How to Evaluate NMC Battery Pack Aging Processes

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Aging Evaluation Background and Objectives

Lithium-ion batteries with nickel manganese cobalt oxide (NMC) cathodes have emerged as a dominant technology in electric vehicles and energy storage systems due to their high energy density, good thermal stability, and relatively low cost. The evolution of NMC battery technology has progressed through several generations, from early NMC111 (equal parts nickel, manganese, and cobalt) to more recent high-nickel formulations like NMC811, each offering improvements in energy density and cycle life.

The aging of NMC battery packs represents a critical challenge for the electric vehicle industry and grid storage applications. Understanding degradation mechanisms is essential for accurate lifetime prediction, warranty determination, and optimization of battery management systems. The technical objective of NMC battery aging evaluation is to develop comprehensive methodologies that can accurately assess degradation under various operating conditions and predict remaining useful life.

Battery aging manifests through capacity fade and power loss, driven by complex electrochemical processes including solid-electrolyte interphase (SEI) growth, lithium plating, active material dissolution, and structural changes in the cathode. These mechanisms are influenced by multiple factors such as temperature, charge/discharge rates, depth of discharge, and calendar aging effects, creating a multidimensional challenge for evaluation methodologies.

Recent technological trends in NMC battery aging assessment include the integration of advanced diagnostic techniques such as electrochemical impedance spectroscopy (EIS), differential voltage analysis (DVA), and incremental capacity analysis (ICA). These methods provide deeper insights into degradation mechanisms than traditional capacity measurements alone. Additionally, the industry is moving toward non-invasive evaluation techniques that can be implemented in real-time during battery operation.

The development of physics-based models coupled with machine learning approaches represents another significant trend, enabling more accurate prediction of aging trajectories based on operational data. These hybrid models aim to balance computational efficiency with mechanistic understanding of degradation processes.

Our technical goals for NMC battery aging evaluation include establishing standardized testing protocols that can accelerate aging assessment while maintaining correlation with real-world degradation patterns. We also aim to develop multi-scale evaluation frameworks that connect cell-level aging phenomena to pack-level performance degradation, accounting for thermal, electrical, and mechanical interactions between cells.

Furthermore, we seek to advance prognostic capabilities that can predict remaining useful life with greater accuracy, incorporating adaptive algorithms that refine predictions as new operational data becomes available. This will support second-life applications and end-of-life decisions, maximizing the economic and environmental value of battery assets throughout their lifecycle.

The aging of NMC battery packs represents a critical challenge for the electric vehicle industry and grid storage applications. Understanding degradation mechanisms is essential for accurate lifetime prediction, warranty determination, and optimization of battery management systems. The technical objective of NMC battery aging evaluation is to develop comprehensive methodologies that can accurately assess degradation under various operating conditions and predict remaining useful life.

Battery aging manifests through capacity fade and power loss, driven by complex electrochemical processes including solid-electrolyte interphase (SEI) growth, lithium plating, active material dissolution, and structural changes in the cathode. These mechanisms are influenced by multiple factors such as temperature, charge/discharge rates, depth of discharge, and calendar aging effects, creating a multidimensional challenge for evaluation methodologies.

Recent technological trends in NMC battery aging assessment include the integration of advanced diagnostic techniques such as electrochemical impedance spectroscopy (EIS), differential voltage analysis (DVA), and incremental capacity analysis (ICA). These methods provide deeper insights into degradation mechanisms than traditional capacity measurements alone. Additionally, the industry is moving toward non-invasive evaluation techniques that can be implemented in real-time during battery operation.

The development of physics-based models coupled with machine learning approaches represents another significant trend, enabling more accurate prediction of aging trajectories based on operational data. These hybrid models aim to balance computational efficiency with mechanistic understanding of degradation processes.

Our technical goals for NMC battery aging evaluation include establishing standardized testing protocols that can accelerate aging assessment while maintaining correlation with real-world degradation patterns. We also aim to develop multi-scale evaluation frameworks that connect cell-level aging phenomena to pack-level performance degradation, accounting for thermal, electrical, and mechanical interactions between cells.

Furthermore, we seek to advance prognostic capabilities that can predict remaining useful life with greater accuracy, incorporating adaptive algorithms that refine predictions as new operational data becomes available. This will support second-life applications and end-of-life decisions, maximizing the economic and environmental value of battery assets throughout their lifecycle.

