Mitigating Heat Generation in High-Voltage Isoelectric Focusing

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Voltage IEF Thermal Challenges and Objectives

Isoelectric focusing (IEF) has evolved significantly since its introduction in the 1960s, becoming a cornerstone technique in protein separation and analysis. The application of high voltage across a pH gradient allows proteins to migrate until they reach their isoelectric point, providing exceptional resolution for complex protein mixtures. However, this process generates substantial heat due to Joule heating effects, presenting a significant challenge to the technique's efficacy and reproducibility.

The thermal management challenges in high-voltage IEF have become increasingly prominent as researchers push for faster separations and higher resolution, necessitating higher voltage applications. Historical data indicates that heat generation increases quadratically with applied voltage, creating a fundamental limitation in the technique's advancement. Temperature increases of even a few degrees can dramatically alter protein behavior, causing band broadening, sample degradation, and in extreme cases, gel breakdown.

Current technological trends in IEF are moving toward miniaturized systems, increased automation, and integration with other analytical techniques. These advancements require more sophisticated thermal management solutions to maintain the integrity of separations while maximizing resolution and throughput. The evolution from traditional slab gels to capillary and microchip formats has exacerbated thermal challenges due to higher surface-to-volume ratios and more concentrated electric fields.

The primary objective of thermal management in high-voltage IEF is to maintain uniform temperature distribution throughout the separation medium while dissipating excess heat efficiently. This requires a multidisciplinary approach combining principles from electrical engineering, fluid dynamics, materials science, and biochemistry. Specific technical goals include developing cooling systems capable of removing heat at rates exceeding 10 W/cm², designing thermally conductive yet electrically insulating materials, and creating predictive models for heat generation and dissipation.

Another critical objective is to enhance the technique's reproducibility by minimizing thermal gradients across the separation medium. These gradients can cause localized pH shifts, affecting protein migration and potentially leading to erroneous results. Research indicates that temperature variations as small as 0.5°C can significantly impact separation quality in high-resolution applications.

Looking forward, the field aims to develop adaptive cooling technologies that can respond in real-time to changing thermal conditions during the separation process. This includes the integration of miniaturized temperature sensors, microfluidic cooling channels, and advanced thermal interface materials. The ultimate goal is to enable higher voltage applications (>10,000 V) while maintaining temperature fluctuations below 0.2°C, thereby pushing the boundaries of separation resolution and speed.

The thermal management challenges in high-voltage IEF have become increasingly prominent as researchers push for faster separations and higher resolution, necessitating higher voltage applications. Historical data indicates that heat generation increases quadratically with applied voltage, creating a fundamental limitation in the technique's advancement. Temperature increases of even a few degrees can dramatically alter protein behavior, causing band broadening, sample degradation, and in extreme cases, gel breakdown.

Current technological trends in IEF are moving toward miniaturized systems, increased automation, and integration with other analytical techniques. These advancements require more sophisticated thermal management solutions to maintain the integrity of separations while maximizing resolution and throughput. The evolution from traditional slab gels to capillary and microchip formats has exacerbated thermal challenges due to higher surface-to-volume ratios and more concentrated electric fields.

The primary objective of thermal management in high-voltage IEF is to maintain uniform temperature distribution throughout the separation medium while dissipating excess heat efficiently. This requires a multidisciplinary approach combining principles from electrical engineering, fluid dynamics, materials science, and biochemistry. Specific technical goals include developing cooling systems capable of removing heat at rates exceeding 10 W/cm², designing thermally conductive yet electrically insulating materials, and creating predictive models for heat generation and dissipation.

Another critical objective is to enhance the technique's reproducibility by minimizing thermal gradients across the separation medium. These gradients can cause localized pH shifts, affecting protein migration and potentially leading to erroneous results. Research indicates that temperature variations as small as 0.5°C can significantly impact separation quality in high-resolution applications.

Looking forward, the field aims to develop adaptive cooling technologies that can respond in real-time to changing thermal conditions during the separation process. This includes the integration of miniaturized temperature sensors, microfluidic cooling channels, and advanced thermal interface materials. The ultimate goal is to enable higher voltage applications (>10,000 V) while maintaining temperature fluctuations below 0.2°C, thereby pushing the boundaries of separation resolution and speed.

