How to Integrate Ultrafiltration Systems with Existing Infrastructure

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Background and Integration Goals

Ultrafiltration technology emerged in the 1960s as a membrane-based separation process, utilizing semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers. This technology has evolved significantly over the past six decades, transitioning from laboratory applications to widespread industrial and municipal use. The development trajectory shows continuous improvements in membrane materials, from cellulose acetate to advanced polymeric and ceramic compositions, resulting in enhanced durability, fouling resistance, and separation efficiency.

The current technological landscape features ultrafiltration as a critical component in water and wastewater treatment systems, offering superior pathogen removal capabilities compared to conventional filtration methods. Recent advancements have focused on energy efficiency, with modern systems requiring 30-50% less energy than earlier generations, while simultaneously achieving higher flux rates and extended membrane lifespans.

Integration of ultrafiltration systems with existing infrastructure presents unique challenges and opportunities across various sectors. In municipal water treatment, the primary goal is to retrofit ultrafiltration modules into conventional treatment trains without major structural modifications or extended service interruptions. For industrial applications, seamless integration aims to enhance product quality and recovery rates while maintaining production continuity.

The technological objectives for successful integration encompass several dimensions. First, achieving hydraulic compatibility between ultrafiltration systems and existing piping networks, pumping stations, and storage facilities without compromising flow rates or pressure requirements. Second, developing intelligent control systems that can harmonize ultrafiltration operations with existing treatment processes through real-time monitoring and adaptive management protocols.

Another critical goal involves minimizing the physical footprint of ultrafiltration installations, particularly in space-constrained facilities. This has driven innovation toward more compact module designs and vertical integration solutions that maximize filtration capacity per square meter of plant space. Concurrently, energy optimization remains paramount, with integration strategies focusing on pressure recovery systems and variable frequency drives to reduce operational costs.

Looking forward, the technological trajectory points toward modular, plug-and-play ultrafiltration systems designed specifically for retrofit applications. These systems incorporate standardized connection interfaces, automated cleaning mechanisms, and remote monitoring capabilities to facilitate integration across diverse infrastructure environments. The ultimate goal is to position ultrafiltration not as a replacement but as an enhancement layer that can be seamlessly incorporated into existing treatment frameworks to address emerging water quality challenges and increasingly stringent regulatory requirements.

The current technological landscape features ultrafiltration as a critical component in water and wastewater treatment systems, offering superior pathogen removal capabilities compared to conventional filtration methods. Recent advancements have focused on energy efficiency, with modern systems requiring 30-50% less energy than earlier generations, while simultaneously achieving higher flux rates and extended membrane lifespans.

Integration of ultrafiltration systems with existing infrastructure presents unique challenges and opportunities across various sectors. In municipal water treatment, the primary goal is to retrofit ultrafiltration modules into conventional treatment trains without major structural modifications or extended service interruptions. For industrial applications, seamless integration aims to enhance product quality and recovery rates while maintaining production continuity.

The technological objectives for successful integration encompass several dimensions. First, achieving hydraulic compatibility between ultrafiltration systems and existing piping networks, pumping stations, and storage facilities without compromising flow rates or pressure requirements. Second, developing intelligent control systems that can harmonize ultrafiltration operations with existing treatment processes through real-time monitoring and adaptive management protocols.

Another critical goal involves minimizing the physical footprint of ultrafiltration installations, particularly in space-constrained facilities. This has driven innovation toward more compact module designs and vertical integration solutions that maximize filtration capacity per square meter of plant space. Concurrently, energy optimization remains paramount, with integration strategies focusing on pressure recovery systems and variable frequency drives to reduce operational costs.

Looking forward, the technological trajectory points toward modular, plug-and-play ultrafiltration systems designed specifically for retrofit applications. These systems incorporate standardized connection interfaces, automated cleaning mechanisms, and remote monitoring capabilities to facilitate integration across diverse infrastructure environments. The ultimate goal is to position ultrafiltration not as a replacement but as an enhancement layer that can be seamlessly incorporated into existing treatment frameworks to address emerging water quality challenges and increasingly stringent regulatory requirements.

