Optimization of Microchannel Dimensions for Reaction Efficiency

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Technology Background and Objectives

Microchannels represent a revolutionary advancement in reaction engineering, emerging from the broader field of microfluidics that began gaining significant attention in the early 1990s. These miniaturized reaction vessels, typically with dimensions ranging from 10 to 500 micrometers, have fundamentally transformed how chemical and biological reactions are conducted at microscale. The evolution of microchannel technology has been driven by the increasing demand for more efficient, precise, and sustainable reaction processes across various industries including pharmaceuticals, fine chemicals, and biotechnology.

The historical development of microchannels traces back to semiconductor fabrication techniques, which were later adapted for creating intricate fluid handling systems. The field experienced exponential growth following the pioneering work of researchers like George Whitesides and Andreas Manz, who demonstrated the potential of miniaturized total analysis systems. Over the past two decades, microchannel technology has matured from academic curiosity to industrial implementation, with significant advancements in fabrication methods, materials science, and process integration.

Current technological trends in microchannel development focus on optimizing geometric parameters to enhance reaction efficiency. This includes investigating the effects of channel width, depth, length, aspect ratio, and cross-sectional shape on flow dynamics, mixing characteristics, heat transfer, and ultimately reaction performance. Recent innovations have explored non-linear channel configurations, hierarchical structures, and surface modifications to further improve reaction outcomes.

The primary objective of microchannel dimension optimization is to achieve maximum reaction efficiency while maintaining operational feasibility. This involves balancing several competing factors: maximizing surface-to-volume ratio to enhance heat and mass transfer, minimizing pressure drop to reduce energy requirements, ensuring adequate residence time for reaction completion, and facilitating effective mixing while preventing channel clogging or fouling.

Secondary objectives include developing scalable manufacturing processes for precisely engineered microchannels, creating robust computational models to predict performance across different dimensional configurations, and establishing standardized testing protocols to evaluate reaction efficiency improvements. Additionally, there is growing interest in designing reconfigurable or modular microchannel systems that can be optimized for different reaction types without requiring complete redesign.

The ultimate goal of this technological pursuit is to establish design principles that correlate specific microchannel dimensions with reaction performance metrics across various reaction classes. This would enable engineers to rapidly prototype and implement optimized microchannel reactors for specific applications, significantly reducing development time and accelerating the adoption of this technology across industrial sectors.

The historical development of microchannels traces back to semiconductor fabrication techniques, which were later adapted for creating intricate fluid handling systems. The field experienced exponential growth following the pioneering work of researchers like George Whitesides and Andreas Manz, who demonstrated the potential of miniaturized total analysis systems. Over the past two decades, microchannel technology has matured from academic curiosity to industrial implementation, with significant advancements in fabrication methods, materials science, and process integration.

Current technological trends in microchannel development focus on optimizing geometric parameters to enhance reaction efficiency. This includes investigating the effects of channel width, depth, length, aspect ratio, and cross-sectional shape on flow dynamics, mixing characteristics, heat transfer, and ultimately reaction performance. Recent innovations have explored non-linear channel configurations, hierarchical structures, and surface modifications to further improve reaction outcomes.

The primary objective of microchannel dimension optimization is to achieve maximum reaction efficiency while maintaining operational feasibility. This involves balancing several competing factors: maximizing surface-to-volume ratio to enhance heat and mass transfer, minimizing pressure drop to reduce energy requirements, ensuring adequate residence time for reaction completion, and facilitating effective mixing while preventing channel clogging or fouling.

Secondary objectives include developing scalable manufacturing processes for precisely engineered microchannels, creating robust computational models to predict performance across different dimensional configurations, and establishing standardized testing protocols to evaluate reaction efficiency improvements. Additionally, there is growing interest in designing reconfigurable or modular microchannel systems that can be optimized for different reaction types without requiring complete redesign.

The ultimate goal of this technological pursuit is to establish design principles that correlate specific microchannel dimensions with reaction performance metrics across various reaction classes. This would enable engineers to rapidly prototype and implement optimized microchannel reactors for specific applications, significantly reducing development time and accelerating the adoption of this technology across industrial sectors.

Market Analysis for Microfluidic Reaction Systems

The global microfluidic reaction systems market is experiencing robust growth, driven by increasing demand across pharmaceutical, biotechnology, and chemical industries. Current market valuations indicate the sector reached approximately $7.5 billion in 2022, with projections suggesting a compound annual growth rate (CAGR) of 11.3% through 2030. This growth trajectory is particularly significant in regions with strong research infrastructure, including North America, Europe, and emerging Asian markets.

The pharmaceutical and biotechnology segments represent the largest market share, accounting for over 45% of total demand. This dominance stems from the critical advantages microfluidic systems offer in drug discovery and development processes, where precise reaction control and minimal reagent consumption translate to substantial cost savings and accelerated development timelines.

Market research indicates that optimization of microchannel dimensions represents a key competitive differentiator, with end-users increasingly prioritizing systems that demonstrate superior reaction efficiency. A recent industry survey revealed that 78% of potential customers rank reaction efficiency as either "very important" or "critical" in their purchasing decisions, highlighting the commercial significance of advancements in this technical domain.

