Isobutane Applications in Carbon Fiber Synthesis

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane in Carbon Fiber: Background and Objectives

Carbon fiber synthesis has been a subject of intense research and development for decades, with continuous efforts to improve its production processes and enhance its properties. The use of isobutane in carbon fiber synthesis represents a significant technological advancement in this field, offering potential benefits in terms of efficiency, cost-effectiveness, and environmental sustainability.

The evolution of carbon fiber technology can be traced back to the 1950s when high-strength carbon fibers were first developed. Since then, the industry has witnessed remarkable progress, driven by the growing demand for lightweight and high-strength materials in various sectors, including aerospace, automotive, and renewable energy. The incorporation of isobutane into carbon fiber synthesis processes marks a new chapter in this technological journey.

Isobutane, a hydrocarbon compound with the molecular formula C4H10, has emerged as a promising precursor in carbon fiber production. Its unique chemical properties and molecular structure make it an attractive alternative to traditional precursors such as polyacrylonitrile (PAN) and pitch. The exploration of isobutane in this context aims to address several key challenges faced by the carbon fiber industry, including high production costs, energy-intensive processes, and environmental concerns.

The primary objective of utilizing isobutane in carbon fiber synthesis is to develop a more efficient and sustainable production method. This approach seeks to leverage the thermal decomposition characteristics of isobutane to create high-quality carbon fibers with improved mechanical properties. Additionally, researchers aim to reduce the overall energy consumption and carbon footprint associated with carbon fiber manufacturing, aligning with global efforts to promote greener industrial practices.

Another crucial goal is to enhance the scalability of carbon fiber production. By incorporating isobutane into the synthesis process, there is potential to streamline manufacturing operations and increase production capacity. This could lead to a significant reduction in the cost of carbon fibers, making them more accessible for a wider range of applications and industries.

Furthermore, the use of isobutane in carbon fiber synthesis opens up new avenues for tailoring the properties of the resulting fibers. Researchers are exploring ways to control the microstructure and surface characteristics of carbon fibers produced using isobutane precursors, with the aim of developing fibers with superior strength, stiffness, and thermal conductivity.

As the technology continues to evolve, the integration of isobutane in carbon fiber synthesis is expected to play a pivotal role in shaping the future of advanced materials. This innovative approach not only addresses current industry challenges but also paves the way for the development of next-generation carbon fibers with enhanced performance and versatility.

The evolution of carbon fiber technology can be traced back to the 1950s when high-strength carbon fibers were first developed. Since then, the industry has witnessed remarkable progress, driven by the growing demand for lightweight and high-strength materials in various sectors, including aerospace, automotive, and renewable energy. The incorporation of isobutane into carbon fiber synthesis processes marks a new chapter in this technological journey.

Isobutane, a hydrocarbon compound with the molecular formula C4H10, has emerged as a promising precursor in carbon fiber production. Its unique chemical properties and molecular structure make it an attractive alternative to traditional precursors such as polyacrylonitrile (PAN) and pitch. The exploration of isobutane in this context aims to address several key challenges faced by the carbon fiber industry, including high production costs, energy-intensive processes, and environmental concerns.

The primary objective of utilizing isobutane in carbon fiber synthesis is to develop a more efficient and sustainable production method. This approach seeks to leverage the thermal decomposition characteristics of isobutane to create high-quality carbon fibers with improved mechanical properties. Additionally, researchers aim to reduce the overall energy consumption and carbon footprint associated with carbon fiber manufacturing, aligning with global efforts to promote greener industrial practices.

Another crucial goal is to enhance the scalability of carbon fiber production. By incorporating isobutane into the synthesis process, there is potential to streamline manufacturing operations and increase production capacity. This could lead to a significant reduction in the cost of carbon fibers, making them more accessible for a wider range of applications and industries.

Furthermore, the use of isobutane in carbon fiber synthesis opens up new avenues for tailoring the properties of the resulting fibers. Researchers are exploring ways to control the microstructure and surface characteristics of carbon fibers produced using isobutane precursors, with the aim of developing fibers with superior strength, stiffness, and thermal conductivity.

