How to Reduce Noise in Hall Effect Sensor Outputs

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Noise Reduction Background and Objectives

Hall Effect sensors have evolved significantly since their discovery by Edwin Hall in 1879. Initially utilized for basic magnetic field detection, these sensors have transformed into sophisticated components integral to modern electronics and automotive systems. The technology has progressed from simple magnetic field measurement to advanced integrated circuits capable of precise position sensing, current measurement, and speed detection applications.

The evolution of Hall Effect sensors has been driven by increasing demands for higher accuracy, reliability, and noise immunity across various industries. Recent technological advancements have focused on miniaturization, enhanced sensitivity, and improved signal processing capabilities, enabling these sensors to operate effectively in increasingly challenging electromagnetic environments.

Despite these advancements, noise interference remains a persistent challenge in Hall Effect sensor applications. External electromagnetic interference (EMI), thermal noise, flicker noise (1/f noise), and quantization noise from analog-to-digital conversion processes all contribute to signal degradation. These noise sources can significantly impact measurement accuracy, particularly in high-precision applications where even minor signal fluctuations can lead to substantial errors.

The primary objective of noise reduction in Hall Effect sensors is to enhance signal integrity while maintaining or improving other performance parameters. This includes increasing the signal-to-noise ratio (SNR), improving measurement resolution, enhancing reliability in harsh environments, and ensuring consistent performance across varying operating conditions. Additionally, noise reduction techniques must be compatible with modern manufacturing processes and cost constraints.

Current industry trends indicate growing demand for Hall Effect sensors in emerging applications such as Internet of Things (IoT) devices, wearable technology, and advanced driver-assistance systems (ADAS). These applications require sensors that can operate with minimal power consumption while maintaining high sensitivity and noise immunity, presenting new challenges for noise reduction strategies.

The technical goals for Hall Effect sensor noise reduction include developing innovative filtering techniques, exploring new materials with superior magnetic properties, implementing advanced signal processing algorithms, and designing optimized sensor geometries. These approaches aim to address both intrinsic noise sources within the sensor itself and extrinsic noise from environmental factors.

Understanding the fundamental principles of noise generation and propagation in Hall Effect sensors is essential for developing effective mitigation strategies. This requires a multidisciplinary approach combining expertise in semiconductor physics, materials science, signal processing, and electromagnetic compatibility to achieve comprehensive noise reduction solutions.

The evolution of Hall Effect sensors has been driven by increasing demands for higher accuracy, reliability, and noise immunity across various industries. Recent technological advancements have focused on miniaturization, enhanced sensitivity, and improved signal processing capabilities, enabling these sensors to operate effectively in increasingly challenging electromagnetic environments.

Despite these advancements, noise interference remains a persistent challenge in Hall Effect sensor applications. External electromagnetic interference (EMI), thermal noise, flicker noise (1/f noise), and quantization noise from analog-to-digital conversion processes all contribute to signal degradation. These noise sources can significantly impact measurement accuracy, particularly in high-precision applications where even minor signal fluctuations can lead to substantial errors.

The primary objective of noise reduction in Hall Effect sensors is to enhance signal integrity while maintaining or improving other performance parameters. This includes increasing the signal-to-noise ratio (SNR), improving measurement resolution, enhancing reliability in harsh environments, and ensuring consistent performance across varying operating conditions. Additionally, noise reduction techniques must be compatible with modern manufacturing processes and cost constraints.

Current industry trends indicate growing demand for Hall Effect sensors in emerging applications such as Internet of Things (IoT) devices, wearable technology, and advanced driver-assistance systems (ADAS). These applications require sensors that can operate with minimal power consumption while maintaining high sensitivity and noise immunity, presenting new challenges for noise reduction strategies.

The technical goals for Hall Effect sensor noise reduction include developing innovative filtering techniques, exploring new materials with superior magnetic properties, implementing advanced signal processing algorithms, and designing optimized sensor geometries. These approaches aim to address both intrinsic noise sources within the sensor itself and extrinsic noise from environmental factors.

Understanding the fundamental principles of noise generation and propagation in Hall Effect sensors is essential for developing effective mitigation strategies. This requires a multidisciplinary approach combining expertise in semiconductor physics, materials science, signal processing, and electromagnetic compatibility to achieve comprehensive noise reduction solutions.

