Lifecycle emissions of hydrogen-based synthetic fuels from green hydrogen

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green Hydrogen Synthetic Fuels Background and Objectives

The evolution of hydrogen-based synthetic fuels represents a significant milestone in the global transition towards sustainable energy systems. Since the early 2000s, research into green hydrogen production has accelerated dramatically, driven by increasing concerns about climate change and the need to decarbonize hard-to-abate sectors. The technological trajectory has evolved from conceptual frameworks to practical demonstrations, with significant breakthroughs in electrolysis efficiency and renewable energy integration.

Green hydrogen, produced through water electrolysis powered by renewable electricity, serves as the foundation for various synthetic fuels including e-methanol, e-diesel, and e-kerosene. These fuels offer the potential for carbon-neutral alternatives to conventional fossil fuels while maintaining compatibility with existing infrastructure and end-use applications. The primary objective in this field is to develop production pathways that minimize lifecycle emissions while achieving economic viability at commercial scale.

Current technological objectives focus on reducing the energy intensity of hydrogen production, optimizing carbon capture for synthesis processes, and enhancing the efficiency of conversion technologies. Research aims to decrease the current 50-70 kWh electricity requirement per kilogram of hydrogen to below 45 kWh/kg, representing a critical threshold for widespread commercial adoption. Additionally, improving catalyst performance and durability remains essential for reducing system costs and extending operational lifetimes.

The broader context of this technological development includes international climate commitments such as the Paris Agreement and various net-zero emissions targets established by governments and corporations worldwide. The European Union's Hydrogen Strategy and similar initiatives in Japan, South Korea, and Australia have created policy frameworks that accelerate research and deployment of hydrogen technologies, with synthetic fuels playing a crucial role in sectors where direct electrification proves challenging.

From a historical perspective, synthetic fuel production dates back to the Fischer-Tropsch processes developed in the early 20th century. However, the integration with green hydrogen represents a fundamental shift from carbon-intensive pathways to potentially carbon-neutral alternatives. This transition aligns with the broader energy system transformation, where sector coupling and energy storage solutions become increasingly important for managing variable renewable energy resources.

The ultimate goal of research in this domain is to establish technically feasible and economically viable pathways for synthetic fuel production that deliver genuine climate benefits across their entire lifecycle, from hydrogen production through to end-use applications, while supporting energy security and industrial competitiveness in a decarbonized global economy.

Green hydrogen, produced through water electrolysis powered by renewable electricity, serves as the foundation for various synthetic fuels including e-methanol, e-diesel, and e-kerosene. These fuels offer the potential for carbon-neutral alternatives to conventional fossil fuels while maintaining compatibility with existing infrastructure and end-use applications. The primary objective in this field is to develop production pathways that minimize lifecycle emissions while achieving economic viability at commercial scale.

Current technological objectives focus on reducing the energy intensity of hydrogen production, optimizing carbon capture for synthesis processes, and enhancing the efficiency of conversion technologies. Research aims to decrease the current 50-70 kWh electricity requirement per kilogram of hydrogen to below 45 kWh/kg, representing a critical threshold for widespread commercial adoption. Additionally, improving catalyst performance and durability remains essential for reducing system costs and extending operational lifetimes.

The broader context of this technological development includes international climate commitments such as the Paris Agreement and various net-zero emissions targets established by governments and corporations worldwide. The European Union's Hydrogen Strategy and similar initiatives in Japan, South Korea, and Australia have created policy frameworks that accelerate research and deployment of hydrogen technologies, with synthetic fuels playing a crucial role in sectors where direct electrification proves challenging.

From a historical perspective, synthetic fuel production dates back to the Fischer-Tropsch processes developed in the early 20th century. However, the integration with green hydrogen represents a fundamental shift from carbon-intensive pathways to potentially carbon-neutral alternatives. This transition aligns with the broader energy system transformation, where sector coupling and energy storage solutions become increasingly important for managing variable renewable energy resources.

The ultimate goal of research in this domain is to establish technically feasible and economically viable pathways for synthetic fuel production that deliver genuine climate benefits across their entire lifecycle, from hydrogen production through to end-use applications, while supporting energy security and industrial competitiveness in a decarbonized global economy.

Market Analysis for Hydrogen-Based Synthetic Fuels

The global market for hydrogen-based synthetic fuels is experiencing significant growth, driven by increasing environmental concerns and the push for decarbonization across various sectors. Current market size estimates indicate that the hydrogen-based synthetic fuels market reached approximately $2.5 billion in 2022, with projections suggesting a compound annual growth rate of 8-10% through 2030, potentially reaching $5-6 billion by that time.