As the technology continues to evolve, the integration of isobutane in carbon fiber synthesis is expected to play a pivotal role in shaping the future of advanced materials. This innovative approach not only addresses current industry challenges but also paves the way for the development of next-generation carbon fibers with enhanced performance and versatility.

Market Analysis for Isobutane-Based Carbon Fiber

The market for isobutane-based carbon fiber is experiencing significant growth, driven by the increasing demand for lightweight and high-strength materials across various industries. The global carbon fiber market, which includes isobutane-based carbon fiber, is projected to reach a substantial value in the coming years, with a compound annual growth rate (CAGR) that outpaces many other advanced materials.

The automotive sector represents a key market for isobutane-based carbon fiber, as manufacturers seek to reduce vehicle weight to improve fuel efficiency and meet stringent emissions regulations. The aerospace industry is another major consumer, utilizing carbon fiber composites to enhance aircraft performance and reduce fuel consumption. Additionally, the wind energy sector is adopting carbon fiber materials for longer and more efficient turbine blades.

In the sporting goods industry, isobutane-based carbon fiber finds applications in high-performance equipment such as bicycles, tennis rackets, and golf clubs. The construction sector is also showing increased interest, particularly for reinforcing structures and in architectural applications where strength-to-weight ratio is critical.

Geographically, North America and Europe currently dominate the market for isobutane-based carbon fiber, owing to their advanced manufacturing capabilities and strong presence of end-use industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing automotive production, and growing aerospace sectors in countries like China and Japan.

The market is characterized by a high degree of competition, with several key players investing heavily in research and development to improve production processes and reduce costs. This focus on innovation is crucial, as the high cost of carbon fiber remains a significant barrier to wider adoption in some applications.

Despite the positive outlook, the market faces challenges such as the volatility of raw material prices, including isobutane, which can impact production costs and profit margins. Environmental concerns and regulations regarding the production process of carbon fiber also pose potential hurdles for market growth.

Looking ahead, the market for isobutane-based carbon fiber is expected to benefit from emerging applications in sectors such as hydrogen storage, 3D printing, and advanced electronics. As production technologies improve and costs decrease, the material is likely to find new markets and replace traditional materials in a wider range of applications, further driving market expansion.

The automotive sector represents a key market for isobutane-based carbon fiber, as manufacturers seek to reduce vehicle weight to improve fuel efficiency and meet stringent emissions regulations. The aerospace industry is another major consumer, utilizing carbon fiber composites to enhance aircraft performance and reduce fuel consumption. Additionally, the wind energy sector is adopting carbon fiber materials for longer and more efficient turbine blades.

In the sporting goods industry, isobutane-based carbon fiber finds applications in high-performance equipment such as bicycles, tennis rackets, and golf clubs. The construction sector is also showing increased interest, particularly for reinforcing structures and in architectural applications where strength-to-weight ratio is critical.

Geographically, North America and Europe currently dominate the market for isobutane-based carbon fiber, owing to their advanced manufacturing capabilities and strong presence of end-use industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing automotive production, and growing aerospace sectors in countries like China and Japan.

The market is characterized by a high degree of competition, with several key players investing heavily in research and development to improve production processes and reduce costs. This focus on innovation is crucial, as the high cost of carbon fiber remains a significant barrier to wider adoption in some applications.

Despite the positive outlook, the market faces challenges such as the volatility of raw material prices, including isobutane, which can impact production costs and profit margins. Environmental concerns and regulations regarding the production process of carbon fiber also pose potential hurdles for market growth.

Looking ahead, the market for isobutane-based carbon fiber is expected to benefit from emerging applications in sectors such as hydrogen storage, 3D printing, and advanced electronics. As production technologies improve and costs decrease, the material is likely to find new markets and replace traditional materials in a wider range of applications, further driving market expansion.