Market Analysis for Advanced Electrophoresis Solutions

The global market for advanced electrophoresis solutions has been experiencing steady growth, driven by increasing applications in proteomics, genomics, and pharmaceutical development. The high-voltage isoelectric focusing (IEF) segment represents a significant portion of this market, valued at approximately $1.2 billion in 2022 with projections to reach $1.8 billion by 2027, reflecting a compound annual growth rate of 8.4%.

Research institutions and biopharmaceutical companies constitute the primary customer base for advanced electrophoresis technologies, particularly those addressing heat generation challenges in high-voltage applications. North America currently dominates the market with a 42% share, followed by Europe (28%) and Asia-Pacific (22%), with the latter showing the fastest growth trajectory due to expanding research infrastructure in China, Japan, and South Korea.

The demand for heat-mitigated IEF systems stems from several market drivers. First, the growing emphasis on precision medicine has increased the need for high-resolution protein separation techniques that can operate efficiently without thermal degradation of samples. Second, advancements in proteomics research require more sophisticated analytical tools capable of maintaining sample integrity during extended separation processes.

Market research indicates that customers are willing to pay a premium of 15-20% for electrophoresis systems that effectively address heat generation issues. This price elasticity reflects the critical importance of temperature control in preserving biological sample integrity and ensuring reproducible results in research and clinical applications.

Competition in this specialized market segment is intensifying, with major players including Bio-Rad Laboratories, Thermo Fisher Scientific, and Agilent Technologies investing significantly in thermal management innovations. Emerging companies like Protein Technologies and NanoSeparations are gaining market share through focused innovations specifically targeting heat dissipation in high-voltage applications.

Regional market analysis reveals varying needs: North American customers prioritize automation and integration with existing workflows, European buyers emphasize energy efficiency and sustainable operation, while Asia-Pacific customers focus on cost-effectiveness alongside performance improvements. These regional preferences must inform product development strategies for heat-mitigated IEF technologies.

The market for consumables associated with heat-optimized electrophoresis systems represents a substantial revenue opportunity, with cooling buffers, specialized gels, and temperature-monitoring accessories generating recurring revenue streams that typically exceed initial equipment sales by a factor of 2.5 over a five-year period.

Research institutions and biopharmaceutical companies constitute the primary customer base for advanced electrophoresis technologies, particularly those addressing heat generation challenges in high-voltage applications. North America currently dominates the market with a 42% share, followed by Europe (28%) and Asia-Pacific (22%), with the latter showing the fastest growth trajectory due to expanding research infrastructure in China, Japan, and South Korea.

The demand for heat-mitigated IEF systems stems from several market drivers. First, the growing emphasis on precision medicine has increased the need for high-resolution protein separation techniques that can operate efficiently without thermal degradation of samples. Second, advancements in proteomics research require more sophisticated analytical tools capable of maintaining sample integrity during extended separation processes.

Market research indicates that customers are willing to pay a premium of 15-20% for electrophoresis systems that effectively address heat generation issues. This price elasticity reflects the critical importance of temperature control in preserving biological sample integrity and ensuring reproducible results in research and clinical applications.

Competition in this specialized market segment is intensifying, with major players including Bio-Rad Laboratories, Thermo Fisher Scientific, and Agilent Technologies investing significantly in thermal management innovations. Emerging companies like Protein Technologies and NanoSeparations are gaining market share through focused innovations specifically targeting heat dissipation in high-voltage applications.

Regional market analysis reveals varying needs: North American customers prioritize automation and integration with existing workflows, European buyers emphasize energy efficiency and sustainable operation, while Asia-Pacific customers focus on cost-effectiveness alongside performance improvements. These regional preferences must inform product development strategies for heat-mitigated IEF technologies.

The market for consumables associated with heat-optimized electrophoresis systems represents a substantial revenue opportunity, with cooling buffers, specialized gels, and temperature-monitoring accessories generating recurring revenue streams that typically exceed initial equipment sales by a factor of 2.5 over a five-year period.

Current Heat Management Limitations in IEF Systems

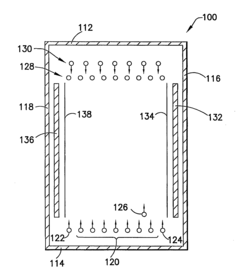

Current heat management systems in high-voltage Isoelectric Focusing (IEF) face significant limitations that impede optimal performance and reliability. Traditional cooling mechanisms primarily rely on passive heat sinks or basic liquid cooling systems that struggle to efficiently dissipate the substantial thermal energy generated during high-voltage operations. These conventional approaches become increasingly inadequate as voltage requirements escalate to meet demands for faster separation and higher resolution in proteomics and genomics applications.

