Hydrofluoric Acid in Seismology: Application for Measuring

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrofluoric Acid Seismology Background and Objectives

Hydrofluoric acid (HF) has emerged as a significant tool in seismological research, marking a notable evolution in measurement techniques within this field. The application of HF in seismology represents an intersection of chemistry and geophysics that has developed over several decades. Initially, seismological measurements relied primarily on mechanical and electronic instruments without chemical components. However, the introduction of chemical methods, particularly those involving HF, has expanded the toolkit available to researchers.

The evolution of this technology can be traced back to the mid-20th century when scientists began exploring chemical reactions as indicators of seismic activity. By the 1970s, preliminary experiments with hydrofluoric acid demonstrated its potential sensitivity to pressure changes associated with seismic events. The subsequent decades witnessed refinement of these techniques, culminating in the sophisticated HF-based measurement systems we observe today.

Current technological trends in this domain focus on enhancing the precision and reliability of HF applications in seismological measurements. Researchers are developing more sensitive chemical formulations, improving containment systems to address HF's corrosive properties, and creating more sophisticated data analysis algorithms to interpret the chemical reactions in relation to seismic activity.

The integration of digital technologies with HF-based measurement systems represents another significant trend. Modern systems often incorporate real-time monitoring capabilities, allowing for immediate data transmission and analysis. This integration has substantially improved the responsiveness of seismic monitoring networks and enhanced early warning systems for seismic events.

The primary technical objectives in this field include developing more environmentally sustainable HF formulations that maintain measurement sensitivity while reducing potential ecological impacts. Additionally, researchers aim to miniaturize HF-based measurement systems to enable deployment in previously inaccessible locations, thereby expanding the global seismic monitoring network.

Another critical objective involves improving the durability of HF-based systems to withstand harsh environmental conditions, particularly in remote or extreme settings where maintenance access is limited. This includes developing corrosion-resistant materials and self-calibrating systems that can maintain accuracy over extended periods without human intervention.

The field also seeks to enhance the integration of HF-based measurements with traditional seismological data, creating more comprehensive models of seismic activity. This multi-modal approach promises to provide deeper insights into the mechanics of earthquakes and improve predictive capabilities.

As we look toward future developments, the convergence of HF applications with emerging technologies such as artificial intelligence and quantum sensing presents exciting possibilities for revolutionary advances in seismological measurement techniques.

The evolution of this technology can be traced back to the mid-20th century when scientists began exploring chemical reactions as indicators of seismic activity. By the 1970s, preliminary experiments with hydrofluoric acid demonstrated its potential sensitivity to pressure changes associated with seismic events. The subsequent decades witnessed refinement of these techniques, culminating in the sophisticated HF-based measurement systems we observe today.

Current technological trends in this domain focus on enhancing the precision and reliability of HF applications in seismological measurements. Researchers are developing more sensitive chemical formulations, improving containment systems to address HF's corrosive properties, and creating more sophisticated data analysis algorithms to interpret the chemical reactions in relation to seismic activity.

The integration of digital technologies with HF-based measurement systems represents another significant trend. Modern systems often incorporate real-time monitoring capabilities, allowing for immediate data transmission and analysis. This integration has substantially improved the responsiveness of seismic monitoring networks and enhanced early warning systems for seismic events.

The primary technical objectives in this field include developing more environmentally sustainable HF formulations that maintain measurement sensitivity while reducing potential ecological impacts. Additionally, researchers aim to miniaturize HF-based measurement systems to enable deployment in previously inaccessible locations, thereby expanding the global seismic monitoring network.

Another critical objective involves improving the durability of HF-based systems to withstand harsh environmental conditions, particularly in remote or extreme settings where maintenance access is limited. This includes developing corrosion-resistant materials and self-calibrating systems that can maintain accuracy over extended periods without human intervention.

The field also seeks to enhance the integration of HF-based measurements with traditional seismological data, creating more comprehensive models of seismic activity. This multi-modal approach promises to provide deeper insights into the mechanics of earthquakes and improve predictive capabilities.

As we look toward future developments, the convergence of HF applications with emerging technologies such as artificial intelligence and quantum sensing presents exciting possibilities for revolutionary advances in seismological measurement techniques.