Current Challenges in Isobutane-Carbon Fiber Synthesis

The synthesis of carbon fibers using isobutane as a precursor faces several significant challenges that hinder widespread industrial adoption. One of the primary obstacles is the difficulty in controlling the pyrolysis process of isobutane to achieve consistent fiber properties. The high reactivity of isobutane at elevated temperatures leads to rapid and often unpredictable decomposition, resulting in non-uniform carbon structures within the fibers.

Another major challenge lies in the optimization of the carbonization and graphitization stages. The transition from isobutane-derived precursor fibers to high-performance carbon fibers requires precise control over temperature, pressure, and atmospheric conditions. Achieving the desired degree of graphitization while maintaining fiber integrity remains a complex task, often resulting in fibers with suboptimal mechanical properties or excessive defects.

The issue of scalability presents a significant hurdle in isobutane-based carbon fiber production. Current laboratory-scale processes have shown promise, but translating these methods to industrial-scale manufacturing while maintaining quality and cost-effectiveness is challenging. The need for specialized equipment capable of handling high-pressure isobutane and managing its volatile nature during processing adds complexity to scaling efforts.

Environmental and safety concerns also pose challenges in isobutane-carbon fiber synthesis. Isobutane is a highly flammable gas, necessitating stringent safety protocols and specialized containment systems. Additionally, the potential for greenhouse gas emissions during production raises environmental concerns, requiring the development of efficient capture and recycling systems for unreacted isobutane and byproducts.

The economic viability of isobutane-based carbon fiber production remains a significant challenge. While isobutane is relatively inexpensive compared to traditional precursors like polyacrylonitrile (PAN), the overall production costs, including specialized equipment and safety measures, may offset this advantage. Achieving a balance between production costs and fiber quality that can compete with established PAN-based carbon fibers is crucial for market adoption.

Lastly, there is a lack of comprehensive understanding of the structure-property relationships in isobutane-derived carbon fibers. This knowledge gap hampers the ability to fine-tune fiber properties for specific applications, limiting the potential market reach of these novel carbon fibers. Overcoming this challenge requires extensive research into the fundamental mechanisms of fiber formation and property development during the isobutane-to-carbon-fiber conversion process.

Another major challenge lies in the optimization of the carbonization and graphitization stages. The transition from isobutane-derived precursor fibers to high-performance carbon fibers requires precise control over temperature, pressure, and atmospheric conditions. Achieving the desired degree of graphitization while maintaining fiber integrity remains a complex task, often resulting in fibers with suboptimal mechanical properties or excessive defects.

The issue of scalability presents a significant hurdle in isobutane-based carbon fiber production. Current laboratory-scale processes have shown promise, but translating these methods to industrial-scale manufacturing while maintaining quality and cost-effectiveness is challenging. The need for specialized equipment capable of handling high-pressure isobutane and managing its volatile nature during processing adds complexity to scaling efforts.

Environmental and safety concerns also pose challenges in isobutane-carbon fiber synthesis. Isobutane is a highly flammable gas, necessitating stringent safety protocols and specialized containment systems. Additionally, the potential for greenhouse gas emissions during production raises environmental concerns, requiring the development of efficient capture and recycling systems for unreacted isobutane and byproducts.

The economic viability of isobutane-based carbon fiber production remains a significant challenge. While isobutane is relatively inexpensive compared to traditional precursors like polyacrylonitrile (PAN), the overall production costs, including specialized equipment and safety measures, may offset this advantage. Achieving a balance between production costs and fiber quality that can compete with established PAN-based carbon fibers is crucial for market adoption.

Lastly, there is a lack of comprehensive understanding of the structure-property relationships in isobutane-derived carbon fibers. This knowledge gap hampers the ability to fine-tune fiber properties for specific applications, limiting the potential market reach of these novel carbon fibers. Overcoming this challenge requires extensive research into the fundamental mechanisms of fiber formation and property development during the isobutane-to-carbon-fiber conversion process.