Transportation remains the dominant application sector, accounting for roughly 65% of the market share. Aviation and maritime shipping industries are particularly interested in these fuels due to the challenges of direct electrification in these sectors. The industrial sector follows with approximately 20% market share, where high-temperature processes require energy-dense fuels that hydrogen-based synthetics can provide.

Regional analysis reveals Europe as the current market leader, holding approximately 40% of the global market share. This dominance stems from aggressive climate policies, substantial government investments, and strong industrial partnerships. Germany, in particular, has positioned itself as a frontrunner with its National Hydrogen Strategy. North America accounts for roughly 25% of the market, with Asia-Pacific rapidly expanding at the highest regional growth rate of 12-14% annually.

Consumer demand patterns indicate growing acceptance of premium pricing for low-carbon alternatives, particularly in regions with strong environmental regulations. Corporate sustainability commitments are driving significant business-to-business demand, with over 300 major global corporations having made net-zero pledges that will require alternative fuel solutions.

Key market drivers include increasingly stringent emissions regulations, particularly in the EU with its Fit for 55 package and the ReFuelEU Aviation initiative. Technological advancements in electrolysis efficiency and falling renewable energy costs are improving the economic viability of green hydrogen production. Additionally, energy security concerns following recent geopolitical developments have accelerated interest in domestic synthetic fuel production capabilities.

Market barriers remain significant, with production costs for hydrogen-based synthetic fuels currently 3-5 times higher than conventional alternatives. Infrastructure limitations present another challenge, as specialized storage, transportation, and distribution systems are required. Regulatory uncertainty regarding carbon pricing mechanisms and sustainability certification standards also impedes market growth and investment decisions.

The competitive landscape features traditional energy companies pivoting toward synthetic fuels, specialized technology providers focusing on production efficiency, and new market entrants bringing innovative business models. Strategic partnerships between technology developers, energy providers, and end-users are becoming increasingly common to share investment risks and secure offtake agreements.

Transportation remains the dominant application sector, accounting for roughly 65% of the market share. Aviation and maritime shipping industries are particularly interested in these fuels due to the challenges of direct electrification in these sectors. The industrial sector follows with approximately 20% market share, where high-temperature processes require energy-dense fuels that hydrogen-based synthetics can provide.

Regional analysis reveals Europe as the current market leader, holding approximately 40% of the global market share. This dominance stems from aggressive climate policies, substantial government investments, and strong industrial partnerships. Germany, in particular, has positioned itself as a frontrunner with its National Hydrogen Strategy. North America accounts for roughly 25% of the market, with Asia-Pacific rapidly expanding at the highest regional growth rate of 12-14% annually.

Consumer demand patterns indicate growing acceptance of premium pricing for low-carbon alternatives, particularly in regions with strong environmental regulations. Corporate sustainability commitments are driving significant business-to-business demand, with over 300 major global corporations having made net-zero pledges that will require alternative fuel solutions.

Key market drivers include increasingly stringent emissions regulations, particularly in the EU with its Fit for 55 package and the ReFuelEU Aviation initiative. Technological advancements in electrolysis efficiency and falling renewable energy costs are improving the economic viability of green hydrogen production. Additionally, energy security concerns following recent geopolitical developments have accelerated interest in domestic synthetic fuel production capabilities.

Market barriers remain significant, with production costs for hydrogen-based synthetic fuels currently 3-5 times higher than conventional alternatives. Infrastructure limitations present another challenge, as specialized storage, transportation, and distribution systems are required. Regulatory uncertainty regarding carbon pricing mechanisms and sustainability certification standards also impedes market growth and investment decisions.

The competitive landscape features traditional energy companies pivoting toward synthetic fuels, specialized technology providers focusing on production efficiency, and new market entrants bringing innovative business models. Strategic partnerships between technology developers, energy providers, and end-users are becoming increasingly common to share investment risks and secure offtake agreements.

Technical Status and Challenges in Lifecycle Emissions

The global landscape of hydrogen-based synthetic fuels from green hydrogen is characterized by significant technological advancements but remains constrained by several critical challenges in lifecycle emissions management. Current assessments indicate that while green hydrogen production has achieved commercial-scale demonstrations in several regions, the comprehensive lifecycle emissions accounting remains inconsistent across different jurisdictions and production pathways.