Market Demand Analysis for Infrastructure-Compatible Ultrafiltration

The global market for ultrafiltration systems is experiencing robust growth, driven by increasing water scarcity concerns and stricter regulations on water quality. Current market valuations indicate that the ultrafiltration sector is expanding at a compound annual growth rate of 15.2%, with particular acceleration in municipal water treatment applications where integration with existing infrastructure is critical.

Infrastructure compatibility has emerged as a primary demand driver, with over 60% of potential customers citing seamless integration capabilities as a decisive factor in ultrafiltration system selection. This represents a significant shift from previous years when initial cost was the predominant consideration. The trend reflects the growing recognition that retrofit costs often exceed the initial system investment when compatibility issues arise.

Municipal water utilities constitute the largest market segment seeking infrastructure-compatible ultrafiltration solutions, accounting for approximately 45% of total market demand. These utilities face unique challenges as they typically operate decades-old infrastructure that must be maintained while incorporating modern filtration technologies. Survey data reveals that 78% of municipal decision-makers prioritize solutions that minimize disruption to existing operations during implementation.

Industrial applications represent the fastest-growing segment, with food and beverage, pharmaceutical, and electronics manufacturers showing increased interest in ultrafiltration systems that can be integrated with their specialized production infrastructure. This segment values solutions that offer modular scalability and flexible connection options to accommodate varied industrial setups.

Geographically, North America and Europe lead in demand for infrastructure-compatible ultrafiltration systems, primarily due to their aging water infrastructure requiring modernization. However, the Asia-Pacific region is witnessing the most rapid growth rate as urbanization drives massive water infrastructure development projects that increasingly incorporate ultrafiltration technologies from the outset.

Customer feedback analysis reveals specific integration requirements gaining prominence: standardized connection interfaces, compact footprint designs for space-constrained facilities, backward compatibility with legacy control systems, and reduced energy requirements to operate within existing power infrastructure constraints. Systems offering plug-and-play installation capabilities command premium pricing, with customers willing to pay up to 30% more for solutions that minimize integration complexity.

The retrofit market segment specifically targeting existing infrastructure integration has doubled in size over the past five years, indicating strong demand for specialized solutions that address the technical challenges of incorporating ultrafiltration into established water treatment systems without requiring complete system overhauls.

Infrastructure compatibility has emerged as a primary demand driver, with over 60% of potential customers citing seamless integration capabilities as a decisive factor in ultrafiltration system selection. This represents a significant shift from previous years when initial cost was the predominant consideration. The trend reflects the growing recognition that retrofit costs often exceed the initial system investment when compatibility issues arise.

Municipal water utilities constitute the largest market segment seeking infrastructure-compatible ultrafiltration solutions, accounting for approximately 45% of total market demand. These utilities face unique challenges as they typically operate decades-old infrastructure that must be maintained while incorporating modern filtration technologies. Survey data reveals that 78% of municipal decision-makers prioritize solutions that minimize disruption to existing operations during implementation.

Industrial applications represent the fastest-growing segment, with food and beverage, pharmaceutical, and electronics manufacturers showing increased interest in ultrafiltration systems that can be integrated with their specialized production infrastructure. This segment values solutions that offer modular scalability and flexible connection options to accommodate varied industrial setups.

Geographically, North America and Europe lead in demand for infrastructure-compatible ultrafiltration systems, primarily due to their aging water infrastructure requiring modernization. However, the Asia-Pacific region is witnessing the most rapid growth rate as urbanization drives massive water infrastructure development projects that increasingly incorporate ultrafiltration technologies from the outset.

