How to Integrate AI in Direct Lithium Extraction for Process Control

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AI-DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technology has evolved significantly over the past decade, emerging as a promising alternative to traditional lithium extraction methods such as evaporation ponds and hard rock mining. The development trajectory of DLE has been characterized by increasing efficiency, reduced environmental impact, and enhanced selectivity for lithium ions. Recent technological advancements have focused on improving sorbent materials, membrane technologies, and electrochemical processes to extract lithium from brine resources more effectively.

The integration of Artificial Intelligence (AI) with DLE represents a convergence of two rapidly evolving technological domains. AI technologies, particularly machine learning and deep learning algorithms, have demonstrated remarkable capabilities in pattern recognition, predictive analytics, and process optimization across various industries. The application of these capabilities to DLE processes presents an opportunity to address persistent challenges in lithium extraction efficiency, resource utilization, and operational costs.

The primary objective of AI integration in DLE process control is to develop intelligent systems capable of real-time monitoring, analysis, and optimization of extraction parameters. These systems aim to maximize lithium recovery rates while minimizing energy consumption, chemical usage, and environmental footprint. Additionally, AI-enhanced DLE seeks to adapt dynamically to variations in brine composition, temperature fluctuations, and other operational conditions that traditionally impact extraction efficiency.

Technical goals for AI-DLE integration include the development of predictive models for process optimization, anomaly detection systems for early identification of equipment failures or process deviations, and decision support tools for operators. Long-term objectives extend to fully autonomous extraction systems that can self-optimize based on changing conditions and business requirements, potentially revolutionizing the economics of lithium production.

The evolution of AI-DLE technology is occurring against the backdrop of rapidly growing demand for lithium, driven primarily by the electric vehicle revolution and renewable energy storage requirements. Global lithium demand is projected to increase by 40% annually through 2025, creating urgent pressure for more efficient extraction technologies. This market dynamic has accelerated research and development efforts in both AI and DLE fields, with significant investments from major mining companies, technology firms, and government entities.

Looking forward, the technological trajectory of AI-DLE integration points toward increasingly sophisticated hybrid systems that combine multiple AI approaches—from traditional statistical methods to advanced neural networks—to address the complex, multivariable nature of lithium extraction processes. The ultimate vision is a highly efficient, environmentally sustainable lithium production system that can help meet global demand while minimizing resource consumption and environmental impact.

The integration of Artificial Intelligence (AI) with DLE represents a convergence of two rapidly evolving technological domains. AI technologies, particularly machine learning and deep learning algorithms, have demonstrated remarkable capabilities in pattern recognition, predictive analytics, and process optimization across various industries. The application of these capabilities to DLE processes presents an opportunity to address persistent challenges in lithium extraction efficiency, resource utilization, and operational costs.

The primary objective of AI integration in DLE process control is to develop intelligent systems capable of real-time monitoring, analysis, and optimization of extraction parameters. These systems aim to maximize lithium recovery rates while minimizing energy consumption, chemical usage, and environmental footprint. Additionally, AI-enhanced DLE seeks to adapt dynamically to variations in brine composition, temperature fluctuations, and other operational conditions that traditionally impact extraction efficiency.

Technical goals for AI-DLE integration include the development of predictive models for process optimization, anomaly detection systems for early identification of equipment failures or process deviations, and decision support tools for operators. Long-term objectives extend to fully autonomous extraction systems that can self-optimize based on changing conditions and business requirements, potentially revolutionizing the economics of lithium production.

The evolution of AI-DLE technology is occurring against the backdrop of rapidly growing demand for lithium, driven primarily by the electric vehicle revolution and renewable energy storage requirements. Global lithium demand is projected to increase by 40% annually through 2025, creating urgent pressure for more efficient extraction technologies. This market dynamic has accelerated research and development efforts in both AI and DLE fields, with significant investments from major mining companies, technology firms, and government entities.