The market landscape shows segmentation based on application requirements, with distinct demand patterns emerging. High-throughput screening applications favor systems with numerous parallel microchannels of smaller dimensions, while process development applications typically require larger channels with enhanced mixing capabilities. This diversification presents both challenges and opportunities for technology developers seeking to address multiple market segments.

Pricing analysis reveals premium positioning for systems with optimized microchannel dimensions, commanding 30-40% higher price points compared to standard configurations. This premium pricing is justified by demonstrable improvements in reaction yields, reduced processing times, and enhanced product quality—factors that directly impact end-user economics.

Regional market analysis shows North America leading with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 13.7% annually, driven by expanding research infrastructure and increasing adoption of advanced manufacturing technologies in countries like China, Japan, and South Korea.

Customer feedback indicates growing interest in customizable microchannel dimensions that can be optimized for specific reaction types, suggesting a potential shift from standardized products toward more flexible, application-specific solutions. This trend aligns with broader industry movements toward personalized manufacturing and process intensification strategies.

The pharmaceutical and biotechnology segments represent the largest market share, accounting for over 45% of total demand. This dominance stems from the critical advantages microfluidic systems offer in drug discovery and development processes, where precise reaction control and minimal reagent consumption translate to substantial cost savings and accelerated development timelines.

Market research indicates that optimization of microchannel dimensions represents a key competitive differentiator, with end-users increasingly prioritizing systems that demonstrate superior reaction efficiency. A recent industry survey revealed that 78% of potential customers rank reaction efficiency as either "very important" or "critical" in their purchasing decisions, highlighting the commercial significance of advancements in this technical domain.

The market landscape shows segmentation based on application requirements, with distinct demand patterns emerging. High-throughput screening applications favor systems with numerous parallel microchannels of smaller dimensions, while process development applications typically require larger channels with enhanced mixing capabilities. This diversification presents both challenges and opportunities for technology developers seeking to address multiple market segments.

Pricing analysis reveals premium positioning for systems with optimized microchannel dimensions, commanding 30-40% higher price points compared to standard configurations. This premium pricing is justified by demonstrable improvements in reaction yields, reduced processing times, and enhanced product quality—factors that directly impact end-user economics.

Regional market analysis shows North America leading with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 13.7% annually, driven by expanding research infrastructure and increasing adoption of advanced manufacturing technologies in countries like China, Japan, and South Korea.

Customer feedback indicates growing interest in customizable microchannel dimensions that can be optimized for specific reaction types, suggesting a potential shift from standardized products toward more flexible, application-specific solutions. This trend aligns with broader industry movements toward personalized manufacturing and process intensification strategies.

Current Challenges in Microchannel Dimensional Optimization

Despite significant advancements in microfluidic technology, the optimization of microchannel dimensions for enhanced reaction efficiency remains a complex challenge. Current microfluidic systems face several critical limitations that impede their widespread industrial adoption and performance optimization. The primary challenge lies in achieving precise control over fluid dynamics at the microscale, where surface forces dominate over volumetric forces, creating unique flow behaviors that are difficult to predict and model accurately.

The relationship between channel geometry and reaction kinetics presents a multivariable optimization problem. Researchers struggle to establish universal design principles as the optimal dimensions vary significantly depending on specific reaction parameters, fluid properties, and desired outcomes. This creates a scenario where optimization often relies on empirical approaches rather than theoretical frameworks, leading to inefficient development cycles and suboptimal designs.

Manufacturing constraints further complicate dimensional optimization. Current fabrication techniques have resolution limitations that restrict the implementation of theoretically optimal geometries. The trade-off between manufacturing precision and cost-effectiveness creates barriers to implementing complex channel designs that might otherwise yield superior reaction efficiencies.

Scale-up challenges represent another significant hurdle. Microfluidic systems that demonstrate excellent performance in laboratory settings often fail to maintain comparable efficiency when scaled for industrial applications. The non-linear relationship between channel dimensions and reaction parameters means that simple dimensional scaling rarely produces proportional results in reaction efficiency.

Heat and mass transfer limitations become increasingly problematic as channel dimensions are modified. Narrower channels may improve surface-to-volume ratios but simultaneously increase pressure drops and residence time distributions. Conversely, wider channels reduce pressure requirements but may introduce mixing inefficiencies and thermal gradients that negatively impact reaction performance.

Material compatibility issues further constrain dimensional optimization efforts. The interaction between channel materials and reactants can lead to adsorption, catalytic effects, or degradation that alters reaction kinetics in unpredictable ways. These surface effects become increasingly dominant as channel dimensions decrease, creating another variable that must be considered in the optimization process.

Computational modeling limitations also hinder progress in this field. Current simulation tools struggle to accurately capture the complex interplay between fluid dynamics, heat transfer, and chemical kinetics at the microscale. This computational gap forces researchers to rely heavily on experimental validation, significantly slowing the optimization process and increasing development costs.

The integration of sensors and control systems for real-time monitoring and adjustment of reaction conditions presents additional challenges, particularly as channel dimensions approach the micro and nanoscale. The ability to precisely measure and control conditions within these confined spaces remains limited by current sensor technology and integration capabilities.

The relationship between channel geometry and reaction kinetics presents a multivariable optimization problem. Researchers struggle to establish universal design principles as the optimal dimensions vary significantly depending on specific reaction parameters, fluid properties, and desired outcomes. This creates a scenario where optimization often relies on empirical approaches rather than theoretical frameworks, leading to inefficient development cycles and suboptimal designs.

