Lifecycle Assessment: Electrochemical Compressors In The Renewable Hydrogen Economy

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Compressor Technology Background and Objectives

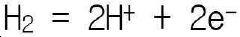

Electrochemical compression technology represents a significant advancement in hydrogen processing systems, emerging as an alternative to conventional mechanical compression methods. The evolution of this technology can be traced back to the early 2000s when researchers began exploring electrochemical principles for gas compression applications. Unlike traditional mechanical compressors that rely on moving parts and lubricants, electrochemical compressors utilize proton exchange membranes and electrochemical reactions to achieve compression, offering a potentially more efficient and environmentally friendly approach.

The technology has progressed through several developmental phases, beginning with fundamental research into membrane materials and electrochemical cell designs, followed by laboratory-scale prototypes, and more recently advancing to pilot-scale demonstrations. This progression has been accelerated by the growing interest in hydrogen as a clean energy carrier and the need for more efficient hydrogen infrastructure solutions.

Current technological trends in electrochemical compression focus on improving energy efficiency, increasing compression ratios, enhancing durability, and reducing system costs. Research efforts are particularly concentrated on developing advanced membrane materials with higher proton conductivity and mechanical stability, optimizing electrode structures for improved reaction kinetics, and designing more efficient cell architectures.

The primary technical objectives for electrochemical compressor development include achieving compression ratios exceeding 100:1 while maintaining high efficiency, developing systems capable of operating at variable loads to accommodate fluctuating renewable energy inputs, extending operational lifetimes to match or exceed those of conventional compressors, and significantly reducing capital and operational costs to enhance commercial viability.

In the context of the renewable hydrogen economy, electrochemical compressors aim to address several critical challenges. These include the need for efficient compression of hydrogen produced through water electrolysis, the ability to integrate seamlessly with intermittent renewable energy sources, and the requirement for reliable operation in decentralized hydrogen production scenarios.

The lifecycle assessment perspective adds another dimension to the technology's development goals, emphasizing the importance of minimizing environmental impacts across the entire product lifecycle. This includes reducing material intensity, eliminating the use of rare or toxic materials, designing for recyclability, and ensuring that the energy savings during operation outweigh the environmental costs of manufacturing and disposal.

As hydrogen continues to gain prominence in the global energy transition, electrochemical compression technology stands at a critical juncture, with its further development potentially enabling more efficient and sustainable hydrogen infrastructure deployment.

The technology has progressed through several developmental phases, beginning with fundamental research into membrane materials and electrochemical cell designs, followed by laboratory-scale prototypes, and more recently advancing to pilot-scale demonstrations. This progression has been accelerated by the growing interest in hydrogen as a clean energy carrier and the need for more efficient hydrogen infrastructure solutions.

Current technological trends in electrochemical compression focus on improving energy efficiency, increasing compression ratios, enhancing durability, and reducing system costs. Research efforts are particularly concentrated on developing advanced membrane materials with higher proton conductivity and mechanical stability, optimizing electrode structures for improved reaction kinetics, and designing more efficient cell architectures.

The primary technical objectives for electrochemical compressor development include achieving compression ratios exceeding 100:1 while maintaining high efficiency, developing systems capable of operating at variable loads to accommodate fluctuating renewable energy inputs, extending operational lifetimes to match or exceed those of conventional compressors, and significantly reducing capital and operational costs to enhance commercial viability.

In the context of the renewable hydrogen economy, electrochemical compressors aim to address several critical challenges. These include the need for efficient compression of hydrogen produced through water electrolysis, the ability to integrate seamlessly with intermittent renewable energy sources, and the requirement for reliable operation in decentralized hydrogen production scenarios.

The lifecycle assessment perspective adds another dimension to the technology's development goals, emphasizing the importance of minimizing environmental impacts across the entire product lifecycle. This includes reducing material intensity, eliminating the use of rare or toxic materials, designing for recyclability, and ensuring that the energy savings during operation outweigh the environmental costs of manufacturing and disposal.

As hydrogen continues to gain prominence in the global energy transition, electrochemical compression technology stands at a critical juncture, with its further development potentially enabling more efficient and sustainable hydrogen infrastructure deployment.