Market Demand Analysis for Battery Degradation Assessment

The global market for battery degradation assessment solutions is experiencing robust growth, primarily driven by the rapid expansion of electric vehicle (EV) adoption worldwide. As NMC (Nickel Manganese Cobalt) batteries continue to dominate the EV market due to their high energy density and relatively stable performance, the need for sophisticated aging evaluation tools has become increasingly critical for manufacturers, fleet operators, and end users alike.

Market research indicates that the battery health monitoring systems market is projected to grow at a compound annual growth rate of 19.5% between 2023 and 2030. This growth is particularly pronounced in regions with aggressive EV adoption targets, including Europe, North America, and parts of Asia, where regulatory frameworks increasingly mandate battery performance transparency and longevity guarantees.

The demand for NMC battery pack aging evaluation solutions stems from several key market factors. First, battery packs represent approximately 30-40% of an electric vehicle's total cost, making their longevity a significant economic consideration. Second, as the secondary market for EVs matures, accurate assessment of remaining battery life becomes essential for determining residual vehicle value. Third, warranty claims management requires precise degradation metrics to differentiate between normal aging and premature failure.

Commercial fleet operators have emerged as a particularly demanding segment, requiring real-time monitoring solutions that can predict maintenance needs and optimize charging strategies to extend battery life. These operators typically manage large fleets with high utilization rates, making even small improvements in battery longevity translate to substantial operational savings.

Energy storage system (ESS) applications represent another growing market segment, where NMC batteries are increasingly deployed for grid stabilization and renewable energy integration. In these applications, accurate degradation assessment directly impacts investment returns and system reliability planning.

The market is also witnessing increased demand for standardized testing protocols and certification services that can provide objective assessments of battery health. This trend is partly driven by insurance companies seeking to quantify risks associated with battery aging and by financial institutions funding EV fleet acquisitions.

Consumer-facing applications are gaining traction as well, with smartphone apps and vehicle dashboard features that translate complex battery health metrics into actionable information for everyday users. This democratization of battery health information is creating new market opportunities for simplified diagnostic tools and services targeting individual vehicle owners.

Market research indicates that the battery health monitoring systems market is projected to grow at a compound annual growth rate of 19.5% between 2023 and 2030. This growth is particularly pronounced in regions with aggressive EV adoption targets, including Europe, North America, and parts of Asia, where regulatory frameworks increasingly mandate battery performance transparency and longevity guarantees.

The demand for NMC battery pack aging evaluation solutions stems from several key market factors. First, battery packs represent approximately 30-40% of an electric vehicle's total cost, making their longevity a significant economic consideration. Second, as the secondary market for EVs matures, accurate assessment of remaining battery life becomes essential for determining residual vehicle value. Third, warranty claims management requires precise degradation metrics to differentiate between normal aging and premature failure.

Commercial fleet operators have emerged as a particularly demanding segment, requiring real-time monitoring solutions that can predict maintenance needs and optimize charging strategies to extend battery life. These operators typically manage large fleets with high utilization rates, making even small improvements in battery longevity translate to substantial operational savings.

Energy storage system (ESS) applications represent another growing market segment, where NMC batteries are increasingly deployed for grid stabilization and renewable energy integration. In these applications, accurate degradation assessment directly impacts investment returns and system reliability planning.

The market is also witnessing increased demand for standardized testing protocols and certification services that can provide objective assessments of battery health. This trend is partly driven by insurance companies seeking to quantify risks associated with battery aging and by financial institutions funding EV fleet acquisitions.

Consumer-facing applications are gaining traction as well, with smartphone apps and vehicle dashboard features that translate complex battery health metrics into actionable information for everyday users. This democratization of battery health information is creating new market opportunities for simplified diagnostic tools and services targeting individual vehicle owners.

Current Challenges in NMC Battery Pack Aging Evaluation

The evaluation of NMC (Nickel Manganese Cobalt) battery pack aging processes faces numerous complex challenges that impede accurate assessment and prediction of battery degradation. One primary challenge is the multifaceted nature of aging mechanisms, which include calendar aging, cycling aging, and their intricate interactions. These mechanisms are influenced by various operational conditions such as temperature fluctuations, charge-discharge rates, depth of discharge, and state of charge during storage, creating a highly complex system that is difficult to model comprehensively.