Research from leading institutions including NREL, Fraunhofer Institute, and the International Energy Agency reveals that current green hydrogen production achieves carbon intensities ranging from 0.5-3 kg CO2e/kg H2 when powered by dedicated renewables, significantly lower than the 9-12 kg CO2e/kg H2 for natural gas-based production with carbon capture. However, these figures often exclude upstream emissions from manufacturing and installation of renewable energy infrastructure.

The synthesis processes for converting hydrogen to fuels (e.g., Fischer-Tropsch synthesis for synthetic diesel or Methanol-to-Gasoline processes) introduce additional emissions challenges. Current technical limitations result in conversion efficiency losses of 20-35%, substantially impacting the overall carbon footprint. The most advanced catalytic processes have demonstrated improvements but remain at technology readiness levels of 6-8, indicating gaps between demonstration and full commercial deployment.

Transportation and storage infrastructure represents another significant emissions source often underrepresented in lifecycle analyses. Compression, liquefaction, and transport of hydrogen can add 0.5-2 kg CO2e/kg H2 depending on distance and method. For synthetic fuels, existing fossil fuel infrastructure may be leveraged, though compatibility issues with certain materials persist.

Geographically, technological capabilities for accurate lifecycle assessment are concentrated in Europe, particularly Germany, Denmark, and the Netherlands, where regulatory frameworks have driven methodological development. The Asia-Pacific region, led by Japan and Australia, has focused on international hydrogen supply chains, revealing additional emissions challenges in long-distance transport scenarios.

A critical technical barrier remains the lack of standardized measurement protocols and real-time monitoring technologies for fugitive emissions throughout the production chain. Current methodologies rely heavily on estimation factors rather than direct measurement, creating significant uncertainty ranges in lifecycle assessments.

The integration of carbon capture technologies with synthetic fuel production processes presents both an opportunity and challenge, with current direct air capture technologies requiring 1.5-2 MWh of energy per ton of CO2 captured, potentially offsetting emissions benefits if not powered by additional renewable capacity.

Research from leading institutions including NREL, Fraunhofer Institute, and the International Energy Agency reveals that current green hydrogen production achieves carbon intensities ranging from 0.5-3 kg CO2e/kg H2 when powered by dedicated renewables, significantly lower than the 9-12 kg CO2e/kg H2 for natural gas-based production with carbon capture. However, these figures often exclude upstream emissions from manufacturing and installation of renewable energy infrastructure.

The synthesis processes for converting hydrogen to fuels (e.g., Fischer-Tropsch synthesis for synthetic diesel or Methanol-to-Gasoline processes) introduce additional emissions challenges. Current technical limitations result in conversion efficiency losses of 20-35%, substantially impacting the overall carbon footprint. The most advanced catalytic processes have demonstrated improvements but remain at technology readiness levels of 6-8, indicating gaps between demonstration and full commercial deployment.

Transportation and storage infrastructure represents another significant emissions source often underrepresented in lifecycle analyses. Compression, liquefaction, and transport of hydrogen can add 0.5-2 kg CO2e/kg H2 depending on distance and method. For synthetic fuels, existing fossil fuel infrastructure may be leveraged, though compatibility issues with certain materials persist.

Geographically, technological capabilities for accurate lifecycle assessment are concentrated in Europe, particularly Germany, Denmark, and the Netherlands, where regulatory frameworks have driven methodological development. The Asia-Pacific region, led by Japan and Australia, has focused on international hydrogen supply chains, revealing additional emissions challenges in long-distance transport scenarios.

A critical technical barrier remains the lack of standardized measurement protocols and real-time monitoring technologies for fugitive emissions throughout the production chain. Current methodologies rely heavily on estimation factors rather than direct measurement, creating significant uncertainty ranges in lifecycle assessments.

The integration of carbon capture technologies with synthetic fuel production processes presents both an opportunity and challenge, with current direct air capture technologies requiring 1.5-2 MWh of energy per ton of CO2 captured, potentially offsetting emissions benefits if not powered by additional renewable capacity.