The primary limitation stems from the inherent thermal conductivity constraints of materials used in IEF systems. Most commercially available platforms utilize glass or ceramic substrates with relatively poor thermal conductivity properties, creating thermal bottlenecks that prevent efficient heat transfer from critical components to cooling elements. This results in localized hotspots that can reach temperatures exceeding 80°C during extended high-voltage operations.

Current liquid cooling systems employed in advanced IEF setups suffer from flow distribution problems, where cooling efficiency varies significantly across the separation chamber. This non-uniform cooling creates temperature gradients that directly compromise separation quality by disrupting the pH gradient stability essential for accurate protein focusing. Industry data indicates temperature variations of up to 15°C can occur across a single separation chamber using current cooling technologies.

Another critical limitation is the reactive rather than predictive nature of existing thermal management systems. Most current solutions respond to temperature increases after they occur rather than anticipating thermal buildup based on operational parameters. This delayed response allows momentary temperature spikes that can irreversibly denature sensitive biological samples before cooling mechanisms fully engage.

Power consumption represents a further constraint, as current active cooling systems require substantial energy input, often consuming 20-30% of the total system power. This inefficiency not only increases operational costs but also introduces additional heat into the laboratory environment, creating a counterproductive thermal cycle that places greater demands on facility climate control systems.

Size constraints also present significant challenges, particularly for miniaturized or portable IEF systems. Current cooling technologies have not scaled down effectively, with cooling components often occupying 40-50% of total system volume in compact designs. This disproportionate space allocation limits the development of truly portable high-performance IEF platforms for field applications or point-of-care diagnostics.

Finally, current heat management approaches fail to address the complex relationship between thermal dynamics and electrochemical processes occurring during IEF. The interaction between Joule heating, electroosmotic flow, and electrolyte conductivity changes creates a dynamic thermal environment that static cooling systems cannot adequately regulate, resulting in unpredictable separation performance and reduced reproducibility.

The primary limitation stems from the inherent thermal conductivity constraints of materials used in IEF systems. Most commercially available platforms utilize glass or ceramic substrates with relatively poor thermal conductivity properties, creating thermal bottlenecks that prevent efficient heat transfer from critical components to cooling elements. This results in localized hotspots that can reach temperatures exceeding 80°C during extended high-voltage operations.

Current liquid cooling systems employed in advanced IEF setups suffer from flow distribution problems, where cooling efficiency varies significantly across the separation chamber. This non-uniform cooling creates temperature gradients that directly compromise separation quality by disrupting the pH gradient stability essential for accurate protein focusing. Industry data indicates temperature variations of up to 15°C can occur across a single separation chamber using current cooling technologies.

Another critical limitation is the reactive rather than predictive nature of existing thermal management systems. Most current solutions respond to temperature increases after they occur rather than anticipating thermal buildup based on operational parameters. This delayed response allows momentary temperature spikes that can irreversibly denature sensitive biological samples before cooling mechanisms fully engage.

Power consumption represents a further constraint, as current active cooling systems require substantial energy input, often consuming 20-30% of the total system power. This inefficiency not only increases operational costs but also introduces additional heat into the laboratory environment, creating a counterproductive thermal cycle that places greater demands on facility climate control systems.

Size constraints also present significant challenges, particularly for miniaturized or portable IEF systems. Current cooling technologies have not scaled down effectively, with cooling components often occupying 40-50% of total system volume in compact designs. This disproportionate space allocation limits the development of truly portable high-performance IEF platforms for field applications or point-of-care diagnostics.

Finally, current heat management approaches fail to address the complex relationship between thermal dynamics and electrochemical processes occurring during IEF. The interaction between Joule heating, electroosmotic flow, and electrolyte conductivity changes creates a dynamic thermal environment that static cooling systems cannot adequately regulate, resulting in unpredictable separation performance and reduced reproducibility.

Contemporary Heat Dissipation Strategies for IEF

01 Cooling systems for heat management in IEF

Various cooling systems are employed to manage heat generation during isoelectric focusing. These include liquid cooling mechanisms, heat sinks, and temperature control devices that help maintain optimal temperature conditions. Effective cooling prevents protein denaturation and ensures accurate separation by counteracting Joule heating effects that occur during the electrophoresis process.- Cooling systems for heat management in IEF: Various cooling systems are employed to manage heat generation during isoelectric focusing (IEF). These systems include liquid cooling mechanisms, heat sinks, and temperature control devices that help maintain optimal temperature conditions during the electrophoresis process. Effective cooling prevents protein denaturation and maintains separation efficiency by dissipating the Joule heating that naturally occurs during the application of electric fields to conductive media.

