Validating Ampholyte Mixtures for Consistent Isoelectric Focusing

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ampholyte Mixtures Background and Validation Objectives

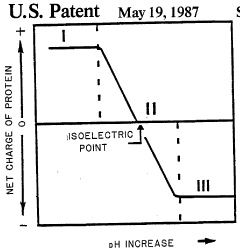

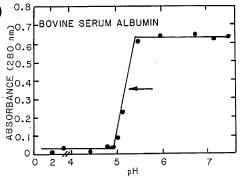

Isoelectric focusing (IEF) represents a cornerstone technique in protein separation and analysis, with its development dating back to the 1960s. This high-resolution electrophoretic method separates proteins based on their isoelectric points (pI), the pH at which proteins carry no net electrical charge. Central to this technique are ampholyte mixtures, complex solutions of amphoteric molecules that establish stable pH gradients when subjected to an electric field.

The evolution of ampholyte technology has progressed significantly over the past decades, transitioning from carrier ampholytes derived from aliphatic oligoamines to synthetic peptide-based ampholytes with enhanced properties. This technological progression has enabled increasingly precise protein separations, critical for applications ranging from proteomics research to clinical diagnostics and biopharmaceutical quality control.

Despite these advancements, the reproducibility and consistency of ampholyte mixtures remain persistent challenges in the field. Batch-to-batch variations in commercial ampholyte preparations can significantly impact the reliability of IEF results, introducing unwanted variables into analytical workflows and complicating data interpretation across different laboratories or time points.

The primary objective of this technical investigation is to establish robust validation methodologies for ampholyte mixtures to ensure consistent isoelectric focusing performance. Specifically, we aim to develop standardized protocols for evaluating key parameters including pH gradient linearity, gradient stability over time, resolution capacity, and reproducibility across multiple runs and batches.

Additionally, this research seeks to identify critical quality attributes of ampholyte mixtures that most significantly impact IEF performance, enabling more informed selection and quality control of these essential reagents. By establishing quantitative acceptance criteria for ampholyte validation, we intend to provide the scientific community with objective standards for assessing ampholyte quality.

The technological trajectory in this field points toward increased precision in pH gradient formation and enhanced stability during extended separations. Recent innovations include immobilized pH gradients (IPGs) and hybrid systems combining carrier ampholytes with immobilized components, offering improved reproducibility but introducing new validation challenges.

This investigation aligns with broader industry trends toward increased standardization and quality control in analytical methodologies, particularly for applications in regulated environments such as clinical diagnostics and biopharmaceutical manufacturing. By addressing the fundamental challenge of ampholyte validation, we aim to strengthen the foundation of numerous downstream applications dependent on reliable IEF performance.

The evolution of ampholyte technology has progressed significantly over the past decades, transitioning from carrier ampholytes derived from aliphatic oligoamines to synthetic peptide-based ampholytes with enhanced properties. This technological progression has enabled increasingly precise protein separations, critical for applications ranging from proteomics research to clinical diagnostics and biopharmaceutical quality control.

Despite these advancements, the reproducibility and consistency of ampholyte mixtures remain persistent challenges in the field. Batch-to-batch variations in commercial ampholyte preparations can significantly impact the reliability of IEF results, introducing unwanted variables into analytical workflows and complicating data interpretation across different laboratories or time points.

The primary objective of this technical investigation is to establish robust validation methodologies for ampholyte mixtures to ensure consistent isoelectric focusing performance. Specifically, we aim to develop standardized protocols for evaluating key parameters including pH gradient linearity, gradient stability over time, resolution capacity, and reproducibility across multiple runs and batches.

Additionally, this research seeks to identify critical quality attributes of ampholyte mixtures that most significantly impact IEF performance, enabling more informed selection and quality control of these essential reagents. By establishing quantitative acceptance criteria for ampholyte validation, we intend to provide the scientific community with objective standards for assessing ampholyte quality.

The technological trajectory in this field points toward increased precision in pH gradient formation and enhanced stability during extended separations. Recent innovations include immobilized pH gradients (IPGs) and hybrid systems combining carrier ampholytes with immobilized components, offering improved reproducibility but introducing new validation challenges.

This investigation aligns with broader industry trends toward increased standardization and quality control in analytical methodologies, particularly for applications in regulated environments such as clinical diagnostics and biopharmaceutical manufacturing. By addressing the fundamental challenge of ampholyte validation, we aim to strengthen the foundation of numerous downstream applications dependent on reliable IEF performance.

