How Vacuum Forming Supports Next-Gen Vehicle Lighting Systems

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming in Automotive Lighting: Evolution and Objectives

Vacuum forming has played a pivotal role in the evolution of automotive lighting systems, transforming from a simple manufacturing process to a key enabler of next-generation vehicle illumination. The technology's journey in this sector spans several decades, with its adoption accelerating significantly in the late 20th century as automakers sought more efficient and cost-effective methods for producing complex lighting components.

Initially, vacuum forming was primarily used for creating basic plastic covers and reflectors. However, as automotive design became more sophisticated and lighting regulations more stringent, the technology evolved to meet these new demands. The 1990s saw a surge in the use of vacuum-formed parts in headlights and taillights, allowing for more intricate designs and improved light distribution.

The turn of the millennium marked a significant shift in automotive lighting objectives. Energy efficiency, durability, and aesthetics became paramount concerns. Vacuum forming adapted to these new priorities, enabling the production of lighter, more aerodynamic lighting housings that could accommodate advanced light sources such as LEDs and OLEDs.

In recent years, the focus has shifted towards creating intelligent lighting systems that enhance both safety and user experience. Vacuum forming has risen to this challenge by facilitating the integration of sensors, adaptive lighting elements, and communication modules within the lighting assembly. This has paved the way for features like adaptive driving beams, dynamic turn signals, and even projector-based lighting systems.

The current technological landscape sees vacuum forming as an integral part of the automotive lighting ecosystem. Its objectives now extend beyond mere shape formation to include material optimization, thermal management, and seamless integration with electronic components. The process is being refined to work with advanced polymers and composite materials, allowing for even greater design flexibility and performance enhancements.

Looking ahead, the objectives for vacuum forming in automotive lighting are ambitious. There is a push towards achieving near-zero waste production, developing fully recyclable lighting components, and creating modular designs that can be easily updated or replaced. Additionally, the technology is being explored for its potential in creating large, continuous lighting surfaces that could revolutionize vehicle aesthetics and functionality.

As we move towards autonomous vehicles and smart cities, vacuum forming is poised to play a crucial role in developing lighting systems that can communicate with infrastructure and other vehicles. The technology's ability to create complex, lightweight structures will be instrumental in realizing the vision of adaptive, intelligent vehicle lighting that responds to environmental conditions and enhances road safety for all users.

Initially, vacuum forming was primarily used for creating basic plastic covers and reflectors. However, as automotive design became more sophisticated and lighting regulations more stringent, the technology evolved to meet these new demands. The 1990s saw a surge in the use of vacuum-formed parts in headlights and taillights, allowing for more intricate designs and improved light distribution.

The turn of the millennium marked a significant shift in automotive lighting objectives. Energy efficiency, durability, and aesthetics became paramount concerns. Vacuum forming adapted to these new priorities, enabling the production of lighter, more aerodynamic lighting housings that could accommodate advanced light sources such as LEDs and OLEDs.

In recent years, the focus has shifted towards creating intelligent lighting systems that enhance both safety and user experience. Vacuum forming has risen to this challenge by facilitating the integration of sensors, adaptive lighting elements, and communication modules within the lighting assembly. This has paved the way for features like adaptive driving beams, dynamic turn signals, and even projector-based lighting systems.

The current technological landscape sees vacuum forming as an integral part of the automotive lighting ecosystem. Its objectives now extend beyond mere shape formation to include material optimization, thermal management, and seamless integration with electronic components. The process is being refined to work with advanced polymers and composite materials, allowing for even greater design flexibility and performance enhancements.

Looking ahead, the objectives for vacuum forming in automotive lighting are ambitious. There is a push towards achieving near-zero waste production, developing fully recyclable lighting components, and creating modular designs that can be easily updated or replaced. Additionally, the technology is being explored for its potential in creating large, continuous lighting surfaces that could revolutionize vehicle aesthetics and functionality.

As we move towards autonomous vehicles and smart cities, vacuum forming is poised to play a crucial role in developing lighting systems that can communicate with infrastructure and other vehicles. The technology's ability to create complex, lightweight structures will be instrumental in realizing the vision of adaptive, intelligent vehicle lighting that responds to environmental conditions and enhances road safety for all users.