Current Lifecycle Assessment Methodologies

01 Production methods for green hydrogen-based synthetic fuels

Various methods for producing synthetic fuels from green hydrogen are disclosed, focusing on renewable energy sources for hydrogen production. These methods include electrolysis powered by renewable electricity, thermochemical processes, and innovative catalytic systems that convert hydrogen and carbon dioxide into liquid fuels. The processes aim to create carbon-neutral or low-carbon synthetic fuels that can replace conventional fossil fuels while maintaining compatibility with existing infrastructure.- Production methods of green hydrogen for synthetic fuels: Various methods are employed to produce green hydrogen for synthetic fuel applications, primarily using renewable energy sources. These methods include water electrolysis powered by renewable electricity, biomass gasification, and innovative catalytic processes. The production techniques focus on minimizing carbon emissions during hydrogen generation, which is crucial for maintaining the environmental benefits of hydrogen-based synthetic fuels throughout their lifecycle.

- Conversion processes for hydrogen-based synthetic fuels: Hydrogen can be converted into various synthetic fuels through different chemical processes. These include Fischer-Tropsch synthesis for producing liquid hydrocarbons, methanation for synthetic natural gas, and methanol synthesis pathways. These conversion technologies transform green hydrogen into more easily transportable and storable energy carriers while maintaining lower lifecycle emissions compared to conventional fossil fuels when renewable hydrogen is used as feedstock.

- Lifecycle emission assessment and carbon footprint reduction: Comprehensive lifecycle assessment of hydrogen-based synthetic fuels evaluates emissions from production to end-use. Studies show that synthetic fuels produced from green hydrogen can achieve significant greenhouse gas reductions compared to conventional fuels. Key factors affecting lifecycle emissions include the source of electricity for hydrogen production, efficiency of conversion processes, and transportation methods. Carbon capture technologies can be integrated to further reduce the overall carbon footprint.

- Storage and distribution infrastructure for hydrogen-based fuels: Specialized infrastructure is required for the storage and distribution of hydrogen and hydrogen-based synthetic fuels. This includes high-pressure storage systems, cryogenic tanks for liquefied hydrogen, and pipeline networks adapted for hydrogen transport. The infrastructure design must address challenges related to hydrogen embrittlement, energy density, and safety considerations. Efficient storage and distribution systems are essential for minimizing energy losses and maintaining the lifecycle emission benefits of green hydrogen fuels.

- Integration with renewable energy systems and grid applications: Hydrogen-based synthetic fuel production can be integrated with renewable energy systems to provide grid balancing services and energy storage solutions. These integrated systems allow for the utilization of excess renewable electricity during peak production periods, converting it to hydrogen and subsequently to synthetic fuels. This approach enhances grid stability while enabling sector coupling between electricity, transportation, and industrial applications, maximizing the emission reduction potential across multiple sectors.

02 Lifecycle emissions assessment of hydrogen synthetic fuels

Comprehensive lifecycle emissions analyses of hydrogen-based synthetic fuels reveal significant reductions in greenhouse gas emissions compared to conventional fuels. These assessments consider emissions from hydrogen production, carbon capture, fuel synthesis, distribution, and end-use. When produced using renewable energy sources, these synthetic fuels can achieve near-zero or negative carbon footprints, especially when carbon capture technologies are integrated into the production process.Expand Specific Solutions03 Fuel cell applications for green hydrogen-derived fuels

Hydrogen-based synthetic fuels can be utilized in various fuel cell systems for efficient energy conversion with minimal emissions. These applications include stationary power generation, transportation, and portable devices. The fuel cells convert the chemical energy in synthetic fuels directly into electricity through electrochemical reactions, offering higher efficiency than conventional combustion methods and producing only water and heat as byproducts when pure hydrogen is used.Expand Specific Solutions04 Integration of carbon capture in synthetic fuel production

Carbon capture technologies are integrated into the production of hydrogen-based synthetic fuels to achieve carbon neutrality or negative emissions. These systems capture CO2 from industrial processes, direct air capture, or biomass sources, which is then combined with green hydrogen to produce synthetic hydrocarbons. This approach creates a circular carbon economy where carbon is recycled rather than adding new carbon to the atmosphere, significantly reducing the lifecycle emissions of the resulting fuels.Expand Specific Solutions05 Infrastructure and storage solutions for hydrogen-based fuels

Specialized infrastructure and storage solutions are developed for hydrogen-based synthetic fuels to address challenges related to hydrogen's low volumetric energy density and material compatibility issues. These innovations include advanced compression and liquefaction technologies, novel storage materials like metal hydrides, and infrastructure adaptations for safe handling and distribution. The solutions aim to enable efficient integration of hydrogen-based fuels into existing energy systems while minimizing energy losses and emissions throughout the supply chain.Expand Specific Solutions

