Optimize Direct Lithium Extraction for Higher Recovery Rates

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a revolutionary approach to lithium production, representing a significant departure from traditional extraction methods that have dominated the industry for decades. Conventional lithium extraction primarily relies on evaporation ponds in salt flats or hard-rock mining, both of which present considerable environmental challenges and operational inefficiencies. The evolution of DLE technology began in the early 2000s, with significant acceleration in development occurring over the past decade as global demand for lithium has surged due to the rapid expansion of electric vehicle markets and energy storage systems.

DLE technologies encompass a diverse range of approaches including adsorption, ion exchange, solvent extraction, and membrane processes, all designed to selectively extract lithium from brine resources with greater efficiency and reduced environmental impact. The technological trajectory has been characterized by incremental improvements in selectivity, recovery rates, and process economics, with recent innovations focusing on enhancing lithium recovery rates while minimizing water consumption and chemical usage.

The primary objective of optimizing DLE for higher recovery rates is to address the fundamental inefficiency in current extraction methods, where significant portions of available lithium remain unrecovered. Traditional evaporation pond methods typically achieve recovery rates of only 30-50%, leaving substantial value unrealized. Advanced DLE technologies aim to push recovery rates beyond 90%, representing a transformative improvement in resource utilization efficiency.

Additional technical objectives include reducing process duration from months to days or hours, minimizing freshwater consumption, decreasing land footprint requirements, and enabling lithium extraction from previously uneconomical low-concentration brines. These objectives align with broader industry goals of establishing more sustainable and economically viable lithium production pathways to meet projected demand growth.

The optimization of DLE technologies also seeks to address specific technical challenges including lithium selectivity in the presence of competing ions, sorbent durability and regeneration efficiency, energy requirements, and process scalability. Recent technological developments have demonstrated promising advances in these areas, with several pilot projects reporting recovery rates exceeding 80% under controlled conditions.

As the technology continues to mature, the ultimate goal is to develop commercially viable DLE processes that can be deployed across diverse brine resources globally, enabling a significant expansion of lithium production capacity while minimizing environmental impacts. This technological evolution represents a critical pathway toward meeting projected lithium demand growth, which is expected to increase by 400-500% by 2030 according to industry forecasts.

DLE technologies encompass a diverse range of approaches including adsorption, ion exchange, solvent extraction, and membrane processes, all designed to selectively extract lithium from brine resources with greater efficiency and reduced environmental impact. The technological trajectory has been characterized by incremental improvements in selectivity, recovery rates, and process economics, with recent innovations focusing on enhancing lithium recovery rates while minimizing water consumption and chemical usage.

The primary objective of optimizing DLE for higher recovery rates is to address the fundamental inefficiency in current extraction methods, where significant portions of available lithium remain unrecovered. Traditional evaporation pond methods typically achieve recovery rates of only 30-50%, leaving substantial value unrealized. Advanced DLE technologies aim to push recovery rates beyond 90%, representing a transformative improvement in resource utilization efficiency.

Additional technical objectives include reducing process duration from months to days or hours, minimizing freshwater consumption, decreasing land footprint requirements, and enabling lithium extraction from previously uneconomical low-concentration brines. These objectives align with broader industry goals of establishing more sustainable and economically viable lithium production pathways to meet projected demand growth.

The optimization of DLE technologies also seeks to address specific technical challenges including lithium selectivity in the presence of competing ions, sorbent durability and regeneration efficiency, energy requirements, and process scalability. Recent technological developments have demonstrated promising advances in these areas, with several pilot projects reporting recovery rates exceeding 80% under controlled conditions.

As the technology continues to mature, the ultimate goal is to develop commercially viable DLE processes that can be deployed across diverse brine resources globally, enabling a significant expansion of lithium production capacity while minimizing environmental impacts. This technological evolution represents a critical pathway toward meeting projected lithium demand growth, which is expected to increase by 400-500% by 2030 according to industry forecasts.

Lithium Market Demand Analysis

The global lithium market is experiencing unprecedented growth driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the global lithium market at approximately $7.5 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 12-14% through 2030, potentially reaching $18-20 billion by decade's end. This remarkable trajectory is fundamentally reshaping mining priorities worldwide.