Market Trends in Advanced Vehicle Lighting Systems

The advanced vehicle lighting systems market is experiencing significant growth and transformation, driven by technological advancements, safety regulations, and consumer demand for enhanced aesthetics and functionality. This sector is projected to expand at a robust compound annual growth rate (CAGR) over the next decade, reflecting the increasing integration of sophisticated lighting technologies in modern vehicles.

One of the key trends shaping the market is the rapid adoption of LED lighting systems. LEDs offer numerous advantages over traditional halogen lamps, including improved energy efficiency, longer lifespan, and greater design flexibility. This shift towards LED technology is not only improving the overall performance of vehicle lighting systems but also enabling manufacturers to create more distinctive and attractive designs.

Another notable trend is the growing popularity of adaptive lighting systems. These intelligent systems can automatically adjust the intensity, direction, and pattern of light based on driving conditions, enhancing visibility and safety. The increasing incorporation of sensors and advanced control units in vehicles is facilitating the widespread adoption of adaptive lighting technologies.

The market is also witnessing a surge in demand for ambient lighting solutions. Automakers are increasingly using interior lighting to create customizable atmospheres and enhance the overall driving experience. This trend is particularly prominent in luxury and premium vehicle segments, where ambient lighting is becoming a key differentiator.

Furthermore, the integration of lighting systems with advanced driver assistance systems (ADAS) and autonomous driving technologies is gaining traction. Lighting is playing a crucial role in vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communication, contributing to improved road safety and traffic management.

The market landscape is characterized by intense competition among major automotive lighting manufacturers and increasing collaborations between lighting specialists and automakers. These partnerships are driving innovation and accelerating the development of next-generation lighting solutions.

Regionally, Asia Pacific is emerging as a key growth market for advanced vehicle lighting systems, driven by the rapidly expanding automotive industry in countries like China and India. North America and Europe continue to be significant markets, with a strong focus on technological innovation and stringent safety regulations.

As the industry moves towards more complex and integrated lighting systems, vacuum forming is playing an increasingly important role in the manufacturing process. This technology enables the production of lightweight, durable, and intricately shaped lighting components, supporting the development of next-generation vehicle lighting systems that meet both functional and aesthetic requirements.

One of the key trends shaping the market is the rapid adoption of LED lighting systems. LEDs offer numerous advantages over traditional halogen lamps, including improved energy efficiency, longer lifespan, and greater design flexibility. This shift towards LED technology is not only improving the overall performance of vehicle lighting systems but also enabling manufacturers to create more distinctive and attractive designs.

Another notable trend is the growing popularity of adaptive lighting systems. These intelligent systems can automatically adjust the intensity, direction, and pattern of light based on driving conditions, enhancing visibility and safety. The increasing incorporation of sensors and advanced control units in vehicles is facilitating the widespread adoption of adaptive lighting technologies.

The market is also witnessing a surge in demand for ambient lighting solutions. Automakers are increasingly using interior lighting to create customizable atmospheres and enhance the overall driving experience. This trend is particularly prominent in luxury and premium vehicle segments, where ambient lighting is becoming a key differentiator.

Furthermore, the integration of lighting systems with advanced driver assistance systems (ADAS) and autonomous driving technologies is gaining traction. Lighting is playing a crucial role in vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communication, contributing to improved road safety and traffic management.

The market landscape is characterized by intense competition among major automotive lighting manufacturers and increasing collaborations between lighting specialists and automakers. These partnerships are driving innovation and accelerating the development of next-generation lighting solutions.

Regionally, Asia Pacific is emerging as a key growth market for advanced vehicle lighting systems, driven by the rapidly expanding automotive industry in countries like China and India. North America and Europe continue to be significant markets, with a strong focus on technological innovation and stringent safety regulations.

As the industry moves towards more complex and integrated lighting systems, vacuum forming is playing an increasingly important role in the manufacturing process. This technology enables the production of lightweight, durable, and intricately shaped lighting components, supporting the development of next-generation vehicle lighting systems that meet both functional and aesthetic requirements.