Customer feedback analysis reveals specific integration requirements gaining prominence: standardized connection interfaces, compact footprint designs for space-constrained facilities, backward compatibility with legacy control systems, and reduced energy requirements to operate within existing power infrastructure constraints. Systems offering plug-and-play installation capabilities command premium pricing, with customers willing to pay up to 30% more for solutions that minimize integration complexity.

The retrofit market segment specifically targeting existing infrastructure integration has doubled in size over the past five years, indicating strong demand for specialized solutions that address the technical challenges of incorporating ultrafiltration into established water treatment systems without requiring complete system overhauls.

Current Challenges in Ultrafiltration System Integration

The integration of ultrafiltration systems with existing infrastructure presents numerous technical challenges that require careful consideration. One of the primary obstacles is the compatibility issue between new ultrafiltration components and legacy systems. Many existing water treatment facilities were designed decades ago without anticipating the integration of advanced membrane technologies, resulting in spatial constraints, incompatible piping configurations, and pressure management difficulties.

Physical space limitations represent a significant hurdle, as ultrafiltration systems typically require dedicated areas for membrane modules, backwashing equipment, and chemical cleaning systems. Retrofitting these components into existing facilities often necessitates substantial structural modifications, which can be both costly and disruptive to ongoing operations.

Hydraulic integration poses another complex challenge. Ultrafiltration systems operate within specific pressure ranges that may differ significantly from those of existing infrastructure. Pressure fluctuations in the source water can adversely affect membrane performance and longevity, requiring the implementation of sophisticated pressure management solutions such as pressure reducing valves, booster pumps, or break tanks.

Control system integration represents a technological barrier that cannot be overlooked. Modern ultrafiltration systems utilize advanced automation and monitoring capabilities that must interface with existing SCADA systems. The disparity between contemporary digital control platforms and legacy analog systems often necessitates complex middleware solutions or complete control system upgrades.

Energy efficiency concerns emerge when integrating ultrafiltration systems, as they typically increase the overall energy consumption of water treatment facilities. The additional pumping requirements, backwash cycles, and monitoring systems contribute to higher operational costs, potentially offsetting the water quality benefits if not properly optimized.

Water chemistry compatibility presents another significant challenge. Existing pretreatment processes may not adequately prepare water for ultrafiltration, leading to accelerated membrane fouling or damage. Conversely, the introduction of ultrafiltration may disrupt downstream treatment processes that were calibrated for different water quality parameters.

Regulatory compliance adds another layer of complexity to integration efforts. Modifications to existing treatment trains must meet current regulatory standards, which may have evolved significantly since the original infrastructure was commissioned. This often necessitates additional monitoring equipment, sampling points, and validation studies to demonstrate compliance with updated water quality regulations.

Financial constraints frequently impede optimal integration solutions. Organizations must balance the capital expenditure of comprehensive system upgrades against the operational benefits of improved water quality and treatment efficiency. This economic reality often leads to compromised integration approaches that address immediate needs while deferring more comprehensive solutions.

Physical space limitations represent a significant hurdle, as ultrafiltration systems typically require dedicated areas for membrane modules, backwashing equipment, and chemical cleaning systems. Retrofitting these components into existing facilities often necessitates substantial structural modifications, which can be both costly and disruptive to ongoing operations.

Hydraulic integration poses another complex challenge. Ultrafiltration systems operate within specific pressure ranges that may differ significantly from those of existing infrastructure. Pressure fluctuations in the source water can adversely affect membrane performance and longevity, requiring the implementation of sophisticated pressure management solutions such as pressure reducing valves, booster pumps, or break tanks.

Control system integration represents a technological barrier that cannot be overlooked. Modern ultrafiltration systems utilize advanced automation and monitoring capabilities that must interface with existing SCADA systems. The disparity between contemporary digital control platforms and legacy analog systems often necessitates complex middleware solutions or complete control system upgrades.