Demand for lithium carbonate equivalent (LCE) has surged from roughly 300,000 metric tons in 2020 to over 600,000 metric tons in 2023, with forecasts suggesting demand could exceed 1.5 million metric tons by 2030. The EV sector alone accounts for approximately 80% of this demand, as battery manufacturers continue scaling operations to meet automotive industry requirements. Major automakers have announced cumulative investments exceeding $500 billion toward electrification strategies through 2030.

Energy storage systems represent the second-largest demand driver, currently consuming about 15% of global lithium production. This segment is growing at 25-30% annually as grid-scale storage deployments accelerate alongside renewable energy installations. Consumer electronics, traditionally the primary lithium consumer, now represents less than 5% of total demand but remains stable.

Supply constraints have created significant market imbalances, with lithium prices experiencing volatility ranging from $8,000 to $80,000 per metric ton over the past three years. Traditional extraction methods from brine and hard rock sources cannot scale quickly enough to meet projected demand, creating a critical technology gap that Direct Lithium Extraction (DLE) technologies are positioned to address.

Regional analysis reveals China currently dominates the lithium processing market with approximately 60% of global capacity, while Australia leads raw material production. The United States and European Union have designated lithium as a critical mineral, implementing policies and funding initiatives to develop domestic supply chains and reduce dependency on imports. These initiatives include the U.S. Inflation Reduction Act and the European Critical Raw Materials Act, both allocating billions toward securing lithium supply chains.

Industry analysts project a potential supply deficit of 200,000-300,000 metric tons LCE by 2025 if extraction technologies remain unchanged. This shortfall represents a compelling market opportunity for optimized DLE technologies that can achieve higher recovery rates while reducing environmental impact and production costs.

Demand for lithium carbonate equivalent (LCE) has surged from roughly 300,000 metric tons in 2020 to over 600,000 metric tons in 2023, with forecasts suggesting demand could exceed 1.5 million metric tons by 2030. The EV sector alone accounts for approximately 80% of this demand, as battery manufacturers continue scaling operations to meet automotive industry requirements. Major automakers have announced cumulative investments exceeding $500 billion toward electrification strategies through 2030.

Energy storage systems represent the second-largest demand driver, currently consuming about 15% of global lithium production. This segment is growing at 25-30% annually as grid-scale storage deployments accelerate alongside renewable energy installations. Consumer electronics, traditionally the primary lithium consumer, now represents less than 5% of total demand but remains stable.

Supply constraints have created significant market imbalances, with lithium prices experiencing volatility ranging from $8,000 to $80,000 per metric ton over the past three years. Traditional extraction methods from brine and hard rock sources cannot scale quickly enough to meet projected demand, creating a critical technology gap that Direct Lithium Extraction (DLE) technologies are positioned to address.

Regional analysis reveals China currently dominates the lithium processing market with approximately 60% of global capacity, while Australia leads raw material production. The United States and European Union have designated lithium as a critical mineral, implementing policies and funding initiatives to develop domestic supply chains and reduce dependency on imports. These initiatives include the U.S. Inflation Reduction Act and the European Critical Raw Materials Act, both allocating billions toward securing lithium supply chains.

Industry analysts project a potential supply deficit of 200,000-300,000 metric tons LCE by 2025 if extraction technologies remain unchanged. This shortfall represents a compelling market opportunity for optimized DLE technologies that can achieve higher recovery rates while reducing environmental impact and production costs.

DLE Technical Challenges and Global Status

Direct Lithium Extraction (DLE) technologies face several significant technical challenges that have limited widespread commercial adoption. The primary challenge remains achieving consistently high lithium recovery rates while maintaining economic viability. Current DLE methods typically achieve recovery rates between 50-90%, with substantial variability depending on brine composition and the specific technology employed.

Selectivity presents another major hurdle, as most lithium-rich brines contain high concentrations of competing ions such as sodium, potassium, magnesium, and calcium. These ions can interfere with extraction processes, reducing efficiency and increasing operational costs. Advanced sorbent materials show promise but often suffer from degradation after multiple regeneration cycles.