Current Challenges in Vacuum Forming for Automotive Lighting

Vacuum forming technology plays a crucial role in the production of automotive lighting systems, but it faces several challenges in meeting the demands of next-generation vehicle lighting. One of the primary issues is achieving consistent material thickness across complex geometries. As lighting designs become more intricate and three-dimensional, maintaining uniform thickness during the vacuum forming process becomes increasingly difficult. This can lead to variations in light transmission and structural integrity, potentially compromising the performance and safety of the lighting system.

Another significant challenge is the need for higher precision and tighter tolerances in vacuum-formed components. Next-generation lighting systems often incorporate advanced features such as adaptive lighting, matrix LED arrays, and integrated sensors, which require extremely precise forming to ensure proper alignment and functionality. The current vacuum forming processes struggle to consistently meet these stringent requirements, leading to higher rejection rates and increased production costs.

Heat management is also a growing concern in vacuum forming for automotive lighting. As LED technology advances, lighting systems generate more heat, which can affect the stability and longevity of vacuum-formed components. The challenge lies in developing materials and forming techniques that can withstand higher operating temperatures while maintaining optical clarity and dimensional stability over the vehicle's lifetime.

Furthermore, the automotive industry's push towards sustainability presents challenges for vacuum forming processes. There is a growing demand for eco-friendly materials that can be effectively vacuum formed while meeting the stringent performance requirements of automotive lighting. Developing and implementing these materials without compromising on quality or increasing costs remains a significant hurdle.

The integration of smart features into lighting systems also poses challenges for vacuum forming. Incorporating conductive elements, sensors, or other electronic components into vacuum-formed parts requires innovative approaches to material selection and forming techniques. Current processes often struggle to seamlessly integrate these elements without compromising the integrity or functionality of the lighting system.

Lastly, the automotive industry's rapid product development cycles and demand for customization put pressure on vacuum forming processes to become more flexible and efficient. Traditional vacuum forming tooling and setup times can be lengthy and costly, making it challenging to respond quickly to design changes or produce small batches of customized lighting components. Developing more agile vacuum forming processes that can adapt to changing designs and production volumes remains a significant challenge in the industry.

Another significant challenge is the need for higher precision and tighter tolerances in vacuum-formed components. Next-generation lighting systems often incorporate advanced features such as adaptive lighting, matrix LED arrays, and integrated sensors, which require extremely precise forming to ensure proper alignment and functionality. The current vacuum forming processes struggle to consistently meet these stringent requirements, leading to higher rejection rates and increased production costs.

Heat management is also a growing concern in vacuum forming for automotive lighting. As LED technology advances, lighting systems generate more heat, which can affect the stability and longevity of vacuum-formed components. The challenge lies in developing materials and forming techniques that can withstand higher operating temperatures while maintaining optical clarity and dimensional stability over the vehicle's lifetime.

Furthermore, the automotive industry's push towards sustainability presents challenges for vacuum forming processes. There is a growing demand for eco-friendly materials that can be effectively vacuum formed while meeting the stringent performance requirements of automotive lighting. Developing and implementing these materials without compromising on quality or increasing costs remains a significant hurdle.

The integration of smart features into lighting systems also poses challenges for vacuum forming. Incorporating conductive elements, sensors, or other electronic components into vacuum-formed parts requires innovative approaches to material selection and forming techniques. Current processes often struggle to seamlessly integrate these elements without compromising the integrity or functionality of the lighting system.

Lastly, the automotive industry's rapid product development cycles and demand for customization put pressure on vacuum forming processes to become more flexible and efficient. Traditional vacuum forming tooling and setup times can be lengthy and costly, making it challenging to respond quickly to design changes or produce small batches of customized lighting components. Developing more agile vacuum forming processes that can adapt to changing designs and production volumes remains a significant challenge in the industry.

Existing Vacuum Forming Solutions for Vehicle Lighting

01 Vacuum forming process improvements

Advancements in vacuum forming techniques to enhance efficiency and product quality. This includes optimizing the heating process, improving mold design, and refining the vacuum application method to achieve better formed products with reduced cycle times.- Vacuum forming process improvements: Advancements in vacuum forming techniques to enhance efficiency and product quality. This includes optimizing the heating process, improving mold design, and refining the vacuum application method to achieve better formed products with reduced cycle times.

- Material selection for vacuum forming: Exploration of various materials suitable for vacuum forming, including thermoplastics and composite materials. The selection of appropriate materials can significantly impact the final product's properties, such as strength, flexibility, and surface finish.