Key Industry Players in Synthetic Fuel Production

The lifecycle emissions of hydrogen-based synthetic fuels from green hydrogen represent an emerging technological frontier currently in early commercial development stages. The market is experiencing rapid growth, projected to reach significant scale as decarbonization efforts intensify globally. From a technological maturity perspective, companies demonstrate varying capabilities: Air Liquide and Haldor Topsøe lead with established industrial hydrogen expertise; Hyundai, Kia, and Cummins are advancing transportation applications; while research institutions like Purdue Research Foundation and IIT Madras drive innovation. Chinese players including State Grid Shanghai and China Tianying are scaling up infrastructure, while specialized firms like Greyrock Energy and Synata Bio focus on conversion technologies. The competitive landscape reflects a fragmented market with players positioning across different segments of the value chain.

Air Liquide SA

Technical Solution: Air Liquide has developed comprehensive lifecycle assessment methodologies for hydrogen-based synthetic fuels production. Their approach integrates electrolysis powered by renewable energy sources to produce green hydrogen with near-zero carbon emissions. The company employs advanced carbon capture technologies coupled with direct air capture systems to source CO2 for synthetic fuel production, ensuring carbon neutrality across the entire value chain. Air Liquide's process optimization focuses on energy efficiency improvements in electrolysis (achieving 70-80% efficiency) and synthesis processes, reducing overall emissions by approximately 60-90% compared to conventional fossil fuels. Their integrated plant designs incorporate heat recovery systems that utilize waste heat from synthesis reactions to power other processes, further reducing the carbon footprint of synthetic fuel production.

Strengths: Extensive global infrastructure for hydrogen production and distribution; proprietary high-efficiency electrolysis technology; integrated approach to renewable energy sourcing. Weaknesses: High capital costs for green hydrogen production facilities; dependence on regional renewable energy availability; energy losses during multiple conversion steps in synthetic fuel production.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a comprehensive well-to-wheel lifecycle assessment framework for hydrogen-based synthetic fuels. Their approach focuses on e-fuel production using green hydrogen from renewable-powered electrolysis combined with captured CO2. Hyundai's proprietary catalyst technology enhances the Fischer-Tropsch synthesis process, achieving carbon conversion efficiencies of approximately 75-85%. Their lifecycle analysis demonstrates that synthetic fuels produced through their pathway can reduce greenhouse gas emissions by 70-80% compared to conventional fossil fuels. Hyundai has implemented a closed-loop water management system that recycles up to 95% of process water, significantly reducing the water footprint of synthetic fuel production. The company's integrated approach includes renewable energy sourcing strategies that optimize the use of surplus renewable electricity during off-peak periods, improving the overall carbon intensity of the produced fuels.

Strengths: Vertical integration capabilities from fuel production to vehicle applications; extensive experience with hydrogen fuel cell technology transferable to synthetic fuel production; strong partnerships with energy providers. Weaknesses: Limited commercial-scale production experience compared to established energy companies; higher production costs compared to conventional fuels; dependency on external CO2 capture technologies.

Critical Technologies for Emissions Reduction

Synthetic fuel and production method thereof

PatentPendingUS20240425760A1

Innovation

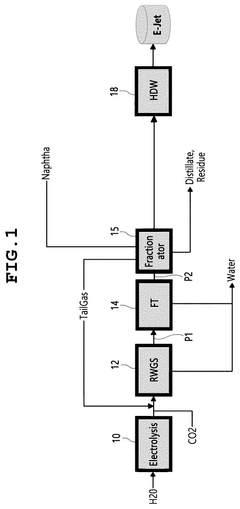

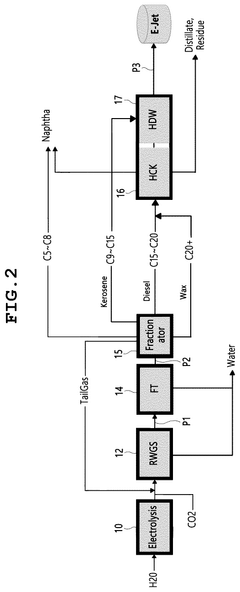

- A method involving the production of synthetic fuel from water and captured carbon dioxide, using green hydrogen generated through electrolysis and carbon capture, followed by a series of chemical reactions to produce synthesis gas, syncrude, and subsequently refining it into carbon-neutral aviation fuel with minimal aromatic content.