Measurement inconsistency presents another significant obstacle. Different testing protocols and evaluation metrics across the industry lead to incomparable results, making standardization efforts crucial yet challenging. The lack of universally accepted testing methodologies further complicates the establishment of reliable aging models and benchmarks for NMC battery packs.

Real-time monitoring capabilities remain limited despite technological advancements. Current sensing technologies often fail to capture the dynamic internal changes occurring within battery cells during operation. This limitation is particularly problematic for large-scale battery packs where individual cell variations can significantly impact overall performance and safety.

The non-linear and path-dependent nature of battery degradation adds another layer of complexity. Aging processes in NMC batteries do not follow simple linear patterns but are highly dependent on previous usage history, making traditional modeling approaches insufficient. This non-linearity challenges the development of accurate predictive models, especially for long-term performance forecasting.

Cell-to-cell variations within battery packs represent a persistent challenge. Manufacturing inconsistencies lead to performance disparities among cells, which are further amplified during aging. These variations can cause uneven stress distribution and accelerated degradation in certain cells, potentially leading to premature pack failure despite the majority of cells remaining functional.

Data acquisition and processing limitations also hinder effective aging evaluation. The vast amount of data required for comprehensive battery health monitoring creates storage and processing challenges, while the integration of battery management systems with advanced diagnostic tools remains technically challenging and costly.

Finally, accelerated aging tests, while necessary for timely evaluation, often fail to accurately replicate real-world aging conditions. The correlation between laboratory test results and actual field performance remains problematic, leading to potential misestimations of battery pack lifespan and reliability in practical applications.

Measurement inconsistency presents another significant obstacle. Different testing protocols and evaluation metrics across the industry lead to incomparable results, making standardization efforts crucial yet challenging. The lack of universally accepted testing methodologies further complicates the establishment of reliable aging models and benchmarks for NMC battery packs.

Real-time monitoring capabilities remain limited despite technological advancements. Current sensing technologies often fail to capture the dynamic internal changes occurring within battery cells during operation. This limitation is particularly problematic for large-scale battery packs where individual cell variations can significantly impact overall performance and safety.

The non-linear and path-dependent nature of battery degradation adds another layer of complexity. Aging processes in NMC batteries do not follow simple linear patterns but are highly dependent on previous usage history, making traditional modeling approaches insufficient. This non-linearity challenges the development of accurate predictive models, especially for long-term performance forecasting.

Cell-to-cell variations within battery packs represent a persistent challenge. Manufacturing inconsistencies lead to performance disparities among cells, which are further amplified during aging. These variations can cause uneven stress distribution and accelerated degradation in certain cells, potentially leading to premature pack failure despite the majority of cells remaining functional.

Data acquisition and processing limitations also hinder effective aging evaluation. The vast amount of data required for comprehensive battery health monitoring creates storage and processing challenges, while the integration of battery management systems with advanced diagnostic tools remains technically challenging and costly.

Finally, accelerated aging tests, while necessary for timely evaluation, often fail to accurately replicate real-world aging conditions. The correlation between laboratory test results and actual field performance remains problematic, leading to potential misestimations of battery pack lifespan and reliability in practical applications.

Established NMC Battery Aging Evaluation Techniques

01 Thermal management systems for NMC battery packs

Effective thermal management systems are crucial for mitigating aging processes in NMC battery packs. These systems help maintain optimal operating temperatures, preventing accelerated degradation caused by thermal stress. Advanced cooling mechanisms, including liquid cooling circuits and heat dissipation structures, can significantly extend battery life by reducing temperature-induced aging effects. Proper thermal management also helps prevent thermal runaway conditions that can lead to catastrophic failure and accelerated aging.- Temperature management in NMC battery packs: Effective temperature management is crucial for mitigating aging processes in NMC battery packs. Temperature control systems help maintain optimal operating conditions, preventing accelerated degradation due to thermal stress. These systems may include cooling mechanisms, thermal insulation, and temperature monitoring devices that work together to regulate the battery pack temperature within the ideal range, thereby extending battery life and maintaining performance over time.