Market Demand Analysis for Low-Noise Hall Sensors

The global market for Hall Effect sensors is experiencing robust growth, driven by increasing demand for low-noise sensing solutions across multiple industries. Current market valuations place the Hall Effect sensor market at approximately 2.1 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 8.2% through 2030. This growth trajectory is particularly pronounced in the automotive sector, where the transition to electric vehicles and advanced driver assistance systems (ADAS) has created substantial demand for high-precision, low-noise Hall sensors.

Industrial automation represents another significant market segment, accounting for roughly 24% of the total Hall sensor market. The push toward Industry 4.0 and smart manufacturing has intensified the need for sensors capable of operating reliably in electromagnetically noisy environments. End-users in this sector consistently report that noise reduction in sensor outputs directly correlates with improved production efficiency and reduced downtime.

Consumer electronics manufacturers have also emerged as key stakeholders in the low-noise Hall sensor market. With the miniaturization of devices and increasing functionality requirements, these manufacturers require sensors that maintain signal integrity despite space constraints and proximity to other electronic components. Market research indicates that approximately 65% of consumer electronics manufacturers consider noise reduction a critical factor in sensor selection.

Healthcare applications present a rapidly expanding market opportunity, with medical device manufacturers increasingly incorporating Hall Effect sensors into diagnostic and monitoring equipment. The demand for ultra-low-noise sensors in this sector stems from the critical nature of accurate measurements in medical contexts, where even minor signal distortions can lead to misdiagnosis or treatment errors.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (22%). China and South Korea, in particular, show accelerated adoption rates due to their robust electronics manufacturing ecosystems and automotive production capabilities.

Voice-of-customer surveys indicate that end-users across industries are willing to pay a premium of 15-20% for Hall sensors that demonstrate superior noise performance. This price elasticity underscores the critical importance of noise reduction in practical applications and represents a significant value-creation opportunity for sensor manufacturers who can deliver enhanced signal-to-noise ratios.

Market forecasts suggest that the segment specifically focused on low-noise Hall sensors will outpace the broader market, with an expected CAGR of 10.5% over the next five years. This accelerated growth reflects the increasing sophistication of applications and the corresponding demand for sensors that can deliver clean, reliable signals even in challenging operational environments.

Industrial automation represents another significant market segment, accounting for roughly 24% of the total Hall sensor market. The push toward Industry 4.0 and smart manufacturing has intensified the need for sensors capable of operating reliably in electromagnetically noisy environments. End-users in this sector consistently report that noise reduction in sensor outputs directly correlates with improved production efficiency and reduced downtime.

Consumer electronics manufacturers have also emerged as key stakeholders in the low-noise Hall sensor market. With the miniaturization of devices and increasing functionality requirements, these manufacturers require sensors that maintain signal integrity despite space constraints and proximity to other electronic components. Market research indicates that approximately 65% of consumer electronics manufacturers consider noise reduction a critical factor in sensor selection.

Healthcare applications present a rapidly expanding market opportunity, with medical device manufacturers increasingly incorporating Hall Effect sensors into diagnostic and monitoring equipment. The demand for ultra-low-noise sensors in this sector stems from the critical nature of accurate measurements in medical contexts, where even minor signal distortions can lead to misdiagnosis or treatment errors.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (22%). China and South Korea, in particular, show accelerated adoption rates due to their robust electronics manufacturing ecosystems and automotive production capabilities.

Voice-of-customer surveys indicate that end-users across industries are willing to pay a premium of 15-20% for Hall sensors that demonstrate superior noise performance. This price elasticity underscores the critical importance of noise reduction in practical applications and represents a significant value-creation opportunity for sensor manufacturers who can deliver enhanced signal-to-noise ratios.

Market forecasts suggest that the segment specifically focused on low-noise Hall sensors will outpace the broader market, with an expected CAGR of 10.5% over the next five years. This accelerated growth reflects the increasing sophistication of applications and the corresponding demand for sensors that can deliver clean, reliable signals even in challenging operational environments.

