Measure Environmental Impact of Direct Lithium Extraction Techniques

SEP 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technologies have emerged as a revolutionary approach to lithium production, representing a significant departure from traditional extraction methods that have dominated the industry for decades. The evolution of lithium extraction techniques began with conventional methods such as solar evaporation from salt flats (salars) and hard-rock mining, both of which present considerable environmental challenges including extensive water consumption, land disturbance, and chemical pollution.

The development of DLE technologies gained momentum in the early 2000s as global demand for lithium surged due to the rapid expansion of the electric vehicle market and portable electronics industry. This growing demand highlighted the limitations of conventional extraction methods, particularly their environmental footprint and inefficiency in resource utilization, prompting research into more sustainable alternatives.

DLE encompasses a diverse range of innovative techniques including adsorption, ion exchange, solvent extraction, and membrane processes, all designed to selectively extract lithium from brines with greater efficiency and reduced environmental impact. These technologies aim to address the critical shortcomings of traditional methods by significantly reducing water consumption, minimizing land disturbance, accelerating production timelines, and improving recovery rates.

The technical objectives of measuring the environmental impact of DLE techniques are multifaceted and essential for sustainable industry development. Primary objectives include quantifying water usage efficiency compared to conventional methods, with DLE potentially reducing water consumption by up to 90%. Additionally, researchers aim to assess land footprint reduction, as DLE facilities require substantially less surface area than evaporation ponds.

Energy consumption measurement represents another crucial objective, as some DLE processes require significant energy inputs that must be balanced against their environmental benefits. Comprehensive lifecycle assessment of chemical usage and waste generation is also vital to ensure that new extraction methods do not simply shift environmental burdens to different areas.

Carbon footprint analysis forms a central component of environmental impact measurement, particularly as the lithium industry faces increasing pressure to align with global decarbonization efforts. This includes evaluating both direct emissions from operations and indirect emissions from energy sources powering DLE facilities.

The technological trajectory suggests continued refinement of DLE methods, with increasing focus on developing standardized metrics and methodologies for environmental impact assessment. This standardization will be essential for meaningful comparison between different extraction technologies and for establishing industry benchmarks that can guide sustainable development in this rapidly evolving sector.

The development of DLE technologies gained momentum in the early 2000s as global demand for lithium surged due to the rapid expansion of the electric vehicle market and portable electronics industry. This growing demand highlighted the limitations of conventional extraction methods, particularly their environmental footprint and inefficiency in resource utilization, prompting research into more sustainable alternatives.

DLE encompasses a diverse range of innovative techniques including adsorption, ion exchange, solvent extraction, and membrane processes, all designed to selectively extract lithium from brines with greater efficiency and reduced environmental impact. These technologies aim to address the critical shortcomings of traditional methods by significantly reducing water consumption, minimizing land disturbance, accelerating production timelines, and improving recovery rates.

The technical objectives of measuring the environmental impact of DLE techniques are multifaceted and essential for sustainable industry development. Primary objectives include quantifying water usage efficiency compared to conventional methods, with DLE potentially reducing water consumption by up to 90%. Additionally, researchers aim to assess land footprint reduction, as DLE facilities require substantially less surface area than evaporation ponds.

Energy consumption measurement represents another crucial objective, as some DLE processes require significant energy inputs that must be balanced against their environmental benefits. Comprehensive lifecycle assessment of chemical usage and waste generation is also vital to ensure that new extraction methods do not simply shift environmental burdens to different areas.

Carbon footprint analysis forms a central component of environmental impact measurement, particularly as the lithium industry faces increasing pressure to align with global decarbonization efforts. This includes evaluating both direct emissions from operations and indirect emissions from energy sources powering DLE facilities.

The technological trajectory suggests continued refinement of DLE methods, with increasing focus on developing standardized metrics and methodologies for environmental impact assessment. This standardization will be essential for meaningful comparison between different extraction technologies and for establishing industry benchmarks that can guide sustainable development in this rapidly evolving sector.

Market Demand Analysis for Sustainable Lithium

The global lithium market is experiencing unprecedented growth driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Annual demand for lithium is projected to increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030, representing a compound annual growth rate of 25%. This exponential growth trajectory has created significant pressure on traditional lithium extraction methods, which are increasingly scrutinized for their environmental impacts.

