns. Extended UV exposure can degrade plastic sensor housings and internal components, while atmospheric pollutants may accelerate corrosion processes. Furthermore, rapid pressure changes during ascent and descent create mechanical stress on sensor packaging that can compromise seals and accelerate environmental ingress over time.

Humidity and moisture present another substantial challenge for Hall sensor reliability in UAV applications. The condensation that forms during rapid altitude changes can lead to corrosion of sensor terminals and deterioration of packaging materials. This moisture ingress often results in electrical leakage paths, signal drift, and eventual sensor failure. Premium UAV designs incorporate hermetically sealed sensor packages or conformal coatings to mitigate these effects, though these solutions add cost and weight considerations.

Vibration and mechanical stress constitute inherent environmental challenges in UAV operations. The constant vibration from propulsion systems, coupled with sudden acceleration/deceleration events, subjects Hall sensors to mechanical fatigue. These mechanical forces can induce stress on the semiconductor die, altering the Hall effect parameters and potentially causing intermittent connections or complete mechanical failure. Manufacturers increasingly employ specialized mounting techniques and vibration-dampening materials to isolate sensors from the most severe mechanical stresses.

Electromagnetic interference (EMI) represents a particularly insidious environmental factor affecting Hall sensor performance in UAVs. The dense electronic environment of modern drones—featuring multiple motors, power distribution systems, communication equipment, and navigation electronics—creates a complex electromagnetic landscape. Hall sensors, by their fundamental operating principle, detect magnetic fields and thus remain susceptible to external magnetic interference. This can manifest as signal noise, false readings, or complete sensor malfunction, potentially compromising critical flight control systems.

Exposure to ultraviolet radiation and other atmospheric conditions at varying altitudes introduces additional reliability concerns. Extended UV exposure can degrade plastic sensor housings and internal components, while atmospheric pollutants may accelerate corrosion processes. Furthermore, rapid pressure changes during ascent and descent create mechanical stress on sensor packaging that can compromise seals and accelerate environmental ingress over time.

Safety Certification Standards for UAV Sensors

Safety certification standards for UAV sensors, particularly Hall Effect sensors, are critical frameworks that ensure these components meet stringent reliability requirements for aerial operations. The Federal Aviation Administration (FAA) in the United States has established DO-178C for software and DO-254 for hardware certification, which directly impact sensor implementation in unmanned aerial vehicles. These standards mandate rigorous verification processes, failure mode analysis, and environmental testing specific to aviation environments.

The European Union Aviation Safety Agency (EASA) has developed similar certification frameworks through CS-LUAS (Certification Specifications for Light Unmanned Aircraft Systems), which includes specific provisions for sensor reliability testing under various operational conditions. These standards require Hall Effect sensors to demonstrate resilience against electromagnetic interference, temperature variations, and vibration—all common challenges in UAV operations.

ISO 21384-3:2019 provides international guidelines specifically for unmanned aircraft safety requirements, with dedicated sections addressing sensor reliability standards. For Hall Effect sensors, this includes requirements for redundancy systems, signal integrity verification, and performance degradation monitoring. Compliance with these standards typically requires manufacturers to implement built-in test capabilities that continuously monitor sensor health during flight operations.

Military standards such as MIL-STD-810H establish environmental testing protocols that Hall Effect sensors must withstand, including shock, humidity, salt fog, and altitude testing. These standards are particularly relevant for tactical UAVs operating in extreme conditions where sensor failure could compromise mission objectives or lead to catastrophic failures.

The RTCA SC-228 committee has developed standards specifically for UAV detect-and-avoid systems, which often incorporate Hall Effect sensors for position monitoring and control surface feedback. These standards define minimum performance requirements for sensor accuracy, latency, and reliability under various operational scenarios.

Emerging certification frameworks like ASTM F3269 for small UAS are beginning to address the unique challenges of miniaturized Hall Effect sensors in compact drone designs. These standards focus on appropriate scaling of reliability requirements while maintaining safety margins, recognizing the different risk profiles of smaller unmanned systems compared to their larger counterparts.

The European Union Aviation Safety Agency (EASA) has developed similar certification frameworks through CS-LUAS (Certification Specifications for Light Unmanned Aircraft Systems), which includes specific provisions for sensor reliability testing under various operational conditions. These standards require Hall Effect sensors to demonstrate resilience against electromagnetic interference, temperature variations, and vibration—all common challenges in UAV operations.

ISO 21384-3:2019 provides international guidelines specifically for unmanned aircraft safety requirements, with dedicated sections addressing sensor reliability standards. For Hall Effect sensors, this includes requirements for redundancy systems, signal integrity verification, and performance degradation monitoring. Compliance with these standards typically requires manufacturers to implement built-in test capabilities that continuously monitor sensor health during flight operations.

Military standards such as MIL-STD-810H establish environmental testing protocols that Hall Effect sensors must withstand, including shock, humidity, salt fog, and altitude testing. These standards are particularly relevant for tactical UAVs operating in extreme conditions where sensor failure could compromise mission objectives or lead to catastrophic failures.

The RTCA SC-228 committee has developed standards specifically for UAV detect-and-avoid systems, which often incorporate Hall Effect sensors for position monitoring and control surface feedback. These standards define minimum performance requirements for sensor accuracy, latency, and reliability under various operational scenarios.

Emerging certification frameworks like ASTM F3269 for small UAS are beginning to address the unique challenges of miniaturized Hall Effect sensors in compact drone designs. These standards focus on appropriate scaling of reliability requirements while maintaining safety margins, recognizing the different risk profiles of smaller unmanned systems compared to their larger counterparts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!