Current Challenges in Hall Effect Sensor Technology

Hall Effect sensors, while widely adopted across various industries for their non-contact measurement capabilities, face significant challenges that limit their performance in high-precision applications. The primary challenge remains signal-to-noise ratio (SNR) optimization, particularly in environments with electromagnetic interference (EMI). Industrial settings with high-power machinery, motor drives, and switching power supplies generate substantial EMI that can overwhelm the relatively weak Hall voltage signals, which typically range from microvolts to millivolts.

Thermal drift presents another substantial challenge, as Hall sensors exhibit temperature-dependent behavior affecting both sensitivity and offset voltage. This temperature dependence can cause measurement errors of up to 0.1% per degree Celsius in some devices, making compensation essential for applications requiring high accuracy across varying temperature conditions.

Offset voltage instability remains problematic even in modern Hall sensors. Initial offset voltages can vary significantly between individual sensors from the same production batch, requiring individual calibration. More concerning is the long-term drift of these offset values, which can change by several microvolts annually due to material aging and mechanical stress effects.

Linearity limitations constitute another significant challenge, particularly at the extremes of the measurement range. Most commercial Hall sensors maintain linearity within 0.5-1% across their specified range, but performance deteriorates markedly beyond these boundaries. This non-linearity becomes especially problematic in applications requiring precise measurements across wide magnetic field ranges.

Power consumption optimization presents a growing challenge as Hall sensors increasingly find applications in battery-powered and IoT devices. Traditional Hall sensor implementations can consume 5-20mA during continuous operation, making them unsuitable for long-term deployment in energy-constrained environments without sophisticated power management strategies.

Miniaturization efforts face fundamental physical constraints related to the Hall element size and the required supporting circuitry. As sensors shrink below certain dimensions (typically sub-millimeter), the signal-to-noise ratio degrades significantly due to increased thermal noise and reduced active sensing area.

Integration challenges persist when incorporating Hall sensors into complex systems. The need for signal conditioning circuits, temperature compensation, and digital interfaces increases design complexity and component count, potentially reducing overall system reliability while increasing costs.

Packaging and environmental protection requirements add further complications, particularly for sensors deployed in harsh environments. Ensuring long-term stability while protecting against moisture, chemicals, and mechanical stress without compromising sensor performance requires sophisticated packaging solutions that often increase production costs significantly.

Thermal drift presents another substantial challenge, as Hall sensors exhibit temperature-dependent behavior affecting both sensitivity and offset voltage. This temperature dependence can cause measurement errors of up to 0.1% per degree Celsius in some devices, making compensation essential for applications requiring high accuracy across varying temperature conditions.

Offset voltage instability remains problematic even in modern Hall sensors. Initial offset voltages can vary significantly between individual sensors from the same production batch, requiring individual calibration. More concerning is the long-term drift of these offset values, which can change by several microvolts annually due to material aging and mechanical stress effects.

Linearity limitations constitute another significant challenge, particularly at the extremes of the measurement range. Most commercial Hall sensors maintain linearity within 0.5-1% across their specified range, but performance deteriorates markedly beyond these boundaries. This non-linearity becomes especially problematic in applications requiring precise measurements across wide magnetic field ranges.

Power consumption optimization presents a growing challenge as Hall sensors increasingly find applications in battery-powered and IoT devices. Traditional Hall sensor implementations can consume 5-20mA during continuous operation, making them unsuitable for long-term deployment in energy-constrained environments without sophisticated power management strategies.

Miniaturization efforts face fundamental physical constraints related to the Hall element size and the required supporting circuitry. As sensors shrink below certain dimensions (typically sub-millimeter), the signal-to-noise ratio degrades significantly due to increased thermal noise and reduced active sensing area.

Integration challenges persist when incorporating Hall sensors into complex systems. The need for signal conditioning circuits, temperature compensation, and digital interfaces increases design complexity and component count, potentially reducing overall system reliability while increasing costs.

Packaging and environmental protection requirements add further complications, particularly for sensors deployed in harsh environments. Ensuring long-term stability while protecting against moisture, chemicals, and mechanical stress without compromising sensor performance requires sophisticated packaging solutions that often increase production costs significantly.