Market Analysis of Isoelectric Focusing Applications

The global market for isoelectric focusing (IEF) technology continues to expand significantly, driven by increasing applications in proteomics research, pharmaceutical development, and clinical diagnostics. Currently valued at approximately $1.3 billion, the IEF market is projected to grow at a compound annual growth rate of 5.7% through 2028, with particularly strong growth in Asia-Pacific regions where biotechnology infrastructure is rapidly developing.

Pharmaceutical and biotechnology sectors represent the largest market segments, collectively accounting for over 60% of IEF applications. These industries rely heavily on consistent and reproducible IEF techniques for protein characterization, quality control, and formulation development. The demand for validated ampholyte mixtures has become particularly critical as regulatory requirements for biopharmaceutical products become more stringent.

Academic and research institutions constitute another significant market segment, representing approximately 25% of the total market. Here, IEF technologies are primarily utilized for fundamental protein research, biomarker discovery, and method development. The consistent performance of ampholyte mixtures directly impacts research reproducibility, a growing concern in the scientific community.

Clinical diagnostics represents a smaller but rapidly growing segment at 15% of the market. The application of IEF in clinical settings for protein-based disease biomarkers and personalized medicine approaches is creating new demand for highly validated and consistent ampholyte formulations. This segment is expected to grow at nearly 8% annually, outpacing the overall market.

Regional analysis reveals North America as the dominant market with 42% share, followed by Europe (30%), Asia-Pacific (20%), and rest of the world (8%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 7.8% annually, driven by expanding biotechnology sectors in China, India, and South Korea.

Key market drivers include the growing emphasis on protein-based therapeutics, increasing research in proteomics, technological advancements in 2D electrophoresis systems, and rising demand for personalized medicine approaches. Conversely, market restraints include the technical complexity of IEF methods, high equipment costs, and competition from alternative protein separation technologies.

Customer needs analysis reveals that end-users prioritize reproducibility (cited by 87% of users), resolution (76%), ease of use (65%), and compatibility with downstream analysis (58%). The validation of ampholyte mixtures directly addresses the primary concern of reproducibility, positioning solutions in this area to capture significant market value.

Pharmaceutical and biotechnology sectors represent the largest market segments, collectively accounting for over 60% of IEF applications. These industries rely heavily on consistent and reproducible IEF techniques for protein characterization, quality control, and formulation development. The demand for validated ampholyte mixtures has become particularly critical as regulatory requirements for biopharmaceutical products become more stringent.

Academic and research institutions constitute another significant market segment, representing approximately 25% of the total market. Here, IEF technologies are primarily utilized for fundamental protein research, biomarker discovery, and method development. The consistent performance of ampholyte mixtures directly impacts research reproducibility, a growing concern in the scientific community.

Clinical diagnostics represents a smaller but rapidly growing segment at 15% of the market. The application of IEF in clinical settings for protein-based disease biomarkers and personalized medicine approaches is creating new demand for highly validated and consistent ampholyte formulations. This segment is expected to grow at nearly 8% annually, outpacing the overall market.

Regional analysis reveals North America as the dominant market with 42% share, followed by Europe (30%), Asia-Pacific (20%), and rest of the world (8%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 7.8% annually, driven by expanding biotechnology sectors in China, India, and South Korea.

Key market drivers include the growing emphasis on protein-based therapeutics, increasing research in proteomics, technological advancements in 2D electrophoresis systems, and rising demand for personalized medicine approaches. Conversely, market restraints include the technical complexity of IEF methods, high equipment costs, and competition from alternative protein separation technologies.

Customer needs analysis reveals that end-users prioritize reproducibility (cited by 87% of users), resolution (76%), ease of use (65%), and compatibility with downstream analysis (58%). The validation of ampholyte mixtures directly addresses the primary concern of reproducibility, positioning solutions in this area to capture significant market value.

Technical Challenges in Ampholyte Mixture Consistency

The development of consistent ampholyte mixtures for isoelectric focusing (IEF) faces several significant technical challenges that have persisted despite decades of research. One of the primary obstacles is the inherent chemical complexity of carrier ampholytes, which typically consist of hundreds to thousands of different amphoteric molecules with closely spaced pI values. This heterogeneity makes precise characterization and quality control extremely difficult, resulting in batch-to-batch variations that compromise reproducibility in IEF experiments.