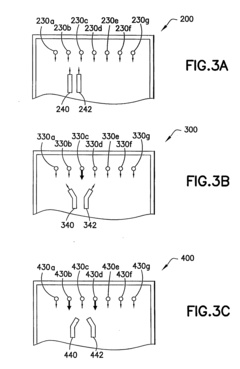

- Power supply control methods to minimize heat generation: Specialized power supply control methods are implemented to minimize heat generation during isoelectric focusing. These include pulsed power application, gradual voltage ramping, and adaptive current limiting techniques. By controlling the electrical parameters during the separation process, these methods help reduce Joule heating while maintaining effective protein separation, thereby improving resolution and preventing thermal degradation of samples.

- Buffer system formulations for thermal stability: Specific buffer system formulations are designed to enhance thermal stability during isoelectric focusing. These formulations include specialized ampholytes, additives, and carrier ampholytes that help maintain pH gradients while minimizing heat-related issues. The optimized buffer compositions improve the conductivity characteristics of the medium, reducing resistance and consequently decreasing heat generation during the electrophoresis process.

- Gel and medium compositions for heat dissipation: Advanced gel and medium compositions are developed specifically for enhanced heat dissipation during isoelectric focusing. These materials include thermally conductive polymers, modified polyacrylamide formulations, and composite gel structures that facilitate better heat transfer away from the separation medium. By improving thermal conductivity of the separation matrix, these compositions help maintain more uniform temperatures throughout the gel, resulting in better resolution and reproducibility.

- Miniaturized and microfluidic IEF systems for reduced heat generation: Miniaturized and microfluidic isoelectric focusing systems are designed to inherently reduce heat generation through decreased current paths and improved surface-to-volume ratios. These systems utilize microchannel architectures, capillary formats, and lab-on-chip designs that minimize the distance between cooling surfaces and separation media. The reduced scale of these systems allows for more efficient heat dissipation and enables higher field strengths without excessive temperature increases.

02 Power supply control for minimizing heat generation

Advanced power supply systems with precise control mechanisms are used to minimize heat generation during isoelectric focusing. These systems include programmable power supplies that can adjust voltage and current parameters, pulsed power delivery methods, and feedback control systems that monitor and regulate electrical parameters to maintain optimal separation conditions while reducing excessive heat production.Expand Specific Solutions03 Buffer and gel compositions for heat reduction

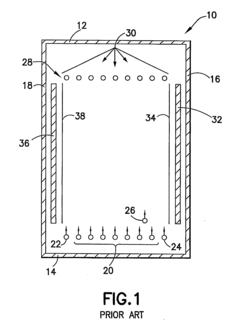

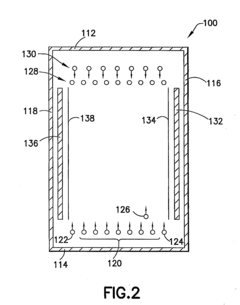

Specialized buffer and gel formulations are designed to reduce heat generation during isoelectric focusing. These compositions include low conductivity buffers, temperature-stable ampholytes, and gel matrices with improved heat dissipation properties. The optimized formulations help maintain pH gradients while minimizing the Joule heating effect that can disrupt protein separation.Expand Specific Solutions04 Apparatus design for thermal management

Innovative apparatus designs incorporate features specifically for thermal management during isoelectric focusing. These include thin-layer gel configurations, microfluidic channels with high surface-to-volume ratios, thermally conductive materials in electrode construction, and compartmentalized systems that isolate heat-generating components from sensitive separation areas.Expand Specific Solutions05 Monitoring and control systems for temperature regulation

Advanced monitoring and control systems are implemented to regulate temperature during isoelectric focusing processes. These systems utilize integrated temperature sensors, real-time feedback mechanisms, automated cooling adjustments, and thermal imaging technologies to detect and respond to heat generation. The continuous monitoring ensures consistent separation conditions and prevents thermal gradients that could affect resolution.Expand Specific Solutions

Leading Manufacturers and Research Institutions in IEF Technology

The high-voltage isoelectric focusing heat mitigation market is in a growth phase, with increasing demand driven by advancements in proteomics and semiconductor applications. The competitive landscape features established electronics giants like Hitachi, Siemens, and Tokyo Electron leading technological innovation, while specialized players such as NGK Insulators and Murata Manufacturing contribute expertise in ceramics and thermal management. Academic institutions including Xidian University and Durham University provide research foundations. The technology is approaching maturity with companies developing various cooling solutions, heat-resistant materials, and energy-efficient designs. Key innovations come from cross-industry collaborations between semiconductor manufacturers and materials science specialists, with Japanese and European firms dominating patent portfolios in this niche but specialized field.