Water consumption remains problematic for many DLE technologies, particularly in water-scarce regions where many lithium deposits are located. Some processes require significant freshwater for regeneration and washing steps, creating environmental sustainability concerns in already water-stressed environments.

Energy requirements constitute another significant challenge. Many DLE technologies demand substantial energy inputs for pumping, heating, and regeneration processes. This energy intensity affects both operational costs and environmental footprint, potentially undermining the sustainability benefits of lithium-based energy storage solutions.

Globally, DLE development shows geographic concentration patterns. North American companies lead in innovation, with several pilot projects in the United States and Canada demonstrating promising results. Notable projects in Nevada's Clayton Valley and California's Salton Sea are advancing rapidly with support from government funding and automotive industry partnerships.

In South America's "Lithium Triangle" (Argentina, Bolivia, Chile), traditional evaporation pond methods still dominate, though several companies are piloting DLE technologies to address environmental concerns and improve recovery rates. These efforts face additional challenges related to complex brine chemistry specific to these regions.

European research institutions and companies are focusing on developing more sustainable DLE technologies, with particular emphasis on closed-loop systems and reduced environmental impact. Germany's Karlsruhe Institute of Technology and several UK-based startups have made notable advances in selective membrane technologies.

Chinese companies have rapidly expanded their DLE research capabilities, with significant investments in both domestic projects and international partnerships. Their focus has been on scaling technologies for industrial application, particularly in Tibet's salt lakes and partnerships in South America.

Australia has emerged as another important player, leveraging its mining expertise to develop hybrid approaches that combine conventional methods with novel DLE technologies for application in both domestic and international projects.

Selectivity presents another major hurdle, as most lithium-rich brines contain high concentrations of competing ions such as sodium, potassium, magnesium, and calcium. These ions can interfere with extraction processes, reducing efficiency and increasing operational costs. Advanced sorbent materials show promise but often suffer from degradation after multiple regeneration cycles.

Water consumption remains problematic for many DLE technologies, particularly in water-scarce regions where many lithium deposits are located. Some processes require significant freshwater for regeneration and washing steps, creating environmental sustainability concerns in already water-stressed environments.

Energy requirements constitute another significant challenge. Many DLE technologies demand substantial energy inputs for pumping, heating, and regeneration processes. This energy intensity affects both operational costs and environmental footprint, potentially undermining the sustainability benefits of lithium-based energy storage solutions.

Globally, DLE development shows geographic concentration patterns. North American companies lead in innovation, with several pilot projects in the United States and Canada demonstrating promising results. Notable projects in Nevada's Clayton Valley and California's Salton Sea are advancing rapidly with support from government funding and automotive industry partnerships.

In South America's "Lithium Triangle" (Argentina, Bolivia, Chile), traditional evaporation pond methods still dominate, though several companies are piloting DLE technologies to address environmental concerns and improve recovery rates. These efforts face additional challenges related to complex brine chemistry specific to these regions.

European research institutions and companies are focusing on developing more sustainable DLE technologies, with particular emphasis on closed-loop systems and reduced environmental impact. Germany's Karlsruhe Institute of Technology and several UK-based startups have made notable advances in selective membrane technologies.

Chinese companies have rapidly expanded their DLE research capabilities, with significant investments in both domestic projects and international partnerships. Their focus has been on scaling technologies for industrial application, particularly in Tibet's salt lakes and partnerships in South America.

Australia has emerged as another important player, leveraging its mining expertise to develop hybrid approaches that combine conventional methods with novel DLE technologies for application in both domestic and international projects.

Current DLE Recovery Rate Solutions

01 Adsorption-based lithium extraction methods

Adsorption-based technologies for direct lithium extraction utilize specialized adsorbents to selectively capture lithium ions from brine solutions. These methods typically achieve recovery rates of 80-95% depending on the adsorbent material and process conditions. Key factors affecting recovery include adsorbent selectivity, contact time, and regeneration efficiency. Advanced adsorbents such as lithium manganese oxides and lithium titanium oxides have demonstrated improved recovery rates compared to conventional materials.- Adsorption-based lithium extraction methods: Adsorption-based methods for direct lithium extraction utilize specialized adsorbent materials that selectively capture lithium ions from brine solutions. These methods typically achieve higher recovery rates compared to traditional evaporation techniques. The process involves passing lithium-containing brines through columns or beds of adsorbent materials, followed by desorption steps to recover concentrated lithium solutions. Key factors affecting recovery rates include adsorbent selectivity, regeneration efficiency, and operational parameters such as flow rate and contact time.