Current Noise Reduction Solutions and Implementations

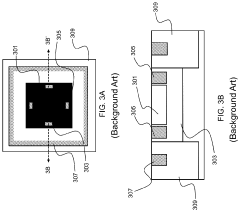

01 Noise reduction through sensor design and structure

Hall effect sensors can be designed with specific structural features to minimize noise. These designs include optimized semiconductor materials, specialized packaging, and integrated circuit layouts that shield the sensor from external electromagnetic interference. By carefully designing the physical structure of the sensor, manufacturers can reduce both intrinsic and extrinsic noise sources, improving the signal-to-noise ratio and overall sensor performance.- Noise reduction through sensor design and structure: Hall effect sensors can be designed with specific structural features to minimize noise. These designs include optimized semiconductor materials, specialized packaging, and integrated circuit layouts that shield the sensing element from external electromagnetic interference. By improving the physical structure of the sensor, manufacturers can reduce both intrinsic and extrinsic noise sources, leading to more accurate magnetic field measurements.

- Signal processing techniques for noise filtering: Various signal processing methods can be implemented to filter out noise in Hall effect sensor outputs. These techniques include digital filtering algorithms, averaging multiple measurements, chopper stabilization, and frequency domain analysis. Advanced signal conditioning circuits can be integrated with the sensor to process the raw signal and remove noise components before the output is used for measurement or control purposes.

- Offset compensation and calibration methods: Hall effect sensors often suffer from offset errors that contribute to measurement noise. Compensation techniques include auto-zero methods, spinning current techniques, and temperature compensation circuits. Calibration procedures during manufacturing or in-field operation can help identify and correct systematic offset errors, improving the signal-to-noise ratio of the sensor output.

- Differential and multi-axis sensing configurations: Differential Hall effect sensor configurations use multiple sensing elements to measure magnetic field differences rather than absolute values, which helps cancel common-mode noise. Multi-axis sensing arrangements can provide additional data points for noise correlation and rejection. These configurations are particularly effective at reducing the impact of temperature variations, power supply fluctuations, and external magnetic interference.

- Power management and thermal noise reduction: Thermal noise is a significant contributor to Hall effect sensor inaccuracy. Power management techniques such as pulsed operation, low-power modes, and optimized biasing can reduce heat generation within the sensor. Thermal isolation structures and temperature-stabilized reference circuits help maintain consistent performance across varying environmental conditions, minimizing noise caused by temperature fluctuations.

02 Signal processing techniques for noise filtering

Various signal processing methods can be implemented to filter out noise in Hall effect sensor outputs. These techniques include digital filtering algorithms, chopper stabilization, and offset compensation circuits. Advanced signal conditioning circuitry can effectively separate the desired Hall voltage signal from random noise, thermal noise, and other interference, resulting in cleaner output signals even in electrically noisy environments.Expand Specific Solutions03 Differential sensing configurations

Differential Hall effect sensor configurations use multiple sensing elements arranged to cancel common-mode noise. By measuring the difference between two or more Hall elements, these designs can effectively eliminate noise that affects all elements equally, such as temperature variations and external magnetic field interference. This approach significantly improves the signal-to-noise ratio and enhances the sensor's ability to detect small magnetic field changes in noisy environments.Expand Specific Solutions04 Temperature compensation methods

Hall effect sensors are susceptible to temperature-induced noise and drift. Various temperature compensation techniques can be implemented, including integrated temperature sensors, biasing circuits that adjust with temperature changes, and specialized materials with reduced temperature sensitivity. These methods help maintain consistent sensor performance across a wide temperature range by minimizing thermal noise and temperature-dependent offset variations.Expand Specific Solutions05 Power supply noise isolation

Power supply fluctuations can introduce significant noise into Hall effect sensor measurements. Specialized power conditioning circuits, voltage regulators, and isolation techniques can be implemented to shield the sensor from power supply noise. These approaches include decoupling capacitors, voltage reference circuits, and power supply rejection ratio (PSRR) enhancement techniques that ensure stable sensor operation even when the power source contains ripple or other noise components.Expand Specific Solutions

Major Players in Hall Effect Sensor Manufacturing

The Hall Effect sensor noise reduction market is in a growth phase, with increasing demand driven by automotive, industrial, and consumer electronics applications. The market size is expanding as these sensors become integral to precision measurement systems. Technologically, companies like Allegro MicroSystems, Texas Instruments, and Infineon Technologies lead innovation with advanced filtering algorithms and integrated signal processing solutions. STMicroelectronics and Bosch have developed robust noise-immune architectures, while emerging players like Novosense Microelectronics are gaining traction with specialized solutions. Academic institutions such as EPFL and Tokyo Institute of Technology contribute fundamental research, creating a competitive landscape where established semiconductor manufacturers compete through differentiated noise reduction techniques across various application domains.