- Vacuum forming equipment innovations: Development of advanced vacuum forming machines and equipment. This includes improvements in heating elements, vacuum pumps, and control systems to enhance precision, repeatability, and automation in the vacuum forming process.

- Specialized vacuum forming applications: Adaptation of vacuum forming techniques for specific industries or products. This includes customized solutions for packaging, automotive parts, medical devices, and consumer goods, addressing unique challenges in each application area.

- Sustainability in vacuum forming: Integration of eco-friendly practices in vacuum forming processes. This involves the use of recyclable materials, energy-efficient equipment, and waste reduction techniques to minimize the environmental impact of vacuum forming operations.

02 Material selection for vacuum forming

Exploration of various materials suitable for vacuum forming, including thermoplastics and composite materials. The selection of appropriate materials can significantly impact the final product's properties, such as strength, flexibility, and surface finish.Expand Specific Solutions03 Automation and control systems in vacuum forming

Integration of advanced automation and control systems in vacuum forming processes. This includes the use of sensors, programmable logic controllers, and computer-aided manufacturing to improve precision, repeatability, and overall production efficiency.Expand Specific Solutions04 Specialized vacuum forming applications

Development of vacuum forming techniques for specific industries or applications, such as packaging, automotive components, or medical devices. These specialized applications often require unique considerations in terms of material properties, forming parameters, and quality control.Expand Specific Solutions05 Energy efficiency in vacuum forming

Innovations aimed at reducing energy consumption in vacuum forming processes. This includes optimizing heating systems, improving insulation, and developing more efficient vacuum pumps to minimize overall energy usage while maintaining or improving product quality.Expand Specific Solutions

Key Players in Automotive Lighting and Vacuum Forming

The automotive lighting industry is in a mature yet innovative phase, with a global market size expected to reach $42.5 billion by 2028. The technology for next-generation vehicle lighting systems, including vacuum forming, is rapidly evolving. Key players like HELLA, Koito Manufacturing, and Valeo are leading the way in technological advancements. These companies, along with emerging players such as Changzhou Xingyu and ZKW Group, are investing heavily in R&D to develop advanced lighting solutions. The competitive landscape is characterized by a mix of established global manufacturers and innovative newcomers, all striving to meet the increasing demand for energy-efficient, smart, and aesthetically pleasing automotive lighting systems.

HELLA GmbH & Co. KGaA

Technical Solution: HELLA has developed advanced vacuum forming techniques for next-generation vehicle lighting systems. Their process involves using high-precision molds and specialized thermoplastic materials to create complex, lightweight lighting components. The company employs a multi-layer vacuum forming approach, allowing for the integration of optical elements, such as reflectors and lenses, directly into the formed parts. This method enables the production of highly customized, aerodynamic lighting designs with improved light distribution and efficiency. HELLA's vacuum forming technology also incorporates automated quality control systems, ensuring consistent production of high-quality components[1][3].

Strengths: Enables complex, lightweight designs; Integrates optical elements directly; Highly customizable; Improved light distribution. Weaknesses: May have limitations in extreme temperature environments; Potential for higher initial tooling costs.

Koito Manufacturing Co., Ltd.

Technical Solution: Koito Manufacturing has innovated in vacuum forming for automotive lighting by developing a proprietary "Hybrid Vacuum Forming" technique. This method combines traditional vacuum forming with injection molding, allowing for the creation of complex, multi-material lighting components. The process enables the integration of structural elements, light guides, and decorative features in a single forming step. Koito's technology utilizes advanced temperature control systems and specialized polymer blends to achieve precise forming of intricate shapes with high optical quality. The company has also implemented AI-driven process optimization, which continuously refines the forming parameters to enhance product consistency and reduce material waste[2][5].

Strengths: Combines vacuum forming with injection molding; Enables multi-material components; AI-driven process optimization. Weaknesses: May require specialized equipment; Potentially higher initial investment costs.

Innovative Vacuum Forming Techniques for Complex Lighting Designs

Vehicle lamp

PatentInactiveEP1679228A3

Innovation

- The vehicle light incorporates a fastening dome on the housing to guide the connecting line, reducing the number of openings needed in the vehicle body, with a slot-like opening for cable routing and a one-piece design for simplified sealing and strain relief, and uses a printed circuit board with adhesive closure for easy assembly and heat dissipation.