Market Analysis for HF-Based Seismic Measurement Tools

The global market for HF-based seismic measurement tools is experiencing significant growth, driven by increasing demand for precise subsurface imaging in oil and gas exploration, geothermal energy development, and geological research. Current market valuation stands at approximately 3.2 billion USD with projected annual growth rates of 5.7% through 2028, according to recent industry analyses.

North America dominates the market share at 42%, followed by Europe at 27% and Asia-Pacific at 21%. This regional distribution correlates strongly with areas of intensive hydrocarbon exploration and production activities. The Middle East, despite its oil-rich geology, represents only 8% of the market but is showing the fastest growth trajectory at nearly 7.9% annually.

Market segmentation reveals distinct categories within HF-based seismic measurement tools. Portable field equipment comprises 38% of the market, permanent monitoring systems account for 29%, and laboratory analysis equipment represents 24%. The remaining 9% consists of specialized custom solutions for unique geological environments.

Customer analysis indicates three primary market segments: major oil and gas corporations (63% of revenue), geological survey organizations and academic institutions (22%), and mining companies (15%). The high concentration of sales among major energy corporations creates both stability and vulnerability in the market structure.

Pricing trends show considerable variation, with high-end integrated systems commanding premium prices between 450,000 to 2.1 million USD, while portable component systems range from 75,000 to 320,000 USD. Service-based business models are gaining traction, with equipment leasing and data analysis services growing at 12.3% annually, outpacing equipment sales.

Market barriers include high initial investment requirements, stringent regulatory frameworks regarding hydrofluoric acid handling, and the specialized technical expertise needed for operation. These factors have contributed to market consolidation, with the top five vendors controlling approximately 67% of global market share.

Future market drivers include the expansion of unconventional oil and gas exploration, growing investment in geothermal energy, and increasing demand for high-resolution subsurface imaging in urban development and infrastructure projects. Environmental concerns and regulations regarding hydrofluoric acid usage present both challenges and opportunities for innovation in safer measurement technologies.

North America dominates the market share at 42%, followed by Europe at 27% and Asia-Pacific at 21%. This regional distribution correlates strongly with areas of intensive hydrocarbon exploration and production activities. The Middle East, despite its oil-rich geology, represents only 8% of the market but is showing the fastest growth trajectory at nearly 7.9% annually.

Market segmentation reveals distinct categories within HF-based seismic measurement tools. Portable field equipment comprises 38% of the market, permanent monitoring systems account for 29%, and laboratory analysis equipment represents 24%. The remaining 9% consists of specialized custom solutions for unique geological environments.

Customer analysis indicates three primary market segments: major oil and gas corporations (63% of revenue), geological survey organizations and academic institutions (22%), and mining companies (15%). The high concentration of sales among major energy corporations creates both stability and vulnerability in the market structure.

Pricing trends show considerable variation, with high-end integrated systems commanding premium prices between 450,000 to 2.1 million USD, while portable component systems range from 75,000 to 320,000 USD. Service-based business models are gaining traction, with equipment leasing and data analysis services growing at 12.3% annually, outpacing equipment sales.

Market barriers include high initial investment requirements, stringent regulatory frameworks regarding hydrofluoric acid handling, and the specialized technical expertise needed for operation. These factors have contributed to market consolidation, with the top five vendors controlling approximately 67% of global market share.

Future market drivers include the expansion of unconventional oil and gas exploration, growing investment in geothermal energy, and increasing demand for high-resolution subsurface imaging in urban development and infrastructure projects. Environmental concerns and regulations regarding hydrofluoric acid usage present both challenges and opportunities for innovation in safer measurement technologies.

Current Applications and Technical Challenges

Hydrofluoric acid (HF) has emerged as a significant tool in seismological research, particularly for measuring various geological parameters. Currently, it is primarily utilized in laboratory settings to prepare rock samples for seismic analysis. The acid's unique property of dissolving silicates makes it invaluable for isolating specific minerals from rock formations, allowing researchers to study their seismic properties in isolation.