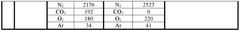

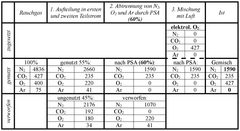

Green hydrogen, synthesis gas, and flue gas with a reduced nitrogen content for the synthesis of ammonia and urea

PatentWO2025125180A1

Innovation

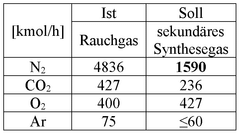

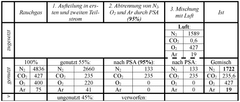

- The solution involves reducing the nitrogen content in the flue gas using less efficient but cost-effective methods such as pressure swing adsorption or temperature swing adsorption, and then compressing the N2-depleted flue gas with electrolytically produced oxygen to create a mixture that is fed into a secondary reformer, thereby providing the necessary carbon dioxide for urea synthesis without the need for complex flue gas scrubbing.

Regulatory Framework and Carbon Pricing Mechanisms

The regulatory landscape for hydrogen-based synthetic fuels is rapidly evolving as governments worldwide recognize the need to address lifecycle emissions. The European Union leads with its Renewable Energy Directive II (RED II) and the forthcoming RED III, which establish sustainability criteria specifically for renewable fuels of non-biological origin (RFNBOs). These directives mandate that green hydrogen-based synthetic fuels must achieve at least 70% greenhouse gas emission savings compared to fossil fuel alternatives to qualify for regulatory support.

In North America, the U.S. Inflation Reduction Act introduces production tax credits for clean hydrogen, with tiered incentives based on lifecycle carbon intensity. The lower the carbon footprint, the higher the available tax credit, creating a direct financial incentive for minimizing emissions throughout the production chain of synthetic fuels derived from green hydrogen.

Carbon pricing mechanisms play a crucial role in establishing economic viability for low-emission synthetic fuels. The EU Emissions Trading System (ETS) has been expanded to include maritime transport and potentially road transport sectors, directly affecting markets for synthetic fuels. Similarly, carbon border adjustment mechanisms are being implemented to prevent carbon leakage and ensure imported synthetic fuels meet domestic emission standards.

Certification schemes are emerging as essential tools for regulatory compliance. CertifHy in Europe and the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) are developing standardized methodologies to verify the carbon intensity of hydrogen and its derivatives. These certification frameworks enable regulators to implement accurate lifecycle assessment requirements for synthetic fuel producers.

Regional variations in regulatory approaches create significant challenges for global market development. While the EU focuses on strict lifecycle emissions criteria, countries like Japan and South Korea emphasize technology neutrality and security of supply in their hydrogen strategies. This regulatory fragmentation necessitates harmonization efforts to facilitate international trade in synthetic fuels.

The integration of carbon accounting across sectors represents another regulatory frontier. As synthetic fuels cross traditional industry boundaries—from electricity to chemical production to transportation—regulators are developing more sophisticated frameworks to track emissions across these interconnected value chains, preventing double-counting and ensuring environmental integrity in carbon reduction claims.

In North America, the U.S. Inflation Reduction Act introduces production tax credits for clean hydrogen, with tiered incentives based on lifecycle carbon intensity. The lower the carbon footprint, the higher the available tax credit, creating a direct financial incentive for minimizing emissions throughout the production chain of synthetic fuels derived from green hydrogen.

Carbon pricing mechanisms play a crucial role in establishing economic viability for low-emission synthetic fuels. The EU Emissions Trading System (ETS) has been expanded to include maritime transport and potentially road transport sectors, directly affecting markets for synthetic fuels. Similarly, carbon border adjustment mechanisms are being implemented to prevent carbon leakage and ensure imported synthetic fuels meet domestic emission standards.

Certification schemes are emerging as essential tools for regulatory compliance. CertifHy in Europe and the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) are developing standardized methodologies to verify the carbon intensity of hydrogen and its derivatives. These certification frameworks enable regulators to implement accurate lifecycle assessment requirements for synthetic fuel producers.

Regional variations in regulatory approaches create significant challenges for global market development. While the EU focuses on strict lifecycle emissions criteria, countries like Japan and South Korea emphasize technology neutrality and security of supply in their hydrogen strategies. This regulatory fragmentation necessitates harmonization efforts to facilitate international trade in synthetic fuels.

