Hydrogen Embrittlement Considerations For Electrochemical Compressor Components

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement Background and Objectives

Hydrogen embrittlement (HE) represents one of the most significant challenges in materials science and engineering, particularly in applications involving hydrogen interaction with metals. The phenomenon, first documented in the late 19th century, has gained increasing attention as hydrogen technologies advance across various industrial sectors. Hydrogen embrittlement occurs when hydrogen atoms penetrate into metallic materials, causing a reduction in ductility and load-bearing capacity, ultimately leading to premature failure under stress conditions that would otherwise be safe for operation.

The evolution of hydrogen technologies has accelerated dramatically over the past two decades, driven by the global push toward decarbonization and sustainable energy solutions. Electrochemical compressors (ECCs) have emerged as promising alternatives to mechanical compressors for hydrogen applications, offering advantages in efficiency, reliability, and operational flexibility. However, the very nature of ECCs—which involve hydrogen permeation through metallic components—makes them particularly susceptible to hydrogen embrittlement challenges.

Current research indicates that hydrogen embrittlement mechanisms vary significantly depending on material composition, microstructure, temperature, pressure, and exposure time. The primary mechanisms include hydrogen-enhanced decohesion (HEDE), hydrogen-enhanced localized plasticity (HELP), and hydrogen-enhanced strain-induced vacancy formation (HESIV). Understanding these mechanisms is crucial for developing effective mitigation strategies for ECC components.

The technical objectives of this investigation are multifaceted. First, to comprehensively characterize the susceptibility of various metallic materials commonly used in ECC components to hydrogen embrittlement under operational conditions. Second, to identify critical threshold parameters (hydrogen concentration, stress levels, temperature ranges) beyond which embrittlement risk increases significantly. Third, to evaluate existing and emerging mitigation strategies, including material selection, surface treatments, and microstructural engineering approaches.

Additionally, this research aims to establish standardized testing protocols specifically designed for ECC applications, as current industry standards may not adequately address the unique conditions present in electrochemical compression systems. The development of predictive models for hydrogen embrittlement behavior in ECC components represents another key objective, potentially enabling more accurate lifetime predictions and maintenance scheduling.

The ultimate goal is to develop design guidelines and material selection criteria that can significantly enhance the reliability and operational lifespan of electrochemical compressor systems. This would directly address one of the primary barriers to widespread adoption of this technology in hydrogen infrastructure applications, supporting broader efforts toward sustainable energy transition and decarbonization of industrial processes.

The evolution of hydrogen technologies has accelerated dramatically over the past two decades, driven by the global push toward decarbonization and sustainable energy solutions. Electrochemical compressors (ECCs) have emerged as promising alternatives to mechanical compressors for hydrogen applications, offering advantages in efficiency, reliability, and operational flexibility. However, the very nature of ECCs—which involve hydrogen permeation through metallic components—makes them particularly susceptible to hydrogen embrittlement challenges.

Current research indicates that hydrogen embrittlement mechanisms vary significantly depending on material composition, microstructure, temperature, pressure, and exposure time. The primary mechanisms include hydrogen-enhanced decohesion (HEDE), hydrogen-enhanced localized plasticity (HELP), and hydrogen-enhanced strain-induced vacancy formation (HESIV). Understanding these mechanisms is crucial for developing effective mitigation strategies for ECC components.

The technical objectives of this investigation are multifaceted. First, to comprehensively characterize the susceptibility of various metallic materials commonly used in ECC components to hydrogen embrittlement under operational conditions. Second, to identify critical threshold parameters (hydrogen concentration, stress levels, temperature ranges) beyond which embrittlement risk increases significantly. Third, to evaluate existing and emerging mitigation strategies, including material selection, surface treatments, and microstructural engineering approaches.

Additionally, this research aims to establish standardized testing protocols specifically designed for ECC applications, as current industry standards may not adequately address the unique conditions present in electrochemical compression systems. The development of predictive models for hydrogen embrittlement behavior in ECC components represents another key objective, potentially enabling more accurate lifetime predictions and maintenance scheduling.