- State of charge (SOC) monitoring and control: Monitoring and controlling the state of charge is essential for managing NMC battery pack aging. Systems that accurately track SOC can prevent over-charging and deep-discharging, both of which accelerate degradation. Advanced battery management systems implement algorithms that optimize charging profiles, balance cells, and adjust operational parameters based on usage patterns to minimize stress on the battery materials, thereby slowing aging processes.

- Structural design for aging mitigation: The physical and structural design of NMC battery packs significantly impacts their aging characteristics. Innovative housing designs, cell arrangement patterns, and mechanical support structures can reduce mechanical stress and vibration damage. Some designs incorporate expansion spaces to accommodate electrode swelling, while others focus on optimizing electrical connections to ensure uniform current distribution, both of which help minimize localized degradation and extend overall battery pack lifespan.

- Chemical additives and electrolyte formulations: Specialized chemical additives and electrolyte formulations can significantly influence NMC battery aging processes. These formulations may include film-forming additives that create stable solid-electrolyte interfaces, reducing unwanted side reactions at electrode surfaces. Other additives can scavenge harmful reaction products, neutralize acidic components, or enhance ionic conductivity while reducing electrolyte decomposition, all contributing to slower capacity fade and extended cycle life.

- Diagnostic and predictive aging models: Advanced diagnostic tools and predictive models help manage NMC battery pack aging by identifying degradation patterns before they cause significant performance loss. These systems employ machine learning algorithms, electrochemical impedance spectroscopy, and other analytical techniques to monitor battery health indicators. By detecting early signs of aging, such as impedance increases or capacity fluctuations, these models enable preemptive maintenance and operational adjustments that can significantly extend battery service life.

02 Battery management systems for monitoring aging parameters

Sophisticated battery management systems (BMS) are essential for monitoring and controlling aging processes in NMC battery packs. These systems track critical parameters such as state of charge, state of health, and impedance changes that indicate aging progression. Advanced algorithms can predict remaining useful life based on usage patterns and environmental conditions. The BMS can implement adaptive charging strategies that minimize stress factors contributing to battery degradation, thereby extending the operational lifespan of NMC battery packs.Expand Specific Solutions03 Chemical degradation mechanisms and mitigation strategies

NMC battery packs undergo various chemical degradation processes during aging, including electrolyte decomposition, solid-electrolyte interphase (SEI) layer growth, and structural changes in cathode materials. Innovative approaches to mitigate these effects include electrolyte additives that stabilize the SEI layer, modified cathode coatings that prevent transition metal dissolution, and novel electrode designs that accommodate volume changes during cycling. Understanding and addressing these chemical mechanisms is crucial for developing NMC battery packs with improved cycle life and reduced aging rates.Expand Specific Solutions04 Diagnostic and prognostic methods for battery aging

Advanced diagnostic and prognostic techniques are employed to assess and predict NMC battery pack aging. These methods include electrochemical impedance spectroscopy, differential voltage analysis, and machine learning algorithms that can identify aging signatures. Real-time monitoring systems can detect early indicators of degradation, allowing for preventive maintenance before significant capacity loss occurs. These diagnostic approaches enable more accurate estimation of remaining useful life and help optimize battery utilization while minimizing aging effects.Expand Specific Solutions05 Charging protocols to minimize aging effects

Specialized charging protocols can significantly impact the aging rate of NMC battery packs. Optimized charging strategies include multi-stage charging profiles, pulse charging techniques, and temperature-compensated charging rates that minimize stress on battery components. Limiting charge and discharge rates during extreme temperature conditions helps prevent accelerated degradation. Advanced charging algorithms that adapt to battery age and usage patterns can extend cycle life by reducing mechanical and chemical stressors that contribute to capacity fade and power loss over time.Expand Specific Solutions