Allegro MicroSystems LLC

Technical Solution: Allegro MicroSystems has developed advanced chopper stabilization techniques for their Hall effect sensors that significantly reduce noise. Their approach involves modulating the sensor signal to a higher frequency band where 1/f noise is minimal, then demodulating it back to baseband after amplification. This technique effectively eliminates DC offset errors and low-frequency noise components. Additionally, Allegro implements proprietary signal conditioning circuits with differential sensing architectures that reject common-mode noise from external sources. Their latest generation sensors incorporate integrated filtering capacitors and on-chip digital signal processing algorithms that perform real-time averaging and adaptive filtering to dynamically respond to changing noise conditions. The company's BiCMOS process technology allows for optimized analog front-end design with reduced intrinsic noise characteristics.

Strengths: Superior noise immunity through proprietary chopper stabilization techniques; integrated signal processing capabilities that adapt to environmental conditions; excellent temperature stability. Weaknesses: Higher power consumption compared to simpler Hall sensors; increased complexity and cost; slightly longer response time due to signal processing overhead.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has pioneered a multi-faceted approach to Hall effect sensor noise reduction combining both analog and digital techniques. Their DRV5000 series implements spinning current techniques that periodically reverse the biasing of the Hall element to cancel offset errors and reduce 1/f noise. TI's sensors feature integrated low-noise amplifiers with carefully optimized input stages to minimize thermal noise contribution. The company has developed advanced filtering techniques including switched-capacitor filters and programmable digital filters that allow users to balance between noise reduction and response time based on application requirements. TI's sensors also incorporate temperature compensation circuits that adjust gain and offset parameters across the operating temperature range to maintain consistent performance. Their latest innovations include chopper-stabilized amplifiers with auto-zeroing capabilities that periodically reset the signal path to eliminate drift.

Strengths: Highly configurable noise filtering options allowing application-specific optimization; excellent temperature stability through advanced compensation; low power consumption designs suitable for battery-powered applications. Weaknesses: Some configurations require external components for optimal performance; trade-off between noise performance and response time in certain applications.

Key Patents and Research in Hall Sensor Signal Processing

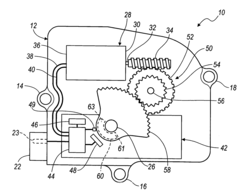

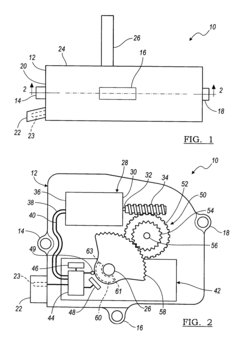

Hall Effect sensor temperature compensator

PatentInactiveUS7365503B2

Innovation

- A system and method that calibrates an actuator with a motor, output shaft, and an uncompensated Hall Effect sensor, using a diode to provide temperature signals to a controller, which calculates correction factors based on temperature differences to compensate the sensor output, allowing accurate position detection regardless of temperature changes.

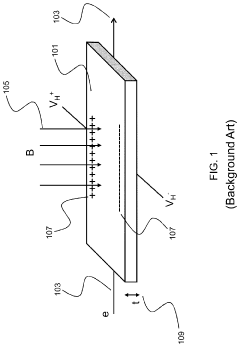

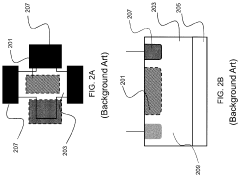

Hall effect sensor with enhanced sensitivity and method for producing the same

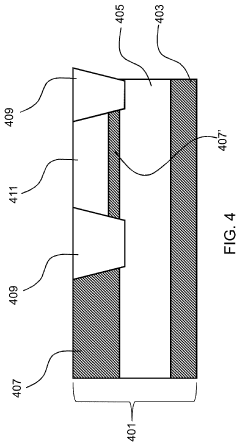

PatentActiveUS10707408B2

Innovation

- A Hall effect sensor is formed with a thin Hall plate and optional front and back gates, and reduced or omitted doping to enhance sensitivity, using a silicon-on-insulator (SOI) substrate with shallow trench isolation (STI) structures and N+ dopant ion implantation to create N+ implantation regions.