The ultimate goal is to develop design guidelines and material selection criteria that can significantly enhance the reliability and operational lifespan of electrochemical compressor systems. This would directly address one of the primary barriers to widespread adoption of this technology in hydrogen infrastructure applications, supporting broader efforts toward sustainable energy transition and decarbonization of industrial processes.

Market Analysis for Electrochemical Compression Technologies

The electrochemical compression technology market is experiencing significant growth, driven by increasing demand for clean energy solutions and hydrogen infrastructure development. Current market valuations indicate the global hydrogen compression market reached approximately 1.5 billion USD in 2022, with electrochemical compression technologies representing a rapidly expanding segment projected to grow at a CAGR of 8-10% through 2030.

Electrochemical compressors offer distinct advantages over mechanical alternatives, particularly in applications requiring high purity hydrogen and energy efficiency. This has created substantial market opportunities in sectors including hydrogen refueling stations, energy storage systems, and industrial processes. The market potential is further amplified by global decarbonization initiatives and hydrogen strategy roadmaps implemented across North America, Europe, and Asia-Pacific regions.

Customer demand analysis reveals three primary market segments: transportation (particularly fuel cell electric vehicles), stationary power generation, and industrial applications. The transportation sector represents the fastest-growing segment, with over 850 hydrogen refueling stations operational globally as of 2023, each requiring reliable compression technology. This infrastructure expansion directly correlates with increasing market demand for electrochemical compression solutions.

Market barriers include high initial capital costs compared to conventional technologies, limited awareness among potential end-users, and competition from established mechanical compression systems. However, total cost of ownership analyses increasingly favor electrochemical systems when factoring in operational efficiency, maintenance requirements, and system longevity.

Regional market assessment shows Europe leading adoption rates, driven by ambitious hydrogen infrastructure targets and substantial public investment. Asia-Pacific, particularly Japan, South Korea, and China, represents the fastest-growing regional market with aggressive hydrogen strategy implementation. North America shows strong growth potential, supported by recent policy initiatives including the Inflation Reduction Act and hydrogen hub development programs.

Market forecasts indicate electrochemical compression technologies could capture 15-20% of the total hydrogen compression market by 2030, representing a significant shift from current market penetration of approximately 5%. This growth trajectory is supported by increasing technological maturity, cost reduction through economies of scale, and expanding application scenarios across multiple industries.

The competitive landscape features both established industrial gas companies expanding into electrochemical technologies and specialized startups focused exclusively on innovative compression solutions. Strategic partnerships between technology developers and end-users are becoming increasingly common, accelerating commercialization pathways and market adoption rates.

Electrochemical compressors offer distinct advantages over mechanical alternatives, particularly in applications requiring high purity hydrogen and energy efficiency. This has created substantial market opportunities in sectors including hydrogen refueling stations, energy storage systems, and industrial processes. The market potential is further amplified by global decarbonization initiatives and hydrogen strategy roadmaps implemented across North America, Europe, and Asia-Pacific regions.

Customer demand analysis reveals three primary market segments: transportation (particularly fuel cell electric vehicles), stationary power generation, and industrial applications. The transportation sector represents the fastest-growing segment, with over 850 hydrogen refueling stations operational globally as of 2023, each requiring reliable compression technology. This infrastructure expansion directly correlates with increasing market demand for electrochemical compression solutions.

Market barriers include high initial capital costs compared to conventional technologies, limited awareness among potential end-users, and competition from established mechanical compression systems. However, total cost of ownership analyses increasingly favor electrochemical systems when factoring in operational efficiency, maintenance requirements, and system longevity.

Regional market assessment shows Europe leading adoption rates, driven by ambitious hydrogen infrastructure targets and substantial public investment. Asia-Pacific, particularly Japan, South Korea, and China, represents the fastest-growing regional market with aggressive hydrogen strategy implementation. North America shows strong growth potential, supported by recent policy initiatives including the Inflation Reduction Act and hydrogen hub development programs.

Market forecasts indicate electrochemical compression technologies could capture 15-20% of the total hydrogen compression market by 2030, representing a significant shift from current market penetration of approximately 5%. This growth trajectory is supported by increasing technological maturity, cost reduction through economies of scale, and expanding application scenarios across multiple industries.