Manufacturing consistency presents another major hurdle. Current synthesis methods for ampholyte mixtures involve complex chemical reactions that are sensitive to slight variations in reaction conditions, reagent purity, and process parameters. Even minor deviations can significantly alter the final pI distribution profile of the mixture, affecting resolution and separation performance in downstream applications.

The stability of ampholyte mixtures during storage and use constitutes a persistent challenge. These mixtures can undergo chemical changes over time, including oxidation, hydrolysis, and aggregation, which alter their buffering capacity and pI values. Environmental factors such as temperature fluctuations, exposure to light, and humidity can accelerate these degradation processes, further complicating efforts to maintain consistent performance.

Analytical limitations represent a substantial technical barrier. Current methods for characterizing ampholyte mixtures lack the resolution and sensitivity needed to fully profile these complex mixtures. Techniques such as mass spectrometry, capillary electrophoresis, and chromatography provide only partial information about composition and pI distribution, making comprehensive validation difficult.

The establishment of standardized validation protocols remains elusive. The industry lacks universally accepted methods and reference standards for evaluating ampholyte mixture performance. This absence of standardization makes it challenging to compare results across different laboratories and manufacturers, hindering scientific progress and quality assurance efforts.

Scaling production while maintaining consistency presents significant engineering challenges. As demand for high-resolution IEF increases in proteomics, diagnostics, and biopharmaceutical applications, manufacturers struggle to scale up production processes without compromising product quality and consistency. The transition from laboratory to industrial scale often introduces new variables that affect product performance.

Finally, the development of synthetic alternatives to traditional carrier ampholytes faces substantial hurdles in achieving the desired pH range coverage, buffering capacity, and conductivity properties while ensuring batch-to-batch reproducibility. Despite advances in polymer chemistry and synthetic biology, creating fully defined and consistent ampholyte systems remains an elusive goal for researchers and manufacturers alike.

Manufacturing consistency presents another major hurdle. Current synthesis methods for ampholyte mixtures involve complex chemical reactions that are sensitive to slight variations in reaction conditions, reagent purity, and process parameters. Even minor deviations can significantly alter the final pI distribution profile of the mixture, affecting resolution and separation performance in downstream applications.

The stability of ampholyte mixtures during storage and use constitutes a persistent challenge. These mixtures can undergo chemical changes over time, including oxidation, hydrolysis, and aggregation, which alter their buffering capacity and pI values. Environmental factors such as temperature fluctuations, exposure to light, and humidity can accelerate these degradation processes, further complicating efforts to maintain consistent performance.

Analytical limitations represent a substantial technical barrier. Current methods for characterizing ampholyte mixtures lack the resolution and sensitivity needed to fully profile these complex mixtures. Techniques such as mass spectrometry, capillary electrophoresis, and chromatography provide only partial information about composition and pI distribution, making comprehensive validation difficult.

The establishment of standardized validation protocols remains elusive. The industry lacks universally accepted methods and reference standards for evaluating ampholyte mixture performance. This absence of standardization makes it challenging to compare results across different laboratories and manufacturers, hindering scientific progress and quality assurance efforts.

Scaling production while maintaining consistency presents significant engineering challenges. As demand for high-resolution IEF increases in proteomics, diagnostics, and biopharmaceutical applications, manufacturers struggle to scale up production processes without compromising product quality and consistency. The transition from laboratory to industrial scale often introduces new variables that affect product performance.

Finally, the development of synthetic alternatives to traditional carrier ampholytes faces substantial hurdles in achieving the desired pH range coverage, buffering capacity, and conductivity properties while ensuring batch-to-batch reproducibility. Despite advances in polymer chemistry and synthetic biology, creating fully defined and consistent ampholyte systems remains an elusive goal for researchers and manufacturers alike.