In field applications, diluted hydrofluoric acid solutions are employed in well logging operations to assess formation permeability and porosity, critical factors in understanding seismic wave propagation through subsurface structures. The acid's reaction with rock formations creates characteristic signatures that can be measured and interpreted to enhance seismic data accuracy.

Recent advancements have seen HF being used in microseismic monitoring systems, where it helps in preparing specialized sensors that can detect minute seismic activities. These applications are particularly valuable in areas prone to induced seismicity from human activities such as hydraulic fracturing or geothermal energy extraction.

Despite its utility, the application of hydrofluoric acid in seismology faces significant technical challenges. Foremost among these is the extreme toxicity and corrosiveness of HF, necessitating stringent safety protocols that complicate field deployments. Specialized containment systems and handling procedures add substantial cost and complexity to research operations.

Another major challenge lies in the acid's reactivity with various minerals, which can lead to inconsistent results when measuring seismic properties across different geological formations. Researchers must carefully calibrate their methodologies to account for these variations, often requiring extensive preliminary testing.

Environmental concerns also pose significant limitations, as even small releases of HF can have severe ecological impacts. Regulatory restrictions increasingly constrain where and how the acid can be used in field settings, forcing researchers to develop alternative approaches for certain applications.

The precision of measurements obtained using HF-based techniques is another ongoing challenge. Variations in acid concentration, temperature, and exposure time can all affect the resulting data, requiring sophisticated calibration methods to ensure reliability. This is particularly problematic when attempting to establish standardized protocols across different research institutions.

Technical innovation is currently focused on developing safer handling systems, more precise application methods, and alternative compounds that might provide similar analytical benefits with reduced hazards. These efforts represent the frontier of research in this specialized field, as scientists work to balance the valuable insights provided by HF-based measurements against their inherent challenges.

In field applications, diluted hydrofluoric acid solutions are employed in well logging operations to assess formation permeability and porosity, critical factors in understanding seismic wave propagation through subsurface structures. The acid's reaction with rock formations creates characteristic signatures that can be measured and interpreted to enhance seismic data accuracy.

Recent advancements have seen HF being used in microseismic monitoring systems, where it helps in preparing specialized sensors that can detect minute seismic activities. These applications are particularly valuable in areas prone to induced seismicity from human activities such as hydraulic fracturing or geothermal energy extraction.

Despite its utility, the application of hydrofluoric acid in seismology faces significant technical challenges. Foremost among these is the extreme toxicity and corrosiveness of HF, necessitating stringent safety protocols that complicate field deployments. Specialized containment systems and handling procedures add substantial cost and complexity to research operations.

Another major challenge lies in the acid's reactivity with various minerals, which can lead to inconsistent results when measuring seismic properties across different geological formations. Researchers must carefully calibrate their methodologies to account for these variations, often requiring extensive preliminary testing.

Environmental concerns also pose significant limitations, as even small releases of HF can have severe ecological impacts. Regulatory restrictions increasingly constrain where and how the acid can be used in field settings, forcing researchers to develop alternative approaches for certain applications.

The precision of measurements obtained using HF-based techniques is another ongoing challenge. Variations in acid concentration, temperature, and exposure time can all affect the resulting data, requiring sophisticated calibration methods to ensure reliability. This is particularly problematic when attempting to establish standardized protocols across different research institutions.

Technical innovation is currently focused on developing safer handling systems, more precise application methods, and alternative compounds that might provide similar analytical benefits with reduced hazards. These efforts represent the frontier of research in this specialized field, as scientists work to balance the valuable insights provided by HF-based measurements against their inherent challenges.

Existing HF-Based Measurement Methodologies

01 Etching applications of hydrofluoric acid

Hydrofluoric acid is widely used as an etching agent in semiconductor manufacturing and glass processing. It effectively removes silicon dioxide layers and can be formulated with other chemicals to control etching rates and selectivity. Various compositions and methods have been developed to optimize etching performance while minimizing damage to underlying materials and reducing environmental impact.- Etching applications of hydrofluoric acid: Hydrofluoric acid is widely used as an etching agent in semiconductor manufacturing and glass processing. It effectively removes silicon dioxide layers and can be formulated with buffering agents to control the etching rate. Various compositions have been developed to enhance etching selectivity while minimizing damage to underlying materials. These formulations often include additives to improve surface quality and reduce defects during the etching process.