The competitive landscape features both established industrial gas companies expanding into electrochemical technologies and specialized startups focused exclusively on innovative compression solutions. Strategic partnerships between technology developers and end-users are becoming increasingly common, accelerating commercialization pathways and market adoption rates.

Current Challenges in Hydrogen-Material Interactions

Hydrogen embrittlement (HE) represents one of the most significant challenges in materials science, particularly for components used in electrochemical hydrogen compressors. The phenomenon occurs when hydrogen atoms penetrate metallic materials, causing a reduction in ductility and load-bearing capacity, ultimately leading to premature failure under stress. This issue is especially critical for electrochemical compressor components that are constantly exposed to hydrogen-rich environments.

The primary challenge lies in understanding the complex mechanisms of hydrogen-material interactions at the atomic and microstructural levels. Current research indicates multiple pathways for hydrogen degradation, including hydrogen-enhanced decohesion (HEDE), hydrogen-enhanced localized plasticity (HELP), and hydrogen-induced phase transformations. However, the relative contribution of each mechanism remains debated, complicating the development of comprehensive mitigation strategies.

Material selection presents another significant hurdle. Traditional high-strength materials often exhibit greater susceptibility to hydrogen embrittlement, creating a paradoxical situation where materials with desirable mechanical properties may be unsuitable for hydrogen service. Nickel alloys, austenitic stainless steels, and certain aluminum alloys show varying degrees of resistance, but none offer complete immunity under all operating conditions relevant to electrochemical compressors.

Surface and interface phenomena further complicate the picture. Hydrogen absorption rates are heavily influenced by surface conditions, including oxide layers, coatings, and contaminants. The presence of catalytic elements can dramatically increase hydrogen uptake, while certain surface treatments may provide temporary barriers. However, maintaining protective surface conditions throughout component lifecycle remains challenging, particularly under cyclic loading and temperature fluctuations common in compressor operations.

Testing methodologies for hydrogen embrittlement resistance present their own set of challenges. Accelerated testing often fails to accurately replicate real-world conditions, while long-term testing is costly and time-consuming. The lack of standardized testing protocols specifically designed for electrochemical compressor components hampers comparative analysis and material qualification processes.

Environmental factors introduce additional variables, as temperature, pressure, pH, and electrolyte composition all significantly affect hydrogen-material interactions. The synergistic effects of these parameters with mechanical stress (stress corrosion cracking) create complex failure modes that are difficult to predict using current models.

Computational modeling approaches, while advancing rapidly, still struggle to bridge the gap between atomistic simulations and component-level performance predictions. Multi-scale modeling that can accurately capture hydrogen diffusion, trapping, and material degradation across relevant time and length scales remains an aspirational goal rather than a practical reality for component designers.

The primary challenge lies in understanding the complex mechanisms of hydrogen-material interactions at the atomic and microstructural levels. Current research indicates multiple pathways for hydrogen degradation, including hydrogen-enhanced decohesion (HEDE), hydrogen-enhanced localized plasticity (HELP), and hydrogen-induced phase transformations. However, the relative contribution of each mechanism remains debated, complicating the development of comprehensive mitigation strategies.

Material selection presents another significant hurdle. Traditional high-strength materials often exhibit greater susceptibility to hydrogen embrittlement, creating a paradoxical situation where materials with desirable mechanical properties may be unsuitable for hydrogen service. Nickel alloys, austenitic stainless steels, and certain aluminum alloys show varying degrees of resistance, but none offer complete immunity under all operating conditions relevant to electrochemical compressors.

Surface and interface phenomena further complicate the picture. Hydrogen absorption rates are heavily influenced by surface conditions, including oxide layers, coatings, and contaminants. The presence of catalytic elements can dramatically increase hydrogen uptake, while certain surface treatments may provide temporary barriers. However, maintaining protective surface conditions throughout component lifecycle remains challenging, particularly under cyclic loading and temperature fluctuations common in compressor operations.