Current Validation Methods for Ampholyte Mixtures

01 Ampholyte mixtures for improved consistency in personal care products

Ampholyte mixtures can be formulated to provide improved consistency in personal care products such as shampoos, conditioners, and body washes. These mixtures typically contain both anionic and cationic components that balance each other to create stable formulations with desired rheological properties. The ampholyte systems help maintain product consistency across varying pH levels and temperature conditions, resulting in better shelf stability and consumer experience.- Ampholyte mixtures for improved consistency in personal care products: Ampholyte mixtures can be formulated to provide improved consistency in personal care products such as shampoos, conditioners, and creams. These mixtures contain both acidic and basic functional groups that can adjust to different pH environments, providing stability and uniform texture. The balanced charge distribution in ampholyte mixtures helps maintain product consistency across varying conditions and improves the sensory properties of the final formulation.

- Ampholyte mixtures in paper manufacturing for consistency control: Ampholyte mixtures are utilized in paper manufacturing processes to control the consistency of pulp and improve paper quality. These mixtures help in maintaining uniform fiber distribution, enhancing retention of fillers, and controlling drainage during the papermaking process. The amphoteric nature allows for effective interaction with both anionic and cationic components in the pulp, resulting in more consistent paper formation and improved mechanical properties.

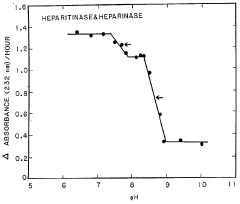

- Electrophoresis applications of ampholyte mixtures: Ampholyte mixtures are crucial in electrophoresis techniques for creating stable pH gradients. These mixtures contain various amphoteric compounds that establish and maintain consistent pH environments during separation processes. The careful formulation of ampholyte mixtures ensures reproducible separation of proteins and other biomolecules by providing uniform electric fields and consistent migration patterns, enhancing the resolution and reliability of analytical results.

- Ampholyte mixtures in water treatment applications: Ampholyte mixtures are employed in water treatment processes to maintain consistent water quality and control impurities. These mixtures can function effectively across a range of pH conditions due to their amphoteric properties, allowing them to neutralize both acidic and basic contaminants. The formulation of specific ampholyte mixtures can be tailored to target particular water quality issues, providing consistent treatment results and improved efficiency in purification systems.

- Stabilization of emulsions using ampholyte mixtures: Ampholyte mixtures serve as effective stabilizers for emulsions in various industrial applications. The dual-charged nature of ampholytes allows them to position at oil-water interfaces, reducing interfacial tension and preventing coalescence of dispersed droplets. By carefully selecting and combining different ampholytic compounds, formulators can achieve consistent emulsion properties including viscosity, droplet size distribution, and long-term stability, even under challenging storage or processing conditions.

02 Ampholyte mixtures in paper manufacturing for consistency control

In paper manufacturing processes, ampholyte mixtures are used to control the consistency of pulp and improve paper formation. These mixtures help in maintaining uniform fiber distribution and enhancing retention of fillers and other additives. The amphoteric nature of these compounds allows them to interact with both anionic and cationic components in the pulp slurry, leading to better drainage, improved sheet formation, and more consistent paper quality.Expand Specific Solutions03 Ampholyte mixtures for electrophoresis and separation techniques

Ampholyte mixtures are crucial in electrophoresis and other separation techniques where consistent pH gradients are required. These mixtures contain various amphoteric compounds with different isoelectric points that, when subjected to an electric field, arrange themselves to form a stable pH gradient. This allows for precise separation of proteins and other biomolecules based on their isoelectric points. The consistency of the ampholyte mixture directly affects the reproducibility and resolution of the separation process.Expand Specific Solutions04 Temperature-responsive ampholyte mixtures for controlled consistency

Temperature-responsive ampholyte mixtures exhibit changes in consistency based on temperature variations. These smart materials can transition from liquid to gel states or change their viscosity in response to temperature stimuli. Such behavior is valuable in applications requiring controlled release, such as drug delivery systems, or in processes where flow properties need to be precisely managed. The amphoteric nature of these mixtures allows for fine-tuning of the temperature response threshold and the magnitude of the consistency change.Expand Specific Solutions05 Digital systems for monitoring and controlling ampholyte mixture consistency

Advanced digital systems have been developed to monitor and control the consistency of ampholyte mixtures in real-time during industrial processes. These systems employ sensors, data analytics, and feedback mechanisms to continuously assess mixture properties and make automatic adjustments to maintain desired consistency. Machine learning algorithms can predict consistency changes based on process variables and recommend corrective actions. This digital approach ensures more uniform product quality and reduces waste from inconsistent batches.Expand Specific Solutions