Sustainability has become a critical market differentiator in the lithium supply chain. Major automotive manufacturers, including Tesla, Volkswagen, and BMW, have publicly committed to sourcing materials with reduced environmental footprints. These companies are willing to pay premium prices for lithium produced through environmentally responsible methods, creating a distinct market segment for sustainable lithium products.

Consumer awareness regarding the environmental impact of battery production has risen substantially, with 68% of consumers in developed markets expressing preference for products manufactured with sustainable materials. This shift in consumer behavior is compelling battery manufacturers to prioritize environmentally responsible sourcing practices, further driving demand for sustainable lithium extraction technologies.

Regulatory frameworks worldwide are evolving to mandate stricter environmental standards for mining operations. The European Union's proposed Battery Regulation includes requirements for carbon footprint declarations and responsible sourcing of raw materials. Similarly, the United States has classified lithium as a critical mineral, emphasizing the need for domestic production with stringent environmental safeguards.

Investment in sustainable lithium extraction technologies has surged, with venture capital funding in this sector reaching record levels. Direct Lithium Extraction (DLE) technologies, which promise reduced water consumption and land disturbance compared to traditional methods, have attracted significant investment interest. Market analysts estimate that DLE methods could capture up to 25% of global lithium production by 2030.

The geographical distribution of lithium demand is expanding beyond traditional markets. While China remains the largest consumer of lithium for battery production, emerging markets in India, Southeast Asia, and Eastern Europe are experiencing rapid growth in demand. This geographical diversification creates opportunities for new production centers utilizing sustainable extraction technologies closer to end markets.

Energy transition policies worldwide are accelerating the deployment of renewable energy storage systems, creating additional demand for lithium beyond the EV sector. Grid-scale energy storage installations are projected to increase tenfold by 2030, further straining lithium supply chains and emphasizing the need for sustainable production methods that can scale to meet this growing demand.

Sustainability has become a critical market differentiator in the lithium supply chain. Major automotive manufacturers, including Tesla, Volkswagen, and BMW, have publicly committed to sourcing materials with reduced environmental footprints. These companies are willing to pay premium prices for lithium produced through environmentally responsible methods, creating a distinct market segment for sustainable lithium products.

Consumer awareness regarding the environmental impact of battery production has risen substantially, with 68% of consumers in developed markets expressing preference for products manufactured with sustainable materials. This shift in consumer behavior is compelling battery manufacturers to prioritize environmentally responsible sourcing practices, further driving demand for sustainable lithium extraction technologies.

Regulatory frameworks worldwide are evolving to mandate stricter environmental standards for mining operations. The European Union's proposed Battery Regulation includes requirements for carbon footprint declarations and responsible sourcing of raw materials. Similarly, the United States has classified lithium as a critical mineral, emphasizing the need for domestic production with stringent environmental safeguards.

Investment in sustainable lithium extraction technologies has surged, with venture capital funding in this sector reaching record levels. Direct Lithium Extraction (DLE) technologies, which promise reduced water consumption and land disturbance compared to traditional methods, have attracted significant investment interest. Market analysts estimate that DLE methods could capture up to 25% of global lithium production by 2030.

The geographical distribution of lithium demand is expanding beyond traditional markets. While China remains the largest consumer of lithium for battery production, emerging markets in India, Southeast Asia, and Eastern Europe are experiencing rapid growth in demand. This geographical diversification creates opportunities for new production centers utilizing sustainable extraction technologies closer to end markets.

Energy transition policies worldwide are accelerating the deployment of renewable energy storage systems, creating additional demand for lithium beyond the EV sector. Grid-scale energy storage installations are projected to increase tenfold by 2030, further straining lithium supply chains and emphasizing the need for sustainable production methods that can scale to meet this growing demand.

Current State and Environmental Challenges of DLE

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives to traditional lithium extraction methods, which primarily rely on evaporation ponds. Currently, DLE technologies are at various stages of development and commercialization, with several pilot projects operational worldwide. These technologies utilize diverse approaches including adsorption, ion exchange, solvent extraction, and membrane processes to selectively extract lithium from brines with higher recovery rates and reduced processing time compared to conventional methods.