Testing methodologies for hydrogen embrittlement resistance present their own set of challenges. Accelerated testing often fails to accurately replicate real-world conditions, while long-term testing is costly and time-consuming. The lack of standardized testing protocols specifically designed for electrochemical compressor components hampers comparative analysis and material qualification processes.

Environmental factors introduce additional variables, as temperature, pressure, pH, and electrolyte composition all significantly affect hydrogen-material interactions. The synergistic effects of these parameters with mechanical stress (stress corrosion cracking) create complex failure modes that are difficult to predict using current models.

Computational modeling approaches, while advancing rapidly, still struggle to bridge the gap between atomistic simulations and component-level performance predictions. Multi-scale modeling that can accurately capture hydrogen diffusion, trapping, and material degradation across relevant time and length scales remains an aspirational goal rather than a practical reality for component designers.

Current Material Solutions for Hydrogen-Resistant Components

01 Materials selection for hydrogen embrittlement resistance

Specific materials can be selected for electrochemical compressor components to resist hydrogen embrittlement. These include specialized alloys, coatings, and surface treatments that minimize hydrogen absorption and diffusion. By carefully selecting materials with inherent resistance to hydrogen embrittlement, the durability and safety of electrochemical compressors can be significantly improved, especially in high-pressure hydrogen environments.- Material selection for hydrogen embrittlement resistance: Specific materials can be selected for electrochemical compressor components to resist hydrogen embrittlement. These include specialized alloys, coatings, and surface treatments that minimize hydrogen absorption and diffusion. Materials such as certain stainless steels, nickel-based alloys, and titanium alloys demonstrate superior resistance to hydrogen embrittlement under electrochemical compression conditions, extending component lifespan and improving system reliability.

- Protective coatings and surface treatments: Applying protective coatings and surface treatments to electrochemical compressor components can significantly reduce hydrogen embrittlement. These treatments create barriers that prevent hydrogen penetration into the base material. Techniques include application of ceramic coatings, metal plating with elements like gold or platinum, nitriding, and specialized passivation processes that form protective oxide layers, effectively extending component life in hydrogen-rich environments.

- Structural design modifications to mitigate embrittlement: Innovative structural designs can be implemented in electrochemical compressor components to minimize stress concentrations and reduce susceptibility to hydrogen embrittlement. These design modifications include optimized geometries, stress-relieving features, and strategic material distribution to lower localized stress. Components can be designed with gradual transitions, rounded corners, and reinforced critical areas to distribute mechanical loads more evenly, thereby reducing the risk of hydrogen-induced cracking.

- Operational parameters and control strategies: Controlling operational parameters in electrochemical compressors can minimize hydrogen embrittlement effects. This includes managing current density, temperature, pressure cycles, and hydrogen partial pressure. Implementing specific startup and shutdown procedures, limiting rapid pressure fluctuations, and maintaining optimal temperature ranges can significantly reduce hydrogen absorption into metallic components. Advanced monitoring systems can detect early signs of embrittlement, allowing for preventive maintenance before catastrophic failure occurs.

- Hydrogen trapping and barrier technologies: Specialized hydrogen trapping and barrier technologies can be incorporated into electrochemical compressor components to mitigate embrittlement. These include microstructural modifications that create hydrogen trapping sites, composite materials with hydrogen-impermeable layers, and engineered interfaces that limit hydrogen diffusion. By incorporating specific alloying elements or nanostructured materials that preferentially trap hydrogen atoms at harmless locations, the damaging effects of hydrogen on the mechanical properties of critical components can be minimized.