Manufacturing constraints further complicate dimensional optimization. Current fabrication techniques have resolution limitations that restrict the implementation of theoretically optimal geometries. The trade-off between manufacturing precision and cost-effectiveness creates barriers to implementing complex channel designs that might otherwise yield superior reaction efficiencies.

Scale-up challenges represent another significant hurdle. Microfluidic systems that demonstrate excellent performance in laboratory settings often fail to maintain comparable efficiency when scaled for industrial applications. The non-linear relationship between channel dimensions and reaction parameters means that simple dimensional scaling rarely produces proportional results in reaction efficiency.

Heat and mass transfer limitations become increasingly problematic as channel dimensions are modified. Narrower channels may improve surface-to-volume ratios but simultaneously increase pressure drops and residence time distributions. Conversely, wider channels reduce pressure requirements but may introduce mixing inefficiencies and thermal gradients that negatively impact reaction performance.

Material compatibility issues further constrain dimensional optimization efforts. The interaction between channel materials and reactants can lead to adsorption, catalytic effects, or degradation that alters reaction kinetics in unpredictable ways. These surface effects become increasingly dominant as channel dimensions decrease, creating another variable that must be considered in the optimization process.

Computational modeling limitations also hinder progress in this field. Current simulation tools struggle to accurately capture the complex interplay between fluid dynamics, heat transfer, and chemical kinetics at the microscale. This computational gap forces researchers to rely heavily on experimental validation, significantly slowing the optimization process and increasing development costs.

The integration of sensors and control systems for real-time monitoring and adjustment of reaction conditions presents additional challenges, particularly as channel dimensions approach the micro and nanoscale. The ability to precisely measure and control conditions within these confined spaces remains limited by current sensor technology and integration capabilities.

Current Approaches to Microchannel Dimension Optimization

01 Microchannel design optimization for enhanced reaction efficiency

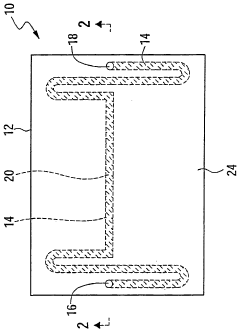

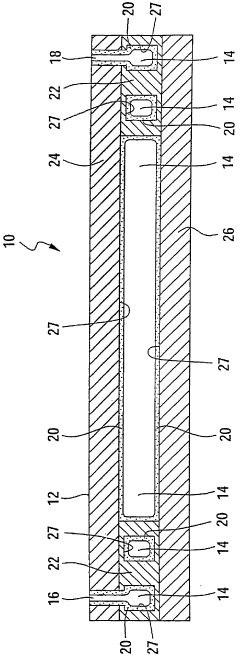

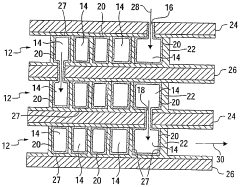

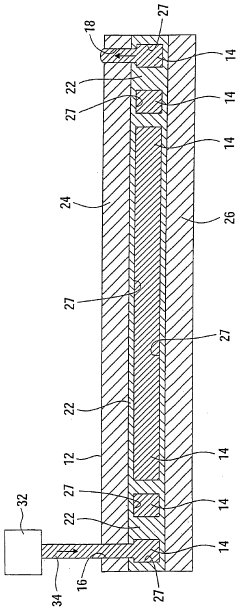

The design of microchannels significantly impacts reaction efficiency. Optimized geometries, including channel width, depth, and pattern configurations, can improve fluid dynamics and mixing characteristics. Advanced designs incorporate features such as curved channels, obstacles, or specialized surface patterns that create controlled turbulence or laminar flow patterns, enhancing mass transfer and reaction rates while minimizing pressure drop and energy requirements.- Microchannel design optimization for enhanced reaction efficiency: The design of microchannels significantly impacts reaction efficiency. Optimized geometries, including channel width, depth, and pattern configurations, can improve fluid dynamics and mixing characteristics. Strategic placement of obstacles or specialized structures within channels creates turbulence that enhances mass transfer and reaction rates. These design considerations are particularly important for reactions requiring precise control over residence time and mixing conditions.

- Surface modification techniques for microchannel reactors: Surface modifications of microchannel walls can significantly improve reaction efficiency by enhancing catalyst adhesion, preventing fouling, or creating specific surface properties. Techniques include coating with catalytic materials, plasma treatment, chemical functionalization, and nanopatterning. These modifications can increase the effective surface area for reactions, improve wettability characteristics, and create specialized reaction zones within the microchannels, leading to higher conversion rates and selectivity.

- Temperature and pressure control systems for microchannel reactions: Precise control of temperature and pressure within microchannels is crucial for optimizing reaction efficiency. Advanced thermal management systems, including integrated heating/cooling elements and temperature sensors, enable isothermal conditions or controlled temperature gradients. Pressure regulation mechanisms help maintain optimal reaction conditions, especially for gas-phase or multiphase reactions. These control systems allow for more efficient energy transfer and can significantly improve yield and selectivity in microchannel reactors.