Despite their potential advantages, DLE technologies face significant environmental challenges that require comprehensive assessment. Water usage remains a critical concern, as many DLE processes require substantial amounts of fresh water for operation, particularly in the regeneration phases of adsorption and ion exchange systems. This creates considerable pressure on water resources, especially in arid regions where lithium reserves are often located, such as the "Lithium Triangle" spanning Argentina, Bolivia, and Chile.

Energy consumption presents another substantial environmental challenge. Most DLE technologies require significant energy inputs for pumping, heating, and processing solutions. The carbon footprint associated with this energy consumption varies widely depending on the energy sources utilized, potentially undermining the environmental benefits of lithium-based clean energy technologies if powered by fossil fuels.

Chemical usage in DLE processes introduces additional environmental risks. Various reagents, including acids, bases, and solvents used in extraction and regeneration steps, can lead to potential contamination if not properly managed. The disposal and treatment of these chemicals require careful consideration to prevent soil and groundwater pollution in surrounding ecosystems.

Waste management represents a growing concern as DLE technologies scale up. The processes generate various waste streams, including spent adsorbents, membranes, and brine effluents with altered chemical compositions. These waste products may contain concentrated levels of potentially harmful elements such as boron, arsenic, and heavy metals naturally present in brines.

Land disturbance from DLE operations, while generally less extensive than evaporation ponds, still impacts local ecosystems. Infrastructure requirements including wells, processing facilities, and transportation networks can fragment habitats and disrupt wildlife corridors in sensitive areas.

Monitoring and quantification methodologies for these environmental impacts remain inconsistent across the industry. Current assessment approaches vary widely in scope and rigor, with limited standardization of metrics and measurement protocols. This inconsistency hampers meaningful comparisons between different DLE technologies and traditional extraction methods, creating challenges for regulators, investors, and companies seeking to identify truly sustainable lithium production pathways.

Despite their potential advantages, DLE technologies face significant environmental challenges that require comprehensive assessment. Water usage remains a critical concern, as many DLE processes require substantial amounts of fresh water for operation, particularly in the regeneration phases of adsorption and ion exchange systems. This creates considerable pressure on water resources, especially in arid regions where lithium reserves are often located, such as the "Lithium Triangle" spanning Argentina, Bolivia, and Chile.

Energy consumption presents another substantial environmental challenge. Most DLE technologies require significant energy inputs for pumping, heating, and processing solutions. The carbon footprint associated with this energy consumption varies widely depending on the energy sources utilized, potentially undermining the environmental benefits of lithium-based clean energy technologies if powered by fossil fuels.

Chemical usage in DLE processes introduces additional environmental risks. Various reagents, including acids, bases, and solvents used in extraction and regeneration steps, can lead to potential contamination if not properly managed. The disposal and treatment of these chemicals require careful consideration to prevent soil and groundwater pollution in surrounding ecosystems.

Waste management represents a growing concern as DLE technologies scale up. The processes generate various waste streams, including spent adsorbents, membranes, and brine effluents with altered chemical compositions. These waste products may contain concentrated levels of potentially harmful elements such as boron, arsenic, and heavy metals naturally present in brines.

Land disturbance from DLE operations, while generally less extensive than evaporation ponds, still impacts local ecosystems. Infrastructure requirements including wells, processing facilities, and transportation networks can fragment habitats and disrupt wildlife corridors in sensitive areas.

Monitoring and quantification methodologies for these environmental impacts remain inconsistent across the industry. Current assessment approaches vary widely in scope and rigor, with limited standardization of metrics and measurement protocols. This inconsistency hampers meaningful comparisons between different DLE technologies and traditional extraction methods, creating challenges for regulators, investors, and companies seeking to identify truly sustainable lithium production pathways.

Current DLE Technical Solutions Assessment

01 Water conservation in direct lithium extraction

Direct lithium extraction techniques that focus on water conservation have been developed to minimize environmental impact. These methods reduce water consumption compared to traditional evaporation pond techniques, which is particularly important in water-scarce regions where lithium deposits are often found. Advanced filtration systems and closed-loop water recycling processes help to significantly decrease freshwater usage while maintaining extraction efficiency.- Water usage and conservation in direct lithium extraction: Direct lithium extraction techniques have varying impacts on water resources. Some methods significantly reduce water consumption compared to traditional evaporation ponds, while others implement water recycling systems to minimize environmental impact. Advanced technologies focus on closed-loop systems that treat and reuse process water, addressing concerns about water scarcity in lithium-rich regions. These conservation approaches are particularly important in arid areas where lithium extraction competes with agricultural and community water needs.