02 Protective coatings and surface treatments

Applying protective coatings or surface treatments to electrochemical compressor components can create barriers against hydrogen penetration. These treatments may include metallic plating, ceramic coatings, or chemical passivation processes that form protective oxide layers. Such surface modifications can effectively reduce hydrogen absorption into the base material, thereby minimizing the risk of hydrogen embrittlement in critical components.Expand Specific Solutions03 Design optimization for stress reduction

Optimizing the design of electrochemical compressor components can minimize stress concentrations that exacerbate hydrogen embrittlement. This includes careful consideration of component geometry, load distribution, and operating parameters. By reducing localized stresses and avoiding sharp transitions or notches in high-stress areas, the susceptibility to hydrogen-induced cracking can be significantly decreased even when hydrogen is present.Expand Specific Solutions04 Hydrogen management systems

Implementing hydrogen management systems within electrochemical compressors can control hydrogen concentration and pressure. These systems may include hydrogen sensors, pressure relief mechanisms, and controlled operating parameters to maintain hydrogen levels below critical thresholds. By actively managing hydrogen exposure conditions, the risk of embrittlement can be reduced even in components that have some susceptibility to hydrogen damage.Expand Specific Solutions05 Testing and monitoring protocols

Developing comprehensive testing and monitoring protocols for electrochemical compressor components can help identify early signs of hydrogen embrittlement. These may include non-destructive testing methods, in-situ monitoring techniques, and accelerated aging tests to evaluate material performance under hydrogen exposure. Regular inspection and condition monitoring enable timely intervention before catastrophic failure occurs due to hydrogen-induced damage.Expand Specific Solutions

Leading Companies in Electrochemical Compressor Development

The hydrogen embrittlement market for electrochemical compressor components is currently in an early growth phase, with increasing interest driven by clean energy transitions. The global market size is expanding as hydrogen technologies gain traction in industrial and automotive applications. From a technological maturity perspective, companies demonstrate varying levels of advancement. Industry leaders like Plug Power, Siemens AG, and Robert Bosch GmbH have established significant technological capabilities, while specialized firms such as H2gremm and Skyre are developing innovative solutions specifically for hydrogen compression challenges. Research institutions including Korea Institute of Machinery & Materials and National Research Council of Canada are contributing fundamental advancements. Asian manufacturers like Kawasaki Heavy Industries and NIPPON STEEL are focusing on material solutions to address embrittlement issues, positioning themselves strategically in this emerging technical domain.

Robert Bosch GmbH

Technical Solution: Bosch has developed a sophisticated approach to mitigating hydrogen embrittlement in electrochemical compressor components through their advanced materials engineering program. Their system employs specially formulated high-strength aluminum alloys with controlled copper and magnesium content that demonstrate significantly reduced susceptibility to hydrogen-induced cracking compared to traditional materials. For critical components exposed to high-pressure hydrogen, Bosch utilizes a proprietary multi-layer coating system consisting of an inner chromium carbide layer for hardness and wear resistance, followed by an amorphous carbon middle layer that acts as a hydrogen diffusion barrier, and an outer ceramic-based coating that provides additional protection against hydrogen permeation. The company's electrochemical cells incorporate composite bipolar plates manufactured using a powder metallurgy process that creates a microstructure specifically designed to minimize hydrogen trapping sites. Bosch's system also features intelligent pressure management that limits differential pressures across components during startup and shutdown phases when embrittlement risks are highest. Their manufacturing process includes specialized heat treatment protocols that optimize grain structure and eliminate microstructural defects that could serve as hydrogen accumulation sites.

Strengths: Innovative multi-material approach provides redundant protection against hydrogen embrittlement. Intelligent system controls actively manage operating conditions to minimize embrittlement risk. Weaknesses: Higher initial system cost due to specialized materials and manufacturing processes. More complex maintenance requirements compared to systems using conventional materials.

Plug Power, Inc.

Technical Solution: Plug Power has developed proprietary electrochemical hydrogen compression technology that addresses hydrogen embrittlement through advanced material selection and surface treatments. Their system utilizes specialized membrane electrode assemblies (MEAs) with platinum-based catalysts that operate at lower current densities to minimize hydrogen absorption into metallic components. The company employs a multi-layered approach where critical components exposed to high-pressure hydrogen are manufactured from austenitic stainless steels with controlled nickel content above 12% and molybdenum additions to enhance resistance to hydrogen-induced cracking. Additionally, Plug Power implements specialized coating technologies including electroless nickel-phosphorus layers with optimized phosphorus content (10-12%) that create effective hydrogen diffusion barriers. Their compression systems operate within carefully controlled temperature ranges (typically below 80°C) to further mitigate embrittlement risks while maintaining compression efficiency.