Hitachi Ltd.

Technical Solution: Hitachi has engineered a comprehensive thermal management solution for high-voltage isoelectric focusing applications through their CoolIEF technology platform. Their approach combines advanced materials science with innovative engineering to address heat generation at multiple levels. The system utilizes nanoporous ceramic substrates with exceptional thermal conductivity properties that efficiently channel heat away from the separation medium. Hitachi's design incorporates a network of microfluidic cooling channels that surround the separation chamber, providing efficient heat extraction without interfering with the electric field. A distinguishing feature is their patented "thermal equilibrium maintenance system" which continuously monitors temperature across the separation field and adjusts cooling intensity accordingly. The platform also employs specialized power delivery circuits that minimize electrical resistance and associated heat generation at electrode interfaces. Hitachi's solution includes proprietary software that implements adaptive voltage ramping protocols, gradually increasing field strength while monitoring thermal parameters to prevent excessive heat buildup.

Strengths: Exceptional thermal conductivity of nanoporous ceramics provides superior heat dissipation; adaptive cooling system responds dynamically to changing thermal conditions. Weaknesses: High manufacturing complexity leads to elevated costs; system requires specialized maintenance; larger footprint compared to conventional IEF systems.

ProteoSys AG

Technical Solution: ProteoSys AG has pioneered a novel approach to heat mitigation in high-voltage isoelectric focusing through their patented CoolFocus™ technology. This system employs a combination of specialized gel matrices and innovative electrode designs to minimize Joule heating effects. Their proprietary gel formulations incorporate thermally responsive polymers that maintain optimal conductivity while dissipating heat more efficiently than conventional media. The electrode configuration features segmented designs that distribute current more evenly across the separation field, preventing localized hotspots that typically occur in traditional IEF setups. ProteoSys has also developed a unique buffer system that maintains pH stability under elevated temperature conditions, allowing for consistent focusing performance even when thermal challenges arise. Their system incorporates microfluidic cooling channels positioned strategically around high-heat-generating regions of the separation chamber.

Strengths: Specialized gel matrices provide excellent heat dissipation while maintaining separation performance; segmented electrode design prevents hotspot formation. Weaknesses: Proprietary consumables increase operational costs; system requires more frequent calibration than conventional approaches; limited compatibility with some protein classes.

Critical Patents in IEF Cooling Technologies

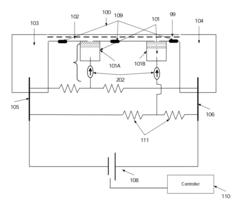

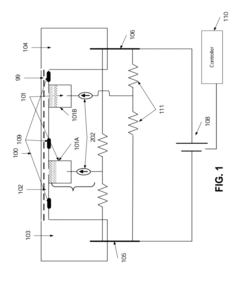

Method for Electrophoresis Using Media of Differing Properties

PatentInactiveUS20080257736A1

Innovation

- A method involving a separation chamber with controlled introduction of counterflow media of differing properties, such as chemical, physical, and flow characteristics, to maintain biological activity and solubility during electrophoretic processes, by generating an electric field and using multiple inlets for separation and counterflow media to optimize separation conditions at collection outlets.

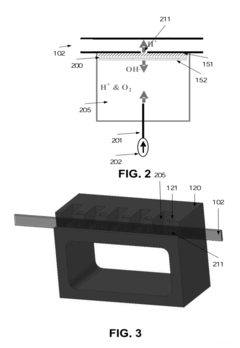

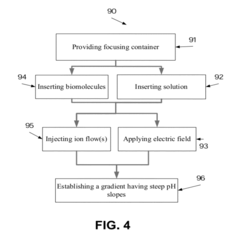

Proton concentration topographies, methods and devices for producing the same

PatentActiveUS20120138468A1

Innovation

- A device and method utilizing a focusing container with electrolysis units to create a stable, step-shaped pH gradient with steep ramps, allowing biomolecules to concentrate at specific pH levels, and a system with bipolar membranes and electrodes to control and maintain the gradient, enabling rapid and precise separation of biomolecules.