- Flow control and mixing enhancement in microchannels: Advanced flow control and mixing strategies are essential for maximizing reaction efficiency in microchannels. Techniques include the implementation of specialized micromixers, flow distributors, and pulsation generators that create controlled turbulence or laminar flow patterns. Passive and active mixing elements can be integrated to enhance mass transfer rates and reduce diffusion limitations. These approaches are particularly valuable for reactions involving immiscible fluids or those requiring precise reactant ratios and contact times.

- Scaling and parallelization of microchannel reactors: Scaling and parallelization strategies enable the practical application of microchannel technology for industrial-scale production while maintaining high reaction efficiency. These approaches involve the development of modular designs, numbering-up methodologies, and uniform flow distribution systems. By connecting multiple microchannel units in parallel rather than increasing individual channel dimensions, the benefits of enhanced heat and mass transfer can be preserved at larger production scales, ensuring consistent reaction performance across the system.

02 Surface modification techniques for microchannel reactors

Surface modifications within microchannels can dramatically improve reaction efficiency by enhancing catalyst adhesion, preventing fouling, or creating specific wettability patterns. Techniques include plasma treatment, chemical etching, coating with functional materials, or creating micro/nano-textured surfaces. These modifications can increase the effective surface area for reactions, improve catalyst performance, and enable better control of fluid behavior at the channel walls.Expand Specific Solutions03 Integration of heating and cooling systems in microchannel reactors

Precise temperature control is crucial for optimizing reaction efficiency in microchannels. Advanced thermal management systems incorporate integrated heating or cooling elements, temperature sensors, and control algorithms to maintain optimal reaction conditions. These systems can create temperature gradients when beneficial or ensure isothermal conditions when required, significantly improving yield, selectivity, and energy efficiency of chemical processes.Expand Specific Solutions04 Mixing enhancement strategies for microchannel reactions

Efficient mixing is essential for maximizing reaction rates in microchannels, especially for diffusion-limited processes. Various strategies have been developed to enhance mixing, including passive structures (baffles, herringbone patterns, split-and-recombine designs) and active methods (acoustic, electrical, or mechanical actuation). These approaches create controlled chaotic advection or secondary flows that significantly reduce diffusion distances and improve mass transfer without excessive pressure drop.Expand Specific Solutions05 Monitoring and control systems for microchannel reaction optimization

Real-time monitoring and control systems enable dynamic optimization of microchannel reactions. These systems incorporate integrated sensors for parameters such as temperature, pressure, flow rate, and even chemical composition. Advanced control algorithms use this data to make real-time adjustments to process conditions, ensuring optimal reaction efficiency despite variations in feedstock or environmental conditions. This approach enables adaptive process control and facilitates continuous process improvement through data analysis.Expand Specific Solutions

Leading Companies and Research Institutions in Microfluidics

The microchannel dimension optimization market is currently in a growth phase, with increasing adoption across chemical processing and energy sectors. The global market size is estimated to exceed $2 billion, driven by demands for process intensification and energy efficiency. Technology maturity varies significantly among key players, with established companies like Corning, Inc. and China Petroleum & Chemical Corp. leading commercial implementation through extensive R&D investments. Research institutions including Advanced Industrial Science & Technology and Centre National de la Recherche Scientifique are advancing fundamental science, while specialized firms like Velocys have developed proprietary microchannel technologies. Companies such as FUJIFILM and Mitsubishi Gas Chemical are exploring applications in specialized chemical manufacturing, indicating the technology's expanding industrial relevance beyond traditional petrochemical applications.

Corning, Inc.

Technical Solution: Corning has developed advanced glass-based microreactor technology through their Corning® Advanced-Flow™ Reactors (AFR) platform. These reactors feature precisely engineered microchannels with dimensions optimized through extensive computational fluid dynamics simulations and experimental validation. The heart of their technology is the proprietary "heart cell" design with channel widths ranging from 0.25-2mm that creates controlled turbulence patterns for enhanced mixing while maintaining laminar flow characteristics. Corning's approach incorporates variable channel geometries within single reactor modules, with wider inlet sections (1-2mm) transitioning to narrower reaction zones (0.25-0.5mm) to optimize residence time distribution. Their glass-based construction enables direct visual observation of reactions and provides exceptional chemical resistance across pH 1-14. The company has documented up to 100-fold improvements in mass transfer coefficients compared to batch reactors, with heat transfer coefficients reaching 10,000 W/m²K, enabling precise temperature control within ±0.5°C.

Strengths: Exceptional chemical compatibility due to glass construction; outstanding optical transparency allowing for real-time reaction monitoring; modular design enabling flexible scaling from laboratory to production. Weaknesses: Higher initial capital investment compared to conventional reactors; potential brittleness concerns in certain industrial environments; limitations in operating pressure (typically <30 bar) compared to some metal-based alternatives.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed proprietary microchannel reactor technology optimized for petrochemical processing applications. Their approach focuses on precision-engineered microchannels with dimensions ranging from 0.5-2mm, specifically designed to enhance reaction efficiency in catalytic processes. Sinopec's technology incorporates variable channel geometries that adapt to reaction progression, with wider inlet sections (1.5-2mm) that gradually narrow (0.5-0.8mm) to optimize residence time distribution and pressure profiles. Their systems feature integrated heat exchange microchannels running perpendicular to reaction channels, maintaining temperature uniformity within ±1°C even for highly exothermic reactions. The company has implemented these reactors in pilot facilities for methanol-to-olefins conversion, achieving yield improvements of 15-20% compared to conventional fixed-bed technologies. Sinopec's microchannel designs incorporate specialized catalyst coating techniques that maximize active surface area while minimizing flow resistance, with documented mass transfer coefficients up to 50 times higher than traditional packed bed reactors.

