Isobutane Leakage Detection Technologies in Chemical Plants

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isobutane Detection Background and Objectives

Isobutane leakage detection in chemical plants has become a critical focus in industrial safety and environmental protection. The evolution of this technology can be traced back to the early days of the petrochemical industry, where rudimentary methods were employed to detect gas leaks. As the industry expanded and safety regulations became more stringent, the need for more sophisticated detection technologies grew exponentially.

The primary objective of isobutane leakage detection is to ensure the safety of personnel and facilities while minimizing environmental impact. This technology aims to provide early warning systems that can detect even minute leaks before they escalate into major incidents. The development of these detection systems has been driven by a combination of regulatory pressures, industry best practices, and technological advancements in sensor technology and data analytics.

Over the years, the focus has shifted from simple alarm systems to comprehensive monitoring solutions that offer real-time data and predictive capabilities. This evolution reflects the industry's growing emphasis on proactive safety measures and the integration of smart technologies in chemical plant operations. The current technological landscape encompasses a wide range of detection methods, from traditional catalytic bead sensors to advanced optical sensing technologies and wireless sensor networks.

The progression of isobutane detection technologies has been marked by several key milestones. These include the introduction of portable gas detectors in the 1980s, the development of infrared sensing technology in the 1990s, and the recent advent of Internet of Things (IoT) enabled detection systems. Each of these advancements has contributed to improving the accuracy, reliability, and response time of leak detection systems.

Looking ahead, the field of isobutane leakage detection is poised for further innovation. Emerging trends include the integration of artificial intelligence for predictive maintenance, the use of drone-based monitoring systems, and the development of nanomaterial-based sensors with enhanced sensitivity. These advancements aim to address current limitations in detection range, false alarm rates, and the ability to operate in harsh industrial environments.

The ongoing research and development in this field are driven by the dual goals of enhancing safety and operational efficiency in chemical plants. As industrial processes become more complex and automated, the demand for more sophisticated, reliable, and integrated leakage detection systems continues to grow. This technological evolution not only supports safer working conditions but also contributes to the broader objectives of sustainable and responsible industrial operations.

The primary objective of isobutane leakage detection is to ensure the safety of personnel and facilities while minimizing environmental impact. This technology aims to provide early warning systems that can detect even minute leaks before they escalate into major incidents. The development of these detection systems has been driven by a combination of regulatory pressures, industry best practices, and technological advancements in sensor technology and data analytics.

Over the years, the focus has shifted from simple alarm systems to comprehensive monitoring solutions that offer real-time data and predictive capabilities. This evolution reflects the industry's growing emphasis on proactive safety measures and the integration of smart technologies in chemical plant operations. The current technological landscape encompasses a wide range of detection methods, from traditional catalytic bead sensors to advanced optical sensing technologies and wireless sensor networks.

The progression of isobutane detection technologies has been marked by several key milestones. These include the introduction of portable gas detectors in the 1980s, the development of infrared sensing technology in the 1990s, and the recent advent of Internet of Things (IoT) enabled detection systems. Each of these advancements has contributed to improving the accuracy, reliability, and response time of leak detection systems.

Looking ahead, the field of isobutane leakage detection is poised for further innovation. Emerging trends include the integration of artificial intelligence for predictive maintenance, the use of drone-based monitoring systems, and the development of nanomaterial-based sensors with enhanced sensitivity. These advancements aim to address current limitations in detection range, false alarm rates, and the ability to operate in harsh industrial environments.

The ongoing research and development in this field are driven by the dual goals of enhancing safety and operational efficiency in chemical plants. As industrial processes become more complex and automated, the demand for more sophisticated, reliable, and integrated leakage detection systems continues to grow. This technological evolution not only supports safer working conditions but also contributes to the broader objectives of sustainable and responsible industrial operations.

Market Demand Analysis for Leak Detection

The market demand for isobutane leak detection technologies in chemical plants has been steadily increasing due to stringent safety regulations, growing environmental concerns, and the need for operational efficiency. Chemical plants handling isobutane face significant risks associated with potential leaks, including fire hazards, explosions, and environmental contamination. This has led to a robust demand for advanced leak detection systems that can provide early warnings and prevent catastrophic incidents.