EMI/EMC Considerations for Hall Effect Sensors

Hall Effect sensors are inherently susceptible to electromagnetic interference (EMI) and electromagnetic compatibility (EMC) issues due to their operating principles based on magnetic field detection. When implementing these sensors in industrial environments or automotive applications, EMI/EMC considerations become critical for ensuring reliable operation and accurate measurements.

External electromagnetic fields from power lines, motors, transformers, and wireless communication devices can significantly impact Hall sensor outputs. These interference sources generate magnetic fields that superimpose on the target field being measured, resulting in erroneous readings. The susceptibility varies with frequency, with most Hall sensors showing increased vulnerability in the 1 kHz to 1 MHz range where many industrial noise sources operate.

Proper shielding represents the first line of defense against EMI. Mu-metal enclosures, which possess high magnetic permeability, can effectively redirect external magnetic fields away from the sensor element. For comprehensive protection, a combination of ferromagnetic and conductive materials may be necessary to address both magnetic and electric field components of EMI.

Circuit design plays a crucial role in EMI/EMC management. Differential sensing configurations, where two Hall elements are arranged to detect the difference between the target field and background noise, can substantially improve noise immunity. This approach is particularly effective against common-mode interference that affects both elements equally.

Grounding strategies must be carefully implemented to prevent ground loops that can introduce additional noise. Star grounding configurations are often preferred for Hall sensor systems, with a single ground reference point to minimize potential differences across the circuit. In multi-sensor arrays, isolated power supplies for each sensor can prevent cross-interference.

PCB layout considerations are equally important. Placing Hall sensors away from high-current traces and potential noise sources on the board can significantly reduce interference. Signal traces should be kept short, and when longer connections are unavoidable, twisted pair or differential signaling should be employed.

Regulatory compliance for EMI/EMC varies by application domain. Automotive applications typically follow standards like CISPR 25 and ISO 11452, while industrial implementations must adhere to IEC 61000 series standards. These regulations specify acceptable emission levels and immunity requirements that Hall sensor systems must meet before deployment in real-world environments.

External electromagnetic fields from power lines, motors, transformers, and wireless communication devices can significantly impact Hall sensor outputs. These interference sources generate magnetic fields that superimpose on the target field being measured, resulting in erroneous readings. The susceptibility varies with frequency, with most Hall sensors showing increased vulnerability in the 1 kHz to 1 MHz range where many industrial noise sources operate.

Proper shielding represents the first line of defense against EMI. Mu-metal enclosures, which possess high magnetic permeability, can effectively redirect external magnetic fields away from the sensor element. For comprehensive protection, a combination of ferromagnetic and conductive materials may be necessary to address both magnetic and electric field components of EMI.

Circuit design plays a crucial role in EMI/EMC management. Differential sensing configurations, where two Hall elements are arranged to detect the difference between the target field and background noise, can substantially improve noise immunity. This approach is particularly effective against common-mode interference that affects both elements equally.

Grounding strategies must be carefully implemented to prevent ground loops that can introduce additional noise. Star grounding configurations are often preferred for Hall sensor systems, with a single ground reference point to minimize potential differences across the circuit. In multi-sensor arrays, isolated power supplies for each sensor can prevent cross-interference.

PCB layout considerations are equally important. Placing Hall sensors away from high-current traces and potential noise sources on the board can significantly reduce interference. Signal traces should be kept short, and when longer connections are unavoidable, twisted pair or differential signaling should be employed.