Looking forward, the technological trajectory of AI-DLE integration points toward increasingly sophisticated hybrid systems that combine multiple AI approaches—from traditional statistical methods to advanced neural networks—to address the complex, multivariable nature of lithium extraction processes. The ultimate vision is a highly efficient, environmentally sustainable lithium production system that can help meet global demand while minimizing resource consumption and environmental impact.

Market Analysis for AI-Enhanced Lithium Extraction

The global market for lithium extraction technologies is experiencing unprecedented growth, driven by the surging demand for lithium-ion batteries in electric vehicles, renewable energy storage systems, and consumer electronics. The integration of AI technologies into Direct Lithium Extraction (DLE) processes represents a significant market opportunity, with the potential to revolutionize the efficiency and sustainability of lithium production.

Current market projections indicate that the global lithium market is expected to grow at a CAGR of 14.8% from 2023 to 2030, reaching a market value of approximately $8.2 billion by 2030. Within this broader market, AI-enhanced extraction technologies are emerging as a high-growth segment, with early adopters reporting productivity improvements of 15-30% compared to conventional methods.

The demand for more efficient lithium extraction processes is particularly acute given the environmental and economic challenges associated with traditional extraction methods. Brine operations typically recover only 50-70% of available lithium, while hard rock mining operations face high energy costs and significant environmental impacts. AI-enhanced DLE technologies address these market pain points by optimizing recovery rates, reducing water usage, and minimizing environmental footprint.

Regional market analysis reveals varying levels of adoption and investment. North America and Europe are leading in terms of research and development investments in AI-enhanced extraction technologies, while major lithium-producing regions in South America's "Lithium Triangle" (Argentina, Bolivia, and Chile) are increasingly exploring these technologies to maintain competitive advantage.

Market segmentation shows distinct customer groups with different needs: major mining corporations seeking to optimize existing operations, technology startups developing novel extraction solutions, and battery manufacturers looking to secure sustainable supply chains. Each segment presents unique market entry opportunities for AI-integrated DLE technologies.

Competitive analysis indicates that early movers in this space are gaining significant market advantages. Companies that have successfully implemented AI-controlled DLE processes report reduced operational costs by 20-25% and increased production capacity by up to 35%, creating compelling value propositions in a market where production efficiency directly impacts profitability.

Market barriers include high initial investment costs for AI implementation, technical expertise requirements, and regulatory uncertainties regarding new extraction technologies. However, these barriers are offset by the long-term economic benefits and sustainability advantages that AI-enhanced DLE offers, particularly as environmental regulations become more stringent globally.

Current market projections indicate that the global lithium market is expected to grow at a CAGR of 14.8% from 2023 to 2030, reaching a market value of approximately $8.2 billion by 2030. Within this broader market, AI-enhanced extraction technologies are emerging as a high-growth segment, with early adopters reporting productivity improvements of 15-30% compared to conventional methods.

The demand for more efficient lithium extraction processes is particularly acute given the environmental and economic challenges associated with traditional extraction methods. Brine operations typically recover only 50-70% of available lithium, while hard rock mining operations face high energy costs and significant environmental impacts. AI-enhanced DLE technologies address these market pain points by optimizing recovery rates, reducing water usage, and minimizing environmental footprint.

Regional market analysis reveals varying levels of adoption and investment. North America and Europe are leading in terms of research and development investments in AI-enhanced extraction technologies, while major lithium-producing regions in South America's "Lithium Triangle" (Argentina, Bolivia, and Chile) are increasingly exploring these technologies to maintain competitive advantage.

Market segmentation shows distinct customer groups with different needs: major mining corporations seeking to optimize existing operations, technology startups developing novel extraction solutions, and battery manufacturers looking to secure sustainable supply chains. Each segment presents unique market entry opportunities for AI-integrated DLE technologies.

Competitive analysis indicates that early movers in this space are gaining significant market advantages. Companies that have successfully implemented AI-controlled DLE processes report reduced operational costs by 20-25% and increased production capacity by up to 35%, creating compelling value propositions in a market where production efficiency directly impacts profitability.