- Purification and recovery methods for hydrofluoric acid: Various techniques have been developed for purifying and recovering hydrofluoric acid from industrial processes. These methods include distillation, adsorption, membrane separation, and chemical precipitation. Purification processes aim to remove metal contaminants and other impurities to produce high-purity hydrofluoric acid suitable for semiconductor and electronics applications. Recovery systems help reduce waste and environmental impact while providing economic benefits through acid recycling.

- Safety measures and neutralization of hydrofluoric acid: Due to its highly corrosive and toxic nature, specialized safety protocols and neutralization methods have been developed for handling hydrofluoric acid. These include the use of specific neutralizing agents like calcium compounds that bind fluoride ions, personal protective equipment designs, emergency response procedures, and detection systems. Various compositions have been formulated to effectively neutralize hydrofluoric acid spills while minimizing secondary hazards.

- Production methods of hydrofluoric acid: Different processes for manufacturing hydrofluoric acid have been developed, including the reaction of calcium fluoride (fluorspar) with sulfuric acid, electrolytic methods, and alternative synthesis routes. These production methods focus on improving yield, purity, energy efficiency, and reducing environmental impact. Innovations include continuous production systems, catalytic processes, and methods to handle byproducts and emissions during manufacturing.

- Specialized formulations containing hydrofluoric acid: Hydrofluoric acid is incorporated into specialized formulations for various industrial applications. These include cleaning compositions for metal surfaces, mixtures for oil well stimulation, solutions for ceramic processing, and formulations for removing scale and deposits. The formulations often contain inhibitors to protect specific materials, surfactants to improve performance, and stabilizers to extend shelf life while maintaining the desired chemical activity of the acid.

02 Purification and recovery methods for hydrofluoric acid

Various techniques have been developed for purifying and recovering hydrofluoric acid from industrial processes. These methods include distillation, adsorption, membrane separation, and chemical treatment approaches. Purification is essential for removing contaminants that could affect performance in high-precision applications, while recovery systems help reduce waste and environmental impact by enabling reuse of the acid.Expand Specific Solutions03 Safety and handling systems for hydrofluoric acid

Specialized equipment and protocols have been developed for the safe handling, storage, and transportation of hydrofluoric acid due to its highly corrosive and toxic nature. These include specialized containment vessels, neutralization systems, leak detection technologies, and emergency response equipment. Safety innovations focus on preventing human exposure and environmental contamination through improved container designs and monitoring systems.Expand Specific Solutions04 Production methods for hydrofluoric acid

Various processes have been developed for manufacturing hydrofluoric acid, primarily from fluorite (calcium fluoride) and sulfuric acid. Innovations in this area include continuous production systems, catalytic methods, and techniques for improving yield and purity. Modern production approaches focus on energy efficiency, reducing byproducts, and minimizing environmental impact through improved reactor designs and process controls.Expand Specific Solutions05 Specialized formulations containing hydrofluoric acid

Hydrofluoric acid is incorporated into specialized formulations for various industrial applications. These include cleaning compositions for metal surfaces, mixtures for oxide removal in electronics manufacturing, and solutions for mineral processing. The formulations typically include buffering agents, stabilizers, surfactants, and inhibitors to control reactivity and enhance performance for specific applications while reducing hazards associated with pure hydrofluoric acid.Expand Specific Solutions

Leading Organizations in HF Seismic Technology

The application of hydrofluoric acid in seismology measurement represents an emerging niche within geophysical exploration technologies, currently in its early development stage. The global market remains relatively small but shows promising growth potential as oil and gas companies seek more precise subsurface imaging techniques. Technologically, this field is still evolving, with Schlumberger leading innovation through its extensive research network across multiple subsidiaries (Services Petroliers Schlumberger SA, Schlumberger Canada, Geoquest Systems). Other significant players include Baker Hughes, China Petroleum & Chemical Corp. (Sinopec), and Shell, who are investing in research partnerships with academic institutions like China Petroleum University and the Institute of Geology & Geophysics. Companies like OptaSense and Seismos are introducing complementary monitoring technologies, while established corporations such as ExxonMobil, TotalEnergies, and BP are exploring applications within their broader exploration portfolios.