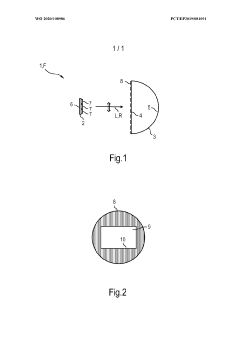

Vehicle light and vehicle comprising same

PatentWO2020108986A1

Innovation

- A vehicle light design featuring a diaphragm applied to the side of free-form optics facing the LED, reducing the dependence of the light emission pattern on the positional relationship between the optics and LED, and ensuring an offset-independent light bundle, facilitated by a compact and precisely attachable aperture.

Environmental Impact of Vacuum Forming in Automotive Industry

Vacuum forming, a widely used manufacturing process in the automotive industry, has significant environmental implications that warrant careful consideration. This technique, while efficient for producing vehicle lighting components, raises concerns about its ecological footprint. The process typically involves heating thermoplastic sheets and shaping them over molds using vacuum suction, which consumes substantial energy and resources.

The primary environmental impact of vacuum forming in automotive lighting systems stems from material usage and energy consumption. Thermoplastics, such as polycarbonate and acrylic, are commonly used in this process. While these materials offer excellent optical properties and durability, their production relies heavily on fossil fuels, contributing to carbon emissions and resource depletion. Additionally, the energy-intensive nature of heating and forming these plastics further increases the carbon footprint of the manufacturing process.

Waste generation is another critical environmental concern. Despite efforts to optimize material usage, vacuum forming inevitably produces trim waste. This excess material, often difficult to recycle due to contamination or mixed composition, frequently ends up in landfills, exacerbating the industry's waste management challenges. The automotive sector's high production volumes amplify this issue, resulting in significant cumulative environmental impact.

Water usage in vacuum forming, although not as prominent as in some other manufacturing processes, still contributes to the overall environmental footprint. Cooling systems used in the process and cleaning of molds and equipment require water resources, potentially straining local water supplies in water-scarce regions where automotive manufacturing facilities are located.

On a positive note, the automotive industry has been making strides in mitigating these environmental impacts. Innovations in material science have led to the development of more eco-friendly thermoplastics, including bio-based and recycled materials. These alternatives can significantly reduce the carbon footprint of vacuum-formed components. Furthermore, advancements in vacuum forming technology have improved energy efficiency, reducing the overall energy consumption of the process.

The industry is also exploring closed-loop manufacturing systems, where waste materials from vacuum forming are recycled and reused in the production process. This approach not only reduces waste but also decreases the demand for virgin materials, further lowering the environmental impact. Additionally, some manufacturers are implementing water recycling systems to minimize water consumption and reduce the strain on local water resources.

The primary environmental impact of vacuum forming in automotive lighting systems stems from material usage and energy consumption. Thermoplastics, such as polycarbonate and acrylic, are commonly used in this process. While these materials offer excellent optical properties and durability, their production relies heavily on fossil fuels, contributing to carbon emissions and resource depletion. Additionally, the energy-intensive nature of heating and forming these plastics further increases the carbon footprint of the manufacturing process.

Waste generation is another critical environmental concern. Despite efforts to optimize material usage, vacuum forming inevitably produces trim waste. This excess material, often difficult to recycle due to contamination or mixed composition, frequently ends up in landfills, exacerbating the industry's waste management challenges. The automotive sector's high production volumes amplify this issue, resulting in significant cumulative environmental impact.

Water usage in vacuum forming, although not as prominent as in some other manufacturing processes, still contributes to the overall environmental footprint. Cooling systems used in the process and cleaning of molds and equipment require water resources, potentially straining local water supplies in water-scarce regions where automotive manufacturing facilities are located.

On a positive note, the automotive industry has been making strides in mitigating these environmental impacts. Innovations in material science have led to the development of more eco-friendly thermoplastics, including bio-based and recycled materials. These alternatives can significantly reduce the carbon footprint of vacuum-formed components. Furthermore, advancements in vacuum forming technology have improved energy efficiency, reducing the overall energy consumption of the process.