Market barriers include high initial investment costs for AI implementation, technical expertise requirements, and regulatory uncertainties regarding new extraction technologies. However, these barriers are offset by the long-term economic benefits and sustainability advantages that AI-enhanced DLE offers, particularly as environmental regulations become more stringent globally.

Current Challenges in AI-Driven Lithium Extraction

The integration of AI in Direct Lithium Extraction (DLE) faces several significant technical challenges that currently limit widespread implementation. One primary obstacle is the complexity of real-time sensor data integration. DLE processes generate massive amounts of heterogeneous data from various sensors monitoring temperature, pressure, flow rates, and chemical compositions, creating difficulties in data synchronization and normalization for AI systems to process effectively.

Data quality issues present another substantial hurdle. Sensor degradation in harsh chemical environments leads to drift and calibration problems, while signal noise from electromagnetic interference in industrial settings compromises measurement accuracy. These factors significantly impact the reliability of AI model predictions, as machine learning algorithms require consistent, high-quality data to function properly.

The dynamic nature of lithium-rich brines presents unique challenges for AI implementation. Brine composition varies significantly across different sources and can change over time within the same source, requiring AI models that can adapt to these variations. Current models struggle to generalize across different brine chemistries, necessitating extensive retraining for each new extraction site.

Process optimization complexity further complicates AI integration. DLE involves multiple interdependent variables that must be optimized simultaneously, creating a high-dimensional optimization problem. Traditional optimization approaches often fail to capture these complex relationships, while AI solutions require sophisticated multi-objective optimization capabilities that are still being developed for this specific application.

Computational resource limitations at remote extraction sites pose practical implementation challenges. Many lithium extraction operations occur in remote locations with limited connectivity and computational infrastructure, making it difficult to deploy sophisticated AI systems that require substantial computing power and reliable network connections.

Regulatory and validation barriers also impede progress. The lithium extraction industry operates under strict environmental and safety regulations, requiring extensive validation of any new control systems. AI systems, particularly those using deep learning approaches, often lack the transparency and explainability needed to satisfy regulatory requirements and gain operator trust.

Lastly, there exists a significant knowledge gap between AI experts and lithium extraction specialists. Effective implementation requires interdisciplinary expertise spanning machine learning, chemical engineering, geology, and process control. This specialized combination of skills is rare, creating bottlenecks in system design, implementation, and maintenance of AI-driven lithium extraction processes.

Data quality issues present another substantial hurdle. Sensor degradation in harsh chemical environments leads to drift and calibration problems, while signal noise from electromagnetic interference in industrial settings compromises measurement accuracy. These factors significantly impact the reliability of AI model predictions, as machine learning algorithms require consistent, high-quality data to function properly.

The dynamic nature of lithium-rich brines presents unique challenges for AI implementation. Brine composition varies significantly across different sources and can change over time within the same source, requiring AI models that can adapt to these variations. Current models struggle to generalize across different brine chemistries, necessitating extensive retraining for each new extraction site.

Process optimization complexity further complicates AI integration. DLE involves multiple interdependent variables that must be optimized simultaneously, creating a high-dimensional optimization problem. Traditional optimization approaches often fail to capture these complex relationships, while AI solutions require sophisticated multi-objective optimization capabilities that are still being developed for this specific application.

Computational resource limitations at remote extraction sites pose practical implementation challenges. Many lithium extraction operations occur in remote locations with limited connectivity and computational infrastructure, making it difficult to deploy sophisticated AI systems that require substantial computing power and reliable network connections.

Regulatory and validation barriers also impede progress. The lithium extraction industry operates under strict environmental and safety regulations, requiring extensive validation of any new control systems. AI systems, particularly those using deep learning approaches, often lack the transparency and explainability needed to satisfy regulatory requirements and gain operator trust.