Services Petroliers Schlumberger SA

Technical Solution: Schlumberger has developed advanced hydrofluoric acid-based techniques for seismic measurements in oil and gas exploration. Their proprietary HF-SeisTrack technology utilizes controlled hydrofluoric acid reactions with silicate formations to generate micro-seismic events that can be detected and analyzed. This approach involves injecting dilute hydrofluoric acid solutions into specific geological formations, where the acid reacts with silicates to produce microscopic fractures. These micro-fractures generate acoustic signals that are captured by specialized sensors. Schlumberger's system includes proprietary signal processing algorithms that filter out background noise and enhance the detection of these acid-induced seismic events. The technology enables high-resolution subsurface mapping in formations where traditional seismic methods provide insufficient data resolution.

Strengths: Superior resolution in silicate-rich formations compared to conventional seismic methods; enables real-time monitoring of subsurface changes; integrates with existing Schlumberger logging tools. Weaknesses: Limited effectiveness in carbonate formations; requires careful acid handling protocols; environmental concerns regarding potential groundwater contamination.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed the HF-SeisDetect system for enhanced seismic measurements in challenging geological formations. Their technology utilizes controlled hydrofluoric acid reactions to generate micro-seismic events that can be detected and analyzed for improved subsurface imaging. Sinopec's approach involves a proprietary acid delivery system that can precisely control the rate and concentration of hydrofluoric acid injection. The company has also developed specialized sensors optimized for detecting the unique acoustic signatures generated by HF-rock interactions. Their system includes advanced data processing algorithms that can differentiate between natural seismic events and those induced by acid reactions. Sinopec has successfully deployed this technology in several major oil fields across China, demonstrating significant improvements in reservoir characterization compared to conventional seismic methods.

Strengths: Cost-effective implementation compared to competitors; well-suited for the geological conditions prevalent in Chinese oil fields; integrated with Sinopec's comprehensive reservoir management systems. Weaknesses: Less field-proven in international deployments; requires specialized training for safe operation; environmental concerns in environmentally sensitive areas.

Key Patents and Research on HF Seismic Applications

Humidity and temperature corrections to improve accuracy of HF ambient air monitors based on tunable diode laser IR absorption measurements

PatentWO2013033493A1

Innovation

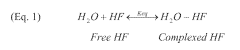

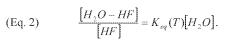

- A method and system that determine the total HF concentration by measuring uncorrected HF concentration, ambient water concentration, and using a reaction equilibrium relationship to calculate the HF hydrate concentration, incorporating a tunable diode laser for infrared absorption and a hygrometer for water measurement, with a processor to output the corrected HF concentration metric.

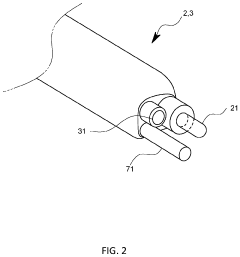

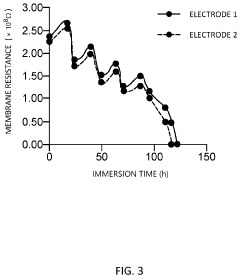

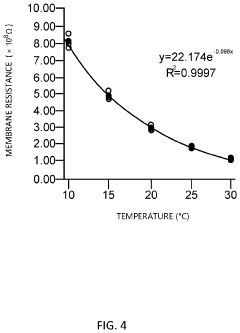

Measurement device and method for determining time to replace responsive glass membrane

PatentInactiveUS20230194466A1

Innovation

- A measurement device that includes a glass electrode with a responsive glass membrane, a membrane resistance measurement unit, a temperature measurement unit, and an output unit that calculates a replacement index based on the membrane resistance value and temperature, allowing for accurate determination of when to replace the membrane.

Safety Protocols and Environmental Impact Assessment

The utilization of hydrofluoric acid (HF) in seismological measurements necessitates rigorous safety protocols due to its highly corrosive and toxic nature. Personnel handling HF must undergo comprehensive training on proper handling techniques, emergency response procedures, and the use of specialized personal protective equipment (PPE). This equipment typically includes chemical-resistant suits, face shields, specialized gloves, and respiratory protection designed specifically for HF exposure.