The global market for gas leak detection equipment is projected to grow substantially in the coming years, with a significant portion attributed to the chemical industry. Factors driving this growth include the expansion of chemical manufacturing facilities, particularly in emerging economies, and the increasing adoption of automation and IoT technologies in industrial processes. The isobutane leak detection segment is expected to witness above-average growth rates within this market.

Chemical plant operators are increasingly recognizing the importance of implementing comprehensive leak detection systems to ensure workplace safety, comply with regulatory requirements, and minimize production losses. This has resulted in a shift towards more sophisticated, real-time monitoring solutions that can detect even minute leaks of isobutane with high accuracy and reliability.

The demand for isobutane leak detection technologies is not limited to new installations but also extends to retrofitting existing chemical plants with upgraded detection systems. This trend is driven by the need to replace outdated equipment and improve overall plant safety standards. Additionally, there is a growing interest in portable and wearable leak detection devices for personnel safety and spot-checking applications.

Market analysis indicates a preference for multi-gas detection systems that can simultaneously monitor various gases, including isobutane, providing a more comprehensive safety solution for chemical plants. These integrated systems offer cost-effectiveness and operational efficiency, which are crucial factors for plant operators looking to optimize their safety investments.

The increasing focus on predictive maintenance and condition monitoring in the chemical industry is also influencing the demand for advanced leak detection technologies. Plant operators are seeking solutions that not only detect leaks but also provide data analytics capabilities to predict potential failure points and optimize maintenance schedules.

As environmental regulations become more stringent globally, there is a rising demand for leak detection technologies that can help chemical plants reduce their environmental footprint and comply with emissions standards. This has led to the development of more sensitive and accurate detection methods capable of identifying even trace amounts of isobutane leaks.

The global market for gas leak detection equipment is projected to grow substantially in the coming years, with a significant portion attributed to the chemical industry. Factors driving this growth include the expansion of chemical manufacturing facilities, particularly in emerging economies, and the increasing adoption of automation and IoT technologies in industrial processes. The isobutane leak detection segment is expected to witness above-average growth rates within this market.

Chemical plant operators are increasingly recognizing the importance of implementing comprehensive leak detection systems to ensure workplace safety, comply with regulatory requirements, and minimize production losses. This has resulted in a shift towards more sophisticated, real-time monitoring solutions that can detect even minute leaks of isobutane with high accuracy and reliability.

The demand for isobutane leak detection technologies is not limited to new installations but also extends to retrofitting existing chemical plants with upgraded detection systems. This trend is driven by the need to replace outdated equipment and improve overall plant safety standards. Additionally, there is a growing interest in portable and wearable leak detection devices for personnel safety and spot-checking applications.

Market analysis indicates a preference for multi-gas detection systems that can simultaneously monitor various gases, including isobutane, providing a more comprehensive safety solution for chemical plants. These integrated systems offer cost-effectiveness and operational efficiency, which are crucial factors for plant operators looking to optimize their safety investments.

The increasing focus on predictive maintenance and condition monitoring in the chemical industry is also influencing the demand for advanced leak detection technologies. Plant operators are seeking solutions that not only detect leaks but also provide data analytics capabilities to predict potential failure points and optimize maintenance schedules.

As environmental regulations become more stringent globally, there is a rising demand for leak detection technologies that can help chemical plants reduce their environmental footprint and comply with emissions standards. This has led to the development of more sensitive and accurate detection methods capable of identifying even trace amounts of isobutane leaks.

Current Challenges in Isobutane Leak Detection

Despite significant advancements in leak detection technologies, the chemical industry still faces several challenges in effectively detecting isobutane leaks in chemical plants. One of the primary obstacles is the need for highly sensitive and selective sensors capable of detecting low concentrations of isobutane in complex industrial environments. Current sensors often struggle to differentiate between isobutane and other hydrocarbon gases, leading to false alarms or missed detections.

The harsh operating conditions in chemical plants pose another significant challenge. Extreme temperatures, high humidity, and the presence of corrosive substances can compromise the reliability and longevity of detection equipment. This necessitates the development of robust sensors that can maintain accuracy and performance under these demanding conditions.

Real-time monitoring and rapid response capabilities remain critical issues in isobutane leak detection. Many existing systems suffer from delayed detection times, which can be problematic given the highly flammable nature of isobutane. The industry requires solutions that can provide instantaneous alerts to prevent potential accidents and minimize environmental impact.