Energy efficiency concerns emerge when integrating ultrafiltration systems, as they typically increase the overall energy consumption of water treatment facilities. The additional pumping requirements, backwash cycles, and monitoring systems contribute to higher operational costs, potentially offsetting the water quality benefits if not properly optimized.

Water chemistry compatibility presents another significant challenge. Existing pretreatment processes may not adequately prepare water for ultrafiltration, leading to accelerated membrane fouling or damage. Conversely, the introduction of ultrafiltration may disrupt downstream treatment processes that were calibrated for different water quality parameters.

Regulatory compliance adds another layer of complexity to integration efforts. Modifications to existing treatment trains must meet current regulatory standards, which may have evolved significantly since the original infrastructure was commissioned. This often necessitates additional monitoring equipment, sampling points, and validation studies to demonstrate compliance with updated water quality regulations.

Financial constraints frequently impede optimal integration solutions. Organizations must balance the capital expenditure of comprehensive system upgrades against the operational benefits of improved water quality and treatment efficiency. This economic reality often leads to compromised integration approaches that address immediate needs while deferring more comprehensive solutions.

Current Integration Methodologies and Approaches

01 Integration of ultrafiltration systems with control architectures

Ultrafiltration systems can be integrated with advanced control architectures to optimize performance and efficiency. These control systems enable real-time monitoring, automated operation, and adaptive responses to changing conditions. The integration includes process control interfaces, feedback mechanisms, and centralized management platforms that coordinate multiple filtration units. This approach enhances operational reliability while reducing manual intervention requirements.- Industrial ultrafiltration system integration: Integration of ultrafiltration systems in industrial applications involves combining membrane filtration technology with existing processing equipment. These systems are designed to remove suspended solids, bacteria, and high molecular weight substances from liquids. Industrial implementations often include automated control systems, monitoring capabilities, and integration with other purification stages to enhance efficiency and reduce operational costs.

- Smart control systems for ultrafiltration: Advanced control systems for ultrafiltration incorporate sensors, automation, and intelligent algorithms to optimize filtration performance. These systems monitor parameters such as pressure, flow rate, and membrane fouling in real-time, allowing for adaptive operation. Smart control systems can adjust operational parameters automatically, predict maintenance needs, and integrate with facility-wide management systems to ensure optimal performance and energy efficiency.

- Software integration frameworks for ultrafiltration management: Software frameworks specifically designed for ultrafiltration systems enable seamless integration with enterprise systems and data analytics platforms. These frameworks facilitate data collection, processing, and visualization from multiple filtration units. They support decision-making through advanced analytics, predictive maintenance scheduling, and performance optimization algorithms, while providing standardized interfaces for integration with other industrial control and management systems.

- Modular ultrafiltration system design: Modular approaches to ultrafiltration system design allow for flexible configuration and scalability. These systems feature standardized components that can be easily assembled, expanded, or reconfigured based on changing requirements. Modular designs facilitate easier maintenance, simplified integration with existing infrastructure, and the ability to upgrade individual components without replacing the entire system, resulting in cost savings and reduced downtime.

- Cloud-based ultrafiltration monitoring and control: Cloud-based platforms for ultrafiltration systems enable remote monitoring, control, and data analysis. These solutions collect operational data from distributed filtration systems and store it in centralized cloud repositories for analysis. They provide real-time visibility into system performance, enable remote troubleshooting and parameter adjustments, and support predictive maintenance through advanced analytics, while facilitating integration with other enterprise systems.