Key Industry Players in Battery Testing and Diagnostics

The NMC battery pack aging evaluation market is in a growth phase, with increasing demand driven by the electric vehicle and energy storage sectors. The market size is expanding rapidly as companies invest in battery technology research to extend lifespan and improve performance. From a technical maturity perspective, major players like LG Energy Solution, Samsung SDI, and Toyota Motor Corp. have established advanced evaluation methodologies, while automotive manufacturers including Mercedes-Benz, BMW, and Honda are developing proprietary assessment protocols. Research institutions such as Industrial Technology Research Institute and Northeastern University collaborate with companies like Bosch and Siemens to standardize aging evaluation metrics. The competitive landscape shows a mix of battery manufacturers, automotive OEMs, and technology providers working to address challenges in predicting battery degradation under various operating conditions.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive battery aging evaluation framework specifically for NMC (Nickel Manganese Cobalt) battery packs. Their approach combines electrochemical impedance spectroscopy (EIS) and differential voltage analysis (DVA) to accurately track capacity fade and resistance increase over time. The company employs advanced machine learning algorithms to process the collected data and predict remaining useful life with over 90% accuracy. Their methodology includes accelerated aging tests under controlled temperature conditions (ranging from -20°C to 60°C) and various C-rates to simulate real-world usage patterns. LG's proprietary Battery Management System (BMS) continuously monitors individual cell parameters including voltage imbalance, temperature distribution, and internal resistance changes to detect early signs of degradation[1]. They have established correlation models between laboratory testing and field data from over 1 million battery packs in various applications, enabling more accurate lifetime predictions across different usage scenarios[3].

Strengths: Industry-leading data analytics capabilities with extensive field validation data; highly accurate remaining useful life prediction algorithms; comprehensive multi-parameter monitoring system. Weaknesses: Their evaluation methods require sophisticated equipment and expertise; the proprietary nature of their algorithms limits transparency for third-party verification.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corporation has established an advanced evaluation framework for NMC battery pack aging that integrates vehicle-level data with laboratory analysis. Their approach employs a combination of in-vehicle monitoring systems and periodic laboratory characterization to track degradation patterns throughout the battery lifecycle. Toyota's methodology includes reference performance tests (RPTs) conducted at regular intervals (typically every 5,000 km or 3 months) to measure capacity retention, internal resistance growth, and power capability. Their evaluation system incorporates drive cycle-specific aging protocols that simulate actual vehicle usage patterns across different markets and driving conditions. Toyota has developed proprietary algorithms that can disaggregate aging effects caused by different stress factors including temperature extremes, high C-rates, and extended storage at high SOC. Their Battery Health Check system utilizes adaptive parameter estimation techniques to account for sensor drift and measurement uncertainties over the vehicle lifetime. Toyota's approach places particular emphasis on pack-level thermal management evaluation, with detailed temperature distribution mapping during various operating conditions to identify potential hotspots that accelerate local degradation[6]. Their aging models incorporate both electrochemical and thermal components, validated against data from over 15 million hybrid and electric vehicles worldwide[7].

Strengths: Unparalleled real-world validation dataset from millions of vehicles; sophisticated integration of vehicle-level and laboratory data; excellent thermal management evaluation capabilities. Weaknesses: Evaluation methods heavily optimized for automotive applications with less focus on stationary storage; proprietary nature limits academic collaboration.

Critical Patents and Research in Battery Degradation Analysis

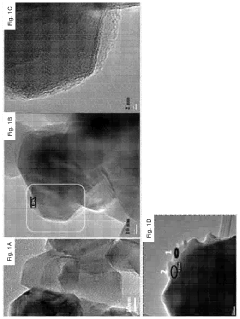

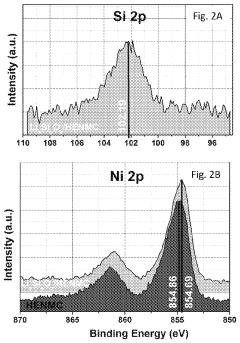

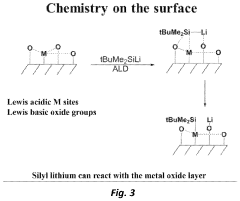

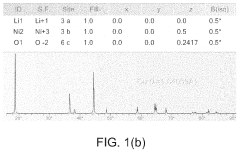

Method for Production of LixSiyOz Coatings Using a Single Source for Li And Si and Resultant Coated Products

PatentPendingUS20230343934A1

Innovation

- Atomic Layer Deposition (ALD) using a volatile organo silyl lithium compound, such as tBuMe2SiLi, as a single source precursor to deposit a LixSiyOz thin film on substrates like 0.35Li2MnO3·0.65LiNi0.35Mn0.45Co0.20O2 (HE-NMC), which improves electrochemical performance by stabilizing the cathode and reducing structural disintegration.