The integration of carbon accounting across sectors represents another regulatory frontier. As synthetic fuels cross traditional industry boundaries—from electricity to chemical production to transportation—regulators are developing more sophisticated frameworks to track emissions across these interconnected value chains, preventing double-counting and ensuring environmental integrity in carbon reduction claims.

Energy Efficiency Comparison with Alternative Fuel Pathways

When comparing the energy efficiency of hydrogen-based synthetic fuels with alternative fuel pathways, it is essential to consider the entire energy conversion chain from primary energy to final use. Green hydrogen-based synthetic fuels typically demonstrate lower overall energy efficiency compared to direct electrification pathways due to multiple conversion steps involved in their production.

The well-to-wheel efficiency of hydrogen-based synthetic fuels ranges between 13-20% for synthetic liquid fuels (e-fuels) and 25-35% for hydrogen fuel cell applications. In contrast, battery electric vehicles achieve 70-80% efficiency in the electricity-to-motion conversion chain. This significant efficiency gap represents one of the primary challenges for synthetic fuel adoption in sectors where direct electrification is feasible.

For aviation and maritime applications where direct electrification faces limitations, synthetic fuels derived from green hydrogen present competitive efficiency metrics compared to other low-carbon alternatives. When compared to biofuels, synthetic fuels offer higher land-use efficiency, producing 5-10 times more fuel per hectare equivalent. However, biofuels generally require less energy input per unit of fuel produced when feedstock availability is not constrained.

Power-to-X pathways that convert electricity to hydrogen and then to various carriers (ammonia, methanol, synthetic hydrocarbons) show varying efficiency profiles. Ammonia synthesis from green hydrogen achieves 50-60% energy retention, while Fischer-Tropsch processes for synthetic hydrocarbon production retain only 40-50% of the initial energy input. These efficiency losses must be weighed against the advantages of higher energy density and compatibility with existing infrastructure.

In hard-to-abate sectors like steel production, hydrogen direct reduction pathways demonstrate 30-40% higher energy efficiency compared to conventional coal-based processes when considering total lifecycle emissions. Similarly, in high-temperature industrial heating applications, hydrogen combustion offers efficiency advantages over electrification in certain temperature ranges above 500°C.

The temporal dimension of efficiency must also be considered. While battery storage systems experience efficiency losses of 10-15% during charge-discharge cycles, hydrogen storage and reconversion can lose 60-70% of the original energy. However, hydrogen and synthetic fuels offer seasonal storage capabilities that batteries cannot match, providing system-level efficiency benefits in energy systems with high renewable penetration requiring long-duration storage.

The well-to-wheel efficiency of hydrogen-based synthetic fuels ranges between 13-20% for synthetic liquid fuels (e-fuels) and 25-35% for hydrogen fuel cell applications. In contrast, battery electric vehicles achieve 70-80% efficiency in the electricity-to-motion conversion chain. This significant efficiency gap represents one of the primary challenges for synthetic fuel adoption in sectors where direct electrification is feasible.

For aviation and maritime applications where direct electrification faces limitations, synthetic fuels derived from green hydrogen present competitive efficiency metrics compared to other low-carbon alternatives. When compared to biofuels, synthetic fuels offer higher land-use efficiency, producing 5-10 times more fuel per hectare equivalent. However, biofuels generally require less energy input per unit of fuel produced when feedstock availability is not constrained.

Power-to-X pathways that convert electricity to hydrogen and then to various carriers (ammonia, methanol, synthetic hydrocarbons) show varying efficiency profiles. Ammonia synthesis from green hydrogen achieves 50-60% energy retention, while Fischer-Tropsch processes for synthetic hydrocarbon production retain only 40-50% of the initial energy input. These efficiency losses must be weighed against the advantages of higher energy density and compatibility with existing infrastructure.

In hard-to-abate sectors like steel production, hydrogen direct reduction pathways demonstrate 30-40% higher energy efficiency compared to conventional coal-based processes when considering total lifecycle emissions. Similarly, in high-temperature industrial heating applications, hydrogen combustion offers efficiency advantages over electrification in certain temperature ranges above 500°C.

The temporal dimension of efficiency must also be considered. While battery storage systems experience efficiency losses of 10-15% during charge-discharge cycles, hydrogen storage and reconversion can lose 60-70% of the original energy. However, hydrogen and synthetic fuels offer seasonal storage capabilities that batteries cannot match, providing system-level efficiency benefits in energy systems with high renewable penetration requiring long-duration storage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!