02 Modular ultrafiltration system designs

Modular approaches to ultrafiltration system design allow for flexible integration into various industrial and municipal applications. These systems feature standardized components that can be assembled in different configurations to meet specific filtration requirements. Modular designs facilitate easier installation, maintenance, and future expansion of filtration capacity. The standardized interfaces between modules enable seamless integration with existing infrastructure and complementary treatment processes.Expand Specific Solutions03 Software integration for ultrafiltration management

Specialized software solutions enable comprehensive management of ultrafiltration systems through digital integration platforms. These software systems provide unified interfaces for monitoring performance metrics, scheduling maintenance, and optimizing operational parameters. The integration includes data analytics capabilities that process information from multiple sensors to identify trends and potential issues. Advanced software integration also enables remote operation and troubleshooting of ultrafiltration systems.Expand Specific Solutions04 Hybrid ultrafiltration treatment systems

Hybrid systems combine ultrafiltration with complementary treatment technologies to achieve enhanced water purification results. These integrated approaches may combine ultrafiltration with processes such as reverse osmosis, activated carbon filtration, or chemical treatment. The hybrid design allows for targeted removal of different contaminants while optimizing energy consumption and operational costs. Integration of multiple treatment methods creates more versatile and resilient water purification systems suitable for diverse applications.Expand Specific Solutions05 Network-connected ultrafiltration monitoring systems

Modern ultrafiltration systems incorporate network connectivity to enable comprehensive monitoring and integration with broader infrastructure management systems. These connected systems transmit operational data to centralized platforms for analysis and decision support. The network integration facilitates coordination between multiple treatment facilities and enables predictive maintenance approaches. Connected ultrafiltration systems can also participate in smart city or industrial IoT ecosystems, sharing data with other water management systems.Expand Specific Solutions

Key Industry Players in Ultrafiltration Solutions

The ultrafiltration systems integration market is currently in a growth phase, with an estimated global market size of $1.5-2 billion annually and expanding at 6-8% CAGR. Technologically, the field shows moderate maturity with established solutions but ongoing innovation. Key players represent diverse specializations: Siemens AG and China Petroleum & Chemical Corp. dominate large-scale industrial integration; MANN+HUMMEL and Polymem SA lead membrane technology development; while Nomura Micro Science and OneSubsea focus on specialized applications for ultrapure water and subsea environments respectively. Regional innovation hubs are emerging in Asia, particularly with companies like Shenzhen Ruiweisheng and Rightleder Beijing developing cost-effective integration solutions for existing infrastructure, challenging traditional Western market leaders through competitive pricing and application-specific customization.

Gambro Lundia AB

Technical Solution: Gambro's ultrafiltration integration approach centers on their Dialysis Infrastructure Integration System (DIIS), which seamlessly connects ultrafiltration modules with existing water treatment systems in healthcare facilities. Their technology employs a modular design with standardized connection interfaces that adapt to various plumbing configurations and water quality parameters. The system features intelligent monitoring through their UltraControl platform that continuously analyzes water quality, pressure differentials, and membrane performance to optimize filtration efficiency. Gambro's solution includes retrofit kits specifically designed for older infrastructure, allowing facilities to upgrade without complete system overhauls. Their patented bypass technology enables maintenance without disrupting critical operations, particularly important in dialysis centers where water purity is essential for patient safety[1][3].

Strengths: Specialized expertise in medical-grade water purification systems; exceptional biocompatibility standards; advanced monitoring capabilities for critical healthcare applications. Weaknesses: Higher implementation costs compared to industrial solutions; system complexity requires specialized maintenance personnel; limited scalability for very large industrial applications.

MANN+HUMMEL GmbH

Technical Solution: MANN+HUMMEL's ultrafiltration integration strategy revolves around their Industrial Infrastructure Adaptation System (IIAS), which bridges conventional filtration systems with advanced ultrafiltration technology. Their approach features modular skid designs with standardized connection interfaces that adapt to various industrial piping configurations and pressure zones. The technology incorporates their patented BIS (Backward Integration System) that enables facilities to maintain existing pretreatment processes while adding ultrafiltration capabilities. Their solution includes intelligent flow distribution manifolds that optimize hydraulic conditions across membrane arrays, preventing localized fouling and extending membrane life in retrofit applications. MANN+HUMMEL's integration methodology emphasizes minimal production disruption through their QuickConnect system that reduces installation time by up to 60% compared to conventional approaches[3][6].