- Membrane and electrochemical extraction technologies: Membrane and electrochemical technologies for direct lithium extraction employ ion-selective membranes, electrodialysis, or electrochemical cells to separate lithium from other ions in solution. These methods can achieve recovery rates of 70-90% depending on the specific technology and brine composition. The processes typically involve applying electrical potential across specialized membranes that allow preferential transport of lithium ions. Factors influencing recovery rates include membrane selectivity, current density, solution conductivity, and system design parameters.

- Solvent extraction and chemical precipitation methods: Solvent extraction and chemical precipitation methods for lithium recovery involve the use of specific solvents or chemical reagents that selectively extract lithium from brines or precipitate lithium compounds. These techniques can achieve recovery rates of 80-95% under optimized conditions. The processes typically include multiple stages of extraction or precipitation followed by separation steps. Recovery rates are influenced by solvent selectivity, reagent efficiency, pH conditions, temperature, and the presence of competing ions in the source material.

- Continuous flow and integrated extraction systems: Continuous flow and integrated extraction systems for direct lithium extraction incorporate multiple technologies in sequence to maximize recovery rates. These systems often combine pre-treatment, extraction, concentration, and purification steps in a continuous process flow. Recovery rates can exceed 90% in well-designed systems. The integrated approach allows for optimization of each process stage and recycling of reagents or solvents. Factors affecting recovery include system integration efficiency, process control precision, and the ability to handle variations in feed composition.

- Recovery rate optimization and monitoring techniques: Optimization and monitoring techniques for direct lithium extraction focus on maximizing recovery rates through process parameter adjustment and real-time monitoring. These approaches employ advanced analytics, sensors, and control systems to maintain optimal extraction conditions. Recovery rate improvements of 10-20% can be achieved through careful optimization. Key techniques include machine learning algorithms for process optimization, in-line concentration monitoring, automated adjustment of extraction parameters, and predictive maintenance to prevent efficiency losses.

02 Membrane and electrochemical extraction techniques

Membrane and electrochemical processes for lithium extraction employ ion-selective membranes or electrochemical cells to separate lithium from other ions in solution. These techniques can achieve recovery rates of 70-90% with high purity. Factors influencing recovery include membrane selectivity, applied voltage, solution chemistry, and flow rates. Recent innovations in membrane materials and electrochemical cell design have led to significant improvements in lithium recovery efficiency while reducing energy consumption.Expand Specific Solutions03 Solvent extraction and chemical precipitation methods

Solvent extraction and chemical precipitation approaches involve the use of specific solvents or chemical reagents to selectively extract or precipitate lithium from brine solutions. These methods typically achieve recovery rates of 75-85%. The efficiency depends on factors such as reagent selectivity, reaction kinetics, and separation efficiency. Recent developments have focused on environmentally friendly solvents and precipitation agents that can improve recovery rates while minimizing chemical waste and environmental impact.Expand Specific Solutions04 Integrated multi-stage extraction systems

Integrated multi-stage extraction systems combine different lithium extraction technologies in sequence to maximize overall recovery rates. These hybrid approaches can achieve recovery rates exceeding 95% by leveraging the strengths of different extraction methods. For example, a primary adsorption stage might be followed by membrane separation and final polishing steps. These integrated systems optimize recovery by addressing different lithium concentration ranges and impurity profiles at each stage of the process.Expand Specific Solutions05 Process optimization and recovery enhancement techniques