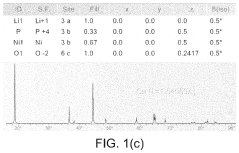

Synthesis and characterization of lithium nickel manganese cobalt phosphorous oxide

PatentActiveUS10847795B2

Innovation

- A novel chemical synthesis route for lithium nickel manganese cobalt oxide (NMC) is developed, replacing a portion of transition metal sites with phosphorous to create a layered crystal structure material, such as Li3Ni2PO6, which stabilizes the material while maintaining high capacity and improving electrical conductivity.

Standardization and Testing Protocols for Battery Aging

The standardization of battery aging evaluation protocols is critical for ensuring consistent and comparable results across different research institutions and industry applications. Currently, there exists a fragmented landscape of testing methodologies for NMC battery pack aging assessment, which complicates cross-study comparisons and industry-wide benchmarking efforts.

International organizations such as IEC, ISO, and IEEE have developed several standards that partially address battery aging evaluation, including IEC 62660 for performance testing of lithium-ion cells and ISO 12405 for electric vehicle battery testing. However, these standards often lack specific protocols tailored to the unique degradation mechanisms of NMC chemistry in pack configurations.

A comprehensive standardized testing protocol for NMC battery pack aging should incorporate both calendar aging and cycle aging assessments. Calendar aging tests typically involve storing batteries at various states of charge (30%, 50%, 70%, 100%) and temperatures (0°C, 25°C, 45°C, 60°C) for extended periods, with periodic performance checks. Cycle aging protocols should specify discharge rates, depth of discharge ranges, and temperature conditions that reflect real-world usage scenarios.

Reference performance tests (RPTs) form the backbone of aging evaluation and should be standardized to include capacity measurements, internal resistance tests, electrochemical impedance spectroscopy (EIS), and pulse power characterization. The frequency of these RPTs must balance the need for data collection against the potential impact of the testing itself on the aging process.

Accelerated aging protocols present particular challenges for standardization, as the correlation between accelerated test results and real-world degradation is not always straightforward. Test protocols must carefully document acceleration factors and validation methodologies to ensure relevance to normal operating conditions.

Data reporting formats also require standardization to facilitate information exchange and meta-analyses. Minimum reporting requirements should include detailed test conditions, battery specifications, measurement uncertainties, and raw data in machine-readable formats. The emergence of digital battery passports may provide a framework for standardized data collection and sharing across the industry.

Collaborative efforts between academia, industry, and regulatory bodies are essential for developing consensus-based standards that balance scientific rigor with practical implementation considerations. Recent initiatives like the Battery Data Genome Project aim to establish common data formats and testing protocols that could significantly advance the field of battery aging research and evaluation.

International organizations such as IEC, ISO, and IEEE have developed several standards that partially address battery aging evaluation, including IEC 62660 for performance testing of lithium-ion cells and ISO 12405 for electric vehicle battery testing. However, these standards often lack specific protocols tailored to the unique degradation mechanisms of NMC chemistry in pack configurations.

A comprehensive standardized testing protocol for NMC battery pack aging should incorporate both calendar aging and cycle aging assessments. Calendar aging tests typically involve storing batteries at various states of charge (30%, 50%, 70%, 100%) and temperatures (0°C, 25°C, 45°C, 60°C) for extended periods, with periodic performance checks. Cycle aging protocols should specify discharge rates, depth of discharge ranges, and temperature conditions that reflect real-world usage scenarios.

Reference performance tests (RPTs) form the backbone of aging evaluation and should be standardized to include capacity measurements, internal resistance tests, electrochemical impedance spectroscopy (EIS), and pulse power characterization. The frequency of these RPTs must balance the need for data collection against the potential impact of the testing itself on the aging process.

Accelerated aging protocols present particular challenges for standardization, as the correlation between accelerated test results and real-world degradation is not always straightforward. Test protocols must carefully document acceleration factors and validation methodologies to ensure relevance to normal operating conditions.

Data reporting formats also require standardization to facilitate information exchange and meta-analyses. Minimum reporting requirements should include detailed test conditions, battery specifications, measurement uncertainties, and raw data in machine-readable formats. The emergence of digital battery passports may provide a framework for standardized data collection and sharing across the industry.