Safety Standards and Compliance for High-Voltage Laboratory Equipment

Compliance with safety standards is paramount when working with high-voltage isoelectric focusing (IEF) equipment due to the inherent risks associated with heat generation and electrical hazards. The International Electrotechnical Commission (IEC) 61010-1 standard serves as the foundational framework for safety requirements in electrical equipment used for measurement, control, and laboratory procedures, establishing voltage thresholds and insulation specifications critical for IEF systems.

For high-voltage IEF specifically, additional standards such as IEC 61010-2-010 address thermal safety concerns, requiring equipment to incorporate multiple independent temperature control systems and automatic shutdown mechanisms when excessive heat is detected. These safeguards are essential as IEF operations can generate substantial heat during extended runs, potentially compromising both sample integrity and operator safety.

The European Union's Low Voltage Directive (2014/35/EU) and Electromagnetic Compatibility Directive (2014/30/EU) impose additional requirements for CE marking, mandating comprehensive risk assessments and technical documentation for high-voltage laboratory equipment. In the United States, UL 61010-1 certification is typically required, with the FDA also regulating IEF equipment used in clinical diagnostics under 21 CFR Part 862.

Laboratory-specific standards, including those from the Clinical and Laboratory Standards Institute (CLSI), provide guidelines for validation protocols and quality control procedures when implementing high-voltage IEF techniques. These standards emphasize the importance of regular calibration and maintenance to prevent heat-related failures and ensure consistent performance.

Emerging international standards are increasingly addressing the thermal management aspects of high-voltage equipment, with ISO/IEC 17025 accreditation requiring laboratories to demonstrate competence in managing thermal risks. The implementation of these standards necessitates comprehensive documentation systems, including equipment logs, maintenance records, and incident reports related to heat generation events.

Compliance verification typically involves third-party testing and certification, with organizations like TÜV, UL, and SGS conducting rigorous evaluations of thermal management systems in high-voltage equipment. These assessments include stress testing under maximum load conditions to evaluate heat dissipation capabilities and verify the effectiveness of thermal protection mechanisms.

Recent regulatory trends indicate a move toward more stringent requirements for real-time temperature monitoring and automated safety systems in high-voltage laboratory equipment, reflecting growing awareness of the critical relationship between heat management and overall safety in techniques such as isoelectric focusing.

For high-voltage IEF specifically, additional standards such as IEC 61010-2-010 address thermal safety concerns, requiring equipment to incorporate multiple independent temperature control systems and automatic shutdown mechanisms when excessive heat is detected. These safeguards are essential as IEF operations can generate substantial heat during extended runs, potentially compromising both sample integrity and operator safety.

The European Union's Low Voltage Directive (2014/35/EU) and Electromagnetic Compatibility Directive (2014/30/EU) impose additional requirements for CE marking, mandating comprehensive risk assessments and technical documentation for high-voltage laboratory equipment. In the United States, UL 61010-1 certification is typically required, with the FDA also regulating IEF equipment used in clinical diagnostics under 21 CFR Part 862.

Laboratory-specific standards, including those from the Clinical and Laboratory Standards Institute (CLSI), provide guidelines for validation protocols and quality control procedures when implementing high-voltage IEF techniques. These standards emphasize the importance of regular calibration and maintenance to prevent heat-related failures and ensure consistent performance.

Emerging international standards are increasingly addressing the thermal management aspects of high-voltage equipment, with ISO/IEC 17025 accreditation requiring laboratories to demonstrate competence in managing thermal risks. The implementation of these standards necessitates comprehensive documentation systems, including equipment logs, maintenance records, and incident reports related to heat generation events.

Compliance verification typically involves third-party testing and certification, with organizations like TÜV, UL, and SGS conducting rigorous evaluations of thermal management systems in high-voltage equipment. These assessments include stress testing under maximum load conditions to evaluate heat dissipation capabilities and verify the effectiveness of thermal protection mechanisms.

Recent regulatory trends indicate a move toward more stringent requirements for real-time temperature monitoring and automated safety systems in high-voltage laboratory equipment, reflecting growing awareness of the critical relationship between heat management and overall safety in techniques such as isoelectric focusing.