- Land use and habitat disruption reduction: Modern direct lithium extraction methods significantly reduce land footprint compared to traditional evaporation pond techniques. These advanced processes require less surface area, minimizing habitat disruption and preserving biodiversity in sensitive ecosystems. By utilizing more compact extraction facilities, these technologies help preserve natural landscapes and reduce the overall environmental impact of lithium mining operations, particularly in ecologically sensitive areas where lithium resources are abundant.

- Chemical usage and waste management: Direct lithium extraction techniques involve various chemicals that can potentially impact the environment. Innovations focus on developing more environmentally friendly solvents and adsorbents, reducing toxic chemical usage, and implementing effective waste treatment systems. These approaches include biodegradable reagents, selective ion exchange materials, and closed-loop chemical recycling processes that minimize discharge of harmful substances into surrounding ecosystems. Proper waste management protocols are essential to prevent soil and groundwater contamination.

- Energy efficiency and carbon footprint reduction: Energy consumption is a significant environmental concern in lithium extraction processes. Recent innovations focus on reducing the carbon footprint through renewable energy integration, process optimization, and heat recovery systems. Some techniques utilize geothermal energy or solar power to drive extraction processes, while others implement energy-efficient equipment and advanced control systems to minimize electricity consumption. These improvements help address climate change concerns associated with lithium production for clean energy technologies.

- Brine restoration and ecosystem protection: After lithium extraction, the management and restoration of brine resources is crucial for environmental sustainability. Advanced techniques focus on maintaining hydrogeological balance by reinjecting treated brine back into aquifers, monitoring groundwater quality, and implementing ecosystem protection measures. These approaches help preserve the chemical composition of brine resources, prevent subsidence, and protect surrounding ecosystems from disruption. Long-term monitoring systems track environmental impacts and enable adaptive management strategies.

02 Reduction of chemical reagent usage

Innovative direct lithium extraction techniques aim to reduce the environmental footprint by minimizing chemical reagent usage. These approaches employ selective adsorption materials and ion exchange technologies that require fewer harsh chemicals compared to conventional methods. By decreasing chemical consumption, these techniques reduce potential soil and water contamination while also lowering the carbon footprint associated with chemical production and transportation.Expand Specific Solutions03 Land use optimization and habitat preservation

Environmental impact mitigation in direct lithium extraction focuses on land use optimization and habitat preservation. Unlike traditional evaporation ponds that require vast land areas, modern extraction facilities utilize compact equipment and vertical integration to minimize surface disturbance. These approaches help preserve natural habitats, reduce ecosystem fragmentation, and maintain biodiversity in lithium-rich regions while still enabling efficient resource extraction.Expand Specific Solutions04 Energy efficiency and carbon footprint reduction

Advanced direct lithium extraction techniques incorporate energy-efficient processes to reduce carbon emissions. These methods utilize renewable energy sources, heat recovery systems, and optimized extraction cycles to minimize energy consumption. Some innovations include low-temperature extraction processes and energy-efficient separation technologies that significantly reduce the carbon footprint compared to conventional lithium production methods, contributing to more sustainable mining practices.Expand Specific Solutions05 Waste management and byproduct utilization

Environmental impact reduction in direct lithium extraction involves comprehensive waste management strategies and byproduct utilization. These techniques focus on minimizing waste generation through selective extraction processes and implementing effective treatment methods for residual materials. Additionally, valuable byproducts such as magnesium, calcium, and potassium compounds can be recovered and commercialized, creating a more circular economy approach to lithium production while reducing overall environmental impact.Expand Specific Solutions