Leading Manufacturers and Research Institutions in IEF

The isoelectric focusing (IEF) market is currently in a growth phase, with increasing demand for consistent ampholyte mixtures for protein separation and analysis. The global market size for electrophoresis techniques, including IEF, is expanding at approximately 5-7% annually, driven by proteomics research and biopharmaceutical development. Leading companies like Bio-Rad Laboratories, F. Hoffmann-La Roche, and Becton, Dickinson & Co. have established strong market positions with validated ampholyte products. Academic institutions such as Texas A&M University and MIT are advancing fundamental research, while pharmaceutical giants Regeneron and Novartis are integrating IEF into their analytical workflows. The technology has reached moderate maturity, with ongoing innovations focused on reproducibility, resolution, and automation, particularly from specialized players like Life Technologies and Hamamatsu Photonics who are developing next-generation detection systems.

Regeneron Pharmaceuticals, Inc.

Technical Solution: Regeneron has developed a sophisticated approach to ampholyte validation specifically tailored for biotherapeutic characterization. Their system employs a combination of synthetic and natural ampholytes that undergo extensive purification to remove contaminants that could interfere with protein analysis. The company's validation methodology includes comprehensive physicochemical characterization of ampholyte mixtures using capillary electrophoresis, conductivity profiling, and dynamic light scattering to ensure consistent performance. Each batch is tested with a panel of reference monoclonal antibodies and fusion proteins to verify reproducible isoelectric point determination across multiple production lots[5]. Regeneron's ampholyte formulations incorporate stabilizing agents that prevent protein aggregation during focusing, particularly important for maintaining the native structure of therapeutic proteins. Their validation process also includes accelerated stability studies to ensure consistent performance throughout the shelf-life of the ampholyte preparations.

Strengths: Specifically optimized for biotherapeutic applications with demonstrated compatibility with complex protein therapeutics; extensive validation data available for regulatory submissions. Weaknesses: Specialized formulations may be less versatile for general research applications; higher cost reflecting pharmaceutical-grade manufacturing standards.

Life Technologies Corp.

Technical Solution: Life Technologies has pioneered a systematic approach to ampholyte mixture validation through their ZOOM® IEF Fractionator system. Their technology employs narrow-range ampholytes that are carefully fractionated and characterized to ensure precise pH gradient formation. The company utilizes a proprietary manufacturing process that involves sequential fractionation of carrier ampholytes followed by extensive quality control testing. Each batch undergoes conductivity profiling, real-time pH monitoring during focusing, and protein separation efficiency tests using standardized marker proteins. Their validation methodology includes measuring the resolving power using a defined set of proteins with known isoelectric points across multiple batches to ensure consistency[2]. Life Technologies' ampholytes are formulated with stabilizing components that minimize electroendosmosis and prevent precipitation during extended focusing times, particularly beneficial for high-resolution applications like proteomics research.

Strengths: Exceptional resolution in narrow pH ranges (as small as 0.2 pH units) allowing for detection of subtle post-translational modifications; comprehensive validation documentation provided with each lot. Weaknesses: More complex setup requirements; higher sensitivity to sample contaminants that can disrupt the gradient formation.

Key Patents and Innovations in Ampholyte Formulation

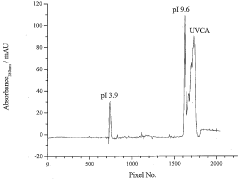

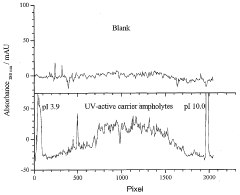

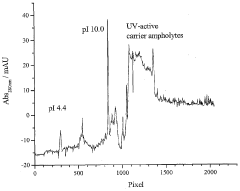

Determination of the operational isoelectric point of isoelectric membranes

PatentWO2005073709A1

Innovation

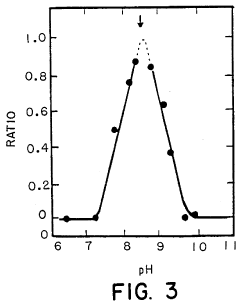

- Development of detectable carrier ampholyte mixtures with UV-absorbing or fluorescent properties, bound to polyethylenimine or other oligoamines, which are used in isoelectric focusing or trapping separations to determine the operational pi value by analyzing the movement of these ampholytes across the membrane.