Regulatory compliance for EMI/EMC varies by application domain. Automotive applications typically follow standards like CISPR 25 and ISO 11452, while industrial implementations must adhere to IEC 61000 series standards. These regulations specify acceptable emission levels and immunity requirements that Hall sensor systems must meet before deployment in real-world environments.

Temperature Compensation Techniques for Signal Stability

Temperature fluctuations represent one of the most significant challenges affecting Hall effect sensor stability. These sensors exhibit inherent temperature sensitivity that can dramatically alter their output characteristics, introducing measurement errors that compromise system reliability. Advanced temperature compensation techniques have therefore become essential for maintaining signal stability across varying environmental conditions.

Passive compensation methods utilize hardware-based approaches to mitigate temperature effects. These include specialized circuit designs incorporating temperature-dependent resistors (thermistors) that automatically adjust signal conditioning parameters as ambient temperature changes. Modern Hall sensor packages often integrate these components directly within the sensor housing, providing first-level temperature stabilization without requiring additional processing resources.

Active compensation techniques leverage computational methods to dynamically correct temperature-induced errors. These systems typically employ dedicated temperature sensors positioned in close proximity to the Hall element, continuously monitoring thermal conditions. The measured temperature data feeds into algorithmic models that apply appropriate correction factors to the raw sensor output. Polynomial compensation functions have proven particularly effective, with third-order equations providing sufficient accuracy for most industrial applications while maintaining computational efficiency.

Digital signal processing (DSP) approaches offer more sophisticated compensation capabilities through real-time adaptive filtering. These systems can identify and isolate temperature-dependent noise components from the sensor signal spectrum, applying dynamic adjustments based on both current and historical temperature profiles. Machine learning algorithms have recently enhanced this approach by enabling systems to recognize complex temperature-dependent patterns and apply predictive corrections before signal degradation occurs.

Calibration-based compensation represents another powerful methodology, wherein sensors undergo extensive characterization across their full operating temperature range during manufacturing. The resulting temperature response curves are stored in non-volatile memory, allowing devices to reference precise correction factors for any given temperature. Multi-point calibration techniques significantly improve accuracy by capturing non-linear temperature effects that simpler models might miss.

For applications requiring extreme precision, chopper-stabilized Hall sensors incorporate specialized modulation techniques that effectively separate temperature-induced drift from the actual magnetic field measurement. By rapidly switching the sensor's excitation current and synchronously demodulating the output, these systems can achieve remarkable temperature stability even in harsh industrial environments.

Passive compensation methods utilize hardware-based approaches to mitigate temperature effects. These include specialized circuit designs incorporating temperature-dependent resistors (thermistors) that automatically adjust signal conditioning parameters as ambient temperature changes. Modern Hall sensor packages often integrate these components directly within the sensor housing, providing first-level temperature stabilization without requiring additional processing resources.

Active compensation techniques leverage computational methods to dynamically correct temperature-induced errors. These systems typically employ dedicated temperature sensors positioned in close proximity to the Hall element, continuously monitoring thermal conditions. The measured temperature data feeds into algorithmic models that apply appropriate correction factors to the raw sensor output. Polynomial compensation functions have proven particularly effective, with third-order equations providing sufficient accuracy for most industrial applications while maintaining computational efficiency.

Digital signal processing (DSP) approaches offer more sophisticated compensation capabilities through real-time adaptive filtering. These systems can identify and isolate temperature-dependent noise components from the sensor signal spectrum, applying dynamic adjustments based on both current and historical temperature profiles. Machine learning algorithms have recently enhanced this approach by enabling systems to recognize complex temperature-dependent patterns and apply predictive corrections before signal degradation occurs.

Calibration-based compensation represents another powerful methodology, wherein sensors undergo extensive characterization across their full operating temperature range during manufacturing. The resulting temperature response curves are stored in non-volatile memory, allowing devices to reference precise correction factors for any given temperature. Multi-point calibration techniques significantly improve accuracy by capturing non-linear temperature effects that simpler models might miss.

For applications requiring extreme precision, chopper-stabilized Hall sensors incorporate specialized modulation techniques that effectively separate temperature-induced drift from the actual magnetic field measurement. By rapidly switching the sensor's excitation current and synchronously demodulating the output, these systems can achieve remarkable temperature stability even in harsh industrial environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!