Cost-effectiveness is another hurdle in implementing comprehensive leak detection systems. While advanced technologies exist, their high installation and maintenance costs often deter widespread adoption, particularly for smaller chemical plants. Striking a balance between performance and affordability is crucial for industry-wide implementation.

The integration of leak detection systems with existing plant infrastructure and control systems presents technical challenges. Seamless communication between various components and the ability to process and analyze large volumes of data in real-time are essential for effective leak management. However, many plants struggle with outdated systems that are not easily compatible with modern detection technologies.

Regulatory compliance and standardization issues further complicate isobutane leak detection efforts. Varying standards across different regions and the lack of unified protocols for leak detection and response can lead to inconsistencies in implementation and effectiveness. This highlights the need for more harmonized approaches and clearer guidelines in the industry.

Lastly, the human factor remains a significant challenge. Proper training of personnel to interpret detection data, respond to alerts, and maintain detection systems is crucial. However, many facilities face difficulties in ensuring all staff are adequately trained and prepared to handle potential leak scenarios effectively.

The harsh operating conditions in chemical plants pose another significant challenge. Extreme temperatures, high humidity, and the presence of corrosive substances can compromise the reliability and longevity of detection equipment. This necessitates the development of robust sensors that can maintain accuracy and performance under these demanding conditions.

Real-time monitoring and rapid response capabilities remain critical issues in isobutane leak detection. Many existing systems suffer from delayed detection times, which can be problematic given the highly flammable nature of isobutane. The industry requires solutions that can provide instantaneous alerts to prevent potential accidents and minimize environmental impact.

Cost-effectiveness is another hurdle in implementing comprehensive leak detection systems. While advanced technologies exist, their high installation and maintenance costs often deter widespread adoption, particularly for smaller chemical plants. Striking a balance between performance and affordability is crucial for industry-wide implementation.

The integration of leak detection systems with existing plant infrastructure and control systems presents technical challenges. Seamless communication between various components and the ability to process and analyze large volumes of data in real-time are essential for effective leak management. However, many plants struggle with outdated systems that are not easily compatible with modern detection technologies.

Regulatory compliance and standardization issues further complicate isobutane leak detection efforts. Varying standards across different regions and the lack of unified protocols for leak detection and response can lead to inconsistencies in implementation and effectiveness. This highlights the need for more harmonized approaches and clearer guidelines in the industry.

Lastly, the human factor remains a significant challenge. Proper training of personnel to interpret detection data, respond to alerts, and maintain detection systems is crucial. However, many facilities face difficulties in ensuring all staff are adequately trained and prepared to handle potential leak scenarios effectively.

Existing Isobutane Detection Solutions

01 Gas sensor-based detection systems

Advanced gas sensors are employed to detect isobutane leakage. These systems utilize specialized sensors that can identify the presence of isobutane in the air, triggering alarms when concentrations exceed safe levels. The technology often includes calibration features and can be integrated into broader safety monitoring systems.- Gas sensor-based detection systems: Advanced gas sensors are employed to detect isobutane leakage. These systems utilize specialized sensors that can identify the presence of isobutane in the air, triggering alarms when concentrations exceed safe levels. The technology often includes calibration features and can be integrated into broader safety monitoring systems.

- Portable leak detection devices: Handheld or portable devices are developed for on-site isobutane leak detection. These tools are designed for ease of use and mobility, allowing technicians to perform spot checks in various locations. They may incorporate multiple sensing technologies and provide real-time readings of gas concentrations.

- Optical detection methods: Optical technologies, such as infrared spectroscopy or laser-based systems, are utilized for non-contact isobutane leak detection. These methods can detect gas leaks from a distance, making them suitable for large-scale industrial applications or hard-to-reach areas. They often offer high sensitivity and rapid response times.

- Network-based monitoring systems: Integrated network systems are developed for continuous monitoring of isobutane leaks across large facilities. These systems combine multiple sensors, data analysis algorithms, and centralized control units to provide comprehensive leak detection coverage. They often include remote monitoring capabilities and automated alert mechanisms.

- Acoustic leak detection technology: Acoustic sensors and signal processing techniques are employed to detect isobutane leaks by identifying the characteristic sounds produced by escaping gas. This technology can be effective in noisy industrial environments and can pinpoint the location of leaks with high accuracy. It may be combined with other detection methods for enhanced reliability.

