How to Reduce Warping in PA12 3D Printing: Settings and Post-Processing Tips

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PA12 3D Printing Warping: Background and Objectives

Polyamide 12 (PA12), also known as Nylon 12, has emerged as a popular material in the field of 3D printing due to its excellent mechanical properties and chemical resistance. However, one of the significant challenges faced in PA12 3D printing is warping, a phenomenon where the printed part deforms during the cooling process, leading to dimensional inaccuracies and potential part failure.

The evolution of PA12 3D printing technology can be traced back to the early 2000s when selective laser sintering (SLS) techniques were first applied to nylon materials. Since then, the technology has expanded to include other methods such as fused deposition modeling (FDM) and multi jet fusion (MJF), each presenting unique challenges in terms of warping control.

Warping in PA12 3D printing occurs due to the material's high crystallinity and thermal expansion coefficient. As the printed layers cool and solidify, they contract, creating internal stresses that can cause the part to deform. This issue is particularly pronounced in large, flat parts or those with thin walls.

The primary objective of this technical research is to investigate and develop effective strategies to reduce warping in PA12 3D printing. This involves a comprehensive examination of various factors influencing warping, including printing parameters, environmental conditions, and post-processing techniques.

Key areas of focus include optimizing bed adhesion, controlling chamber temperature, adjusting cooling rates, and exploring innovative design strategies to mitigate warping effects. Additionally, the research aims to evaluate the effectiveness of different post-processing methods in reducing residual stresses and improving dimensional accuracy.

Understanding the molecular structure of PA12 and its behavior during the printing process is crucial for developing targeted solutions. This includes analyzing the crystallization kinetics, thermal properties, and rheological characteristics of PA12 under various printing conditions.

The technological trend in this field is moving towards more precise control of the printing environment, development of advanced PA12 formulations with improved thermal stability, and integration of in-situ monitoring systems to detect and correct warping in real-time.

By addressing the warping issue, this research seeks to enhance the overall quality, reliability, and applicability of PA12 3D printed parts across various industries, including aerospace, automotive, and medical sectors. The ultimate goal is to establish a set of best practices and innovative solutions that can significantly reduce warping in PA12 3D printing, thereby expanding its potential applications and driving further adoption of this technology in advanced manufacturing processes.

The evolution of PA12 3D printing technology can be traced back to the early 2000s when selective laser sintering (SLS) techniques were first applied to nylon materials. Since then, the technology has expanded to include other methods such as fused deposition modeling (FDM) and multi jet fusion (MJF), each presenting unique challenges in terms of warping control.

Warping in PA12 3D printing occurs due to the material's high crystallinity and thermal expansion coefficient. As the printed layers cool and solidify, they contract, creating internal stresses that can cause the part to deform. This issue is particularly pronounced in large, flat parts or those with thin walls.

The primary objective of this technical research is to investigate and develop effective strategies to reduce warping in PA12 3D printing. This involves a comprehensive examination of various factors influencing warping, including printing parameters, environmental conditions, and post-processing techniques.

Key areas of focus include optimizing bed adhesion, controlling chamber temperature, adjusting cooling rates, and exploring innovative design strategies to mitigate warping effects. Additionally, the research aims to evaluate the effectiveness of different post-processing methods in reducing residual stresses and improving dimensional accuracy.

Understanding the molecular structure of PA12 and its behavior during the printing process is crucial for developing targeted solutions. This includes analyzing the crystallization kinetics, thermal properties, and rheological characteristics of PA12 under various printing conditions.

The technological trend in this field is moving towards more precise control of the printing environment, development of advanced PA12 formulations with improved thermal stability, and integration of in-situ monitoring systems to detect and correct warping in real-time.

By addressing the warping issue, this research seeks to enhance the overall quality, reliability, and applicability of PA12 3D printed parts across various industries, including aerospace, automotive, and medical sectors. The ultimate goal is to establish a set of best practices and innovative solutions that can significantly reduce warping in PA12 3D printing, thereby expanding its potential applications and driving further adoption of this technology in advanced manufacturing processes.

Market Demand for Warp-Free PA12 Printed Parts

The market demand for warp-free PA12 (Polyamide 12) 3D printed parts has been steadily increasing across various industries. This growth is primarily driven by the material's excellent mechanical properties, chemical resistance, and thermal stability, making it ideal for functional prototypes and end-use parts. However, the persistent issue of warping during the printing process has been a significant barrier to wider adoption.