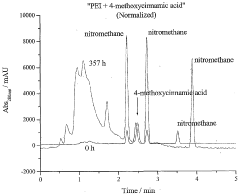

Rapid method for determining the isoelectric point for amphoteric molecules

PatentInactiveUS4666855A

Innovation

- A novel method involving the preparation of test solutions and suspensions at varying pH values, using ion-exchange materials like SP-Sephadex or QAE-Sephadex, where the binding affinity of amphoteric molecules is measured to determine the isoelectric point within one hour, avoiding carrier ampholyte interactions and allowing measurements at any temperature.

Quality Control Frameworks for Analytical Reagents

Quality control frameworks for analytical reagents in the context of ampholyte mixture validation represent a critical component for ensuring reproducible isoelectric focusing (IEF) results. These frameworks establish systematic approaches to verify reagent quality, consistency, and performance characteristics before implementation in analytical procedures.

Comprehensive quality control systems typically incorporate multi-tiered testing protocols that evaluate ampholyte mixtures across several parameters. Primary among these are pH range verification, conductivity measurements, and resolution capacity assessment. Each batch of carrier ampholytes must demonstrate consistent pH gradient formation under standardized conditions to ensure reliable protein separation during IEF applications.

Regulatory standards from organizations such as ISO, USP, and ICH provide foundational guidelines for analytical reagent quality control. These standards emphasize traceability, documentation, and validation methodologies specific to separation media like ampholytes. Implementation of these standards requires establishing acceptance criteria that reflect the critical quality attributes necessary for successful IEF performance.

Statistical process control methods play an essential role in ampholyte quality frameworks. Techniques such as control charting, capability analysis, and trend monitoring enable detection of drift in manufacturing processes before they impact analytical outcomes. For carrier ampholytes, statistical monitoring of batch-to-batch consistency in pH gradient formation represents a key quality indicator.

Reference material certification constitutes another cornerstone of quality control frameworks. Well-characterized standard ampholyte mixtures with certified properties serve as benchmarks against which new batches can be compared. These reference materials should ideally be traceable to internationally recognized standards to ensure global consistency in analytical methods.

Stability testing protocols form an integral component of ampholyte quality control frameworks. These protocols evaluate how storage conditions and time affect critical parameters such as pH range stability, conductivity, and separation efficiency. Accelerated aging studies can help predict shelf-life limitations and establish appropriate storage recommendations for maintaining ampholyte performance.

Advanced analytical characterization techniques further strengthen quality control frameworks. Methods such as capillary electrophoresis, mass spectrometry, and conductivity profiling provide detailed compositional information about ampholyte mixtures. These techniques enable manufacturers to establish detailed fingerprints of acceptable ampholyte formulations against which future batches can be compared.

Comprehensive quality control systems typically incorporate multi-tiered testing protocols that evaluate ampholyte mixtures across several parameters. Primary among these are pH range verification, conductivity measurements, and resolution capacity assessment. Each batch of carrier ampholytes must demonstrate consistent pH gradient formation under standardized conditions to ensure reliable protein separation during IEF applications.

Regulatory standards from organizations such as ISO, USP, and ICH provide foundational guidelines for analytical reagent quality control. These standards emphasize traceability, documentation, and validation methodologies specific to separation media like ampholytes. Implementation of these standards requires establishing acceptance criteria that reflect the critical quality attributes necessary for successful IEF performance.

Statistical process control methods play an essential role in ampholyte quality frameworks. Techniques such as control charting, capability analysis, and trend monitoring enable detection of drift in manufacturing processes before they impact analytical outcomes. For carrier ampholytes, statistical monitoring of batch-to-batch consistency in pH gradient formation represents a key quality indicator.

Reference material certification constitutes another cornerstone of quality control frameworks. Well-characterized standard ampholyte mixtures with certified properties serve as benchmarks against which new batches can be compared. These reference materials should ideally be traceable to internationally recognized standards to ensure global consistency in analytical methods.

Stability testing protocols form an integral component of ampholyte quality control frameworks. These protocols evaluate how storage conditions and time affect critical parameters such as pH range stability, conductivity, and separation efficiency. Accelerated aging studies can help predict shelf-life limitations and establish appropriate storage recommendations for maintaining ampholyte performance.