02 Portable leak detection devices

Handheld or portable devices are developed for on-site isobutane leak detection. These tools allow for mobile and flexible inspection in various environments. They often incorporate multiple sensing technologies and may include features like data logging and wireless connectivity for real-time monitoring and reporting.Expand Specific Solutions03 Optical detection methods

Optical technologies, such as infrared spectroscopy or laser-based systems, are used for non-contact isobutane leak detection. These methods can detect gas leaks from a distance, making them suitable for large-scale industrial applications or hard-to-reach areas. They often provide high sensitivity and can differentiate between various gases.Expand Specific Solutions04 Integrated monitoring and alarm systems

Comprehensive systems that combine multiple detection technologies, data processing, and alarm functionalities are developed for isobutane leak monitoring. These systems often feature centralized control units, network connectivity, and can be integrated with building management or industrial control systems for automated responses to detected leaks.Expand Specific Solutions05 Environmental and safety-enhanced detection methods

Advanced detection technologies that focus on improving safety and environmental impact are developed. These may include low-power consumption sensors, eco-friendly materials, or methods that reduce false alarms. The emphasis is on creating reliable, sustainable, and user-friendly detection solutions that comply with stringent safety regulations.Expand Specific Solutions

Key Players in Industrial Gas Detection

The isobutane leakage detection technology market in chemical plants is in a growth phase, driven by increasing safety regulations and environmental concerns. The market size is expanding, with a growing demand for advanced detection systems. Technologically, the field is evolving rapidly, with companies like BASF Corp., China Petroleum & Chemical Corp., and Honeywell International Technologies Ltd. leading innovation. These firms are developing sophisticated sensors, IoT-enabled monitoring systems, and AI-driven analytics for early leak detection. The technology's maturity varies, with some established solutions and emerging cutting-edge approaches, indicating a dynamic competitive landscape with opportunities for both incumbents and new entrants.

BASF Corp.

Technical Solution: BASF has developed an integrated isobutane leakage detection system as part of their broader commitment to plant safety and environmental protection. Their approach combines traditional fixed gas detectors with innovative smart sensor technology and data analytics[11]. BASF's system utilizes a network of IoT-enabled sensors that continuously monitor for isobutane leaks throughout their chemical plants. These sensors are integrated with the company's proprietary digital twin technology, allowing for real-time 3D visualization of potential leak locations[13]. BASF has also implemented machine learning algorithms to analyze historical leak data and predict potential failure points, enabling proactive maintenance and risk mitigation strategies[15].

Strengths: Comprehensive integration with plant digital twin technology, predictive maintenance capabilities, leverages BASF's extensive chemical industry expertise. Weaknesses: System may be highly customized to BASF's specific plant layouts and processes, potentially limiting its applicability to other companies without significant adaptation.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced isobutane leakage detection technologies for chemical plants, leveraging their expertise in industrial automation and safety systems. Their solution incorporates a multi-layered approach, combining infrared gas sensors, ultrasonic detectors, and advanced analytics[1]. The system uses distributed sensor networks strategically placed throughout the facility to provide real-time monitoring and early warning capabilities. Honeywell's technology employs machine learning algorithms to analyze sensor data, enabling predictive maintenance and reducing false alarms[3]. The company has also integrated their detection system with their Experion® Process Knowledge System (PKS) for comprehensive plant management and safety control[5].

Strengths: Comprehensive solution integrating multiple detection technologies, advanced analytics for predictive maintenance, seamless integration with existing plant control systems. Weaknesses: Potentially higher initial implementation costs, may require specialized training for plant personnel.

Core Innovations in Gas Sensor Technology

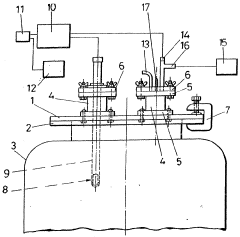

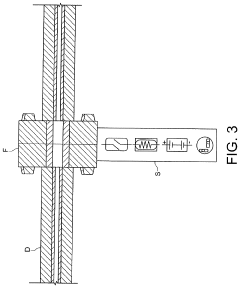

Method and device for checking leaktightness and/or detecting leaks in tanks

PatentWO2009065972A1

Innovation

- A method and device for leak detection in empty and degassed tanks using signal conditioning and analysis techniques, including matrix decomposition, statistical methods, and power spectral analysis, with a portable, intrinsically safe system that applies internal pressure up to 0.75 bar to diagnose tightness and leaks, providing a spectral signature for predictive maintenance.