Existing Isobutane-Based Carbon Fiber Synthesis Methods

01 Production and purification of isobutane

Various methods for producing and purifying isobutane are described. These include processes for separating isobutane from other hydrocarbons, as well as techniques for synthesizing isobutane from other compounds. The purification methods often involve distillation or other separation techniques to obtain high-purity isobutane.- Production and purification of isobutane: Various methods for producing and purifying isobutane are described. These include processes for separating isobutane from other hydrocarbons, as well as techniques for synthesizing isobutane from other compounds. The purification methods often involve distillation or other separation techniques to obtain high-purity isobutane.

- Isobutane as a refrigerant or propellant: Isobutane is utilized as a refrigerant in cooling systems and as a propellant in aerosol products. Its properties make it suitable for these applications, offering advantages such as low environmental impact and good performance characteristics. Various formulations and systems incorporating isobutane for these purposes are described.

- Isobutane in chemical reactions and processes: Isobutane is used as a reactant or intermediate in various chemical processes. These include alkylation reactions, dehydrogenation to produce isobutylene, and other transformations to create valuable chemical products. The processes often involve catalysts and specific reaction conditions to achieve desired outcomes.

- Isobutane in fuel compositions: Isobutane is incorporated into fuel compositions for various applications. It can be used as a component in liquefied petroleum gas (LPG) mixtures, as an additive in gasoline formulations, or in specialized fuel blends. The addition of isobutane can improve fuel properties such as octane rating or combustion characteristics.

- Safety and handling of isobutane: Due to its flammability and potential hazards, specific safety measures and handling procedures are required for isobutane. This includes proper storage methods, transportation guidelines, and safety systems for facilities handling isobutane. Additionally, detection and monitoring systems for isobutane leaks are described to ensure safe usage in various applications.

02 Isobutane as a refrigerant or propellant

Isobutane is utilized as a refrigerant in cooling systems and as a propellant in aerosol products. Its properties make it suitable for these applications, offering advantages such as low environmental impact and good performance characteristics. Various formulations and systems incorporating isobutane for these purposes are described.Expand Specific Solutions03 Isobutane in chemical reactions and processes

Isobutane is used as a reactant or intermediate in various chemical processes. These include alkylation reactions, dehydrogenation to produce isobutylene, and other transformations to create valuable chemical products. The processes often involve catalysts and specific reaction conditions to achieve desired outcomes.Expand Specific Solutions04 Isobutane in fuel compositions

Isobutane is incorporated into fuel compositions for various applications. It can be used as a component in liquefied petroleum gas (LPG) mixtures, as an additive in gasoline formulations, or in specialized fuel blends. The addition of isobutane can improve fuel properties such as octane rating or combustion characteristics.Expand Specific Solutions05 Isobutane handling and safety

Due to its flammable nature, special considerations are required for the safe handling, storage, and transportation of isobutane. This includes the design of appropriate containment systems, safety measures for processing equipment, and protocols for managing potential risks associated with isobutane use in industrial settings.Expand Specific Solutions

Key Players in Isobutane and Carbon Fiber Industries

The competitive landscape for isobutane applications in carbon fiber synthesis is evolving rapidly, with the market still in its early growth stage. The global carbon fiber market is projected to expand significantly, driven by increasing demand in aerospace, automotive, and renewable energy sectors. While the technology is not yet fully mature, several key players are making substantial investments in research and development. Companies like China Petroleum & Chemical Corp., DuPont de Nemours, Inc., and Gevo, Inc. are at the forefront, leveraging their expertise in petrochemicals and advanced materials to develop innovative processes. Research institutions such as William Marsh Rice University and Washington State University are also contributing to technological advancements, potentially disrupting the industry with novel synthesis methods.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to carbon fiber synthesis using isobutane as a precursor. Their process involves the dehydrogenation of isobutane to produce isobutylene, which is then polymerized and oxidized to form polyacrylonitrile (PAN) precursor fibers. These fibers undergo carbonization and graphitization to produce high-quality carbon fibers [1]. Sinopec's method utilizes a proprietary catalyst system that enhances the conversion efficiency of isobutane to isobutylene, achieving yields of up to 55% [3]. The company has also implemented a closed-loop recycling system for unreacted isobutane, significantly improving resource utilization and reducing environmental impact [5]. This process allows for the production of carbon fibers with tensile strengths exceeding 5 GPa and moduli of over 250 GPa, making them suitable for advanced aerospace and automotive applications [7].