Advanced analytical characterization techniques further strengthen quality control frameworks. Methods such as capillary electrophoresis, mass spectrometry, and conductivity profiling provide detailed compositional information about ampholyte mixtures. These techniques enable manufacturers to establish detailed fingerprints of acceptable ampholyte formulations against which future batches can be compared.

Regulatory Compliance for Laboratory Analytical Methods

Regulatory compliance for laboratory analytical methods in the context of validating ampholyte mixtures for consistent isoelectric focusing (IEF) encompasses a complex framework of standards and guidelines that must be adhered to for ensuring reliable and reproducible results. The primary regulatory bodies overseeing these methods include the FDA, ICH, ISO, and USP, each providing specific guidance for analytical method validation in laboratory settings.

For IEF applications utilizing ampholyte mixtures, compliance with FDA's 21 CFR Part 11 for electronic records and signatures is essential when documenting validation procedures and results. Additionally, ICH Q2(R1) guidelines provide specific parameters for analytical method validation, including specificity, linearity, range, accuracy, precision, detection limit, and robustness—all critical factors when validating ampholyte mixtures for consistent IEF performance.

ISO/IEC 17025 standards establish general requirements for the competence of testing and calibration laboratories, providing a framework for quality management systems that ensure technical competence and valid results. Laboratories performing ampholyte mixture validation must demonstrate compliance with these standards through proper documentation, personnel training, and equipment calibration.

The validation process for ampholyte mixtures must address specific regulatory concerns regarding batch-to-batch consistency, stability, and performance characteristics. This includes comprehensive documentation of the validation protocol, acceptance criteria, and statistical analysis methods used to evaluate the ampholyte mixtures' performance in IEF applications.

Risk assessment frameworks, such as those outlined in ICH Q9, should be incorporated into the validation strategy to identify potential failure points in the IEF process related to ampholyte mixture variability. This approach allows laboratories to implement appropriate control measures and establish monitoring protocols that satisfy regulatory expectations.

Regulatory agencies increasingly emphasize the need for lifecycle management of analytical methods, requiring ongoing verification of method performance beyond initial validation. For ampholyte mixtures used in IEF, this translates to periodic revalidation, particularly when changes occur in manufacturing processes or when new lots of ampholytes are introduced.

Compliance with Good Laboratory Practices (GLP) and Good Manufacturing Practices (GMP) is mandatory for laboratories validating ampholyte mixtures, especially when these are used in regulated environments such as pharmaceutical development or clinical diagnostics. These practices ensure that validation studies are conducted with appropriate rigor and that the resulting data maintains integrity throughout the analytical process.

For IEF applications utilizing ampholyte mixtures, compliance with FDA's 21 CFR Part 11 for electronic records and signatures is essential when documenting validation procedures and results. Additionally, ICH Q2(R1) guidelines provide specific parameters for analytical method validation, including specificity, linearity, range, accuracy, precision, detection limit, and robustness—all critical factors when validating ampholyte mixtures for consistent IEF performance.

ISO/IEC 17025 standards establish general requirements for the competence of testing and calibration laboratories, providing a framework for quality management systems that ensure technical competence and valid results. Laboratories performing ampholyte mixture validation must demonstrate compliance with these standards through proper documentation, personnel training, and equipment calibration.

The validation process for ampholyte mixtures must address specific regulatory concerns regarding batch-to-batch consistency, stability, and performance characteristics. This includes comprehensive documentation of the validation protocol, acceptance criteria, and statistical analysis methods used to evaluate the ampholyte mixtures' performance in IEF applications.

Risk assessment frameworks, such as those outlined in ICH Q9, should be incorporated into the validation strategy to identify potential failure points in the IEF process related to ampholyte mixture variability. This approach allows laboratories to implement appropriate control measures and establish monitoring protocols that satisfy regulatory expectations.

Regulatory agencies increasingly emphasize the need for lifecycle management of analytical methods, requiring ongoing verification of method performance beyond initial validation. For ampholyte mixtures used in IEF, this translates to periodic revalidation, particularly when changes occur in manufacturing processes or when new lots of ampholytes are introduced.

Compliance with Good Laboratory Practices (GLP) and Good Manufacturing Practices (GMP) is mandatory for laboratories validating ampholyte mixtures, especially when these are used in regulated environments such as pharmaceutical development or clinical diagnostics. These practices ensure that validation studies are conducted with appropriate rigor and that the resulting data maintains integrity throughout the analytical process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!