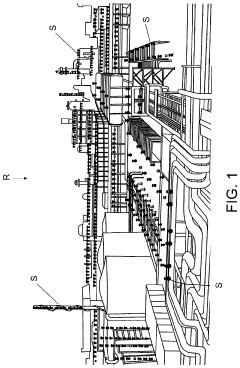

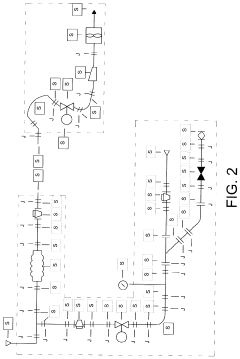

Monitoring chemicals and gases along pipes, valves and flanges

PatentActiveUS20210335116A1

Innovation

- An automated and digitized LDAR system utilizing a network of sensors integrated with components prone to leaks, which detect chemical emissions in real-time and communicate wirelessly, allowing for data-driven decision-making and reducing manual sampling efforts by using nano-sensors, IoT technology, and Machine to Machine Communication to monitor and track leaks effectively.

Safety Regulations in Chemical Plants

Safety regulations in chemical plants play a crucial role in preventing accidents and protecting workers, the environment, and surrounding communities. These regulations are designed to address various hazards, including the potential leakage of dangerous substances such as isobutane. In the context of isobutane leakage detection technologies, safety regulations provide a framework for implementing and maintaining effective detection systems.

Chemical plant operators are required to comply with a range of national and international safety standards. These include regulations set by organizations such as the Occupational Safety and Health Administration (OSHA) in the United States, the European Chemical Agency (ECHA) in Europe, and similar bodies in other regions. These regulations often mandate the use of specific detection technologies and protocols for monitoring potential leaks of hazardous substances like isobutane.

One key aspect of safety regulations is the requirement for regular inspections and maintenance of detection equipment. This ensures that leakage detection systems remain in optimal working condition and can effectively identify potential hazards. Regulations typically specify the frequency of these inspections and the qualifications required for personnel conducting them.

Safety regulations also often dictate the placement and distribution of detection devices throughout chemical plants. This includes guidelines on the number of sensors required, their positioning relative to potential leak sources, and the integration of these sensors into broader safety management systems. The goal is to create a comprehensive detection network that can quickly identify and localize any isobutane leaks.

Emergency response procedures are another critical component of safety regulations related to isobutane leakage detection. These regulations outline the steps that must be taken in the event of a detected leak, including evacuation protocols, notification procedures for relevant authorities, and containment strategies. Plant operators are typically required to have detailed emergency response plans in place and to conduct regular drills to ensure readiness.

Training requirements for personnel working with isobutane detection systems are also specified in safety regulations. This includes training on the operation and maintenance of detection equipment, as well as education on the properties and hazards of isobutane. Regulations often mandate regular refresher courses to keep staff up-to-date with the latest safety practices and technologies.

Reporting and documentation requirements form another important aspect of safety regulations. Chemical plant operators are typically required to maintain detailed records of all leakage detection activities, including regular sensor readings, maintenance logs, and incident reports. These records must be made available for inspection by regulatory authorities and can play a crucial role in improving safety practices over time.

Chemical plant operators are required to comply with a range of national and international safety standards. These include regulations set by organizations such as the Occupational Safety and Health Administration (OSHA) in the United States, the European Chemical Agency (ECHA) in Europe, and similar bodies in other regions. These regulations often mandate the use of specific detection technologies and protocols for monitoring potential leaks of hazardous substances like isobutane.

One key aspect of safety regulations is the requirement for regular inspections and maintenance of detection equipment. This ensures that leakage detection systems remain in optimal working condition and can effectively identify potential hazards. Regulations typically specify the frequency of these inspections and the qualifications required for personnel conducting them.

Safety regulations also often dictate the placement and distribution of detection devices throughout chemical plants. This includes guidelines on the number of sensors required, their positioning relative to potential leak sources, and the integration of these sensors into broader safety management systems. The goal is to create a comprehensive detection network that can quickly identify and localize any isobutane leaks.

Emergency response procedures are another critical component of safety regulations related to isobutane leakage detection. These regulations outline the steps that must be taken in the event of a detected leak, including evacuation protocols, notification procedures for relevant authorities, and containment strategies. Plant operators are typically required to have detailed emergency response plans in place and to conduct regular drills to ensure readiness.