Various process optimization techniques have been developed to enhance lithium recovery rates in direct lithium extraction processes. These include optimized flow patterns, temperature control, pH adjustment, and impurity management strategies. Advanced process control systems using real-time monitoring and artificial intelligence can dynamically adjust operating parameters to maintain optimal recovery conditions. Pretreatment methods to remove interfering ions and post-treatment steps to recover residual lithium can increase overall recovery rates by 5-15% compared to standard processes.Expand Specific Solutions

Key Industry Players in DLE Technology

Direct Lithium Extraction (DLE) technology is currently in an early growth phase, with the global market expected to expand significantly due to increasing demand for lithium in battery production. The market size is projected to reach several billion dollars by 2030, driven by the electric vehicle revolution. Technologically, DLE remains in development with varying degrees of maturity across different approaches. Leading players like Lilac Solutions and International Battery Metals are pioneering commercial-scale implementations, while established companies including Schlumberger, Koch Technology Solutions, and BYD are investing heavily in R&D. Academic institutions such as Xi'an Jiaotong University and the University of Tokyo are contributing fundamental research. Traditional mining companies like Sumitomo Metal Mining and Mitsubishi Materials are also entering this space, recognizing DLE's potential to revolutionize lithium production with higher recovery rates and reduced environmental impact.

Lilac Solutions, Inc.

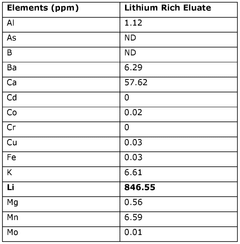

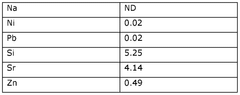

Technical Solution: Lilac Solutions has developed an innovative ion-exchange technology specifically designed for direct lithium extraction (DLE) from brine resources. Their proprietary ceramic ion-exchange beads selectively absorb lithium ions from brine while rejecting other elements. The process operates in a continuous flow system where lithium-loaded beads are regenerated using a mild acid solution, producing a concentrated lithium solution that can be further processed into battery-grade lithium products. This technology achieves recovery rates of over 90% compared to traditional evaporation pond methods that typically recover only 30-50% of lithium. Lilac's system can be deployed modularly, allowing for scalable implementation and reduced time-to-market. The technology also significantly reduces water consumption by eliminating the need for large evaporation ponds, making it environmentally superior to conventional methods while maintaining economic viability across various brine compositions.

Strengths: High lithium selectivity and recovery rates (>90%); dramatically reduced processing time (hours vs. months); minimal environmental footprint with significantly lower water usage; modular and scalable design suitable for various brine compositions. Weaknesses: Requires specialized ion-exchange materials that may have limited operational lifespans; regeneration process creates secondary waste streams that require management; higher upfront capital costs compared to traditional evaporation methods.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed NeoLith Energy, an advanced direct lithium extraction platform that leverages the company's extensive experience in oilfield technologies and subsurface expertise. Their approach combines selective adsorption technology with sophisticated process control systems to extract lithium from brine resources with significantly higher efficiency than conventional methods. The NeoLith system utilizes proprietary adsorbent materials that selectively capture lithium ions while rejecting competing elements such as sodium, magnesium, and calcium. The process operates in a continuous cycle where lithium-loaded adsorbents are regenerated using a carefully controlled chemical process, producing a concentrated lithium solution. Schlumberger's technology achieves recovery rates of 85-95% compared to traditional evaporation methods' 30-50%, while reducing water consumption by approximately 90%. The system incorporates advanced digital monitoring and control capabilities derived from Schlumberger's oilfield expertise, allowing for real-time optimization of extraction parameters based on brine composition variations. Their pilot plant in Clayton Valley, Nevada has demonstrated the ability to produce battery-grade lithium materials in a matter of weeks rather than the 18+ months required for traditional evaporation ponds.

Strengths: Leverages extensive subsurface expertise and global operational capabilities; achieves high recovery rates (85-95%); significantly reduced processing time from months to weeks; advanced digital monitoring and control systems for process optimization; substantial reduction in water usage and environmental footprint. Weaknesses: Technology still being scaled to full commercial implementation; requires significant technical expertise to operate; higher initial capital costs compared to traditional methods; potential challenges with long-term adsorbent performance and replacement costs.