Lastly, there exists a significant knowledge gap between AI experts and lithium extraction specialists. Effective implementation requires interdisciplinary expertise spanning machine learning, chemical engineering, geology, and process control. This specialized combination of skills is rare, creating bottlenecks in system design, implementation, and maintenance of AI-driven lithium extraction processes.

Current AI Solutions for DLE Process Control

01 AI-driven monitoring and optimization in DLE processes

Artificial intelligence systems are being integrated into Direct Lithium Extraction (DLE) processes to continuously monitor and optimize extraction parameters. These AI systems analyze real-time data from sensors throughout the extraction process, making automatic adjustments to flow rates, pressure, temperature, and chemical dosing to maintain optimal extraction efficiency. The AI algorithms can detect patterns and anomalies that might affect lithium recovery rates and quality, enabling predictive maintenance and reducing operational downtime.- AI-driven optimization of lithium extraction processes: Artificial intelligence algorithms are being integrated into direct lithium extraction (DLE) processes to optimize operational parameters in real-time. These AI systems analyze multiple variables such as temperature, pressure, flow rates, and solution chemistry to maximize lithium recovery while minimizing energy consumption and reagent use. Machine learning models continuously improve extraction efficiency by learning from historical data and adapting to changing brine compositions.

- Predictive maintenance and fault detection systems: AI-based predictive maintenance systems are being implemented in DLE facilities to monitor equipment health and predict potential failures before they occur. These systems use sensor data and machine learning algorithms to detect anomalies in equipment performance, schedule maintenance activities, and reduce unplanned downtime. Real-time monitoring of critical components such as pumps, membranes, and adsorption materials helps maintain consistent extraction efficiency and extend equipment lifespan.

- Automated control systems for selective ion extraction: Advanced control systems incorporating AI are being developed to enhance the selectivity of lithium extraction from complex brines. These systems dynamically adjust extraction parameters based on real-time monitoring of ion concentrations, enabling higher purity lithium recovery with fewer processing steps. The automated systems can compensate for variations in feed composition by modifying adsorption conditions, elution protocols, and regeneration cycles to maintain consistent product quality.

- Digital twin technology for process simulation and optimization: Digital twin technology is being integrated with AI to create comprehensive virtual models of DLE operations. These digital replicas simulate the entire extraction process, allowing operators to test different scenarios and optimization strategies without disrupting actual production. The AI-enhanced digital twins continuously update based on real-time data, enabling accurate predictions of process outcomes and identification of improvement opportunities across the extraction workflow.

- AI-enhanced resource management and sustainability monitoring: AI systems are being deployed to improve resource management and environmental sustainability in DLE operations. These systems optimize water usage, energy consumption, and chemical inputs while monitoring environmental impacts in real-time. Machine learning algorithms analyze operational data to identify efficiency improvements that reduce the carbon footprint and water consumption of lithium extraction processes, supporting more sustainable mining practices and regulatory compliance.

02 Machine learning for selective ion capture optimization

Machine learning algorithms are being employed to enhance the selectivity of ion capture materials used in DLE processes. These algorithms analyze the performance of different sorbent materials under varying conditions to identify optimal formulations and operational parameters. By processing data on ion exchange kinetics, selectivity coefficients, and regeneration efficiency, the ML models can predict the most effective sorbent compositions for specific brine chemistries, leading to improved lithium recovery rates and reduced contamination from competing ions like sodium, magnesium, and calcium.Expand Specific Solutions03 Automated process control systems with predictive analytics

Advanced automated control systems incorporating predictive analytics are being developed for DLE operations. These systems use AI to forecast process outcomes based on current operational data and historical performance. By anticipating changes in brine composition, equipment performance, and environmental conditions, these systems can proactively adjust extraction parameters to maintain optimal efficiency. The predictive capabilities also enable better resource planning, energy management, and scheduling of maintenance activities, resulting in more consistent lithium production and reduced operational costs.Expand Specific Solutions04 Digital twins and simulation for DLE process optimization