Hydrogen Market Demand Analysis in Renewable Energy Sector

The global hydrogen market is experiencing unprecedented growth, driven primarily by the transition towards renewable energy sources and the urgent need to decarbonize various sectors. Current estimates value the global hydrogen market at approximately 150 billion USD, with projections indicating potential growth to 600 billion USD by 2050. This exponential growth trajectory is particularly evident in regions with ambitious climate targets, such as the European Union, Japan, South Korea, and increasingly, China and the United States.

Within the renewable energy sector, hydrogen demand is segmented across multiple applications. Industrial processes, particularly in chemical manufacturing and refining, currently constitute about 70% of hydrogen consumption. However, emerging applications in energy storage, transportation, and power generation are rapidly expanding market segments, collectively expected to represent over 50% of hydrogen demand by 2040.

The transportation sector presents particularly promising growth opportunities, with fuel cell electric vehicles (FCEVs) gaining traction in heavy-duty transport, shipping, and potentially aviation. Market analysis indicates that hydrogen demand for mobility applications could increase from less than 1 million tons annually today to over 100 million tons by 2050, representing a compound annual growth rate exceeding 20%.

Energy storage applications are another critical demand driver, as intermittent renewable energy sources like wind and solar require efficient long-duration storage solutions. Hydrogen's ability to store large quantities of energy for extended periods positions it as a complementary technology to battery storage, particularly for seasonal energy balancing. Industry forecasts suggest that power sector hydrogen demand could reach 200 million tons annually by 2050.

Regional analysis reveals varying adoption rates and market maturity. Europe leads in policy support and infrastructure development, with Germany, the Netherlands, and the Nordic countries establishing comprehensive hydrogen strategies. The Asia-Pacific region demonstrates the fastest growth rate, driven by Japan's and South Korea's ambitious deployment targets and China's emerging focus on hydrogen as part of its carbon neutrality pledge.

Market barriers include high production costs, infrastructure limitations, and regulatory uncertainties. However, technological advancements in electrochemical compression and other hydrogen technologies are expected to significantly reduce costs. Industry analysts project that green hydrogen production costs could decrease by up to 60% by 2030, substantially expanding market viability across sectors.

The integration of electrochemical compressors specifically addresses critical efficiency challenges in the hydrogen value chain, potentially reducing compression energy requirements by 30-40% compared to mechanical alternatives, thus further enhancing market adoption potential in cost-sensitive applications.

Within the renewable energy sector, hydrogen demand is segmented across multiple applications. Industrial processes, particularly in chemical manufacturing and refining, currently constitute about 70% of hydrogen consumption. However, emerging applications in energy storage, transportation, and power generation are rapidly expanding market segments, collectively expected to represent over 50% of hydrogen demand by 2040.

The transportation sector presents particularly promising growth opportunities, with fuel cell electric vehicles (FCEVs) gaining traction in heavy-duty transport, shipping, and potentially aviation. Market analysis indicates that hydrogen demand for mobility applications could increase from less than 1 million tons annually today to over 100 million tons by 2050, representing a compound annual growth rate exceeding 20%.

Energy storage applications are another critical demand driver, as intermittent renewable energy sources like wind and solar require efficient long-duration storage solutions. Hydrogen's ability to store large quantities of energy for extended periods positions it as a complementary technology to battery storage, particularly for seasonal energy balancing. Industry forecasts suggest that power sector hydrogen demand could reach 200 million tons annually by 2050.

Regional analysis reveals varying adoption rates and market maturity. Europe leads in policy support and infrastructure development, with Germany, the Netherlands, and the Nordic countries establishing comprehensive hydrogen strategies. The Asia-Pacific region demonstrates the fastest growth rate, driven by Japan's and South Korea's ambitious deployment targets and China's emerging focus on hydrogen as part of its carbon neutrality pledge.

Market barriers include high production costs, infrastructure limitations, and regulatory uncertainties. However, technological advancements in electrochemical compression and other hydrogen technologies are expected to significantly reduce costs. Industry analysts project that green hydrogen production costs could decrease by up to 60% by 2030, substantially expanding market viability across sectors.

The integration of electrochemical compressors specifically addresses critical efficiency challenges in the hydrogen value chain, potentially reducing compression energy requirements by 30-40% compared to mechanical alternatives, thus further enhancing market adoption potential in cost-sensitive applications.