Critical Patents and Innovations in DLE

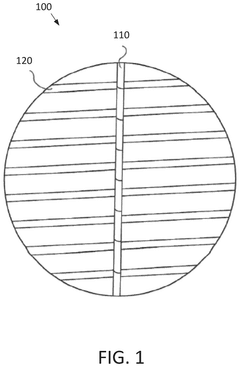

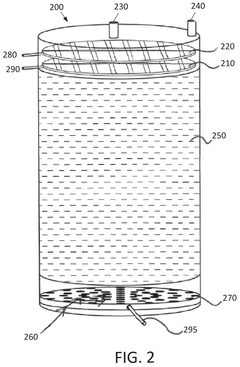

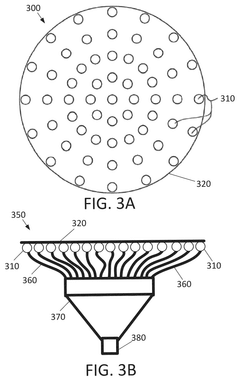

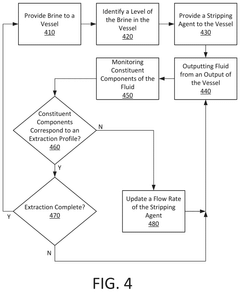

Ion extraction column for brine

PatentPendingUS20250092490A1

Innovation

- A method and apparatus for direct lithium extraction (DLE) using a porous media bed with a uniform extractant material that absorbs target ions like lithium, followed by a stripping solution to separate and regenerate the extractant, maintaining a sharp interface between brine and stripping solution to maximize extraction efficiency.

Process and product

PatentWO2025105970A1

Innovation

- A DLE process using a lithium sorbent with a high specific surface area, combined with ultrafiltration or nanofiltration membranes for separation, and a pH-controlled upload step to optimize lithium absorption and reduce impurity carryover.

Environmental Impact Assessment of DLE Methods

Direct Lithium Extraction (DLE) technologies, while promising higher recovery rates and efficiency compared to traditional methods, carry significant environmental implications that must be thoroughly assessed. The environmental footprint of DLE varies considerably depending on the specific technology employed, with some methods demonstrating substantial advantages over conventional evaporation ponds.

Water usage represents a critical environmental consideration for DLE operations. Unlike traditional evaporation methods that consume vast quantities of water through evaporation, advanced DLE technologies can significantly reduce water requirements. Some ion-exchange and adsorption-based systems have demonstrated water consumption reductions of up to 90% compared to conventional methods. However, certain DLE approaches still require substantial water for processing and regeneration cycles, particularly in closed-loop systems.

Chemical usage in DLE processes presents another environmental concern. Most DLE methods utilize specialized sorbents, solvents, or membranes that require periodic regeneration with chemical solutions. These chemicals, if improperly managed, pose potential contamination risks to surrounding ecosystems. Recent advancements in biodegradable sorbents and environmentally benign regeneration chemicals show promise in mitigating these impacts, though their commercial viability remains under investigation.

Land disturbance represents a notable environmental advantage for DLE technologies. The physical footprint of DLE facilities is dramatically smaller than traditional evaporation ponds, with some installations requiring less than 10% of the land area. This reduction minimizes habitat disruption and preserves natural landscapes in often sensitive desert ecosystems where lithium brine resources are typically located.

Energy consumption patterns vary significantly across DLE technologies. While some methods require substantial energy inputs for pumping, heating, or electrochemical processes, others have demonstrated relatively modest energy demands. The environmental impact of this energy usage depends heavily on the source of electricity, with renewable-powered DLE operations offering substantially lower carbon footprints than those relying on fossil fuels.

Waste management considerations for DLE include the handling of spent sorbents, membranes, and process residues. The composition and toxicity of these waste streams vary by technology, with some producing benign materials suitable for safe disposal or recycling, while others generate more problematic waste requiring specialized treatment. Advanced DLE systems increasingly incorporate waste minimization strategies and circular economy principles to address these concerns.

Groundwater impacts remain an area requiring careful monitoring, as extensive brine extraction could potentially affect regional hydrological systems. However, properly designed DLE operations with appropriate monitoring protocols can minimize these risks through responsible resource management practices.