In the automotive sector, there is a growing need for lightweight, durable components that can withstand high temperatures and chemical exposure. PA12 parts with reduced warping are particularly sought after for under-hood applications, interior components, and functional prototypes. The aerospace industry also shows strong demand for warp-free PA12 parts, especially for complex geometries and lightweight structures that require high dimensional accuracy.

The medical device industry has been increasingly turning to PA12 for producing customized surgical guides, prosthetics, and medical equipment components. The ability to create warp-free, biocompatible parts with intricate designs is crucial in this field, driving the demand for improved printing techniques and post-processing methods.

Consumer goods manufacturers are exploring PA12 for producing durable, heat-resistant products such as sports equipment, household appliances, and electronic device casings. The market for these applications is expanding, but the need for consistent, warp-free parts is essential for maintaining product quality and consumer satisfaction.

In the industrial sector, there is a growing demand for PA12 parts in machinery components, tooling, and jigs and fixtures. These applications require high dimensional accuracy and structural integrity, making warp reduction a critical factor in meeting industry standards and performance requirements.

The rapid prototyping market, spanning multiple industries, has also seen an increased demand for warp-free PA12 parts. Quick turnaround times and the ability to produce complex geometries without warping are crucial for accelerating product development cycles and reducing time-to-market.

As additive manufacturing continues to mature, the market for warp-free PA12 parts is expected to expand further. This growth is fueled by the ongoing development of advanced 3D printing technologies, improved material formulations, and innovative post-processing techniques. Manufacturers and research institutions are investing in solutions to address warping issues, recognizing the significant market potential for high-quality PA12 printed parts across diverse industries.

In the automotive sector, there is a growing need for lightweight, durable components that can withstand high temperatures and chemical exposure. PA12 parts with reduced warping are particularly sought after for under-hood applications, interior components, and functional prototypes. The aerospace industry also shows strong demand for warp-free PA12 parts, especially for complex geometries and lightweight structures that require high dimensional accuracy.

The medical device industry has been increasingly turning to PA12 for producing customized surgical guides, prosthetics, and medical equipment components. The ability to create warp-free, biocompatible parts with intricate designs is crucial in this field, driving the demand for improved printing techniques and post-processing methods.

Consumer goods manufacturers are exploring PA12 for producing durable, heat-resistant products such as sports equipment, household appliances, and electronic device casings. The market for these applications is expanding, but the need for consistent, warp-free parts is essential for maintaining product quality and consumer satisfaction.

In the industrial sector, there is a growing demand for PA12 parts in machinery components, tooling, and jigs and fixtures. These applications require high dimensional accuracy and structural integrity, making warp reduction a critical factor in meeting industry standards and performance requirements.

The rapid prototyping market, spanning multiple industries, has also seen an increased demand for warp-free PA12 parts. Quick turnaround times and the ability to produce complex geometries without warping are crucial for accelerating product development cycles and reducing time-to-market.

As additive manufacturing continues to mature, the market for warp-free PA12 parts is expected to expand further. This growth is fueled by the ongoing development of advanced 3D printing technologies, improved material formulations, and innovative post-processing techniques. Manufacturers and research institutions are investing in solutions to address warping issues, recognizing the significant market potential for high-quality PA12 printed parts across diverse industries.

Current Challenges in PA12 3D Printing Warping

PA12 (Polyamide 12) 3D printing has gained significant traction in various industries due to its excellent mechanical properties and chemical resistance. However, warping remains a persistent challenge that affects the quality and dimensional accuracy of printed parts. This issue arises from the material's inherent characteristics and the thermal stresses induced during the printing process.

One of the primary challenges in PA12 3D printing is the material's high crystallinity and shrinkage rate. As the molten polymer cools and solidifies, it undergoes significant volumetric contraction, leading to internal stresses that can cause warping, especially in larger parts or those with complex geometries. This shrinkage is particularly pronounced in PA12 compared to other common 3D printing materials like PLA or ABS.

Temperature management presents another significant hurdle. PA12 requires high printing temperatures, typically around 250-260°C, which creates a substantial temperature gradient between the molten material and the ambient environment. This gradient exacerbates the warping tendency as different parts of the print cool at varying rates, leading to uneven contraction and stress distribution.

