Microfluidic ELISA for Environmental Pollutant Detection

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic ELISA Technology Background and Objectives

Microfluidic ELISA technology represents a significant advancement in analytical methods for environmental pollutant detection, evolving from traditional Enzyme-Linked Immunosorbent Assay (ELISA) techniques first developed in the 1970s. This miniaturized platform integrates the sensitivity and specificity of conventional ELISA with the advantages of microfluidic systems, including reduced sample volumes, faster reaction kinetics, and potential for automation and portability.

The evolution of this technology has been driven by increasing environmental concerns and regulatory requirements for monitoring pollutants in various matrices including water, soil, and air. Traditional detection methods often require sophisticated laboratory equipment, trained personnel, and considerable time for sample processing and analysis, creating barriers for real-time environmental monitoring and rapid response to contamination events.

Microfluidic ELISA systems have progressed through several developmental phases, beginning with simple channel designs for proof-of-concept demonstrations, advancing to more complex integrated systems incorporating sample preparation, reaction chambers, and detection components. Recent innovations have focused on materials science advancements, surface chemistry modifications, and signal amplification strategies to enhance sensitivity and specificity.

The primary objective of current microfluidic ELISA development for environmental applications is to create field-deployable systems capable of detecting multiple pollutants simultaneously at environmentally relevant concentrations. These systems aim to provide real-time or near-real-time monitoring capabilities while maintaining laboratory-grade analytical performance. Specific technical goals include achieving detection limits that meet or exceed regulatory requirements, developing robust platforms resistant to environmental interferences, and creating user-friendly interfaces that enable operation by non-specialists.

Additional objectives include reducing manufacturing costs to enable widespread deployment, particularly in resource-limited settings, and developing sustainable designs that minimize reagent consumption and waste generation. The integration of microfluidic ELISA with digital technologies for data acquisition, processing, and transmission represents another important development trajectory, supporting the creation of networked environmental monitoring systems.

The convergence of advances in microfluidics, immunoassay chemistry, materials science, and digital technologies is creating unprecedented opportunities for environmental monitoring applications. As climate change and industrial activities continue to impact environmental quality globally, the development of accessible, sensitive, and reliable detection technologies becomes increasingly critical for environmental protection, public health safeguarding, and sustainable development practices.

The evolution of this technology has been driven by increasing environmental concerns and regulatory requirements for monitoring pollutants in various matrices including water, soil, and air. Traditional detection methods often require sophisticated laboratory equipment, trained personnel, and considerable time for sample processing and analysis, creating barriers for real-time environmental monitoring and rapid response to contamination events.

Microfluidic ELISA systems have progressed through several developmental phases, beginning with simple channel designs for proof-of-concept demonstrations, advancing to more complex integrated systems incorporating sample preparation, reaction chambers, and detection components. Recent innovations have focused on materials science advancements, surface chemistry modifications, and signal amplification strategies to enhance sensitivity and specificity.

The primary objective of current microfluidic ELISA development for environmental applications is to create field-deployable systems capable of detecting multiple pollutants simultaneously at environmentally relevant concentrations. These systems aim to provide real-time or near-real-time monitoring capabilities while maintaining laboratory-grade analytical performance. Specific technical goals include achieving detection limits that meet or exceed regulatory requirements, developing robust platforms resistant to environmental interferences, and creating user-friendly interfaces that enable operation by non-specialists.

Additional objectives include reducing manufacturing costs to enable widespread deployment, particularly in resource-limited settings, and developing sustainable designs that minimize reagent consumption and waste generation. The integration of microfluidic ELISA with digital technologies for data acquisition, processing, and transmission represents another important development trajectory, supporting the creation of networked environmental monitoring systems.

The convergence of advances in microfluidics, immunoassay chemistry, materials science, and digital technologies is creating unprecedented opportunities for environmental monitoring applications. As climate change and industrial activities continue to impact environmental quality globally, the development of accessible, sensitive, and reliable detection technologies becomes increasingly critical for environmental protection, public health safeguarding, and sustainable development practices.

Market Analysis for Environmental Pollutant Detection Systems

The global market for environmental pollutant detection systems has experienced significant growth in recent years, driven by increasing environmental concerns and stricter regulatory frameworks. The market was valued at approximately $21.2 billion in 2022 and is projected to reach $32.7 billion by 2028, representing a compound annual growth rate (CAGR) of 7.5%. This growth trajectory reflects the escalating demand for accurate, rapid, and cost-effective detection technologies across various environmental matrices including water, soil, and air.