Global Status and Technical Challenges of Electrochemical Compression

Electrochemical compression (ECC) technology represents a promising alternative to conventional mechanical compression methods for hydrogen gas. Currently, the global landscape of ECC development shows significant regional variations. Leading research and development efforts are concentrated in North America, Europe, and parts of Asia, particularly Japan and South Korea. The United States Department of Energy has identified ECC as a critical technology for advancing hydrogen infrastructure, while the European Union has incorporated it into their hydrogen strategy roadmap.

Despite growing interest, ECC technology faces several substantial technical challenges. The primary limitation is the relatively low compression ratios achievable with current systems, typically ranging from 10:1 to 100:1, which falls short of the 350-700 bar pressures required for many hydrogen applications. This necessitates multi-stage compression designs that increase system complexity and cost.

Durability remains a significant concern, with membrane degradation occurring due to mechanical stress, chemical degradation, and thermal cycling. Current electrochemical compressor membranes demonstrate lifespans of 5,000-10,000 hours, considerably below the 50,000+ hours required for commercial viability in stationary applications.

Energy efficiency presents another major challenge. While theoretical models suggest electrochemical compression could achieve 60-70% efficiency, practical systems currently operate at 40-55% efficiency ranges. This efficiency gap stems from ohmic losses, activation overpotentials, and mass transport limitations within the cell architecture.

Scale-up challenges persist as laboratory demonstrations have primarily focused on small-scale systems with hydrogen throughput below 1 kg/day. Commercial applications would require systems capable of processing 50-1000 kg/day, revealing significant engineering challenges in maintaining performance at larger scales.

Cost factors remain prohibitive, with current ECC systems estimated at $1,500-3,000 per kW of compression power, compared to $800-1,200 for conventional mechanical compressors. The high cost of specialized materials, including platinum-group metal catalysts and perfluorinated membranes, contributes significantly to this economic barrier.

Water management within ECC systems presents unique challenges, as proper hydration is essential for proton conductivity in polymer electrolyte membranes, yet excess water can impede gas transport. Balancing these competing requirements across varying operational conditions remains technically difficult.

Integration with renewable energy sources introduces additional complexities, as the intermittent nature of renewable power requires ECC systems capable of handling variable input power while maintaining compression performance and efficiency.

Despite growing interest, ECC technology faces several substantial technical challenges. The primary limitation is the relatively low compression ratios achievable with current systems, typically ranging from 10:1 to 100:1, which falls short of the 350-700 bar pressures required for many hydrogen applications. This necessitates multi-stage compression designs that increase system complexity and cost.

Durability remains a significant concern, with membrane degradation occurring due to mechanical stress, chemical degradation, and thermal cycling. Current electrochemical compressor membranes demonstrate lifespans of 5,000-10,000 hours, considerably below the 50,000+ hours required for commercial viability in stationary applications.

Energy efficiency presents another major challenge. While theoretical models suggest electrochemical compression could achieve 60-70% efficiency, practical systems currently operate at 40-55% efficiency ranges. This efficiency gap stems from ohmic losses, activation overpotentials, and mass transport limitations within the cell architecture.

Scale-up challenges persist as laboratory demonstrations have primarily focused on small-scale systems with hydrogen throughput below 1 kg/day. Commercial applications would require systems capable of processing 50-1000 kg/day, revealing significant engineering challenges in maintaining performance at larger scales.

Cost factors remain prohibitive, with current ECC systems estimated at $1,500-3,000 per kW of compression power, compared to $800-1,200 for conventional mechanical compressors. The high cost of specialized materials, including platinum-group metal catalysts and perfluorinated membranes, contributes significantly to this economic barrier.

Water management within ECC systems presents unique challenges, as proper hydration is essential for proton conductivity in polymer electrolyte membranes, yet excess water can impede gas transport. Balancing these competing requirements across varying operational conditions remains technically difficult.

Integration with renewable energy sources introduces additional complexities, as the intermittent nature of renewable power requires ECC systems capable of handling variable input power while maintaining compression performance and efficiency.

Current Electrochemical Compression Technical Solutions

01 Environmental impact assessment of electrochemical compressors

Lifecycle assessment methodologies are applied to evaluate the environmental impact of electrochemical compressors throughout their entire lifecycle. This includes analyzing energy consumption, carbon footprint, and resource utilization from manufacturing to disposal. The assessment helps in identifying areas for improvement in design and operation to reduce environmental impact and enhance sustainability of these compressor systems.- Environmental impact assessment of electrochemical compressors: Lifecycle assessment methodologies are applied to evaluate the environmental impacts of electrochemical compressors throughout their entire lifecycle. This includes analyzing energy consumption, carbon footprint, resource utilization, and waste generation from manufacturing to disposal. These assessments help in identifying environmental hotspots and opportunities for sustainability improvements in electrochemical compression technology.