Adhesion to the build platform is crucial in preventing warping, yet it remains a challenge with PA12. The material's low surface energy and high printing temperature make it difficult to achieve consistent first-layer adhesion. Insufficient adhesion can result in corners lifting off the build plate, initiating the warping process.

Moisture sensitivity is another factor contributing to warping in PA12 prints. The material is hygroscopic, readily absorbing moisture from the environment. When moisture-laden filament is heated during printing, it can cause inconsistencies in extrusion and material properties, potentially exacerbating warping issues.

The printing environment itself poses challenges in controlling warping. Fluctuations in ambient temperature, drafts, or uneven cooling can all contribute to differential cooling rates across the print, increasing the likelihood of warping. Maintaining a stable, controlled environment throughout the entire print duration is often difficult, especially for large or time-consuming prints.

Post-processing techniques to mitigate warping in PA12 prints also present challenges. While annealing can help relieve internal stresses, the process itself can introduce additional warping if not carefully controlled. Finding the right balance between stress relief and dimensional stability remains a complex task.

Addressing these challenges requires a multifaceted approach, combining optimized printer settings, environmental control, and post-processing techniques. As the adoption of PA12 in 3D printing continues to grow, overcoming these warping issues becomes increasingly critical for expanding the material's applications and improving the overall quality of printed parts.

One of the primary challenges in PA12 3D printing is the material's high crystallinity and shrinkage rate. As the molten polymer cools and solidifies, it undergoes significant volumetric contraction, leading to internal stresses that can cause warping, especially in larger parts or those with complex geometries. This shrinkage is particularly pronounced in PA12 compared to other common 3D printing materials like PLA or ABS.

Temperature management presents another significant hurdle. PA12 requires high printing temperatures, typically around 250-260°C, which creates a substantial temperature gradient between the molten material and the ambient environment. This gradient exacerbates the warping tendency as different parts of the print cool at varying rates, leading to uneven contraction and stress distribution.

Adhesion to the build platform is crucial in preventing warping, yet it remains a challenge with PA12. The material's low surface energy and high printing temperature make it difficult to achieve consistent first-layer adhesion. Insufficient adhesion can result in corners lifting off the build plate, initiating the warping process.

Moisture sensitivity is another factor contributing to warping in PA12 prints. The material is hygroscopic, readily absorbing moisture from the environment. When moisture-laden filament is heated during printing, it can cause inconsistencies in extrusion and material properties, potentially exacerbating warping issues.

The printing environment itself poses challenges in controlling warping. Fluctuations in ambient temperature, drafts, or uneven cooling can all contribute to differential cooling rates across the print, increasing the likelihood of warping. Maintaining a stable, controlled environment throughout the entire print duration is often difficult, especially for large or time-consuming prints.

Post-processing techniques to mitigate warping in PA12 prints also present challenges. While annealing can help relieve internal stresses, the process itself can introduce additional warping if not carefully controlled. Finding the right balance between stress relief and dimensional stability remains a complex task.

Addressing these challenges requires a multifaceted approach, combining optimized printer settings, environmental control, and post-processing techniques. As the adoption of PA12 in 3D printing continues to grow, overcoming these warping issues becomes increasingly critical for expanding the material's applications and improving the overall quality of printed parts.

Existing Warping Reduction Techniques for PA12

01 Temperature control and heating strategies

Implementing precise temperature control and heating strategies during the PA12 3D printing process can help reduce warping. This includes maintaining a consistent temperature throughout the build chamber, using heated build platforms, and applying gradual cooling techniques. These methods help minimize thermal stress and prevent uneven shrinkage of the printed parts.- Temperature control and heating strategies: Implementing precise temperature control and heating strategies during the PA12 3D printing process can help reduce warping. This includes maintaining a consistent chamber temperature, using heated build platforms, and applying gradual cooling techniques to minimize thermal stress and prevent deformation of the printed parts.

- Optimizing print parameters and design: Adjusting print parameters such as layer height, print speed, and infill density, as well as optimizing the design of the 3D model can significantly reduce warping in PA12 prints. This may involve using support structures, modifying part orientation, and implementing design features that minimize thermal stress during printing.

- Material modifications and additives: Incorporating additives or modifying the PA12 material composition can improve its printing characteristics and reduce warping tendencies. This may include the use of nucleating agents, plasticizers, or other additives that enhance the material's thermal stability and reduce shrinkage during cooling.