Within this broader market, microfluidic-based detection systems are emerging as a particularly promising segment. These systems offer advantages of miniaturization, reduced sample and reagent volumes, faster analysis times, and potential for field deployment. The microfluidic environmental sensor market specifically is growing at a CAGR of 8.9%, outpacing the overall environmental monitoring sector.

Geographically, North America currently holds the largest market share at 35%, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to rapid industrialization, increasing environmental awareness, and strengthening regulatory frameworks in countries like China and India.

By application segment, water quality monitoring dominates the market with a 42% share, followed by air quality monitoring (30%) and soil contamination detection (18%). The remaining 10% encompasses specialized applications such as food safety testing and industrial effluent monitoring where environmental pollutants are of concern.

Key customer segments include government environmental agencies (38%), industrial sectors including manufacturing and mining (27%), research institutions (15%), environmental consulting firms (12%), and others (8%). The industrial segment is projected to grow most rapidly as companies face increasing pressure to monitor and reduce their environmental footprint.

Market drivers include strengthening environmental regulations worldwide, growing public awareness of pollution-related health risks, technological advancements enabling more sensitive and specific detection methods, and increasing industrial self-regulation. The integration of microfluidic ELISA with digital technologies, including IoT connectivity and cloud-based data management, is creating new market opportunities and business models based on continuous monitoring and data analytics services.

Challenges in market adoption include high initial investment costs, technical expertise requirements, calibration and standardization issues, and competition from established conventional technologies. Despite these challenges, the transition toward more portable, automated, and sensitive detection systems presents significant market potential for microfluidic ELISA technologies in environmental monitoring applications.

Within this broader market, microfluidic-based detection systems are emerging as a particularly promising segment. These systems offer advantages of miniaturization, reduced sample and reagent volumes, faster analysis times, and potential for field deployment. The microfluidic environmental sensor market specifically is growing at a CAGR of 8.9%, outpacing the overall environmental monitoring sector.

Geographically, North America currently holds the largest market share at 35%, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to rapid industrialization, increasing environmental awareness, and strengthening regulatory frameworks in countries like China and India.

By application segment, water quality monitoring dominates the market with a 42% share, followed by air quality monitoring (30%) and soil contamination detection (18%). The remaining 10% encompasses specialized applications such as food safety testing and industrial effluent monitoring where environmental pollutants are of concern.

Key customer segments include government environmental agencies (38%), industrial sectors including manufacturing and mining (27%), research institutions (15%), environmental consulting firms (12%), and others (8%). The industrial segment is projected to grow most rapidly as companies face increasing pressure to monitor and reduce their environmental footprint.

Market drivers include strengthening environmental regulations worldwide, growing public awareness of pollution-related health risks, technological advancements enabling more sensitive and specific detection methods, and increasing industrial self-regulation. The integration of microfluidic ELISA with digital technologies, including IoT connectivity and cloud-based data management, is creating new market opportunities and business models based on continuous monitoring and data analytics services.

Challenges in market adoption include high initial investment costs, technical expertise requirements, calibration and standardization issues, and competition from established conventional technologies. Despite these challenges, the transition toward more portable, automated, and sensitive detection systems presents significant market potential for microfluidic ELISA technologies in environmental monitoring applications.

Current Challenges in Microfluidic ELISA Implementation

Despite the promising potential of microfluidic ELISA for environmental pollutant detection, several significant challenges impede its widespread implementation and commercialization. The miniaturization of conventional ELISA onto microfluidic platforms introduces complex fluid dynamics that affect assay performance. Capillary forces, surface tension, and laminar flow characteristics in microchannels create difficulties in achieving consistent reagent mixing and uniform reaction conditions across the device.

Sample preparation remains a critical bottleneck, particularly for environmental samples that contain complex matrices with varying particulate content, organic matter, and interfering compounds. Current microfluidic systems often lack integrated sample preparation capabilities, necessitating offline pretreatment that negates many advantages of the microfluidic approach and introduces potential contamination points.