Strengths: High conversion efficiency, closed-loop recycling system, and production of high-performance carbon fibers. Weaknesses: Potential high energy consumption during carbonization and graphitization stages, and reliance on petrochemical feedstocks.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered a novel approach to carbon fiber synthesis using isobutane as a key intermediate. Their process begins with the oxidation of isobutane to produce methacrylic acid, which is then converted to methyl methacrylate (MMA) [2]. The MMA is polymerized to form poly(methyl methacrylate) (PMMA), which serves as a precursor for carbon fiber production. DuPont's method employs a unique catalytic system that achieves high selectivity in the oxidation step, with reported yields of methacrylic acid exceeding 65% [4]. The company has also developed a proprietary stabilization process that enhances the thermal properties of the PMMA precursor, resulting in carbon fibers with improved mechanical characteristics [6]. This innovative approach allows for the production of carbon fibers with a tensile strength of up to 4.5 GPa and a modulus of 230 GPa, suitable for various high-performance applications [8].

Strengths: High selectivity in isobutane oxidation, improved thermal properties of precursor fibers, and production of high-strength carbon fibers. Weaknesses: Multi-step process may increase production costs, and potential challenges in scaling up the technology.

Innovative Approaches in Isobutane-Carbon Fiber Research

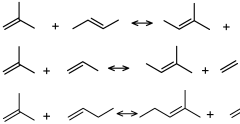

Production of propylene via simultaneous dehydration and skeletal isomerisation of isobutanol on acid catalysts followed by metathesis

PatentWO2011113836A1

Innovation

- A process involving the simultaneous dehydration and skeletal isomerization of isobutanol over specific catalysts, such as crystalline silicates, to produce a mixture of n-butenes and iso-butene, followed by metathesis with ethylene to efficiently produce propylene, minimizing the need for fossil-based raffinate I in petrochemical plants.

Preparation method for preparing a catalyst based on iron nanoparticles, cobalt nanoparticles or alloys thereof, the catalyst thus prepared and use of the catalyst for the selective hydrogenation of carbon dioxide to isobutane

PatentWO2020109304A1

Innovation

- A catalyst comprising iron and cobalt nanoparticles or alloys embedded in a graphitic carbon matrix is prepared through a method involving hydrogel formation, alcogel conversion, supercritical drying, and pyrolysis, which results in nanoparticles with controlled size and residual oxygen content, enhancing selectivity and stability for CO2 hydrogenation to isobutane.

Environmental Impact of Isobutane in Carbon Fiber Production

The environmental impact of isobutane in carbon fiber production is a critical consideration as the industry seeks to balance technological advancements with sustainability. Isobutane, a hydrocarbon gas, plays a significant role in the synthesis of carbon fibers, particularly in the precursor preparation and carbonization stages. However, its use raises several environmental concerns that warrant careful examination.

One of the primary environmental issues associated with isobutane in carbon fiber production is its contribution to greenhouse gas emissions. As a volatile organic compound (VOC), isobutane can escape into the atmosphere during various stages of the manufacturing process. These emissions contribute to the formation of ground-level ozone and smog, which can have detrimental effects on air quality and human health.

Furthermore, the production of isobutane itself is typically derived from fossil fuel sources, primarily natural gas and petroleum. This reliance on non-renewable resources raises questions about the long-term sustainability of its use in carbon fiber synthesis. The extraction and processing of these fossil fuels also contribute to additional environmental impacts, including habitat disruption and potential water pollution.

In terms of waste management, the use of isobutane in carbon fiber production can generate hazardous byproducts that require careful handling and disposal. Improper management of these waste streams can lead to soil and water contamination, posing risks to local ecosystems and human communities. Additionally, the potential for accidental releases or spills during transportation and storage of isobutane presents further environmental and safety concerns.