- Post-processing and annealing techniques: Applying post-processing techniques such as annealing or stress-relieving treatments can help reduce residual stresses in PA12 printed parts, minimizing warping after the printing process. These techniques involve controlled heating and cooling cycles to improve dimensional stability and mechanical properties.

- Advanced printer hardware and environmental control: Utilizing advanced 3D printer hardware features and environmental control systems can significantly reduce warping in PA12 prints. This may include enclosed printing chambers, multi-zone heating systems, and active cooling mechanisms that provide a more stable and controlled printing environment.

02 Optimizing print parameters and design

Adjusting print parameters such as layer height, print speed, and infill density can significantly reduce warping in PA12 3D printing. Additionally, optimizing the design of the printed object, including the use of support structures and strategic part orientation, can help distribute stress more evenly and minimize warping tendencies.Expand Specific Solutions03 Material modifications and additives

Incorporating additives or modifying the PA12 material composition can improve its resistance to warping. This may include the use of reinforcing fibers, nanoparticles, or other stabilizing agents that enhance the material's dimensional stability and reduce its tendency to warp during the printing process.Expand Specific Solutions04 Post-processing techniques

Applying post-processing techniques after the PA12 3D printing process can help mitigate warping effects. These techniques may include controlled cooling, annealing, or surface treatments that can relieve internal stresses and improve the overall dimensional accuracy of the printed parts.Expand Specific Solutions05 Advanced printer hardware and software solutions

Utilizing advanced 3D printer hardware and software solutions specifically designed for PA12 printing can help minimize warping issues. This may include closed-loop temperature control systems, real-time monitoring and adjustment capabilities, and intelligent slicing algorithms that optimize print paths to reduce warping tendencies.Expand Specific Solutions

Key Players in PA12 3D Printing Industry

The competitive landscape for reducing warpage in PA12 3D printing is characterized by a mature market with established players and ongoing innovation. The industry is in a growth phase, driven by increasing demand for high-performance 3D printed parts across various sectors. Key players like EOS GmbH, 3D Systems, and Farsoon Technologies are leading the market with advanced solutions. These companies, along with others such as Arkema and Creality, are continuously developing new materials, process parameters, and post-processing techniques to mitigate warping issues. The market size is expanding as more industries adopt PA12 3D printing for prototyping and production applications, with a focus on improving part quality and dimensional accuracy.

EOS GmbH

Technical Solution: EOS GmbH has developed advanced PA12 3D printing solutions to reduce warping. Their approach includes optimized printing parameters and a patented thermal management system. The EOS P 500 system features a pre-heating station and exchangeable frame for improved temperature control[1]. They utilize a closed-loop powder handling system that maintains consistent material properties throughout the build process. EOS has also introduced their EOSPRINT 2 software, which allows for intelligent part positioning and parameter optimization to minimize warping effects[2]. Additionally, they have developed specialized PA12 materials like PA 2200 with improved thermal stability and reduced shrinkage rates[3].

Strengths: Comprehensive ecosystem approach, combining hardware, software, and materials. Advanced thermal management reduces temperature gradients. Weaknesses: Higher initial investment cost, may require specialized training for operators.

Arkema France SA

Technical Solution: Arkema France SA has focused on material innovation to address warping in PA12 3D printing. They have developed a range of high-performance polyamide powders under the Rilsan® brand. Their advanced PA12 powders feature optimized particle size distribution and morphology, which contribute to improved flowability and packing density during the printing process[4]. Arkema has also introduced additives that enhance the thermal stability of PA12, reducing the tendency for warping during cooling. Their latest innovation includes a bio-based PA11 powder that exhibits lower shrinkage rates compared to traditional PA12, potentially offering a more environmentally friendly solution to warping issues[5].

Strengths: Material-centric approach allows for compatibility with various 3D printing systems. Bio-based options provide sustainability benefits. Weaknesses: Relies on printer manufacturers for optimal parameter settings, may require fine-tuning for specific applications.