Strengths: Extensive experience in scaling microchannel technology to industrial production volumes; robust designs suitable for harsh petrochemical environments; significant improvements in product selectivity for complex reactions. Weaknesses: Higher manufacturing complexity and associated capital costs; potential for channel fouling in certain hydrocarbon processing applications; challenges in catalyst replacement compared to conventional reactor systems.

Critical Patents and Research on Reaction Efficiency Enhancement

Systems and methods for thermally actuated flow control

PatentActiveUS20180038513A1

Innovation

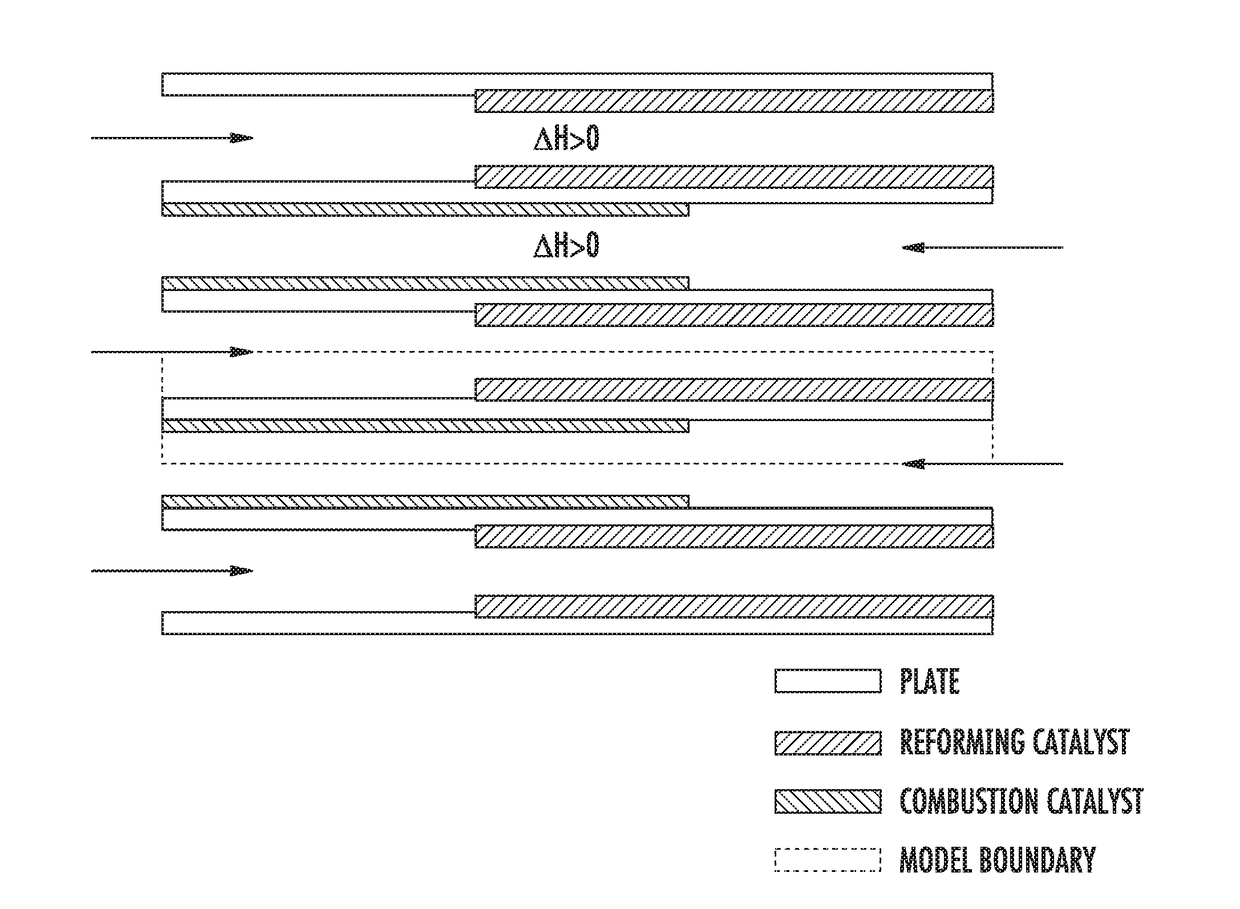

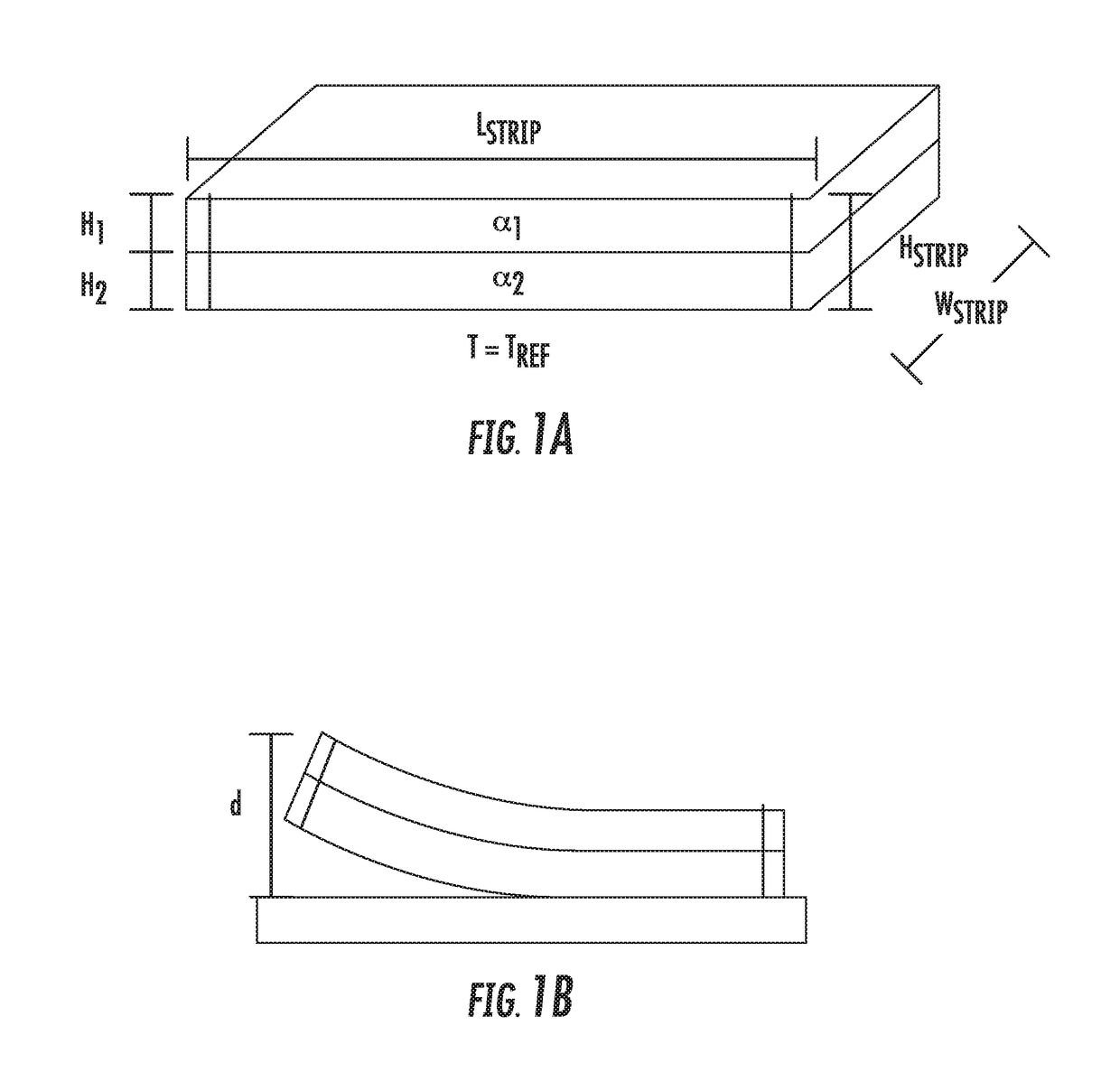

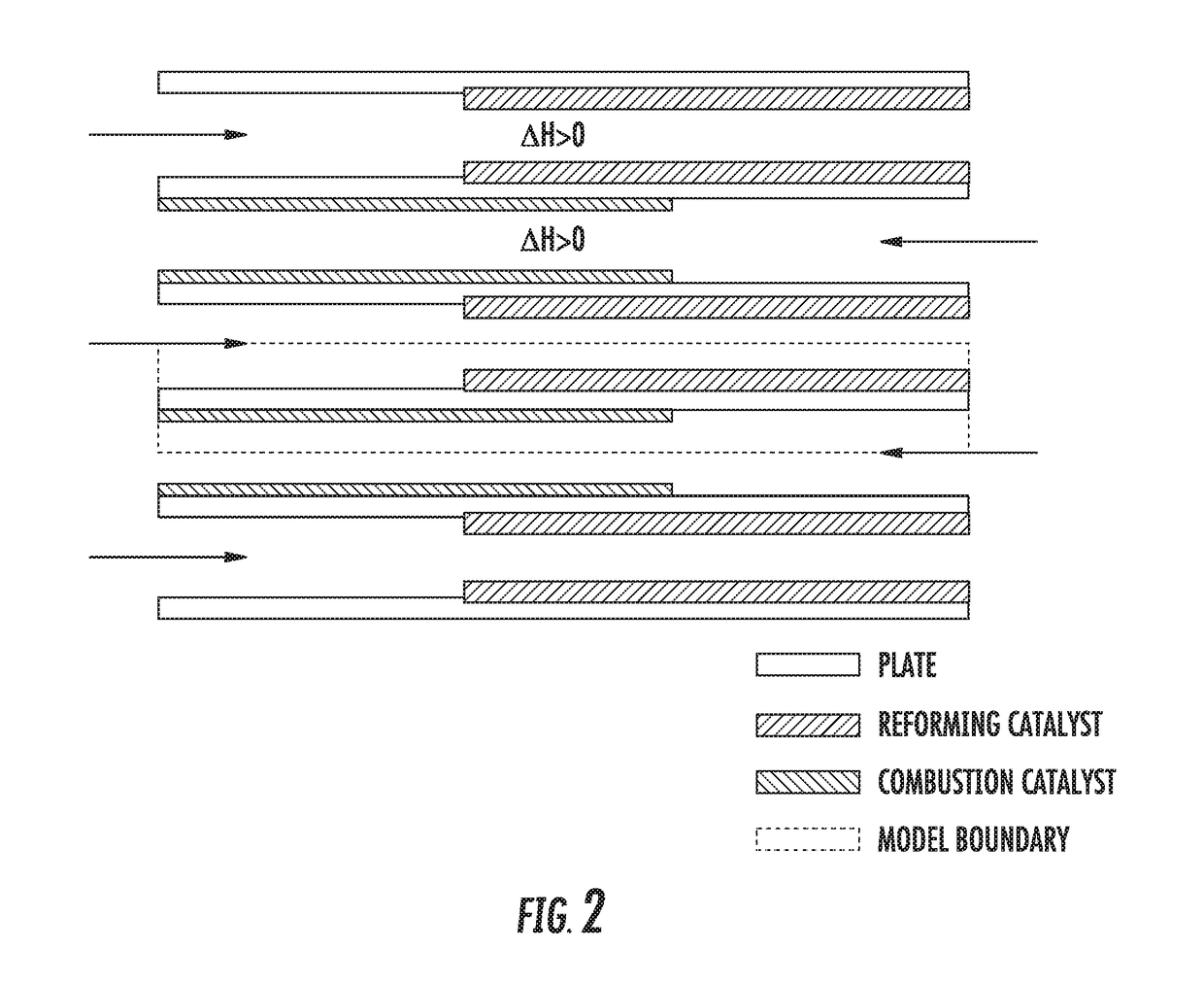

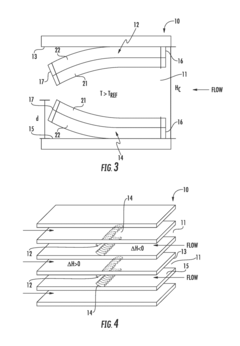

- Incorporating bimetallic strips within the combustion channel to create a thermally-actuated valve that regulates fluid flow based on temperature changes, restricting heat generation by deflecting as temperature increases, thereby controlling heat flux coordination between exothermic and endothermic reactions.

Coated microstructures and methods of coating same

PatentWO2005065816A1

Innovation

- A microstructure with coated internal surfaces using a sol-gel based slurry containing a catalyst or catalyst support powder, applied in multiple layers to maximize reactant-catalyst contact, enhance adhesion, and maintain stability, allowing for thicker coatings without delamination, and incorporating a support structure for flow control and thermal management.

Computational Fluid Dynamics for Microchannel Design