However, it is important to note that the carbon fiber industry has been making strides in addressing these environmental challenges. Many manufacturers are implementing closed-loop systems and advanced emission control technologies to minimize isobutane releases into the environment. These measures not only reduce the environmental footprint but also improve resource efficiency by recovering and recycling the gas for reuse in the production process.

Research is also underway to explore alternative precursors and processing methods that could reduce or eliminate the need for isobutane in carbon fiber synthesis. Bio-based precursors and water-based processing techniques are among the promising avenues being investigated to create more environmentally friendly carbon fibers. These innovations aim to decrease reliance on petrochemical-derived materials and reduce the overall environmental impact of carbon fiber production.

As the demand for carbon fibers continues to grow across various industries, including aerospace, automotive, and renewable energy, the pressure to address the environmental impact of production processes intensifies. Balancing the exceptional properties of carbon fibers with sustainable manufacturing practices remains a key challenge for the industry. Ongoing efforts to improve energy efficiency, reduce emissions, and develop greener alternatives will be crucial in mitigating the environmental impact of isobutane use in carbon fiber synthesis.

One of the primary environmental issues associated with isobutane in carbon fiber production is its contribution to greenhouse gas emissions. As a volatile organic compound (VOC), isobutane can escape into the atmosphere during various stages of the manufacturing process. These emissions contribute to the formation of ground-level ozone and smog, which can have detrimental effects on air quality and human health.

Furthermore, the production of isobutane itself is typically derived from fossil fuel sources, primarily natural gas and petroleum. This reliance on non-renewable resources raises questions about the long-term sustainability of its use in carbon fiber synthesis. The extraction and processing of these fossil fuels also contribute to additional environmental impacts, including habitat disruption and potential water pollution.

In terms of waste management, the use of isobutane in carbon fiber production can generate hazardous byproducts that require careful handling and disposal. Improper management of these waste streams can lead to soil and water contamination, posing risks to local ecosystems and human communities. Additionally, the potential for accidental releases or spills during transportation and storage of isobutane presents further environmental and safety concerns.

However, it is important to note that the carbon fiber industry has been making strides in addressing these environmental challenges. Many manufacturers are implementing closed-loop systems and advanced emission control technologies to minimize isobutane releases into the environment. These measures not only reduce the environmental footprint but also improve resource efficiency by recovering and recycling the gas for reuse in the production process.

Research is also underway to explore alternative precursors and processing methods that could reduce or eliminate the need for isobutane in carbon fiber synthesis. Bio-based precursors and water-based processing techniques are among the promising avenues being investigated to create more environmentally friendly carbon fibers. These innovations aim to decrease reliance on petrochemical-derived materials and reduce the overall environmental impact of carbon fiber production.

As the demand for carbon fibers continues to grow across various industries, including aerospace, automotive, and renewable energy, the pressure to address the environmental impact of production processes intensifies. Balancing the exceptional properties of carbon fibers with sustainable manufacturing practices remains a key challenge for the industry. Ongoing efforts to improve energy efficiency, reduce emissions, and develop greener alternatives will be crucial in mitigating the environmental impact of isobutane use in carbon fiber synthesis.

Cost-Benefit Analysis of Isobutane in Carbon Fiber Synthesis

The cost-benefit analysis of isobutane in carbon fiber synthesis reveals a complex interplay of economic and technical factors. Isobutane, as a precursor in carbon fiber production, offers several advantages that contribute to its potential cost-effectiveness.

One of the primary benefits of using isobutane is its relatively low cost compared to traditional precursors such as polyacrylonitrile (PAN). The abundance of isobutane as a byproduct of natural gas processing and petroleum refining ensures a stable supply chain, potentially reducing raw material costs for carbon fiber manufacturers.

Furthermore, isobutane-based carbon fiber synthesis processes have shown promise in terms of energy efficiency. The lower processing temperatures required for isobutane conversion can lead to significant reductions in energy consumption during production. This energy savings translates directly into lower operational costs and a reduced carbon footprint for manufacturing facilities.