- Performance and efficiency evaluation of electrochemical compression systems: Methods and systems for evaluating the performance metrics and operational efficiency of electrochemical compressors throughout their lifecycle. This includes monitoring energy efficiency, compression ratios, durability, and reliability under various operating conditions. The assessment helps in optimizing design parameters and operational strategies to extend service life and improve overall system performance.

- Economic analysis and cost modeling for electrochemical compression technology: Comprehensive economic assessment frameworks for electrochemical compressors, including initial capital expenditure, operational costs, maintenance requirements, and end-of-life considerations. These analyses incorporate total cost of ownership models, return on investment calculations, and comparative evaluations against conventional compression technologies to determine economic viability and market potential.

- Material selection and sustainability in electrochemical compressor design: Evaluation of materials used in electrochemical compressors focusing on sustainability aspects such as resource scarcity, recyclability, and environmental impact. This includes assessment of electrode materials, membranes, catalysts, and structural components to identify more sustainable alternatives. The analysis considers both performance requirements and environmental implications throughout the product lifecycle.

- Digital tools and software for lifecycle management of electrochemical systems: Advanced software solutions and digital platforms developed specifically for lifecycle assessment and management of electrochemical compression systems. These tools enable simulation, modeling, data analytics, and predictive maintenance capabilities to optimize system performance, extend operational lifetime, and improve sustainability outcomes. They facilitate comprehensive monitoring and assessment throughout the product lifecycle.

02 Performance and efficiency evaluation of electrochemical compression systems

Methods and systems for evaluating the performance and efficiency of electrochemical compressors throughout their operational lifecycle. This includes monitoring key performance indicators, energy efficiency metrics, and operational parameters to optimize system performance. The evaluation helps in identifying factors affecting compressor efficiency and developing strategies to extend service life while maintaining optimal performance levels.Expand Specific Solutions03 Lifecycle cost analysis for electrochemical compression technology

Comprehensive cost analysis frameworks for electrochemical compressors that consider initial investment, operational expenses, maintenance requirements, and end-of-life disposal costs. These analyses help in understanding the total cost of ownership and identifying cost-effective solutions for implementing electrochemical compression technology in various applications. The assessment includes economic models that factor in energy prices, component replacement schedules, and potential revenue streams.Expand Specific Solutions04 Reliability and durability assessment methodologies

Techniques for evaluating the reliability and durability of electrochemical compressors under various operating conditions. These methodologies include accelerated life testing, failure mode analysis, and predictive maintenance approaches to estimate component lifespans and system durability. The assessment helps in identifying potential failure points and developing strategies to enhance the longevity and reliability of electrochemical compression systems.Expand Specific Solutions05 Digital tools for lifecycle management of electrochemical compressors

Software solutions and digital platforms designed for comprehensive lifecycle management of electrochemical compression systems. These tools enable real-time monitoring, predictive maintenance, performance optimization, and lifecycle data analysis. The digital approach facilitates better decision-making regarding system upgrades, component replacements, and end-of-life planning, ultimately improving the sustainability and cost-effectiveness of electrochemical compressor implementations.Expand Specific Solutions

Key Industry Players in Electrochemical Compression Technology

The electrochemical compressor market in the renewable hydrogen economy is in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The market size remains relatively modest but is projected to expand significantly as hydrogen gains prominence in decarbonization strategies. Technologically, the field is advancing from laboratory-scale demonstrations toward commercial viability, with companies at varying maturity levels. Industry leaders like Plug Power and Electric Hydrogen are developing large-scale solutions, while specialized firms such as Skyre and H2gremm focus on innovative compression technologies. Academic institutions (Xi'an Jiaotong University, Shandong University) and research organizations (CNRS, CEA) are advancing fundamental science, while established industrial players like Siemens Energy and Praxair bring manufacturing expertise and market access capabilities to accelerate commercialization.

Skyre, Inc.