Digital twin technology is being integrated with AI to create comprehensive virtual models of DLE operations. These digital replicas simulate the entire extraction process in real-time, allowing operators to test process modifications virtually before implementing them in the actual plant. AI algorithms continuously update these models based on real operational data, improving their accuracy over time. The digital twins enable scenario planning, operator training, and optimization of complex multi-variable processes without disrupting ongoing operations, leading to faster process improvements and reduced risk during operational changes.Expand Specific Solutions05 AI-enhanced quality control and impurity management

AI systems are being implemented to enhance quality control and manage impurities throughout the DLE process. These systems analyze spectroscopic data, chemical compositions, and physical properties of process streams in real-time to detect and quantify impurities. Machine learning algorithms can identify subtle correlations between process conditions and final product quality, enabling precise adjustments to maintain product specifications. The AI-driven quality control systems also optimize the use of purification resources, directing more intensive treatments only to streams that require them, thereby reducing chemical consumption and waste generation.Expand Specific Solutions

Key Industry Players in AI-DLE Integration

The direct lithium extraction (DLE) AI integration market is in its early growth phase, characterized by increasing investments and technological advancements. The global lithium market is projected to expand significantly, driven by electric vehicle demand, with DLE technologies representing a growing segment. Companies demonstrate varying levels of technological maturity: established players like Schlumberger and LG Chem bring industrial automation expertise; specialized firms like Lilac Solutions and Forager Station offer innovative DLE-specific technologies; while technology providers such as Siemens and Yokogawa contribute AI and process control capabilities. The competitive landscape features collaboration between resource companies (Saudi Aramco), technology developers, and research institutions (Beijing Institute of Technology, Iowa State University), indicating an ecosystem still evolving toward standardized AI-integrated DLE solutions.

Schlumberger Technologies, Inc.

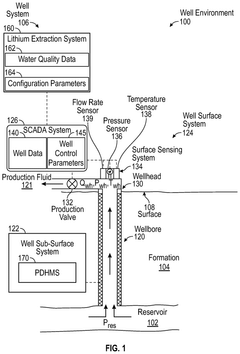

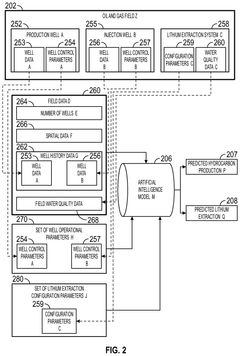

Technical Solution: Schlumberger has developed an AI-integrated Direct Lithium Extraction (DLE) system that combines machine learning algorithms with advanced sensor networks for real-time monitoring and optimization of the extraction process. Their technology utilizes predictive analytics to continuously adjust operational parameters based on brine composition variations, maximizing lithium recovery rates while minimizing reagent consumption. The system employs digital twins to simulate extraction conditions and optimize sorbent performance across different geological settings. Schlumberger's AI platform integrates with their existing oilfield digital infrastructure, leveraging decades of experience in subsurface characterization and fluid handling to enhance lithium extraction efficiency. Their solution includes adaptive control systems that can automatically respond to changing brine chemistry, ensuring consistent product quality despite input variability[1][3].

Strengths: Extensive experience in subsurface characterization and fluid handling from oil and gas operations provides unique insights for lithium extraction. Integration with existing digital oilfield infrastructure enables rapid deployment and scaling. Weaknesses: Heavy reliance on proprietary systems may limit compatibility with third-party equipment. Technology primarily optimized for brine reservoirs similar to oil fields, potentially limiting applicability in some lithium-rich regions.

Lilac Solutions, Inc.