Key Industry Players in DLE Development

The direct lithium extraction (DLE) technology market is in an early growth phase, characterized by rapid innovation and increasing competition among established energy companies and emerging specialists. Key players like Schlumberger, Koch Technology Solutions, and Saudi Aramco are leveraging their industrial expertise, while innovative startups such as Watercycle Technologies, Evove, and Li Industries are developing novel extraction methods with reduced environmental footprints. Academic institutions including MIT, Tsinghua University, and The University of Manchester are contributing significant research. The market is projected to grow substantially as demand for lithium increases for electric vehicle batteries, with companies focusing on developing technologies that minimize water usage, reduce land disturbance, and lower carbon emissions compared to traditional extraction methods.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed NeoLith Energy, an advanced direct lithium extraction (DLE) technology that significantly reduces environmental impact compared to traditional evaporation methods. Their process utilizes selective adsorption materials that can extract lithium from brine without extensive evaporation ponds, reducing water consumption by up to 85% compared to conventional methods. The technology employs a closed-loop system where brine is returned to its source after lithium extraction, minimizing disruption to local hydrology. Schlumberger's approach also reduces the physical footprint by approximately 65% versus traditional operations, requiring less land disturbance. Their process can be completed in weeks rather than the 18+ months needed for evaporation ponds, allowing for more responsive production scaling while maintaining environmental monitoring through integrated sensor networks that track water usage, emissions, and energy consumption in real-time.

Strengths: Significantly reduced water consumption, smaller physical footprint, faster extraction timeframe, and closed-loop system that returns brine to source. Weaknesses: Higher initial capital expenditure requirements, increased energy consumption for the extraction process, and potential challenges with scaling the technology to match the output volumes of traditional methods.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed a proprietary ion exchange-based Direct Lithium Extraction (DLE) technology that focuses on minimizing environmental impact while maximizing lithium recovery efficiency. Their system employs specialized ion-selective adsorbents that can extract lithium from various brine sources with minimal pre-treatment requirements. The technology operates on a continuous flow process that reduces water consumption by approximately 90% compared to traditional evaporation methods. Koch's approach incorporates water recycling systems that recover and reuse process water, further reducing freshwater demands. Their DLE technology also features modular design elements that allow for scalable implementation with a significantly reduced land footprint—up to 70% smaller than conventional evaporation pond operations. The process utilizes energy recovery systems to minimize overall energy consumption, with reported reductions of 30-40% compared to other DLE technologies. Koch has implemented comprehensive environmental monitoring protocols that track water quality parameters, energy usage, and potential contaminant releases throughout the extraction process.

Strengths: Highly selective ion exchange technology with minimal chemical consumption, significant water conservation through recycling systems, modular and scalable design with reduced land requirements, and integrated energy recovery systems. Weaknesses: Potentially higher operational complexity requiring specialized technical expertise, higher initial capital costs compared to traditional methods, and possible challenges with adsorbent regeneration and lifespan in varied brine chemistries.

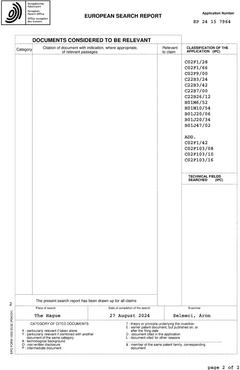

Critical Patents and Innovations in DLE Methods

Process for selective purification of lithium from an aqueous lithium salt-containing solution

PatentPendingEP4442343A1

Innovation

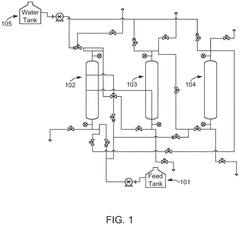

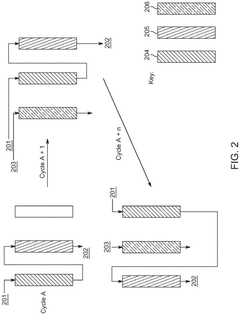

- Configuring columns in a carousel or lead-lag configuration with three or more packed-bed columns, where at least two are at adsorption stages and one at a desorption stage, allowing direct transitions without intermediate washing stages, to maximize uptime and reduce cycle time.

process

PatentWO2025106417A1

Innovation

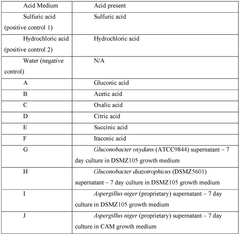

- The use of an acid medium comprising organic acids with a lowest pKa value of at least 4 or dicarboxylic acids with 3 or more carbon atoms and a lowest pKa value of at least 3.5 for desorbing lithium from adsorbents, which minimizes adsorbent damage and allows for environmentally friendly production of these acids through microorganisms.