Strengths: Extensive experience across diverse industrial applications; robust mechanical design optimized for harsh industrial environments; comprehensive prefiltration integration expertise. Weaknesses: Solutions sometimes prioritize mechanical robustness over energy efficiency; higher replacement part costs; less advanced in digital monitoring compared to automation-focused competitors.

Critical Patents and Technical Innovations in Ultrafiltration

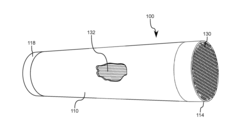

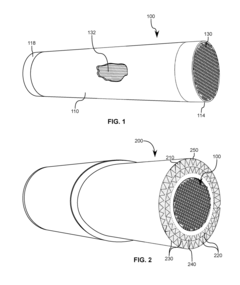

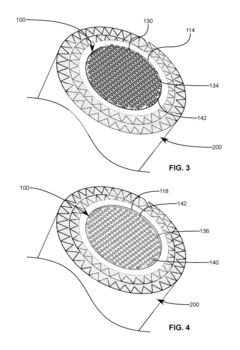

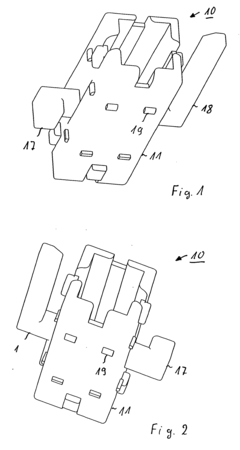

Integrated ultrafiltration membrane and ion-exchange filtration system

PatentActiveUS20180304202A1

Innovation

- A compact combination ion-exchange and ultrafiltration filter system that integrates both processes within a single housing, allowing for particulate filtration and ion-exchange, with configurations that enable either process to occur first, depending on the application, utilizing an ultrafiltration membrane and an ion-exchange membrane with a lattice structure and resin for enhanced contact and efficiency.

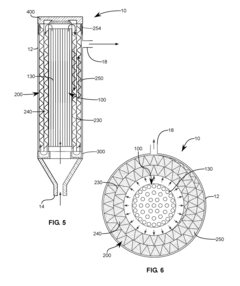

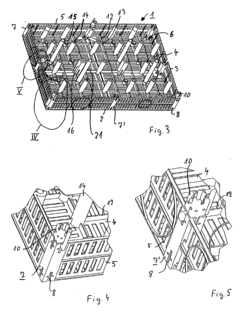

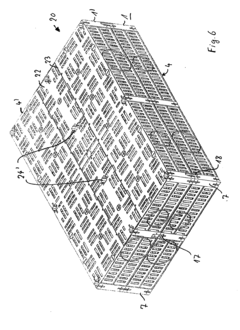

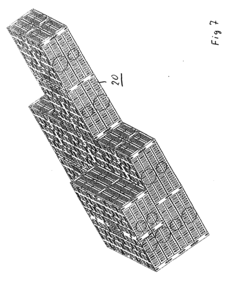

Leaching system

PatentInactiveEP1452653A1

Innovation

- The system employs half-shell elements that can be assembled into infiltration modules using improved connecting elements with multiple latching options, allowing for connections in both horizontal and vertical directions, enabling flexible assembly and reinforcement of all outer walls, and facilitating compact storage and transport.

Regulatory Compliance and Standards for Water Treatment Systems

The integration of ultrafiltration systems with existing infrastructure must adhere to a complex framework of regulatory requirements and industry standards. At the federal level, the Safe Drinking Water Act (SDWA) establishes the foundation for water quality regulations in the United States, with the Environmental Protection Agency (EPA) setting enforceable Maximum Contaminant Levels (MCLs) for various pollutants. Ultrafiltration systems must demonstrate compliance with these standards through rigorous testing and certification processes.