Technical Solution: Lilac Solutions has pioneered an AI-enhanced ion exchange technology for Direct Lithium Extraction that utilizes proprietary ceramic ion exchange beads with exceptional selectivity for lithium. Their AI system continuously monitors extraction efficiency and adaptively controls the regeneration cycle timing based on real-time data analysis. The technology employs machine learning algorithms to predict optimal operational parameters based on incoming brine chemistry, maximizing lithium recovery while minimizing water and chemical usage. Lilac's platform integrates computer vision systems to monitor bead condition and performance degradation, triggering maintenance protocols before efficiency drops. Their AI control system can manage multiple extraction units simultaneously, balancing production rates across a field to optimize overall output while responding to changing environmental conditions or energy availability[2][5]. The system also incorporates predictive maintenance capabilities that analyze performance patterns to schedule interventions before failures occur.

Strengths: Highly selective ion exchange material specifically engineered for lithium extraction provides superior performance compared to conventional methods. AI-optimized regeneration cycles significantly reduce water and chemical consumption. Weaknesses: Relatively new technology with limited long-term operational data in commercial settings. Higher initial capital investment compared to traditional extraction methods, though potentially offset by improved efficiency.

Core Patents in AI-Enhanced Lithium Extraction

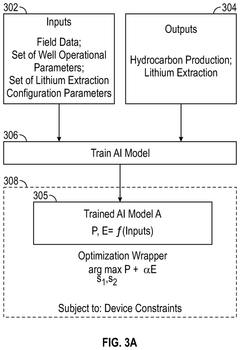

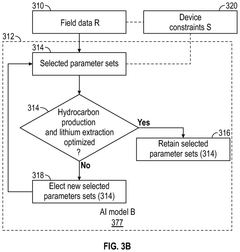

Artificial intelligence based framework for the optimization of lithium extraction in reservoir brine

PatentPendingUS20250223893A1

Innovation

- An artificial intelligence (AI) model is used to predict hydrocarbon production and lithium extraction based on well operational and lithium extraction configuration parameters, allowing for the automatic adjustment of these parameters in real-time to maximize both outputs simultaneously.

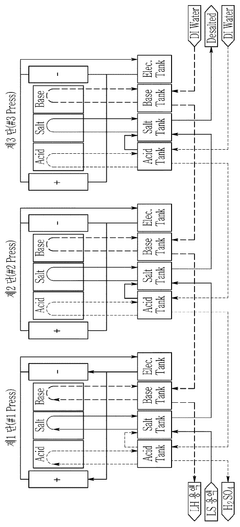

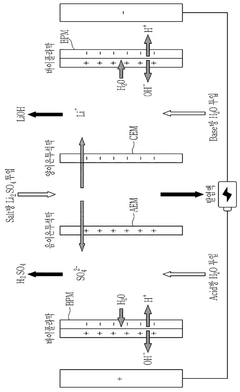

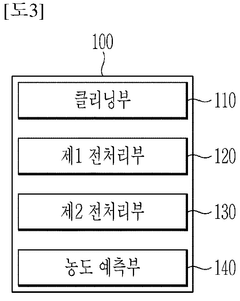

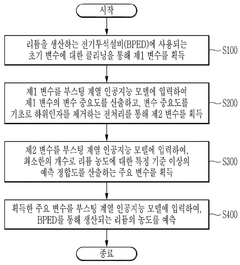

Method and device for predicting lithium concentration based on artificial intelligence

PatentWO2025127474A1

Innovation

- An artificial intelligence-based lithium concentration prediction method and device utilizing a boosting series artificial intelligence model, which preprocesses variables based on permutation importance and mean absolute percentage error (MAPE), effectively predicts lithium concentration with a minimum number of variables.

Environmental Impact Assessment of AI-DLE Technologies

The integration of AI technologies with Direct Lithium Extraction (DLE) processes presents significant environmental implications that warrant comprehensive assessment. When evaluating the environmental impact of AI-DLE technologies, it becomes evident that these systems offer potential benefits in reducing the ecological footprint compared to traditional lithium extraction methods such as evaporation ponds or hard rock mining.

AI-controlled DLE systems demonstrate improved water efficiency by enabling precise management of water resources during extraction processes. Traditional evaporation methods consume approximately 500,000 gallons of water per ton of lithium produced, whereas AI-optimized DLE can reduce this consumption by 30-50% through real-time monitoring and adaptive control mechanisms. This water conservation aspect is particularly crucial in arid regions where lithium reserves are often located.