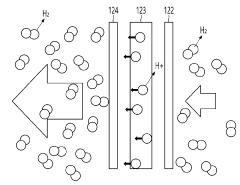

Technical Solution: Skyre (formerly Sustainable Innovations) has developed advanced electrochemical hydrogen compression technology that utilizes proton exchange membrane (PEM) cells to compress hydrogen without mechanical parts. Their H2RENEW™ system integrates hydrogen compression, purification, and separation in a single electrochemical process. The technology applies voltage across a membrane electrode assembly, causing hydrogen to be oxidized at the anode, transported as protons through the electrolyte membrane, and then reduced back to hydrogen at higher pressure at the cathode. This process can achieve compression ratios exceeding 100:1 with minimal energy input. Skyre's systems can compress hydrogen from near-ambient pressure to over 3,000 psi while simultaneously removing impurities, making the output suitable for fuel cell applications. Their lifecycle assessments indicate up to 30% reduction in energy consumption compared to mechanical compressors when integrated with renewable energy sources.

Strengths: Zero mechanical moving parts reduces maintenance requirements and increases reliability; simultaneous purification during compression; scalable modular design; lower noise and vibration; potential for direct coupling with renewable energy sources. Weaknesses: Higher upfront capital costs compared to mechanical systems; membrane degradation over time affecting long-term performance; limited maximum pressure compared to some mechanical alternatives; requires high-purity input water for optimal operation.

Electric Hydrogen Co.

Technical Solution: Electric Hydrogen Co. has pioneered large-scale electrochemical hydrogen compression systems specifically designed for integration with renewable energy sources. Their technology employs a proprietary high-performance membrane architecture that enables efficient hydrogen compression while minimizing energy losses. The company's approach focuses on grid-scale applications, with systems capable of processing hundreds of kilograms of hydrogen per day. Their compression technology is integrated directly with their electrolysis systems, creating a seamless hydrogen production and compression solution that dynamically responds to variable renewable energy inputs. Electric Hydrogen's lifecycle assessment methodology accounts for the full environmental impact of their systems, including manufacturing, operation, and end-of-life considerations. Their systems demonstrate approximately 40% lower lifecycle carbon emissions compared to conventional mechanical compression when powered by renewable electricity sources. The company has also developed advanced control systems that optimize compression operations based on real-time electricity pricing and grid carbon intensity.

Strengths: Purpose-built for renewable energy integration with dynamic load management capabilities; vertical integration with electrolysis systems improves overall efficiency; advanced materials science reduces degradation issues; scalable to industrial applications. Weaknesses: Technology still scaling to reach cost parity with traditional methods; requires specialized expertise for maintenance and operation; optimal performance dependent on specific operating conditions; higher water consumption compared to some competing technologies.

Critical Patents and Innovations in Electrochemical Compression

Electrochemical hydrogen compressor

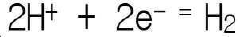

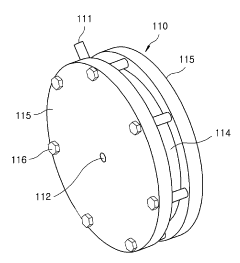

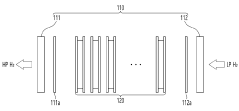

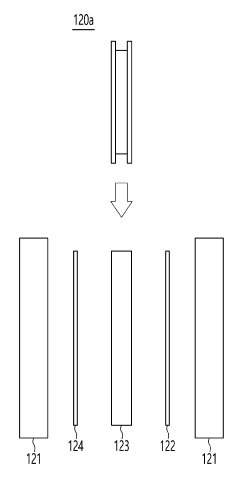

PatentActiveKR1020210001556A

Innovation

- An electrochemical hydrogen compressor with a stacked anode and cathode structure, using a hydrogen ion permeable membrane, allows for high-efficiency hydrogen compression and pumping by facilitating oxidation and reduction reactions, reducing system size and energy consumption.

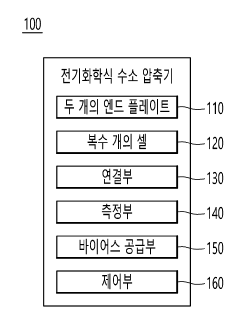

Electrochemical hydrogen compressor with repeatable compression

PatentInactiveKR1020240047517A

Innovation

- The electrochemical hydrogen compressor employs a repetitive compression function that allows hydrogen to be compressed multiple times within a stack by circulating compressed hydrogen through a connection part, utilizing a measuring unit to determine pressure, and a control unit to manage bias application, thereby optimizing compression without increasing the number of cells.