Innovative Approaches to Minimize PA12 Warping

Anti-nucleating agent for laser sintering powder

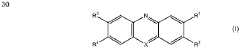

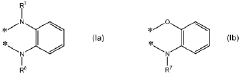

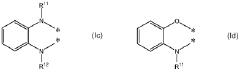

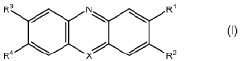

PatentWO2017140779A1

Innovation

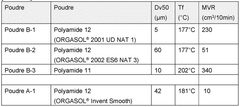

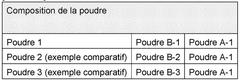

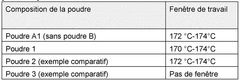

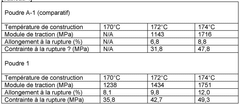

- Incorporating specific additives, such as compounds of formula (I), into the polyamide sintering powder to widen the sintering window, reduce warpage, and improve color stability, allowing for more uniform and reusable sintering powders with reduced distortion.

Polyamide 12-based powder for 3D printing

PatentWO2025133204A1

Innovation

- A composition of polymer powders is developed by adding a small amount (0.1 to 3% by mass) of a thermoplastic polymer powder B with a lower melting temperature and smaller particle size to polyamide 12 powder A, improving the working window and mechanical properties of the printed parts.

Thermal Management Strategies in PA12 Printing

Thermal management is a critical aspect of PA12 3D printing, particularly in addressing the issue of warping. Effective thermal control strategies can significantly reduce the occurrence and severity of warping, leading to improved print quality and dimensional accuracy. One key approach is the implementation of a heated build chamber, which maintains a consistent ambient temperature throughout the printing process. This helps to minimize thermal gradients and reduce internal stresses that can cause warping.

Another important strategy is the optimization of bed temperature. For PA12, a bed temperature range of 80-100°C is typically recommended, with the exact temperature depending on the specific formulation and print parameters. A properly heated bed promotes better adhesion of the first layer and helps maintain consistent temperatures throughout the print.

Gradual cooling techniques can also play a crucial role in reducing warping. This can be achieved through controlled cooling of the print chamber after the print is complete, allowing the part to cool slowly and evenly. Some advanced printers incorporate active cooling systems that can be programmed to gradually reduce temperature over time.

The use of draft shields or enclosures can further enhance thermal management by creating a more stable thermal environment around the print. These structures help to minimize sudden temperature fluctuations caused by external factors such as air currents.

Layer cooling fan speed and timing are also important considerations. While some cooling is necessary to solidify each layer, excessive cooling can lead to warping. Adjusting fan speeds based on layer geometry and print progress can help maintain optimal thermal conditions throughout the print.

Advanced thermal management systems may incorporate infrared sensors or thermal cameras to monitor temperature distribution across the print in real-time. This data can be used to make dynamic adjustments to heating elements or cooling systems, ensuring consistent thermal conditions throughout the printing process.

Lastly, the use of thermal simulation software in the pre-printing stage can help predict and mitigate potential warping issues. These tools allow designers and engineers to analyze thermal behavior and optimize print parameters before physical production begins, potentially saving time and materials.

Another important strategy is the optimization of bed temperature. For PA12, a bed temperature range of 80-100°C is typically recommended, with the exact temperature depending on the specific formulation and print parameters. A properly heated bed promotes better adhesion of the first layer and helps maintain consistent temperatures throughout the print.

Gradual cooling techniques can also play a crucial role in reducing warping. This can be achieved through controlled cooling of the print chamber after the print is complete, allowing the part to cool slowly and evenly. Some advanced printers incorporate active cooling systems that can be programmed to gradually reduce temperature over time.

The use of draft shields or enclosures can further enhance thermal management by creating a more stable thermal environment around the print. These structures help to minimize sudden temperature fluctuations caused by external factors such as air currents.

Layer cooling fan speed and timing are also important considerations. While some cooling is necessary to solidify each layer, excessive cooling can lead to warping. Adjusting fan speeds based on layer geometry and print progress can help maintain optimal thermal conditions throughout the print.

Advanced thermal management systems may incorporate infrared sensors or thermal cameras to monitor temperature distribution across the print in real-time. This data can be used to make dynamic adjustments to heating elements or cooling systems, ensuring consistent thermal conditions throughout the printing process.

Lastly, the use of thermal simulation software in the pre-printing stage can help predict and mitigate potential warping issues. These tools allow designers and engineers to analyze thermal behavior and optimize print parameters before physical production begins, potentially saving time and materials.