Laboratory facilities where HF is used must be equipped with dedicated safety infrastructure including emergency showers, eyewash stations, calcium gluconate gel for immediate treatment of exposures, and specialized spill containment systems. Ventilation systems must meet specific standards to prevent accumulation of toxic vapors, with regular monitoring of air quality to ensure safe working conditions.

Storage protocols for HF require specialized corrosion-resistant containers with clear labeling and secondary containment systems. Transportation of HF to field sites demands compliance with hazardous materials regulations, including proper documentation and specialized transport containers designed to withstand potential accidents.

Environmental impact assessment of HF use in seismological applications reveals significant concerns. Even small releases can severely impact aquatic ecosystems, with potential to alter water pH dramatically and cause widespread mortality among aquatic organisms. Soil contamination can persist for extended periods, affecting plant growth and potentially entering groundwater systems.

Regulatory compliance frameworks vary globally but typically include strict reporting requirements for HF usage and disposal. Many jurisdictions require detailed environmental impact studies before permitting HF-based seismological measurements, particularly in sensitive ecosystems or protected areas.

Waste management presents particular challenges, as HF-containing waste cannot be disposed of through conventional channels. Neutralization processes using calcium compounds must be carefully controlled, and the resulting waste often requires specialized disposal through licensed hazardous waste facilities.

Alternative technologies and methodologies are increasingly being explored to reduce reliance on HF in seismological measurements. These include the development of less hazardous acid formulations and entirely different measurement approaches that eliminate the need for strong acids. Cost-benefit analyses increasingly factor in the substantial safety infrastructure and environmental mitigation measures required when using HF.

Monitoring protocols must be established for both immediate detection of spills or releases and long-term environmental surveillance in areas where HF has been deployed for seismological measurements. These typically include regular soil and water testing, with particular attention to fluoride levels and pH changes in surrounding ecosystems.

Laboratory facilities where HF is used must be equipped with dedicated safety infrastructure including emergency showers, eyewash stations, calcium gluconate gel for immediate treatment of exposures, and specialized spill containment systems. Ventilation systems must meet specific standards to prevent accumulation of toxic vapors, with regular monitoring of air quality to ensure safe working conditions.

Storage protocols for HF require specialized corrosion-resistant containers with clear labeling and secondary containment systems. Transportation of HF to field sites demands compliance with hazardous materials regulations, including proper documentation and specialized transport containers designed to withstand potential accidents.

Environmental impact assessment of HF use in seismological applications reveals significant concerns. Even small releases can severely impact aquatic ecosystems, with potential to alter water pH dramatically and cause widespread mortality among aquatic organisms. Soil contamination can persist for extended periods, affecting plant growth and potentially entering groundwater systems.

Regulatory compliance frameworks vary globally but typically include strict reporting requirements for HF usage and disposal. Many jurisdictions require detailed environmental impact studies before permitting HF-based seismological measurements, particularly in sensitive ecosystems or protected areas.

Waste management presents particular challenges, as HF-containing waste cannot be disposed of through conventional channels. Neutralization processes using calcium compounds must be carefully controlled, and the resulting waste often requires specialized disposal through licensed hazardous waste facilities.

Alternative technologies and methodologies are increasingly being explored to reduce reliance on HF in seismological measurements. These include the development of less hazardous acid formulations and entirely different measurement approaches that eliminate the need for strong acids. Cost-benefit analyses increasingly factor in the substantial safety infrastructure and environmental mitigation measures required when using HF.

Monitoring protocols must be established for both immediate detection of spills or releases and long-term environmental surveillance in areas where HF has been deployed for seismological measurements. These typically include regular soil and water testing, with particular attention to fluoride levels and pH changes in surrounding ecosystems.

Comparative Analysis with Alternative Measurement Techniques

When evaluating hydrofluoric acid (HF) as a measurement tool in seismology, it is essential to compare its performance against established alternative techniques. Traditional seismic measurement methods include mechanical seismometers, electronic accelerometers, and fiber optic sensing systems. Each of these technologies offers distinct advantages and limitations that must be considered alongside HF-based approaches.