Environmental Impact Assessment of Electrochemical Compression Systems

The environmental impact assessment of electrochemical compression systems reveals significant advantages over conventional mechanical compression technologies in the renewable hydrogen economy. These systems demonstrate reduced direct emissions during operation due to their electricity-driven nature, eliminating the combustion processes typically associated with mechanical compressors. When powered by renewable energy sources, electrochemical compressors can achieve near-zero operational carbon footprints, positioning them as key enablers for truly sustainable hydrogen infrastructure.

Life cycle analysis indicates that electrochemical compressors require fewer moving parts, resulting in reduced material consumption and associated environmental impacts during manufacturing. The primary materials used—including membranes, catalysts, and electrodes—present different environmental challenges compared to conventional compression technologies. Particularly noteworthy is the reduced reliance on lubricants and sealing materials that often contribute to environmental contamination in traditional systems.

Water consumption represents another critical environmental parameter. Electrochemical systems typically require deionized water for optimal operation, though in significantly smaller quantities than other hydrogen production methods. The water footprint across the entire life cycle remains favorable compared to alternative compression technologies, especially when considering maintenance requirements.

Energy efficiency metrics demonstrate that electrochemical compressors can achieve theoretical efficiencies of 60-70% under optimal conditions, compared to 45-55% for mechanical alternatives. This translates to substantial energy savings over the operational lifetime, with corresponding reductions in indirect emissions from power generation. However, real-world performance may vary based on operating conditions, compression ratios, and system integration approaches.

Waste generation and end-of-life considerations reveal both challenges and opportunities. The specialized materials used in electrochemical systems, particularly noble metal catalysts and ion-exchange membranes, require dedicated recycling pathways. Current recycling infrastructure for these components remains underdeveloped, though emerging technologies show promise for recovering critical materials and reducing environmental burdens.

Noise pollution represents an often-overlooked environmental advantage of electrochemical systems. The absence of large moving components results in significantly reduced noise levels compared to mechanical compressors, eliminating the need for sound insulation and improving working conditions in hydrogen facilities. This characteristic makes electrochemical compression particularly suitable for distributed hydrogen applications in noise-sensitive environments.

Overall, the environmental assessment indicates that electrochemical compression systems offer substantial environmental benefits throughout their life cycle when properly integrated with renewable energy sources, though continued development of recycling pathways for specialized components remains necessary to maximize their sustainability potential.

Life cycle analysis indicates that electrochemical compressors require fewer moving parts, resulting in reduced material consumption and associated environmental impacts during manufacturing. The primary materials used—including membranes, catalysts, and electrodes—present different environmental challenges compared to conventional compression technologies. Particularly noteworthy is the reduced reliance on lubricants and sealing materials that often contribute to environmental contamination in traditional systems.

Water consumption represents another critical environmental parameter. Electrochemical systems typically require deionized water for optimal operation, though in significantly smaller quantities than other hydrogen production methods. The water footprint across the entire life cycle remains favorable compared to alternative compression technologies, especially when considering maintenance requirements.

Energy efficiency metrics demonstrate that electrochemical compressors can achieve theoretical efficiencies of 60-70% under optimal conditions, compared to 45-55% for mechanical alternatives. This translates to substantial energy savings over the operational lifetime, with corresponding reductions in indirect emissions from power generation. However, real-world performance may vary based on operating conditions, compression ratios, and system integration approaches.

Waste generation and end-of-life considerations reveal both challenges and opportunities. The specialized materials used in electrochemical systems, particularly noble metal catalysts and ion-exchange membranes, require dedicated recycling pathways. Current recycling infrastructure for these components remains underdeveloped, though emerging technologies show promise for recovering critical materials and reducing environmental burdens.

Noise pollution represents an often-overlooked environmental advantage of electrochemical systems. The absence of large moving components results in significantly reduced noise levels compared to mechanical compressors, eliminating the need for sound insulation and improving working conditions in hydrogen facilities. This characteristic makes electrochemical compression particularly suitable for distributed hydrogen applications in noise-sensitive environments.

Overall, the environmental assessment indicates that electrochemical compression systems offer substantial environmental benefits throughout their life cycle when properly integrated with renewable energy sources, though continued development of recycling pathways for specialized components remains necessary to maximize their sustainability potential.