Environmental Factors Affecting PA12 Warping

Environmental factors play a crucial role in the warping behavior of PA12 (Polyamide 12) during 3D printing processes. The primary environmental factors that significantly impact PA12 warping include ambient temperature, humidity, and air circulation within the printing environment.

Ambient temperature is one of the most critical factors affecting PA12 warping. The temperature difference between the printed part and the surrounding environment can lead to uneven cooling and subsequent warping. Ideally, the printing environment should be maintained at a consistent temperature, typically between 20°C to 25°C (68°F to 77°F). Fluctuations in ambient temperature can cause thermal stress within the printed part, resulting in dimensional inaccuracies and warping.

Humidity levels in the printing environment also have a substantial impact on PA12 warping. PA12 is hygroscopic, meaning it readily absorbs moisture from the air. High humidity can cause the material to absorb water, leading to changes in its physical properties and printing behavior. Excessive moisture absorption can result in poor layer adhesion, increased warping, and reduced overall print quality. It is recommended to maintain a relative humidity level below 50% in the printing area to minimize these effects.

Air circulation is another environmental factor that can influence PA12 warping. Proper air circulation helps maintain a uniform temperature distribution around the printed part, reducing the likelihood of localized cooling and subsequent warping. However, excessive air movement can cause rapid and uneven cooling, potentially exacerbating warping issues. Controlled air circulation, such as using enclosures or strategically placed fans, can help mitigate these effects.

The printing chamber's design and insulation also play a role in managing environmental factors. Enclosed printing chambers provide better control over temperature and humidity, creating a more stable environment for PA12 printing. Some advanced 3D printers incorporate heated build chambers, which help maintain a consistent temperature throughout the printing process, significantly reducing the risk of warping.

To mitigate the impact of environmental factors on PA12 warping, several strategies can be employed. Using a dedicated printing enclosure can help isolate the printing environment from external temperature fluctuations and maintain consistent humidity levels. Additionally, implementing proper material storage and handling practices, such as keeping PA12 filaments in sealed containers with desiccants, can prevent moisture absorption before printing.

In conclusion, understanding and controlling environmental factors is crucial for minimizing warping in PA12 3D printing. By maintaining optimal ambient temperature, managing humidity levels, and ensuring proper air circulation, manufacturers can significantly improve the quality and dimensional accuracy of PA12 printed parts.

Ambient temperature is one of the most critical factors affecting PA12 warping. The temperature difference between the printed part and the surrounding environment can lead to uneven cooling and subsequent warping. Ideally, the printing environment should be maintained at a consistent temperature, typically between 20°C to 25°C (68°F to 77°F). Fluctuations in ambient temperature can cause thermal stress within the printed part, resulting in dimensional inaccuracies and warping.

Humidity levels in the printing environment also have a substantial impact on PA12 warping. PA12 is hygroscopic, meaning it readily absorbs moisture from the air. High humidity can cause the material to absorb water, leading to changes in its physical properties and printing behavior. Excessive moisture absorption can result in poor layer adhesion, increased warping, and reduced overall print quality. It is recommended to maintain a relative humidity level below 50% in the printing area to minimize these effects.

Air circulation is another environmental factor that can influence PA12 warping. Proper air circulation helps maintain a uniform temperature distribution around the printed part, reducing the likelihood of localized cooling and subsequent warping. However, excessive air movement can cause rapid and uneven cooling, potentially exacerbating warping issues. Controlled air circulation, such as using enclosures or strategically placed fans, can help mitigate these effects.

The printing chamber's design and insulation also play a role in managing environmental factors. Enclosed printing chambers provide better control over temperature and humidity, creating a more stable environment for PA12 printing. Some advanced 3D printers incorporate heated build chambers, which help maintain a consistent temperature throughout the printing process, significantly reducing the risk of warping.

To mitigate the impact of environmental factors on PA12 warping, several strategies can be employed. Using a dedicated printing enclosure can help isolate the printing environment from external temperature fluctuations and maintain consistent humidity levels. Additionally, implementing proper material storage and handling practices, such as keeping PA12 filaments in sealed containers with desiccants, can prevent moisture absorption before printing.

In conclusion, understanding and controlling environmental factors is crucial for minimizing warping in PA12 3D printing. By maintaining optimal ambient temperature, managing humidity levels, and ensuring proper air circulation, manufacturers can significantly improve the quality and dimensional accuracy of PA12 printed parts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!