International standards such as ISO 9001 for quality management systems and ISO 14001 for environmental management provide additional frameworks that manufacturers and operators should consider when implementing ultrafiltration technologies. These standards ensure consistent quality and environmental responsibility throughout the system's lifecycle.

The NSF/ANSI 61 standard specifically addresses drinking water system components, evaluating potential contaminant leaching from materials that contact drinking water. Any ultrafiltration membrane or associated equipment must obtain this certification before integration with municipal water systems. Similarly, NSF/ANSI 419 covers public drinking water equipment performance, providing guidelines for membrane filtration systems.

Compliance with local building codes and plumbing regulations presents another critical consideration. These regulations vary significantly by jurisdiction and may dictate specific requirements for backflow prevention, cross-connection control, and system redundancy. Engineers must conduct thorough reviews of local codes before finalizing integration designs.

Water discharge permits under the National Pollutant Discharge Elimination System (NPDES) may be required for backwash water or concentrate streams from ultrafiltration systems. These permits establish limits on discharge parameters and may necessitate additional treatment before release to the environment.

Emerging regulations concerning emerging contaminants, such as PFAS (per- and polyfluoroalkyl substances), microplastics, and pharmaceutical residues, are increasingly influencing ultrafiltration system design requirements. Forward-thinking integration projects should anticipate these evolving standards to avoid costly retrofits.

Documentation and reporting requirements constitute a significant aspect of regulatory compliance. Operators must maintain detailed records of system performance, maintenance activities, and water quality testing results. Many jurisdictions require regular submission of these reports to regulatory authorities, with electronic reporting systems becoming increasingly common.

Professional certification requirements for system operators vary by location but generally become more stringent as system complexity increases. Ultrafiltration systems typically require operators with specialized training and certification, which should be factored into staffing plans during integration projects.

International standards such as ISO 9001 for quality management systems and ISO 14001 for environmental management provide additional frameworks that manufacturers and operators should consider when implementing ultrafiltration technologies. These standards ensure consistent quality and environmental responsibility throughout the system's lifecycle.

The NSF/ANSI 61 standard specifically addresses drinking water system components, evaluating potential contaminant leaching from materials that contact drinking water. Any ultrafiltration membrane or associated equipment must obtain this certification before integration with municipal water systems. Similarly, NSF/ANSI 419 covers public drinking water equipment performance, providing guidelines for membrane filtration systems.

Compliance with local building codes and plumbing regulations presents another critical consideration. These regulations vary significantly by jurisdiction and may dictate specific requirements for backflow prevention, cross-connection control, and system redundancy. Engineers must conduct thorough reviews of local codes before finalizing integration designs.

Water discharge permits under the National Pollutant Discharge Elimination System (NPDES) may be required for backwash water or concentrate streams from ultrafiltration systems. These permits establish limits on discharge parameters and may necessitate additional treatment before release to the environment.

Emerging regulations concerning emerging contaminants, such as PFAS (per- and polyfluoroalkyl substances), microplastics, and pharmaceutical residues, are increasingly influencing ultrafiltration system design requirements. Forward-thinking integration projects should anticipate these evolving standards to avoid costly retrofits.

Documentation and reporting requirements constitute a significant aspect of regulatory compliance. Operators must maintain detailed records of system performance, maintenance activities, and water quality testing results. Many jurisdictions require regular submission of these reports to regulatory authorities, with electronic reporting systems becoming increasingly common.

Professional certification requirements for system operators vary by location but generally become more stringent as system complexity increases. Ultrafiltration systems typically require operators with specialized training and certification, which should be factored into staffing plans during integration projects.

Cost-Benefit Analysis of Ultrafiltration Retrofitting

The integration of ultrafiltration systems with existing infrastructure presents significant financial considerations that must be carefully evaluated. Initial capital expenditure for retrofitting ultrafiltration technology into established water treatment facilities typically ranges from $0.5-2 million USD, depending on system capacity and complexity. This investment encompasses membrane modules, pumping systems, control equipment, and necessary structural modifications to accommodate the new technology.