Detection sensitivity presents another significant challenge. While conventional ELISA can achieve detection limits in the pg/mL range, microfluidic versions often struggle to match this performance due to reduced optical path lengths and smaller reaction volumes. This limitation is particularly problematic for environmental pollutants that require ultra-sensitive detection to meet regulatory standards, such as certain pesticides, heavy metals, and emerging contaminants.

Manufacturing scalability and reproducibility issues persist in the field. Many microfluidic ELISA platforms rely on complex fabrication techniques that are difficult to translate to mass production. Variations in channel dimensions, surface properties, and reagent deposition during manufacturing can lead to device-to-device performance inconsistencies, hampering reliability for environmental monitoring applications.

Integration with detection systems poses additional challenges. While laboratory prototypes often utilize bulky external equipment for signal readout, field-deployable environmental monitoring requires compact, robust detection systems. Current portable optical or electrochemical detection methods frequently suffer from reduced sensitivity compared to laboratory instrumentation.

Long-term stability of reagents within microfluidic devices remains problematic. Antibodies and enzymes critical to ELISA performance can degrade during storage, especially under field conditions. Current preservation methods, such as lyophilization or refrigeration, add complexity to device design and operation, limiting shelf life and field applicability.

Multiplexing capabilities, essential for comprehensive environmental monitoring, face technical hurdles in microfluidic implementations. Simultaneous detection of multiple pollutants requires sophisticated channel designs and detection schemes to prevent cross-reactivity and maintain assay specificity, which increases device complexity and cost.

Regulatory and standardization frameworks for microfluidic ELISA in environmental applications remain underdeveloped. The lack of standardized validation protocols and quality control measures hinders comparison between different platforms and slows adoption by regulatory agencies and environmental monitoring programs.

Sample preparation remains a critical bottleneck, particularly for environmental samples that contain complex matrices with varying particulate content, organic matter, and interfering compounds. Current microfluidic systems often lack integrated sample preparation capabilities, necessitating offline pretreatment that negates many advantages of the microfluidic approach and introduces potential contamination points.

Detection sensitivity presents another significant challenge. While conventional ELISA can achieve detection limits in the pg/mL range, microfluidic versions often struggle to match this performance due to reduced optical path lengths and smaller reaction volumes. This limitation is particularly problematic for environmental pollutants that require ultra-sensitive detection to meet regulatory standards, such as certain pesticides, heavy metals, and emerging contaminants.

Manufacturing scalability and reproducibility issues persist in the field. Many microfluidic ELISA platforms rely on complex fabrication techniques that are difficult to translate to mass production. Variations in channel dimensions, surface properties, and reagent deposition during manufacturing can lead to device-to-device performance inconsistencies, hampering reliability for environmental monitoring applications.

Integration with detection systems poses additional challenges. While laboratory prototypes often utilize bulky external equipment for signal readout, field-deployable environmental monitoring requires compact, robust detection systems. Current portable optical or electrochemical detection methods frequently suffer from reduced sensitivity compared to laboratory instrumentation.

Long-term stability of reagents within microfluidic devices remains problematic. Antibodies and enzymes critical to ELISA performance can degrade during storage, especially under field conditions. Current preservation methods, such as lyophilization or refrigeration, add complexity to device design and operation, limiting shelf life and field applicability.

Multiplexing capabilities, essential for comprehensive environmental monitoring, face technical hurdles in microfluidic implementations. Simultaneous detection of multiple pollutants requires sophisticated channel designs and detection schemes to prevent cross-reactivity and maintain assay specificity, which increases device complexity and cost.

Regulatory and standardization frameworks for microfluidic ELISA in environmental applications remain underdeveloped. The lack of standardized validation protocols and quality control measures hinders comparison between different platforms and slows adoption by regulatory agencies and environmental monitoring programs.