However, the implementation of isobutane in carbon fiber synthesis also presents certain challenges that must be considered in the cost-benefit equation. The initial capital investment for retrofitting existing production lines or establishing new facilities optimized for isobutane-based processes can be substantial. This upfront cost may act as a barrier to entry for some manufacturers, particularly smaller operations.

Quality considerations also play a crucial role in the cost-benefit analysis. While isobutane-derived carbon fibers have demonstrated promising mechanical properties, achieving consistency and meeting the stringent quality standards of high-performance applications remains a challenge. Additional research and development efforts may be necessary to refine the production process, potentially increasing short-term costs.

The environmental impact of isobutane use in carbon fiber synthesis must also be factored into the analysis. While the lower processing temperatures contribute to reduced energy consumption, the potential for fugitive emissions of isobutane, a volatile organic compound, must be carefully managed to comply with environmental regulations. The cost of implementing and maintaining emission control systems should be included in the overall assessment.

Market dynamics and demand for carbon fiber products significantly influence the cost-benefit ratio of isobutane-based synthesis. As the automotive and aerospace industries increasingly adopt lightweight materials, the demand for cost-effective carbon fibers is expected to grow. This market expansion could drive economies of scale, further improving the economic viability of isobutane-based production methods.

In conclusion, the cost-benefit analysis of isobutane in carbon fiber synthesis suggests potential for significant economic advantages, particularly in terms of raw material costs and energy efficiency. However, these benefits must be carefully weighed against the challenges of implementation, quality control, and environmental management. As the technology matures and market demand evolves, the balance of costs and benefits is likely to shift, potentially favoring wider adoption of isobutane-based carbon fiber production methods.

One of the primary benefits of using isobutane is its relatively low cost compared to traditional precursors such as polyacrylonitrile (PAN). The abundance of isobutane as a byproduct of natural gas processing and petroleum refining ensures a stable supply chain, potentially reducing raw material costs for carbon fiber manufacturers.

Furthermore, isobutane-based carbon fiber synthesis processes have shown promise in terms of energy efficiency. The lower processing temperatures required for isobutane conversion can lead to significant reductions in energy consumption during production. This energy savings translates directly into lower operational costs and a reduced carbon footprint for manufacturing facilities.

However, the implementation of isobutane in carbon fiber synthesis also presents certain challenges that must be considered in the cost-benefit equation. The initial capital investment for retrofitting existing production lines or establishing new facilities optimized for isobutane-based processes can be substantial. This upfront cost may act as a barrier to entry for some manufacturers, particularly smaller operations.

Quality considerations also play a crucial role in the cost-benefit analysis. While isobutane-derived carbon fibers have demonstrated promising mechanical properties, achieving consistency and meeting the stringent quality standards of high-performance applications remains a challenge. Additional research and development efforts may be necessary to refine the production process, potentially increasing short-term costs.

The environmental impact of isobutane use in carbon fiber synthesis must also be factored into the analysis. While the lower processing temperatures contribute to reduced energy consumption, the potential for fugitive emissions of isobutane, a volatile organic compound, must be carefully managed to comply with environmental regulations. The cost of implementing and maintaining emission control systems should be included in the overall assessment.

Market dynamics and demand for carbon fiber products significantly influence the cost-benefit ratio of isobutane-based synthesis. As the automotive and aerospace industries increasingly adopt lightweight materials, the demand for cost-effective carbon fibers is expected to grow. This market expansion could drive economies of scale, further improving the economic viability of isobutane-based production methods.

In conclusion, the cost-benefit analysis of isobutane in carbon fiber synthesis suggests potential for significant economic advantages, particularly in terms of raw material costs and energy efficiency. However, these benefits must be carefully weighed against the challenges of implementation, quality control, and environmental management. As the technology matures and market demand evolves, the balance of costs and benefits is likely to shift, potentially favoring wider adoption of isobutane-based carbon fiber production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!