Strengths: Proprietary MEA technology provides superior resistance to hydrogen degradation while maintaining high compression efficiency. Their integrated system design allows for continuous monitoring of critical parameters to prevent conditions conducive to embrittlement. Weaknesses: Higher manufacturing costs compared to conventional mechanical compressors due to specialized materials and coatings. Performance degradation may still occur during extended operation under fluctuating load conditions.

Critical Patents and Research on Embrittlement Prevention

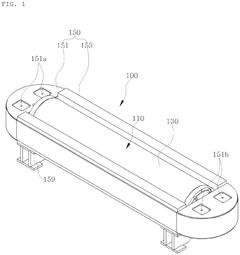

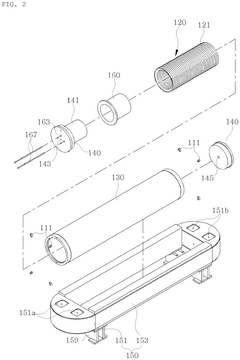

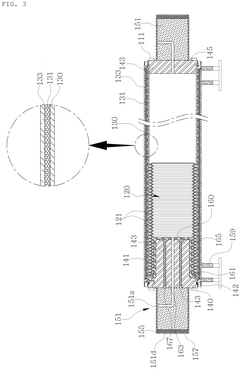

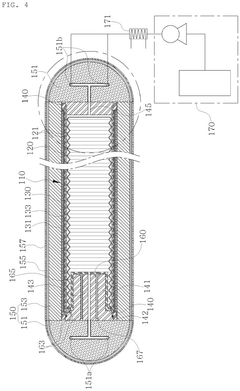

Electrochemical hydrogen compressor for operation at pressures exceeding 12,500 psi

PatentActiveUS12119525B2

Innovation

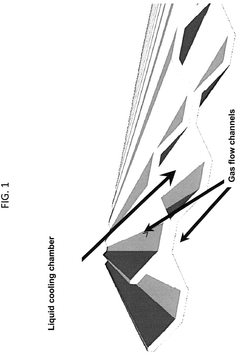

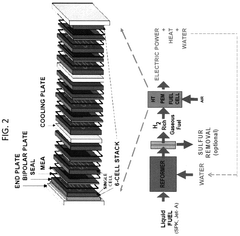

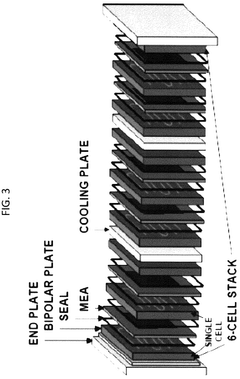

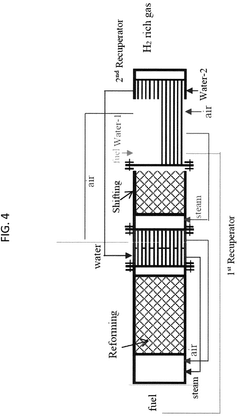

- The development of inorganic-organic composite polymer membranes and liquid-cooled metallic bipolar plates, which enhance proton conduction, mechanical strength, and temperature tolerance, along with an electrochemical hydrogen compressor that uses a composite membrane to efficiently compress and purify hydrogen.

Variable volume hydrogen container or hydrogen compressor with improved hydrogen embrittlement resistance

PatentPendingEP4549804A1

Innovation

- A variable volume hydrogen container or hydrogen compressor is designed with a variable vessel installed in a pressure vessel, featuring an embrittlement blocking member at the vessel cap to prevent hydrogen penetration and an external pressure action recess for direct hydrogen discharge, allowing for uniform hydrogen discharge pressure and reduced material costs.

Safety Standards and Certification Requirements

The safety standards and certification requirements for electrochemical compressors dealing with hydrogen embrittlement are governed by multiple international and regional regulatory frameworks. These standards are critical due to hydrogen's potential to cause catastrophic material failures when proper safety protocols are not followed.