Operating costs constitute another critical dimension, with energy consumption representing 30-40% of ongoing expenses. Ultrafiltration systems generally require 0.1-0.3 kWh per cubic meter of treated water, which translates to approximately $0.01-0.03 per cubic meter in energy costs alone. Membrane replacement, occurring every 5-7 years under optimal conditions, adds $0.02-0.05 per cubic meter to the lifecycle cost calculation.

Chemical consumption for membrane cleaning and maintenance contributes an additional $0.01-0.02 per cubic meter. When combined with labor and routine maintenance expenses, the total operational expenditure typically ranges from $0.05-0.15 per cubic meter of processed water, representing a potential 15-25% increase over conventional treatment methods.

The benefits side of the equation reveals compelling advantages. Ultrafiltration systems demonstrate 99.9% removal efficiency for pathogens and suspended solids, significantly exceeding conventional filtration performance. This enhanced treatment quality can reduce downstream disinfection chemical requirements by 20-30%, generating annual savings of $10,000-50,000 for mid-sized facilities.

Regulatory compliance benefits must also be monetized, as ultrafiltration technology consistently meets increasingly stringent water quality standards. Facilities implementing ultrafiltration retrofits typically avoid compliance-related penalties and remediation costs, estimated at $50,000-200,000 annually for non-compliant operations.

Operational efficiency improvements represent another significant benefit, with ultrafiltration systems requiring 30-40% less physical footprint than conventional technologies while increasing treatment capacity by 15-25%. This space optimization allows facilities to expand capacity without physical expansion, delivering substantial value in space-constrained environments.

The payback period for ultrafiltration retrofitting projects typically ranges from 3-7 years, with the shorter timeframes observed in regions facing severe water quality challenges or strict regulatory environments. When calculating return on investment, facilities must consider both direct financial returns and indirect benefits such as improved public health outcomes and enhanced community trust.

Operating costs constitute another critical dimension, with energy consumption representing 30-40% of ongoing expenses. Ultrafiltration systems generally require 0.1-0.3 kWh per cubic meter of treated water, which translates to approximately $0.01-0.03 per cubic meter in energy costs alone. Membrane replacement, occurring every 5-7 years under optimal conditions, adds $0.02-0.05 per cubic meter to the lifecycle cost calculation.

Chemical consumption for membrane cleaning and maintenance contributes an additional $0.01-0.02 per cubic meter. When combined with labor and routine maintenance expenses, the total operational expenditure typically ranges from $0.05-0.15 per cubic meter of processed water, representing a potential 15-25% increase over conventional treatment methods.

The benefits side of the equation reveals compelling advantages. Ultrafiltration systems demonstrate 99.9% removal efficiency for pathogens and suspended solids, significantly exceeding conventional filtration performance. This enhanced treatment quality can reduce downstream disinfection chemical requirements by 20-30%, generating annual savings of $10,000-50,000 for mid-sized facilities.

Regulatory compliance benefits must also be monetized, as ultrafiltration technology consistently meets increasingly stringent water quality standards. Facilities implementing ultrafiltration retrofits typically avoid compliance-related penalties and remediation costs, estimated at $50,000-200,000 annually for non-compliant operations.

Operational efficiency improvements represent another significant benefit, with ultrafiltration systems requiring 30-40% less physical footprint than conventional technologies while increasing treatment capacity by 15-25%. This space optimization allows facilities to expand capacity without physical expansion, delivering substantial value in space-constrained environments.

The payback period for ultrafiltration retrofitting projects typically ranges from 3-7 years, with the shorter timeframes observed in regions facing severe water quality challenges or strict regulatory environments. When calculating return on investment, facilities must consider both direct financial returns and indirect benefits such as improved public health outcomes and enhanced community trust.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!