Collaborative efforts between academia, industry, and regulatory bodies are essential for developing consensus-based standards that balance scientific rigor with practical implementation considerations. Recent initiatives like the Battery Data Genome Project aim to establish common data formats and testing protocols that could significantly advance the field of battery aging research and evaluation.

Environmental Impact of Battery Lifecycle Management

The environmental footprint of NMC (Nickel Manganese Cobalt) battery packs extends far beyond their operational phase, encompassing raw material extraction, manufacturing, use, and end-of-life management. As these batteries age, their environmental impact profile shifts significantly, creating both challenges and opportunities for sustainable management.

During the aging process, NMC batteries experience capacity fade and increased internal resistance, which directly impacts their efficiency and usable lifetime. This degradation accelerates the need for replacement, potentially increasing the overall environmental burden through additional manufacturing and resource consumption. Studies indicate that extending battery life through proper aging management can reduce lifecycle carbon emissions by 20-30% compared to premature replacement scenarios.

The extraction of critical materials for NMC batteries—particularly nickel, cobalt, and lithium—presents significant environmental concerns including habitat destruction, water pollution, and high energy consumption. When evaluating aging processes, it becomes essential to consider how degradation patterns affect the recoverability of these materials. Research shows that batteries aged under optimal conditions maintain higher material integrity, improving recycling efficiency by up to 15%.

Battery aging evaluation methodologies must incorporate environmental metrics alongside performance parameters. Advanced lifecycle assessment (LCA) frameworks that track carbon footprint, water usage, and toxicity potential throughout the aging process provide valuable insights for environmentally optimized battery management strategies. These assessments reveal that controlled aging environments can reduce harmful emissions by minimizing the formation of toxic byproducts during degradation.

The circular economy potential of aged NMC batteries represents a significant environmental opportunity. Second-life applications for batteries that have reached 70-80% of their original capacity can delay recycling needs while providing valuable energy storage services in less demanding applications. This approach has demonstrated potential to offset up to 40% of the initial manufacturing environmental impact through extended utilization.

Regulatory frameworks increasingly recognize the environmental implications of battery aging, with policies in Europe, Asia, and North America establishing extended producer responsibility requirements. These regulations incentivize manufacturers to design for longevity and recyclability, fundamentally altering how aging processes are evaluated and managed. Companies implementing comprehensive aging evaluation protocols have reported 25-35% improvements in their environmental compliance metrics.

During the aging process, NMC batteries experience capacity fade and increased internal resistance, which directly impacts their efficiency and usable lifetime. This degradation accelerates the need for replacement, potentially increasing the overall environmental burden through additional manufacturing and resource consumption. Studies indicate that extending battery life through proper aging management can reduce lifecycle carbon emissions by 20-30% compared to premature replacement scenarios.

The extraction of critical materials for NMC batteries—particularly nickel, cobalt, and lithium—presents significant environmental concerns including habitat destruction, water pollution, and high energy consumption. When evaluating aging processes, it becomes essential to consider how degradation patterns affect the recoverability of these materials. Research shows that batteries aged under optimal conditions maintain higher material integrity, improving recycling efficiency by up to 15%.

Battery aging evaluation methodologies must incorporate environmental metrics alongside performance parameters. Advanced lifecycle assessment (LCA) frameworks that track carbon footprint, water usage, and toxicity potential throughout the aging process provide valuable insights for environmentally optimized battery management strategies. These assessments reveal that controlled aging environments can reduce harmful emissions by minimizing the formation of toxic byproducts during degradation.

The circular economy potential of aged NMC batteries represents a significant environmental opportunity. Second-life applications for batteries that have reached 70-80% of their original capacity can delay recycling needs while providing valuable energy storage services in less demanding applications. This approach has demonstrated potential to offset up to 40% of the initial manufacturing environmental impact through extended utilization.

Regulatory frameworks increasingly recognize the environmental implications of battery aging, with policies in Europe, Asia, and North America establishing extended producer responsibility requirements. These regulations incentivize manufacturers to design for longevity and recyclability, fundamentally altering how aging processes are evaluated and managed. Companies implementing comprehensive aging evaluation protocols have reported 25-35% improvements in their environmental compliance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!