Computational Fluid Dynamics (CFD) has emerged as an indispensable tool for optimizing microchannel dimensions to enhance reaction efficiency. This advanced simulation technique enables engineers to model fluid flow, heat transfer, and chemical reactions within microchannels without the need for extensive physical prototyping. The application of CFD in microchannel design has grown exponentially over the past decade, driven by increasing demands for more efficient microreactors in various industries.

CFD simulations provide detailed insights into complex phenomena occurring within microchannels, including laminar flow patterns, mixing behaviors, and concentration gradients. These simulations can accurately predict how changes in channel geometry affect residence time distribution, which directly impacts reaction efficiency. Modern CFD software packages incorporate sophisticated models that account for multiphase flows, surface reactions, and mass transfer limitations—all critical factors in microchannel reactor performance.

The integration of CFD with optimization algorithms represents a significant advancement in microchannel design methodology. Researchers can now perform parametric studies by systematically varying channel dimensions, including width, height, length, and aspect ratio, to identify optimal configurations for specific reactions. These optimization processes typically aim to maximize reaction yield while minimizing pressure drop, which represents a fundamental engineering trade-off in microchannel design.

Recent developments in mesh generation techniques have substantially improved the accuracy of CFD simulations for microchannels. Adaptive meshing approaches can now resolve boundary layers and regions of high gradient with unprecedented precision, ensuring that critical flow features are captured correctly. This advancement is particularly important for microchannels, where surface-to-volume ratios are high and boundary effects dominate flow behavior.

The computational efficiency of CFD simulations has also improved dramatically, enabling more complex and realistic models. High-performance computing clusters now allow for detailed 3D simulations of entire microchannel networks, rather than simplified 2D approximations. This capability is essential for accurately predicting the performance of advanced microchannel designs featuring complex geometries such as obstacles, curves, or bifurcations that enhance mixing and reaction efficiency.

Validation of CFD models against experimental data remains a critical aspect of the design process. Researchers typically employ micro-PIV (Particle Image Velocimetry) and other advanced measurement techniques to verify simulation results. This validation step ensures that the optimized dimensions predicted by CFD will indeed deliver the expected performance improvements when implemented in physical microreactors.

CFD simulations provide detailed insights into complex phenomena occurring within microchannels, including laminar flow patterns, mixing behaviors, and concentration gradients. These simulations can accurately predict how changes in channel geometry affect residence time distribution, which directly impacts reaction efficiency. Modern CFD software packages incorporate sophisticated models that account for multiphase flows, surface reactions, and mass transfer limitations—all critical factors in microchannel reactor performance.