The International Electrotechnical Commission (IEC) has established IEC 62282 series standards specifically addressing fuel cell technologies, which include provisions for hydrogen handling components. These standards outline material selection criteria, testing methodologies, and safety parameters that manufacturers must adhere to when designing components exposed to hydrogen environments.

ASME B31.12 "Hydrogen Piping and Pipelines" provides comprehensive guidelines for materials selection and qualification testing to mitigate hydrogen embrittlement risks. This standard requires specific testing protocols including slow strain rate testing (SSRT) and fracture mechanics assessments for materials used in hydrogen service.

In the European Union, the Pressure Equipment Directive (PED 2014/68/EU) and ATEX Directive 2014/34/EU establish mandatory safety requirements for equipment operating in potentially explosive atmospheres, including hydrogen-rich environments. Manufacturers must obtain CE marking through conformity assessment procedures that include material verification for hydrogen compatibility.

ISO 11114-4 specifically addresses test methods for selecting metallic materials resistant to hydrogen embrittlement, providing standardized testing protocols that manufacturers can follow to validate their material selections. This is complemented by ISO 16573, which focuses on the evaluation of hydrogen embrittlement in high-strength steels.

Certification bodies such as TÜV, UL, and CSA offer product certification services specifically for hydrogen equipment, requiring extensive documentation of material selection processes, quality control measures, and hydrogen compatibility testing. These certifications are increasingly becoming market requirements for electrochemical compressor components.

The National Fire Protection Association (NFPA) standard NFPA 2 "Hydrogen Technologies Code" provides comprehensive safety guidelines for hydrogen systems, including material compatibility requirements that address embrittlement concerns. This standard is widely adopted in North America and influences global practices.

Emerging standards from organizations like SAE International are developing specific protocols for hydrogen-compatible materials in transportation applications, which may eventually extend to stationary applications like electrochemical compressors. These standards emphasize lifecycle testing under cyclic hydrogen exposure conditions that more accurately reflect real-world operating environments.

The International Electrotechnical Commission (IEC) has established IEC 62282 series standards specifically addressing fuel cell technologies, which include provisions for hydrogen handling components. These standards outline material selection criteria, testing methodologies, and safety parameters that manufacturers must adhere to when designing components exposed to hydrogen environments.

ASME B31.12 "Hydrogen Piping and Pipelines" provides comprehensive guidelines for materials selection and qualification testing to mitigate hydrogen embrittlement risks. This standard requires specific testing protocols including slow strain rate testing (SSRT) and fracture mechanics assessments for materials used in hydrogen service.

In the European Union, the Pressure Equipment Directive (PED 2014/68/EU) and ATEX Directive 2014/34/EU establish mandatory safety requirements for equipment operating in potentially explosive atmospheres, including hydrogen-rich environments. Manufacturers must obtain CE marking through conformity assessment procedures that include material verification for hydrogen compatibility.

ISO 11114-4 specifically addresses test methods for selecting metallic materials resistant to hydrogen embrittlement, providing standardized testing protocols that manufacturers can follow to validate their material selections. This is complemented by ISO 16573, which focuses on the evaluation of hydrogen embrittlement in high-strength steels.

Certification bodies such as TÜV, UL, and CSA offer product certification services specifically for hydrogen equipment, requiring extensive documentation of material selection processes, quality control measures, and hydrogen compatibility testing. These certifications are increasingly becoming market requirements for electrochemical compressor components.

The National Fire Protection Association (NFPA) standard NFPA 2 "Hydrogen Technologies Code" provides comprehensive safety guidelines for hydrogen systems, including material compatibility requirements that address embrittlement concerns. This standard is widely adopted in North America and influences global practices.

Emerging standards from organizations like SAE International are developing specific protocols for hydrogen-compatible materials in transportation applications, which may eventually extend to stationary applications like electrochemical compressors. These standards emphasize lifecycle testing under cyclic hydrogen exposure conditions that more accurately reflect real-world operating environments.