Water Resource Impact and Management Strategies

Direct Lithium Extraction (DLE) techniques have significant implications for water resources, requiring comprehensive assessment and management strategies. The water footprint of DLE operations varies considerably depending on the specific technology employed, with some methods consuming between 50-150 gallons of water per kilogram of lithium produced, substantially lower than traditional evaporation pond methods that may require up to 500,000 gallons per ton.

Water quality impacts present another critical concern, as DLE processes may introduce chemical additives that potentially contaminate groundwater systems if not properly managed. These chemicals, including solvents, ion exchange resins, and membrane fouling agents, require careful handling and treatment protocols to prevent environmental degradation. Additionally, the extraction process may alter the hydrogeological balance of aquifers, particularly in water-stressed regions like the Lithium Triangle spanning Chile, Argentina, and Bolivia.

Effective water management strategies must incorporate closed-loop water recycling systems that can recover up to 90% of process water, significantly reducing freshwater withdrawal requirements. Such systems typically employ multi-stage filtration, reverse osmosis, and advanced oxidation processes to treat and recirculate water within the extraction facility. Implementation of these technologies can reduce net water consumption by 60-80% compared to conventional approaches.

Real-time monitoring networks represent another essential component of water resource management for DLE operations. These systems utilize sensor arrays to continuously track water quality parameters, flow rates, and aquifer levels, enabling rapid response to potential contamination events or unsustainable withdrawal patterns. Leading DLE projects have demonstrated that integrated monitoring systems can detect anomalies within minutes, allowing for immediate corrective action.

Regulatory frameworks and community engagement form the foundation of responsible water stewardship in lithium extraction. Progressive operators have established water management committees that include local stakeholders, indigenous representatives, and environmental experts to ensure transparent decision-making and equitable resource allocation. These collaborative governance models have proven effective in balancing economic development with ecological preservation.

Future-focused water management approaches increasingly incorporate predictive modeling and climate change adaptation strategies. Advanced hydrogeological simulations can forecast long-term impacts of extraction activities under various climate scenarios, enabling proactive adjustment of operations to maintain sustainable water balances. These forward-looking approaches will be essential as the lithium industry expands to meet growing demand from the electric vehicle and energy storage sectors.

Water quality impacts present another critical concern, as DLE processes may introduce chemical additives that potentially contaminate groundwater systems if not properly managed. These chemicals, including solvents, ion exchange resins, and membrane fouling agents, require careful handling and treatment protocols to prevent environmental degradation. Additionally, the extraction process may alter the hydrogeological balance of aquifers, particularly in water-stressed regions like the Lithium Triangle spanning Chile, Argentina, and Bolivia.

Effective water management strategies must incorporate closed-loop water recycling systems that can recover up to 90% of process water, significantly reducing freshwater withdrawal requirements. Such systems typically employ multi-stage filtration, reverse osmosis, and advanced oxidation processes to treat and recirculate water within the extraction facility. Implementation of these technologies can reduce net water consumption by 60-80% compared to conventional approaches.

Real-time monitoring networks represent another essential component of water resource management for DLE operations. These systems utilize sensor arrays to continuously track water quality parameters, flow rates, and aquifer levels, enabling rapid response to potential contamination events or unsustainable withdrawal patterns. Leading DLE projects have demonstrated that integrated monitoring systems can detect anomalies within minutes, allowing for immediate corrective action.

Regulatory frameworks and community engagement form the foundation of responsible water stewardship in lithium extraction. Progressive operators have established water management committees that include local stakeholders, indigenous representatives, and environmental experts to ensure transparent decision-making and equitable resource allocation. These collaborative governance models have proven effective in balancing economic development with ecological preservation.

Future-focused water management approaches increasingly incorporate predictive modeling and climate change adaptation strategies. Advanced hydrogeological simulations can forecast long-term impacts of extraction activities under various climate scenarios, enabling proactive adjustment of operations to maintain sustainable water balances. These forward-looking approaches will be essential as the lithium industry expands to meet growing demand from the electric vehicle and energy storage sectors.