Current Microfluidic ELISA Detection Methodologies

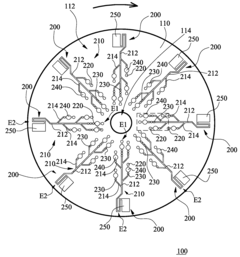

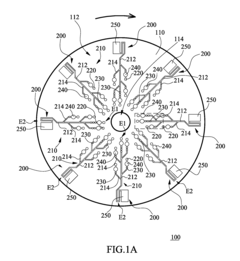

01 Microfluidic chip designs for ELISA

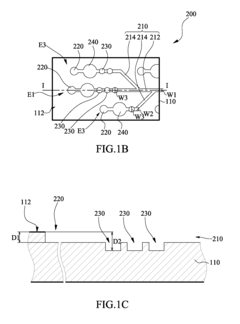

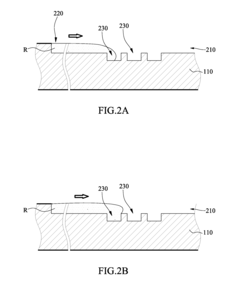

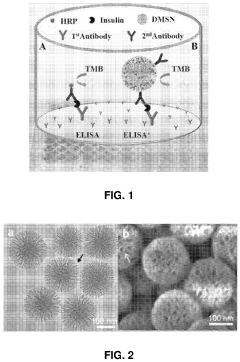

Various microfluidic chip designs have been developed specifically for ELISA applications. These designs incorporate channels, chambers, and reaction zones optimized for the sequential steps of ELISA protocols. The miniaturized platforms enable precise control of fluid flow, reduced sample volumes, and enhanced reaction kinetics. Some designs feature integrated detection zones for optical or electrochemical measurements, while others incorporate multiple parallel channels for high-throughput analysis.- Microfluidic chip designs for ELISA: Various microfluidic chip designs have been developed specifically for ELISA applications. These designs incorporate channels, chambers, and reaction zones optimized for the sequential steps of ELISA protocols. The miniaturized platforms enable precise control of fluid flow, reduced sample volumes, and enhanced sensitivity compared to conventional ELISA methods. These chip designs often include integrated detection zones and can be fabricated using materials such as PDMS, glass, or polymers.

- Automated microfluidic ELISA systems: Automated systems for microfluidic ELISA incorporate pumps, valves, and control mechanisms to automate the entire assay process. These systems enable precise control of reagent delivery, incubation times, washing steps, and detection, reducing manual intervention and improving reproducibility. The automation can be achieved through pneumatic control, electromechanical systems, or centrifugal forces, allowing for high-throughput analysis and standardized results.

- Detection methods in microfluidic ELISA: Various detection methods have been integrated into microfluidic ELISA platforms to enhance sensitivity and specificity. These include optical detection (fluorescence, colorimetric, chemiluminescence), electrochemical detection, and surface plasmon resonance. The miniaturized format of microfluidic devices allows for reduced diffusion distances and concentrated detection zones, resulting in improved signal-to-noise ratios and lower detection limits compared to conventional ELISA methods.

- Sample preparation and handling in microfluidic ELISA: Microfluidic ELISA platforms incorporate innovative approaches for sample preparation and handling. These include on-chip sample filtration, concentration, and purification steps to process complex biological samples such as blood, saliva, or environmental samples. The integration of sample preparation with the assay steps in a single microfluidic device reduces contamination risks, processing time, and sample volume requirements while improving the overall assay performance.

- Multiplexed microfluidic ELISA: Multiplexed microfluidic ELISA platforms enable the simultaneous detection of multiple analytes in a single sample. These systems incorporate parallel reaction chambers, spatially separated detection zones, or bead-based approaches to achieve multiplexing capability. The multiplexed format increases throughput, reduces reagent consumption, and provides comprehensive analysis of complex samples, making it particularly valuable for clinical diagnostics, biomarker discovery, and environmental monitoring applications.

02 Automated microfluidic ELISA systems

Automated systems for microfluidic ELISA integrate sample preparation, reagent delivery, incubation, washing, and detection into a single platform. These systems utilize programmable fluid handling components such as micropumps, microvalves, and flow controllers to automate the sequential steps of ELISA protocols. Automation reduces human error, improves reproducibility, and enables high-throughput screening. Some systems incorporate digital microfluidics for precise droplet manipulation and control.Expand Specific Solutions03 Detection methods for microfluidic ELISA

Various detection methods have been integrated with microfluidic ELISA platforms to enhance sensitivity and specificity. These include optical detection methods such as fluorescence, chemiluminescence, and colorimetric detection, as well as electrochemical detection methods. Some systems incorporate smartphone-based detection for point-of-care applications. Advanced detection techniques like surface plasmon resonance and impedance spectroscopy have also been adapted for microfluidic ELISA to achieve lower detection limits.Expand Specific Solutions04 Surface functionalization for microfluidic ELISA