Energy consumption patterns also show notable improvements with AI integration. Machine learning algorithms optimize pumping schedules, chemical dosing, and separation processes, resulting in an estimated 15-25% reduction in overall energy requirements. This translates to lower greenhouse gas emissions associated with lithium production, supporting broader climate change mitigation goals within the mining sector.

Chemical usage in DLE processes presents another environmental consideration significantly impacted by AI implementation. Intelligent systems can precisely calibrate chemical inputs based on real-time brine composition data, minimizing excess chemical application. Studies indicate that AI-controlled systems can reduce chemical reagent usage by up to 20%, decreasing the potential for harmful chemical discharge into surrounding ecosystems.

Land disturbance metrics reveal that AI-DLE technologies require substantially smaller physical footprints compared to traditional extraction methods. While conventional evaporation ponds may occupy thousands of hectares, AI-enhanced DLE facilities typically require less than 10% of this area. This reduced spatial requirement preserves natural habitats and minimizes ecosystem disruption in lithium-rich regions.

Waste management capabilities are enhanced through AI-powered predictive maintenance and process optimization. These systems can identify potential equipment failures before they result in spills or leaks, while also maximizing resource recovery from process streams. The result is a significant reduction in waste generation, with some operations reporting 30-40% less solid waste production compared to conventional extraction methods.

Long-term environmental monitoring is strengthened through AI integration, as these systems can continuously track environmental parameters and detect subtle changes that might indicate emerging ecological impacts. This enables more responsive environmental management and helps ensure regulatory compliance throughout the operational lifecycle of lithium extraction facilities.

AI-controlled DLE systems demonstrate improved water efficiency by enabling precise management of water resources during extraction processes. Traditional evaporation methods consume approximately 500,000 gallons of water per ton of lithium produced, whereas AI-optimized DLE can reduce this consumption by 30-50% through real-time monitoring and adaptive control mechanisms. This water conservation aspect is particularly crucial in arid regions where lithium reserves are often located.

Energy consumption patterns also show notable improvements with AI integration. Machine learning algorithms optimize pumping schedules, chemical dosing, and separation processes, resulting in an estimated 15-25% reduction in overall energy requirements. This translates to lower greenhouse gas emissions associated with lithium production, supporting broader climate change mitigation goals within the mining sector.

Chemical usage in DLE processes presents another environmental consideration significantly impacted by AI implementation. Intelligent systems can precisely calibrate chemical inputs based on real-time brine composition data, minimizing excess chemical application. Studies indicate that AI-controlled systems can reduce chemical reagent usage by up to 20%, decreasing the potential for harmful chemical discharge into surrounding ecosystems.

Land disturbance metrics reveal that AI-DLE technologies require substantially smaller physical footprints compared to traditional extraction methods. While conventional evaporation ponds may occupy thousands of hectares, AI-enhanced DLE facilities typically require less than 10% of this area. This reduced spatial requirement preserves natural habitats and minimizes ecosystem disruption in lithium-rich regions.

Waste management capabilities are enhanced through AI-powered predictive maintenance and process optimization. These systems can identify potential equipment failures before they result in spills or leaks, while also maximizing resource recovery from process streams. The result is a significant reduction in waste generation, with some operations reporting 30-40% less solid waste production compared to conventional extraction methods.

Long-term environmental monitoring is strengthened through AI integration, as these systems can continuously track environmental parameters and detect subtle changes that might indicate emerging ecological impacts. This enables more responsive environmental management and helps ensure regulatory compliance throughout the operational lifecycle of lithium extraction facilities.