Lifecycle Assessment of Electrochemical Compressor Materials

The lifecycle assessment of electrochemical compressor materials requires comprehensive evaluation of material performance throughout the operational lifespan, with particular focus on hydrogen embrittlement phenomena. Materials commonly used in electrochemical compressors, including various stainless steels, nickel alloys, and specialized polymers, exhibit different susceptibility to hydrogen-induced degradation over time.

Primary materials utilized in critical components such as electrodes, membranes, and bipolar plates demonstrate varying degradation patterns when exposed to hydrogen environments. Austenitic stainless steels (316L, 304L) show moderate resistance initially but experience microstructural changes after prolonged hydrogen exposure, particularly at high pressures exceeding 20 MPa. Nickel-based alloys like Inconel 625 and Hastelloy C-276 demonstrate superior long-term stability but at significantly higher material costs.

Environmental factors substantially influence material longevity in electrochemical compressor applications. Operating temperature fluctuations between -20°C and 80°C create thermal expansion stresses that accelerate hydrogen diffusion pathways. Similarly, pressure cycling between atmospheric and compression targets (typically 35-70 MPa) induces mechanical fatigue that compounds embrittlement effects, reducing expected service life by approximately 15-30% compared to static operation conditions.

Material end-of-life considerations reveal that hydrogen-exposed components often require specialized recycling protocols. Embrittled metallic components cannot be conventionally recycled without prior heat treatment to release trapped hydrogen. This additional processing step increases the environmental footprint of material lifecycle by approximately 12-18% compared to non-embrittled counterparts.

Recent advances in material science have introduced self-healing polymer composites and nano-structured metallic alloys that demonstrate up to 40% improved resistance to hydrogen embrittlement. These materials incorporate hydrogen trapping sites that effectively sequester atomic hydrogen before it can accumulate at grain boundaries. While promising, these advanced materials currently increase initial production costs by 30-45%, though lifecycle cost analysis suggests potential long-term economic benefits through extended service intervals.

Quantitative lifecycle assessment metrics indicate that material selection significantly impacts operational sustainability. Components manufactured from conventional materials typically require replacement after 8,000-12,000 operational hours in hydrogen-rich environments, while advanced materials can extend this to 15,000-20,000 hours. This extension translates to approximately 22% reduction in lifetime material consumption and associated environmental impacts.

Primary materials utilized in critical components such as electrodes, membranes, and bipolar plates demonstrate varying degradation patterns when exposed to hydrogen environments. Austenitic stainless steels (316L, 304L) show moderate resistance initially but experience microstructural changes after prolonged hydrogen exposure, particularly at high pressures exceeding 20 MPa. Nickel-based alloys like Inconel 625 and Hastelloy C-276 demonstrate superior long-term stability but at significantly higher material costs.

Environmental factors substantially influence material longevity in electrochemical compressor applications. Operating temperature fluctuations between -20°C and 80°C create thermal expansion stresses that accelerate hydrogen diffusion pathways. Similarly, pressure cycling between atmospheric and compression targets (typically 35-70 MPa) induces mechanical fatigue that compounds embrittlement effects, reducing expected service life by approximately 15-30% compared to static operation conditions.

Material end-of-life considerations reveal that hydrogen-exposed components often require specialized recycling protocols. Embrittled metallic components cannot be conventionally recycled without prior heat treatment to release trapped hydrogen. This additional processing step increases the environmental footprint of material lifecycle by approximately 12-18% compared to non-embrittled counterparts.

Recent advances in material science have introduced self-healing polymer composites and nano-structured metallic alloys that demonstrate up to 40% improved resistance to hydrogen embrittlement. These materials incorporate hydrogen trapping sites that effectively sequester atomic hydrogen before it can accumulate at grain boundaries. While promising, these advanced materials currently increase initial production costs by 30-45%, though lifecycle cost analysis suggests potential long-term economic benefits through extended service intervals.

Quantitative lifecycle assessment metrics indicate that material selection significantly impacts operational sustainability. Components manufactured from conventional materials typically require replacement after 8,000-12,000 operational hours in hydrogen-rich environments, while advanced materials can extend this to 15,000-20,000 hours. This extension translates to approximately 22% reduction in lifetime material consumption and associated environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!