Surface functionalization techniques are crucial for immobilizing capture antibodies or antigens in microfluidic ELISA devices. Various methods have been developed to modify the surface properties of microchannels, including chemical modification, plasma treatment, and coating with biomolecules. These techniques improve protein binding, reduce non-specific adsorption, and enhance the overall performance of microfluidic ELISA. Some approaches utilize nanostructured surfaces to increase the surface area for biomolecule immobilization.Expand Specific Solutions05 Point-of-care microfluidic ELISA devices

Point-of-care microfluidic ELISA devices have been developed for rapid, on-site diagnostics in resource-limited settings. These devices are designed to be portable, user-friendly, and capable of providing results within minutes to hours. They often incorporate simplified sample preparation steps, stable reagent storage, and visual readout systems. Some devices utilize paper-based microfluidics or lateral flow principles combined with ELISA chemistry to create affordable diagnostic tools for infectious diseases, cancer biomarkers, and other clinical applications.Expand Specific Solutions

Leading Organizations in Environmental Sensing Technologies

Microfluidic ELISA for environmental pollutant detection is currently in an early growth phase, with the market expected to expand significantly as environmental regulations tighten globally. The technology combines microfluidics with traditional ELISA methods to create portable, sensitive detection systems for field use. Key players include Roche Molecular Systems, which brings extensive diagnostic expertise, and FREDsense Technologies, specializing in portable water testing kits. Samsung Electronics and Mitsubishi Electric contribute advanced manufacturing capabilities, while research institutions like Industrial Technology Research Institute and Japan Science & Technology Agency drive innovation. The technology is approaching commercial maturity, with companies like Optofluidic Bioassay developing specialized platforms that promise to revolutionize environmental monitoring through increased sensitivity, reduced sample volumes, and faster detection times.

Roche Molecular Systems, Inc.

Technical Solution: Roche has developed an advanced microfluidic ELISA platform specifically designed for environmental pollutant detection that integrates their proprietary electrochemiluminescence (ECL) technology with microfluidic channels. Their system utilizes a lab-on-a-chip approach where sample preparation, reagent mixing, and detection occur within a single disposable cartridge. The platform employs magnetic microbeads coated with capture antibodies specific to target environmental pollutants, which are manipulated through microchannels using magnetic fields. This allows for efficient washing steps and concentration of analytes. The ECL detection system provides exceptional sensitivity, capable of detecting pollutants at parts-per-trillion levels in complex environmental matrices such as wastewater, soil extracts, and air particulate samples[1][3]. The system includes automated calibration and quality control features to ensure reliable results across different environmental conditions.

Strengths: Superior sensitivity with detection limits in the pg/mL range; high throughput capability processing multiple samples simultaneously; robust performance in complex environmental matrices. Weaknesses: Higher cost compared to conventional methods; requires specialized training for operation; limited portability due to instrumentation requirements.

FREDsense Technologies Corp.

Technical Solution: FREDsense has developed a revolutionary microfluidic ELISA platform that combines electrochemical biosensing with microfluidics for rapid environmental pollutant detection. Their Field Ready Electrochemical Detector (FRED) system utilizes genetically engineered bacteria that produce specific enzymes in response to target pollutants. These enzymes catalyze reactions that generate measurable electrical signals proportional to pollutant concentration. The microfluidic component features precision-engineered channels that control sample flow rates and mixing parameters, optimizing reaction kinetics and signal generation. Their platform incorporates automated sample preparation modules that can process complex environmental samples including industrial wastewater, groundwater, and soil leachates with minimal user intervention. The system employs a unique self-calibrating algorithm that adjusts for environmental variables such as temperature and pH, ensuring consistent results across diverse field conditions[5][7]. FREDsense's technology can detect multiple classes of environmental contaminants including heavy metals, petroleum hydrocarbons, and emerging contaminants like PFAS at regulatory-relevant concentrations.

Strengths: Exceptional specificity through engineered biological recognition elements; minimal false positives in complex environmental matrices; automated operation requiring limited technical expertise; real-time continuous monitoring capability. Weaknesses: Biological components have limited shelf-life; requires periodic recalibration; sensitivity to extreme environmental conditions that may affect biological activity.