Regulatory Compliance and ESG Considerations

The regulatory landscape surrounding Direct Lithium Extraction (DLE) technologies is rapidly evolving as governments worldwide recognize the strategic importance of lithium resources and the environmental implications of their extraction. Companies operating in this space must navigate complex regulatory frameworks that vary significantly across jurisdictions, with particular attention to water usage permits, land access rights, and waste disposal regulations. In the United States, the Environmental Protection Agency (EPA) has established specific guidelines for groundwater protection that directly impact DLE operations, while the European Union's more stringent environmental standards require comprehensive environmental impact assessments before project approval.

Environmental, Social, and Governance (ESG) considerations have become increasingly central to lithium extraction projects, with investors and stakeholders demanding transparent reporting on sustainability metrics. Leading lithium producers are now publishing annual sustainability reports that detail water consumption rates, carbon emissions, and land disturbance metrics associated with their DLE operations. These reports typically follow established frameworks such as the Global Reporting Initiative (GRI) or the Sustainability Accounting Standards Board (SASB) guidelines, providing standardized metrics for comparison across the industry.

Community engagement represents another critical dimension of ESG compliance for DLE projects. Companies must establish meaningful consultation processes with local communities, particularly indigenous populations with historical connections to lithium-rich regions. Several high-profile projects have faced significant delays due to inadequate community engagement strategies, highlighting the business case for robust social license to operate practices. Best practices in this area include early stakeholder mapping, transparent benefit-sharing agreements, and ongoing dialogue throughout the project lifecycle.

Carbon footprint considerations are gaining prominence in regulatory frameworks, with several jurisdictions implementing carbon pricing mechanisms that directly impact the economics of DLE operations. Life cycle assessment (LCA) studies indicate that while DLE technologies generally have lower carbon emissions than traditional evaporation pond methods, the energy intensity of certain DLE processes remains a concern. Forward-thinking companies are addressing this by incorporating renewable energy sources into their operations, with some projects in Chile and Australia now powered predominantly by solar energy.

Water stewardship represents perhaps the most scrutinized aspect of DLE operations from a regulatory perspective. Regulators in water-stressed regions are implementing increasingly stringent requirements for water recycling and reuse, with some jurisdictions mandating minimum recycling rates exceeding 80%. Companies that can demonstrate closed-loop water systems with minimal freshwater consumption gain significant advantages in permitting processes and community acceptance. Industry leaders are responding by developing innovative water treatment technologies specifically designed for the unique chemistry of lithium brines.

Environmental, Social, and Governance (ESG) considerations have become increasingly central to lithium extraction projects, with investors and stakeholders demanding transparent reporting on sustainability metrics. Leading lithium producers are now publishing annual sustainability reports that detail water consumption rates, carbon emissions, and land disturbance metrics associated with their DLE operations. These reports typically follow established frameworks such as the Global Reporting Initiative (GRI) or the Sustainability Accounting Standards Board (SASB) guidelines, providing standardized metrics for comparison across the industry.

Community engagement represents another critical dimension of ESG compliance for DLE projects. Companies must establish meaningful consultation processes with local communities, particularly indigenous populations with historical connections to lithium-rich regions. Several high-profile projects have faced significant delays due to inadequate community engagement strategies, highlighting the business case for robust social license to operate practices. Best practices in this area include early stakeholder mapping, transparent benefit-sharing agreements, and ongoing dialogue throughout the project lifecycle.

Carbon footprint considerations are gaining prominence in regulatory frameworks, with several jurisdictions implementing carbon pricing mechanisms that directly impact the economics of DLE operations. Life cycle assessment (LCA) studies indicate that while DLE technologies generally have lower carbon emissions than traditional evaporation pond methods, the energy intensity of certain DLE processes remains a concern. Forward-thinking companies are addressing this by incorporating renewable energy sources into their operations, with some projects in Chile and Australia now powered predominantly by solar energy.

Water stewardship represents perhaps the most scrutinized aspect of DLE operations from a regulatory perspective. Regulators in water-stressed regions are implementing increasingly stringent requirements for water recycling and reuse, with some jurisdictions mandating minimum recycling rates exceeding 80%. Companies that can demonstrate closed-loop water systems with minimal freshwater consumption gain significant advantages in permitting processes and community acceptance. Industry leaders are responding by developing innovative water treatment technologies specifically designed for the unique chemistry of lithium brines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!