The industry is also exploring closed-loop manufacturing systems, where waste materials from vacuum forming are recycled and reused in the production process. This approach not only reduces waste but also decreases the demand for virgin materials, further lowering the environmental impact. Additionally, some manufacturers are implementing water recycling systems to minimize water consumption and reduce the strain on local water resources.

Safety Regulations for Next-Gen Vehicle Lighting Systems

Safety regulations for next-generation vehicle lighting systems are becoming increasingly stringent and complex as automotive technology advances. These regulations aim to ensure that new lighting technologies enhance road safety while minimizing potential risks to drivers, passengers, and pedestrians.

One of the primary focuses of safety regulations is the prevention of glare and discomfort to other road users. Advanced lighting systems, such as matrix LED headlights and adaptive driving beams, must comply with strict guidelines regarding light intensity, distribution, and adaptive capabilities. Regulatory bodies are developing new testing procedures and performance criteria to evaluate these sophisticated systems effectively.

Color requirements for vehicle lighting are also evolving to accommodate new technologies. While traditional regulations specified narrow ranges for permissible colors, next-gen lighting systems may require more flexible standards to allow for innovative designs that enhance visibility and communication on the road.

Durability and reliability standards are being updated to address the unique challenges posed by advanced lighting technologies. Regulators are establishing new test protocols to ensure that LED and OLED lighting systems maintain their performance and safety characteristics throughout the vehicle's lifetime, even under extreme environmental conditions.

The integration of lighting with other vehicle systems, such as advanced driver assistance systems (ADAS) and autonomous driving technologies, is prompting regulators to develop new safety standards. These regulations aim to ensure that lighting systems can effectively communicate the vehicle's intentions and status to other road users, particularly in autonomous driving scenarios.

Electromagnetic compatibility (EMC) regulations are becoming more critical as vehicle lighting systems incorporate more electronic components. Next-gen lighting must comply with stringent EMC standards to prevent interference with other vehicle systems and external electronic devices.

Energy efficiency and environmental impact are also key considerations in safety regulations for next-gen vehicle lighting. Regulators are implementing standards that encourage the development of energy-efficient lighting solutions while maintaining or improving safety performance.

As vehicle lighting technology continues to advance, safety regulations are likely to evolve rapidly. Regulatory bodies are working closely with automotive manufacturers, suppliers, and research institutions to develop forward-looking standards that can accommodate future innovations while ensuring the highest levels of safety on our roads.

One of the primary focuses of safety regulations is the prevention of glare and discomfort to other road users. Advanced lighting systems, such as matrix LED headlights and adaptive driving beams, must comply with strict guidelines regarding light intensity, distribution, and adaptive capabilities. Regulatory bodies are developing new testing procedures and performance criteria to evaluate these sophisticated systems effectively.

Color requirements for vehicle lighting are also evolving to accommodate new technologies. While traditional regulations specified narrow ranges for permissible colors, next-gen lighting systems may require more flexible standards to allow for innovative designs that enhance visibility and communication on the road.

Durability and reliability standards are being updated to address the unique challenges posed by advanced lighting technologies. Regulators are establishing new test protocols to ensure that LED and OLED lighting systems maintain their performance and safety characteristics throughout the vehicle's lifetime, even under extreme environmental conditions.

The integration of lighting with other vehicle systems, such as advanced driver assistance systems (ADAS) and autonomous driving technologies, is prompting regulators to develop new safety standards. These regulations aim to ensure that lighting systems can effectively communicate the vehicle's intentions and status to other road users, particularly in autonomous driving scenarios.

Electromagnetic compatibility (EMC) regulations are becoming more critical as vehicle lighting systems incorporate more electronic components. Next-gen lighting must comply with stringent EMC standards to prevent interference with other vehicle systems and external electronic devices.

Energy efficiency and environmental impact are also key considerations in safety regulations for next-gen vehicle lighting. Regulators are implementing standards that encourage the development of energy-efficient lighting solutions while maintaining or improving safety performance.

As vehicle lighting technology continues to advance, safety regulations are likely to evolve rapidly. Regulatory bodies are working closely with automotive manufacturers, suppliers, and research institutions to develop forward-looking standards that can accommodate future innovations while ensuring the highest levels of safety on our roads.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!