Regulatory Framework for AI in Critical Mineral Extraction

The regulatory landscape for AI implementation in critical mineral extraction, particularly lithium, is evolving rapidly as governments recognize both the strategic importance of these resources and the transformative potential of AI technologies. In the United States, the Department of Energy has established preliminary guidelines for AI applications in energy-critical mineral extraction, emphasizing safety protocols, data security, and environmental impact assessments. These regulations require companies to demonstrate that AI systems maintain human oversight capabilities and include fail-safe mechanisms for process control operations.

The European Union's approach, through its AI Act and Critical Raw Materials Act, creates a dual regulatory framework specifically addressing AI applications in mineral extraction. Companies operating in EU jurisdictions must conduct mandatory algorithmic impact assessments before deploying AI systems in lithium extraction facilities, with particular attention to water usage optimization and environmental monitoring capabilities.

In Australia, which holds significant lithium reserves, the regulatory framework focuses on water conservation and indigenous land rights considerations when implementing AI technologies. Their "AI in Mining" regulatory guidelines require extensive consultation with traditional landowners and detailed water management plans before AI-controlled extraction systems can be approved.

China, as both a major lithium processor and AI developer, has implemented regulations that prioritize efficiency and production targets, with secondary emphasis on environmental considerations. Their regulatory approach mandates state review of AI algorithms used in critical mineral extraction, particularly focusing on data sovereignty requirements.

International standards bodies, including ISO and IEEE, are developing specific technical standards for AI applications in mineral extraction processes. The ISO/TC 82/SC 8 subcommittee is currently drafting standards specifically addressing AI integration in mining operations, including direct lithium extraction, with expected publication within the next 18 months.

Regulatory compliance challenges for companies implementing AI in direct lithium extraction include navigating fragmented jurisdictional requirements, addressing data localization mandates, and meeting increasingly stringent environmental impact documentation requirements. The lack of harmonized international standards creates significant compliance costs, particularly for operations spanning multiple countries.

Emerging regulatory trends indicate movement toward mandatory sustainability metrics for AI-controlled extraction processes, requirements for explainable AI in environmental monitoring systems, and potential carbon footprint limitations for computational resources used in extraction control systems. Companies developing integrated AI solutions for lithium extraction must build regulatory adaptability into their technology roadmaps to accommodate this rapidly evolving compliance landscape.

The European Union's approach, through its AI Act and Critical Raw Materials Act, creates a dual regulatory framework specifically addressing AI applications in mineral extraction. Companies operating in EU jurisdictions must conduct mandatory algorithmic impact assessments before deploying AI systems in lithium extraction facilities, with particular attention to water usage optimization and environmental monitoring capabilities.

In Australia, which holds significant lithium reserves, the regulatory framework focuses on water conservation and indigenous land rights considerations when implementing AI technologies. Their "AI in Mining" regulatory guidelines require extensive consultation with traditional landowners and detailed water management plans before AI-controlled extraction systems can be approved.

China, as both a major lithium processor and AI developer, has implemented regulations that prioritize efficiency and production targets, with secondary emphasis on environmental considerations. Their regulatory approach mandates state review of AI algorithms used in critical mineral extraction, particularly focusing on data sovereignty requirements.

International standards bodies, including ISO and IEEE, are developing specific technical standards for AI applications in mineral extraction processes. The ISO/TC 82/SC 8 subcommittee is currently drafting standards specifically addressing AI integration in mining operations, including direct lithium extraction, with expected publication within the next 18 months.

Regulatory compliance challenges for companies implementing AI in direct lithium extraction include navigating fragmented jurisdictional requirements, addressing data localization mandates, and meeting increasingly stringent environmental impact documentation requirements. The lack of harmonized international standards creates significant compliance costs, particularly for operations spanning multiple countries.

Emerging regulatory trends indicate movement toward mandatory sustainability metrics for AI-controlled extraction processes, requirements for explainable AI in environmental monitoring systems, and potential carbon footprint limitations for computational resources used in extraction control systems. Companies developing integrated AI solutions for lithium extraction must build regulatory adaptability into their technology roadmaps to accommodate this rapidly evolving compliance landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!