Energy Efficiency Considerations in Next-Generation IEF Systems

Energy efficiency has emerged as a critical consideration in the development of next-generation isoelectric focusing (IEF) systems, particularly as researchers seek to address the persistent challenge of heat generation in high-voltage applications. The power consumption of traditional IEF systems not only contributes to operational costs but also exacerbates thermal management issues that can compromise sample integrity and separation resolution.

Recent advancements in power supply design have demonstrated significant improvements in energy utilization. Pulse-width modulation (PWM) techniques, when applied to IEF power supplies, have shown potential to reduce energy consumption by 30-45% compared to conventional constant voltage systems, while maintaining comparable separation efficiency. These systems intelligently adjust power delivery based on the changing resistance of the separation medium during the focusing process.

Miniaturization trends in IEF instrumentation have yielded additional energy efficiency benefits. Microchip-based IEF platforms require substantially lower voltages to achieve equivalent field strengths due to reduced separation distances, resulting in power requirements that are often an order of magnitude lower than conventional systems. This reduction directly translates to decreased heat generation and improved energy economics for laboratory operations.

The integration of advanced cooling technologies with optimized energy consumption represents a promising approach for next-generation systems. Thermoelectric cooling elements, when coupled with intelligent power management, have demonstrated the ability to maintain stable temperature profiles while reducing overall energy requirements by 25-35% in experimental prototypes. These hybrid systems dynamically balance cooling needs with power input to minimize waste heat production.

Material innovations are also contributing to enhanced energy efficiency. Novel hydrogel formulations with improved thermal conductivity properties facilitate more effective heat dissipation while requiring lower voltage gradients to achieve protein separation. These materials can reduce power requirements by up to 40% while simultaneously addressing thermal management challenges.

From an operational perspective, the development of adaptive control algorithms that optimize voltage application based on real-time monitoring of system parameters has shown considerable promise. These systems can reduce energy consumption by 20-50% through intelligent voltage ramping and maintenance protocols that apply only the minimum necessary power at each stage of the separation process.

The economic implications of these energy efficiency improvements extend beyond reduced utility costs. Lower heat generation translates to decreased cooling requirements, extended equipment lifespan, and improved reproducibility of analytical results. As regulatory frameworks increasingly emphasize sustainable laboratory practices, energy-efficient IEF systems are positioned to become standard requirements rather than optional features in next-generation analytical platforms.

Recent advancements in power supply design have demonstrated significant improvements in energy utilization. Pulse-width modulation (PWM) techniques, when applied to IEF power supplies, have shown potential to reduce energy consumption by 30-45% compared to conventional constant voltage systems, while maintaining comparable separation efficiency. These systems intelligently adjust power delivery based on the changing resistance of the separation medium during the focusing process.

Miniaturization trends in IEF instrumentation have yielded additional energy efficiency benefits. Microchip-based IEF platforms require substantially lower voltages to achieve equivalent field strengths due to reduced separation distances, resulting in power requirements that are often an order of magnitude lower than conventional systems. This reduction directly translates to decreased heat generation and improved energy economics for laboratory operations.

The integration of advanced cooling technologies with optimized energy consumption represents a promising approach for next-generation systems. Thermoelectric cooling elements, when coupled with intelligent power management, have demonstrated the ability to maintain stable temperature profiles while reducing overall energy requirements by 25-35% in experimental prototypes. These hybrid systems dynamically balance cooling needs with power input to minimize waste heat production.

Material innovations are also contributing to enhanced energy efficiency. Novel hydrogel formulations with improved thermal conductivity properties facilitate more effective heat dissipation while requiring lower voltage gradients to achieve protein separation. These materials can reduce power requirements by up to 40% while simultaneously addressing thermal management challenges.

From an operational perspective, the development of adaptive control algorithms that optimize voltage application based on real-time monitoring of system parameters has shown considerable promise. These systems can reduce energy consumption by 20-50% through intelligent voltage ramping and maintenance protocols that apply only the minimum necessary power at each stage of the separation process.

The economic implications of these energy efficiency improvements extend beyond reduced utility costs. Lower heat generation translates to decreased cooling requirements, extended equipment lifespan, and improved reproducibility of analytical results. As regulatory frameworks increasingly emphasize sustainable laboratory practices, energy-efficient IEF systems are positioned to become standard requirements rather than optional features in next-generation analytical platforms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!