Economic Viability Analysis of Electrochemical Compressors

The economic viability of electrochemical compressors (ECCs) in the renewable hydrogen economy hinges on several interconnected factors that determine their commercial feasibility compared to conventional mechanical compression technologies. Current cost analyses indicate that ECCs require significant capital investment, with estimates ranging from $1,500-2,500 per kW of compression power, which exceeds traditional mechanical compressors by approximately 30-40%. However, this higher initial investment must be evaluated against operational cost advantages.

Operating expenditures for ECCs demonstrate promising economic benefits, particularly in energy efficiency. ECCs typically achieve 60-70% efficiency compared to 45-55% for mechanical alternatives when compressing hydrogen from atmospheric pressure to 700 bar. This efficiency differential translates to approximately 20-30% reduction in electricity consumption over the system lifetime, representing substantial operational savings in energy-intensive hydrogen infrastructure.

Maintenance costs further strengthen the economic case for ECCs. With minimal moving parts and simplified mechanical design, maintenance expenses are estimated at 40-60% lower than conventional compressors. The extended service life of 15-20 years (versus 8-12 years for mechanical systems) significantly improves total cost of ownership calculations when properly discounted to present value.

Scale economies present both challenges and opportunities for ECC adoption. Current production volumes remain limited, preventing cost reductions through manufacturing optimization. Market projections suggest that achieving price parity with conventional technologies requires production scale increases of 5-10x current volumes, which analysts predict could occur within 5-7 years as hydrogen infrastructure expands globally.

Integration with renewable energy systems provides additional economic advantages. ECCs can operate efficiently at variable loads, making them particularly suitable for direct coupling with intermittent renewable power sources. Economic modeling indicates potential cost savings of 15-25% when ECCs are integrated with solar or wind generation compared to grid-powered mechanical compression systems.

Return on investment calculations vary significantly by application scenario. In distributed hydrogen refueling stations, payback periods currently range from 7-9 years, while industrial applications with continuous operation may achieve breakeven in 5-6 years. These timeframes exceed typical industrial equipment investment thresholds of 3-5 years, indicating that policy support or further cost reductions remain necessary for widespread commercial adoption.

Sensitivity analysis reveals that electricity prices represent the most critical variable affecting long-term economic viability. A 10% reduction in electricity costs improves lifetime economics by approximately 15-20%, highlighting the importance of access to low-cost renewable energy for maximizing ECC economic benefits in the hydrogen value chain.

Operating expenditures for ECCs demonstrate promising economic benefits, particularly in energy efficiency. ECCs typically achieve 60-70% efficiency compared to 45-55% for mechanical alternatives when compressing hydrogen from atmospheric pressure to 700 bar. This efficiency differential translates to approximately 20-30% reduction in electricity consumption over the system lifetime, representing substantial operational savings in energy-intensive hydrogen infrastructure.

Maintenance costs further strengthen the economic case for ECCs. With minimal moving parts and simplified mechanical design, maintenance expenses are estimated at 40-60% lower than conventional compressors. The extended service life of 15-20 years (versus 8-12 years for mechanical systems) significantly improves total cost of ownership calculations when properly discounted to present value.

Scale economies present both challenges and opportunities for ECC adoption. Current production volumes remain limited, preventing cost reductions through manufacturing optimization. Market projections suggest that achieving price parity with conventional technologies requires production scale increases of 5-10x current volumes, which analysts predict could occur within 5-7 years as hydrogen infrastructure expands globally.

Integration with renewable energy systems provides additional economic advantages. ECCs can operate efficiently at variable loads, making them particularly suitable for direct coupling with intermittent renewable power sources. Economic modeling indicates potential cost savings of 15-25% when ECCs are integrated with solar or wind generation compared to grid-powered mechanical compression systems.

Return on investment calculations vary significantly by application scenario. In distributed hydrogen refueling stations, payback periods currently range from 7-9 years, while industrial applications with continuous operation may achieve breakeven in 5-6 years. These timeframes exceed typical industrial equipment investment thresholds of 3-5 years, indicating that policy support or further cost reductions remain necessary for widespread commercial adoption.

Sensitivity analysis reveals that electricity prices represent the most critical variable affecting long-term economic viability. A 10% reduction in electricity costs improves lifetime economics by approximately 15-20%, highlighting the importance of access to low-cost renewable energy for maximizing ECC economic benefits in the hydrogen value chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!