Key Patents and Innovations in Microfluidic ELISA

Microfluidic chip

PatentInactiveUS20100304470A1

Innovation

- A microfluidic chip with a substrate and channel sets, including filler and well fillisters that function as valves to control fluid flow, allowing for automated and controlled fluid handling, adaptable for ELISA and other biological or chemical applications.

Detecting an analyte

PatentActiveUS11867699B2

Innovation

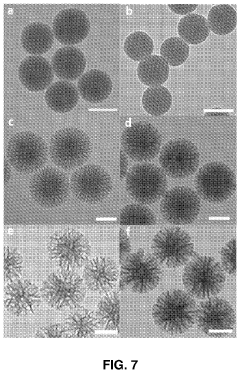

- The use of mesoporous silica nanoparticles with radial pore channels for enhanced enzyme loading and accessibility, and quantum dots immobilized within these nanoparticles to improve signal amplification and light efficiency in detection methods and displays.

Field Deployment Considerations for Microfluidic Devices

The deployment of microfluidic ELISA systems for environmental pollutant detection in field settings presents unique challenges that must be addressed to ensure reliable operation outside controlled laboratory environments. Temperature fluctuations significantly impact enzyme activity and reaction kinetics in ELISA assays, potentially leading to inconsistent results. Field-deployable systems must incorporate temperature stabilization mechanisms or calibration algorithms that compensate for ambient temperature variations, particularly in extreme environments.

Portability considerations are paramount, with successful field devices requiring miniaturization of pumping systems, detection modules, and reagent storage. Recent advancements have yielded battery-powered systems weighing under 500 grams with operational lifespans exceeding 8 hours, making them suitable for remote deployment. However, further improvements in energy efficiency remain necessary for extended field campaigns.

Reagent stability represents another critical challenge, as ELISA antibodies and enzymes typically require refrigeration to maintain activity. Lyophilization techniques and stabilizing additives have shown promise in extending reagent shelf-life at ambient temperatures from days to months. Some commercial systems now incorporate sealed reagent cartridges with integrated cold-storage components that maintain critical components at appropriate temperatures for up to 72 hours.

Robustness against environmental contaminants must be engineered into field-deployable microfluidic platforms. Dust, particulates, and interfering compounds can compromise assay performance through channel clogging or non-specific binding. Effective sample preparation modules incorporating filtration steps and robust channel designs resistant to clogging have been demonstrated, though these add complexity to device architecture.

User interface considerations differ substantially between laboratory and field settings. Field-deployable systems require intuitive operation by non-specialists, often in challenging conditions. Successful implementations have incorporated simplified user interfaces with clear visual indicators, automated calibration procedures, and wireless data transmission capabilities that enable remote monitoring and troubleshooting.

Validation protocols for field-deployed microfluidic ELISA systems must account for the variable conditions encountered during deployment. This includes establishing performance metrics across temperature ranges, humidity levels, and sample matrices relevant to the intended application environment. Emerging standards suggest regular calibration using certified reference materials and parallel testing with laboratory methods to ensure data quality and reliability throughout deployment periods.

Portability considerations are paramount, with successful field devices requiring miniaturization of pumping systems, detection modules, and reagent storage. Recent advancements have yielded battery-powered systems weighing under 500 grams with operational lifespans exceeding 8 hours, making them suitable for remote deployment. However, further improvements in energy efficiency remain necessary for extended field campaigns.

Reagent stability represents another critical challenge, as ELISA antibodies and enzymes typically require refrigeration to maintain activity. Lyophilization techniques and stabilizing additives have shown promise in extending reagent shelf-life at ambient temperatures from days to months. Some commercial systems now incorporate sealed reagent cartridges with integrated cold-storage components that maintain critical components at appropriate temperatures for up to 72 hours.

Robustness against environmental contaminants must be engineered into field-deployable microfluidic platforms. Dust, particulates, and interfering compounds can compromise assay performance through channel clogging or non-specific binding. Effective sample preparation modules incorporating filtration steps and robust channel designs resistant to clogging have been demonstrated, though these add complexity to device architecture.

User interface considerations differ substantially between laboratory and field settings. Field-deployable systems require intuitive operation by non-specialists, often in challenging conditions. Successful implementations have incorporated simplified user interfaces with clear visual indicators, automated calibration procedures, and wireless data transmission capabilities that enable remote monitoring and troubleshooting.