Training requirements for personnel working with isobutane detection systems are also specified in safety regulations. This includes training on the operation and maintenance of detection equipment, as well as education on the properties and hazards of isobutane. Regulations often mandate regular refresher courses to keep staff up-to-date with the latest safety practices and technologies.

Reporting and documentation requirements form another important aspect of safety regulations. Chemical plant operators are typically required to maintain detailed records of all leakage detection activities, including regular sensor readings, maintenance logs, and incident reports. These records must be made available for inspection by regulatory authorities and can play a crucial role in improving safety practices over time.

Environmental Impact of Isobutane Leaks

Isobutane leaks in chemical plants can have significant environmental impacts, ranging from local air quality degradation to broader climate change implications. The release of isobutane, a volatile organic compound (VOC), contributes to the formation of ground-level ozone, a key component of smog. This can lead to respiratory issues in humans and damage to vegetation in the surrounding areas.

In terms of climate change, isobutane is a potent greenhouse gas with a global warming potential (GWP) approximately 3 times that of carbon dioxide over a 100-year period. Large-scale leaks can therefore contribute to the overall greenhouse effect, albeit on a smaller scale compared to more prevalent greenhouse gases like methane or carbon dioxide.

Soil and water contamination are also potential consequences of isobutane leaks. Although isobutane is highly volatile and tends to evaporate quickly, prolonged or substantial leaks can result in the compound seeping into soil or water bodies. This can disrupt local ecosystems, potentially harming plant and animal life in the affected areas.

The impact on biodiversity should not be overlooked. Acute exposure to high concentrations of isobutane can be toxic to various organisms, particularly in aquatic environments. Chronic low-level exposure may lead to long-term effects on local flora and fauna, potentially altering ecosystem dynamics.

From a regulatory perspective, isobutane leaks can trigger violations of environmental regulations, such as those set by the Environmental Protection Agency (EPA) in the United States or similar bodies in other countries. These violations can result in fines, mandatory remediation actions, and increased scrutiny of plant operations.

The economic implications of environmental damage caused by isobutane leaks extend beyond regulatory fines. They may include costs associated with cleanup efforts, ecosystem restoration, and potential legal liabilities from affected communities or individuals. Moreover, the reputational damage to the company responsible for the leak can have long-lasting effects on its market position and stakeholder relationships.

In light of these environmental concerns, the development and implementation of effective isobutane leakage detection technologies in chemical plants are crucial. Advanced detection systems can help minimize the environmental impact by enabling rapid response to leaks, reducing the volume of released isobutane, and preventing prolonged exposure of the environment to this compound.

In terms of climate change, isobutane is a potent greenhouse gas with a global warming potential (GWP) approximately 3 times that of carbon dioxide over a 100-year period. Large-scale leaks can therefore contribute to the overall greenhouse effect, albeit on a smaller scale compared to more prevalent greenhouse gases like methane or carbon dioxide.

Soil and water contamination are also potential consequences of isobutane leaks. Although isobutane is highly volatile and tends to evaporate quickly, prolonged or substantial leaks can result in the compound seeping into soil or water bodies. This can disrupt local ecosystems, potentially harming plant and animal life in the affected areas.

The impact on biodiversity should not be overlooked. Acute exposure to high concentrations of isobutane can be toxic to various organisms, particularly in aquatic environments. Chronic low-level exposure may lead to long-term effects on local flora and fauna, potentially altering ecosystem dynamics.

From a regulatory perspective, isobutane leaks can trigger violations of environmental regulations, such as those set by the Environmental Protection Agency (EPA) in the United States or similar bodies in other countries. These violations can result in fines, mandatory remediation actions, and increased scrutiny of plant operations.

The economic implications of environmental damage caused by isobutane leaks extend beyond regulatory fines. They may include costs associated with cleanup efforts, ecosystem restoration, and potential legal liabilities from affected communities or individuals. Moreover, the reputational damage to the company responsible for the leak can have long-lasting effects on its market position and stakeholder relationships.

In light of these environmental concerns, the development and implementation of effective isobutane leakage detection technologies in chemical plants are crucial. Advanced detection systems can help minimize the environmental impact by enabling rapid response to leaks, reducing the volume of released isobutane, and preventing prolonged exposure of the environment to this compound.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!