The integration of CFD with optimization algorithms represents a significant advancement in microchannel design methodology. Researchers can now perform parametric studies by systematically varying channel dimensions, including width, height, length, and aspect ratio, to identify optimal configurations for specific reactions. These optimization processes typically aim to maximize reaction yield while minimizing pressure drop, which represents a fundamental engineering trade-off in microchannel design.

Recent developments in mesh generation techniques have substantially improved the accuracy of CFD simulations for microchannels. Adaptive meshing approaches can now resolve boundary layers and regions of high gradient with unprecedented precision, ensuring that critical flow features are captured correctly. This advancement is particularly important for microchannels, where surface-to-volume ratios are high and boundary effects dominate flow behavior.

The computational efficiency of CFD simulations has also improved dramatically, enabling more complex and realistic models. High-performance computing clusters now allow for detailed 3D simulations of entire microchannel networks, rather than simplified 2D approximations. This capability is essential for accurately predicting the performance of advanced microchannel designs featuring complex geometries such as obstacles, curves, or bifurcations that enhance mixing and reaction efficiency.

Validation of CFD models against experimental data remains a critical aspect of the design process. Researchers typically employ micro-PIV (Particle Image Velocimetry) and other advanced measurement techniques to verify simulation results. This validation step ensures that the optimized dimensions predicted by CFD will indeed deliver the expected performance improvements when implemented in physical microreactors.

Scaling and Manufacturing Considerations for Optimized Microchannels

The transition from laboratory-scale microreactor prototypes to industrial-scale production systems presents significant engineering challenges that must be addressed to maintain the enhanced reaction efficiency observed at smaller scales. When scaling up microchannel reactors, maintaining consistent channel dimensions becomes increasingly difficult due to manufacturing tolerances and material constraints. Industry standards typically require dimensional precision within ±2-5 μm for channels in the 100-500 μm range, which becomes more challenging as production volumes increase.

Manufacturing techniques for optimized microchannels vary based on material selection and production scale. Photolithography and etching processes offer excellent precision for silicon and glass substrates but face throughput limitations. Laser ablation provides flexibility for polymer-based microchannels but may introduce surface roughness that affects flow dynamics. Advanced techniques such as 3D printing and micro-injection molding are emerging as scalable alternatives, though they currently face resolution limitations for sub-100 μm features.

Material selection significantly impacts both manufacturing feasibility and reaction performance. While glass and silicon offer excellent chemical resistance and thermal stability, their processing costs increase substantially at larger scales. Polymeric materials like PDMS, PMMA, and COC present more economical alternatives for high-volume production but may introduce compatibility issues with certain solvents and high-temperature reactions. Hybrid approaches using metal-coated polymers are showing promise for balancing cost and performance considerations.

Surface-to-volume ratio preservation represents a critical challenge in scaling microchannel dimensions. As channels are scaled up, this ratio naturally decreases, potentially reducing heat and mass transfer efficiencies. Innovative designs incorporating hierarchical channel structures or internal features can help maintain these ratios while increasing throughput. Computational fluid dynamics modeling has become essential for predicting how dimensional changes will affect reaction kinetics at larger scales.

Economic considerations ultimately drive manufacturing decisions for optimized microchannels. Initial tooling costs for precision microfabrication can be substantial, ranging from $50,000 to $500,000 depending on complexity and materials. However, unit costs decrease significantly at higher production volumes, particularly for polymer-based systems. Recent industry analyses suggest that the economic crossover point favoring microchannel technology over conventional reactors occurs at production scales of approximately 100-1,000 tons per year for specialty chemicals and pharmaceuticals.

Manufacturing techniques for optimized microchannels vary based on material selection and production scale. Photolithography and etching processes offer excellent precision for silicon and glass substrates but face throughput limitations. Laser ablation provides flexibility for polymer-based microchannels but may introduce surface roughness that affects flow dynamics. Advanced techniques such as 3D printing and micro-injection molding are emerging as scalable alternatives, though they currently face resolution limitations for sub-100 μm features.

Material selection significantly impacts both manufacturing feasibility and reaction performance. While glass and silicon offer excellent chemical resistance and thermal stability, their processing costs increase substantially at larger scales. Polymeric materials like PDMS, PMMA, and COC present more economical alternatives for high-volume production but may introduce compatibility issues with certain solvents and high-temperature reactions. Hybrid approaches using metal-coated polymers are showing promise for balancing cost and performance considerations.

Surface-to-volume ratio preservation represents a critical challenge in scaling microchannel dimensions. As channels are scaled up, this ratio naturally decreases, potentially reducing heat and mass transfer efficiencies. Innovative designs incorporating hierarchical channel structures or internal features can help maintain these ratios while increasing throughput. Computational fluid dynamics modeling has become essential for predicting how dimensional changes will affect reaction kinetics at larger scales.

Economic considerations ultimately drive manufacturing decisions for optimized microchannels. Initial tooling costs for precision microfabrication can be substantial, ranging from $50,000 to $500,000 depending on complexity and materials. However, unit costs decrease significantly at higher production volumes, particularly for polymer-based systems. Recent industry analyses suggest that the economic crossover point favoring microchannel technology over conventional reactors occurs at production scales of approximately 100-1,000 tons per year for specialty chemicals and pharmaceuticals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!