Mechanical seismometers have been the historical standard for seismic monitoring, providing reliable data through pendulum-based systems that respond to ground motion. While these instruments offer excellent sensitivity for low-frequency events, they typically lack the precision that HF-based chemical sensors can achieve in detecting subtle changes in subsurface conditions. Additionally, mechanical systems often require more maintenance and are susceptible to mechanical wear over time.

Electronic accelerometers represent a more modern approach, utilizing microelectromechanical systems (MEMS) technology to detect ground acceleration. These devices offer advantages in terms of size, cost, and digital integration capabilities. However, when compared to HF-based measurement techniques, accelerometers generally cannot provide the same level of chemical interaction data that helps characterize subsurface composition—a key advantage of the HF approach.

Fiber optic sensing systems, particularly distributed acoustic sensing (DAS), have emerged as powerful tools for seismic monitoring. These systems can measure strain along extensive lengths of fiber optic cable, providing high spatial resolution data. While DAS technology excels in coverage area and continuous monitoring capabilities, it lacks the specific chemical reactivity that makes HF valuable for analyzing rock composition and porosity characteristics.

HF-based measurement techniques demonstrate unique advantages in their ability to interact chemically with silicate minerals and provide direct information about rock composition. This chemical specificity allows for more detailed characterization of subsurface formations than purely mechanical or electronic methods can achieve. However, this comes with significant safety considerations and operational complexities not present in alternative technologies.

Cost-benefit analysis reveals that while HF techniques may require specialized handling equipment and safety protocols, they can provide valuable complementary data that would otherwise require multiple alternative technologies or extensive laboratory analysis of core samples. This suggests that an integrated approach, combining HF measurements with conventional seismic techniques, may offer the most comprehensive subsurface characterization.

In terms of deployment flexibility, portable electronic systems and fiber optic solutions generally outperform HF-based approaches, which require careful handling of hazardous materials. However, for specific applications requiring detailed mineral composition analysis alongside seismic data, the chemical properties of HF provide capabilities that alternative technologies cannot match.

Mechanical seismometers have been the historical standard for seismic monitoring, providing reliable data through pendulum-based systems that respond to ground motion. While these instruments offer excellent sensitivity for low-frequency events, they typically lack the precision that HF-based chemical sensors can achieve in detecting subtle changes in subsurface conditions. Additionally, mechanical systems often require more maintenance and are susceptible to mechanical wear over time.

Electronic accelerometers represent a more modern approach, utilizing microelectromechanical systems (MEMS) technology to detect ground acceleration. These devices offer advantages in terms of size, cost, and digital integration capabilities. However, when compared to HF-based measurement techniques, accelerometers generally cannot provide the same level of chemical interaction data that helps characterize subsurface composition—a key advantage of the HF approach.

Fiber optic sensing systems, particularly distributed acoustic sensing (DAS), have emerged as powerful tools for seismic monitoring. These systems can measure strain along extensive lengths of fiber optic cable, providing high spatial resolution data. While DAS technology excels in coverage area and continuous monitoring capabilities, it lacks the specific chemical reactivity that makes HF valuable for analyzing rock composition and porosity characteristics.

HF-based measurement techniques demonstrate unique advantages in their ability to interact chemically with silicate minerals and provide direct information about rock composition. This chemical specificity allows for more detailed characterization of subsurface formations than purely mechanical or electronic methods can achieve. However, this comes with significant safety considerations and operational complexities not present in alternative technologies.

Cost-benefit analysis reveals that while HF techniques may require specialized handling equipment and safety protocols, they can provide valuable complementary data that would otherwise require multiple alternative technologies or extensive laboratory analysis of core samples. This suggests that an integrated approach, combining HF measurements with conventional seismic techniques, may offer the most comprehensive subsurface characterization.

In terms of deployment flexibility, portable electronic systems and fiber optic solutions generally outperform HF-based approaches, which require careful handling of hazardous materials. However, for specific applications requiring detailed mineral composition analysis alongside seismic data, the chemical properties of HF provide capabilities that alternative technologies cannot match.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!