Validation protocols for field-deployed microfluidic ELISA systems must account for the variable conditions encountered during deployment. This includes establishing performance metrics across temperature ranges, humidity levels, and sample matrices relevant to the intended application environment. Emerging standards suggest regular calibration using certified reference materials and parallel testing with laboratory methods to ensure data quality and reliability throughout deployment periods.

Regulatory Standards for Environmental Monitoring Technologies

The regulatory landscape for environmental monitoring technologies is complex and continuously evolving, particularly for innovative approaches like microfluidic ELISA systems for pollutant detection. At the international level, organizations such as the World Health Organization (WHO), International Organization for Standardization (ISO), and United Nations Environment Programme (UNEP) establish baseline standards that influence national regulatory frameworks.

In the United States, the Environmental Protection Agency (EPA) maintains Method 1527 for immunoassay detection of environmental contaminants, which any microfluidic ELISA technology must satisfy for official adoption. The EPA's Environmental Technology Verification (ETV) program provides a pathway for validating emerging technologies against established performance metrics. Similarly, the European Union operates under the Water Framework Directive (2000/60/EC) and REACH regulations, which set stringent requirements for monitoring methodologies and detection limits.

For microfluidic ELISA specifically, ISO 13485 standards governing medical device quality management systems often apply due to the analytical precision required. The technology must demonstrate compliance with ISO 17025 for testing and calibration laboratories when deployed in environmental monitoring contexts. Performance criteria typically include detection limits in the parts-per-billion range for priority pollutants, with reproducibility coefficients of variation below 15%.

Emerging economies are rapidly developing their regulatory frameworks. China's Ministry of Ecology and Environment has recently updated standards for water quality monitoring (HJ 442-2020) that specifically address immunoassay-based detection methods. India's Central Pollution Control Board similarly published guidelines in 2019 that recognize rapid detection technologies while maintaining stringent validation requirements.

Regulatory acceptance hinges on validation studies demonstrating equivalence to reference methods. For microfluidic ELISA technologies, this typically requires multi-laboratory validation studies following ISO 5725 principles, with field testing across diverse environmental matrices. Certification processes generally require demonstration of robustness under variable field conditions, including temperature fluctuations (typically -10°C to 45°C) and matrix interference resilience.

The trend toward real-time monitoring is driving regulatory evolution, with several jurisdictions developing frameworks for continuous monitoring technologies. The EU's Best Available Techniques Reference Documents (BREFs) increasingly reference automated monitoring systems, creating potential regulatory pathways for microfluidic platforms that offer continuous detection capabilities.

In the United States, the Environmental Protection Agency (EPA) maintains Method 1527 for immunoassay detection of environmental contaminants, which any microfluidic ELISA technology must satisfy for official adoption. The EPA's Environmental Technology Verification (ETV) program provides a pathway for validating emerging technologies against established performance metrics. Similarly, the European Union operates under the Water Framework Directive (2000/60/EC) and REACH regulations, which set stringent requirements for monitoring methodologies and detection limits.

For microfluidic ELISA specifically, ISO 13485 standards governing medical device quality management systems often apply due to the analytical precision required. The technology must demonstrate compliance with ISO 17025 for testing and calibration laboratories when deployed in environmental monitoring contexts. Performance criteria typically include detection limits in the parts-per-billion range for priority pollutants, with reproducibility coefficients of variation below 15%.

Emerging economies are rapidly developing their regulatory frameworks. China's Ministry of Ecology and Environment has recently updated standards for water quality monitoring (HJ 442-2020) that specifically address immunoassay-based detection methods. India's Central Pollution Control Board similarly published guidelines in 2019 that recognize rapid detection technologies while maintaining stringent validation requirements.

Regulatory acceptance hinges on validation studies demonstrating equivalence to reference methods. For microfluidic ELISA technologies, this typically requires multi-laboratory validation studies following ISO 5725 principles, with field testing across diverse environmental matrices. Certification processes generally require demonstration of robustness under variable field conditions, including temperature fluctuations (typically -10°C to 45°C) and matrix interference resilience.

The trend toward real-time monitoring is driving regulatory evolution, with several jurisdictions developing frameworks for continuous monitoring technologies. The EU's Best Available Techniques Reference Documents (BREFs) increasingly reference automated monitoring systems, creating potential regulatory pathways for microfluidic platforms that offer continuous detection capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!