Water usage represents a critical environmental consideration for DLE operations. Unlike traditional evaporation methods that consume vast quantities of water through evaporation, advanced DLE technologies can significantly reduce water requirements. Some ion-exchange and adsorption-based systems have demonstrated water consumption reductions of up to 90% compared to conventional methods. However, certain DLE approaches still require substantial water for processing and regeneration cycles, particularly in closed-loop systems.

Chemical usage in DLE processes presents another environmental concern. Most DLE methods utilize specialized sorbents, solvents, or membranes that require periodic regeneration with chemical solutions. These chemicals, if improperly managed, pose potential contamination risks to surrounding ecosystems. Recent advancements in biodegradable sorbents and environmentally benign regeneration chemicals show promise in mitigating these impacts, though their commercial viability remains under investigation.

Land disturbance represents a notable environmental advantage for DLE technologies. The physical footprint of DLE facilities is dramatically smaller than traditional evaporation ponds, with some installations requiring less than 10% of the land area. This reduction minimizes habitat disruption and preserves natural landscapes in often sensitive desert ecosystems where lithium brine resources are typically located.

Energy consumption patterns vary significantly across DLE technologies. While some methods require substantial energy inputs for pumping, heating, or electrochemical processes, others have demonstrated relatively modest energy demands. The environmental impact of this energy usage depends heavily on the source of electricity, with renewable-powered DLE operations offering substantially lower carbon footprints than those relying on fossil fuels.

Waste management considerations for DLE include the handling of spent sorbents, membranes, and process residues. The composition and toxicity of these waste streams vary by technology, with some producing benign materials suitable for safe disposal or recycling, while others generate more problematic waste requiring specialized treatment. Advanced DLE systems increasingly incorporate waste minimization strategies and circular economy principles to address these concerns.

Groundwater impacts remain an area requiring careful monitoring, as extensive brine extraction could potentially affect regional hydrological systems. However, properly designed DLE operations with appropriate monitoring protocols can minimize these risks through responsible resource management practices.

Scalability and Economic Feasibility Analysis

The scalability of Direct Lithium Extraction (DLE) technologies represents a critical factor in their commercial viability. Current laboratory-scale DLE processes demonstrating 90%+ recovery rates face significant challenges when scaled to industrial production levels, where recovery rates typically decrease to 70-80% due to process inefficiencies and material limitations.

Economic analysis reveals that DLE operations require substantial initial capital investment, ranging from $15-30 million for small-scale operations to over $100 million for large commercial facilities. However, the operational expenditure can be 30-40% lower than traditional evaporation pond methods when optimized systems are implemented, primarily due to reduced land requirements and faster production cycles.

The economic feasibility of DLE is heavily influenced by lithium market prices, which have shown volatility in recent years. At current market prices ($15,000-$20,000 per ton of lithium carbonate equivalent), DLE projects with recovery rates above 75% can achieve positive ROI within 5-7 years. Sensitivity analysis indicates that each 5% improvement in recovery rate translates to approximately 8-12% increase in project NPV.

Infrastructure requirements present another scaling challenge. DLE facilities demand reliable access to electricity (3-5 MW for medium-scale operations), water treatment capabilities, and chemical reagent supply chains. Remote brine field locations often lack this infrastructure, necessitating additional investment that can represent 15-25% of total project costs.

Environmental compliance costs must also be factored into scalability assessments. While DLE offers environmental advantages over evaporation ponds, regulatory requirements for water discharge, chemical handling, and waste management add $2-4 million in annual compliance costs for large-scale operations.

Recent pilot projects by major mining companies demonstrate that modular DLE systems offer the most promising path to scalability. These systems allow for incremental capacity expansion with lower initial capital requirements, though at a 10-15% premium on per-unit production costs compared to optimized large-scale facilities.

The technology readiness level (TRL) of various DLE approaches varies significantly, with ion exchange technologies at TRL 7-8 showing the most immediate commercial scalability, while more experimental approaches like novel selective membranes remain at TRL 4-5, requiring substantial development before economic feasibility at scale can be demonstrated.

Economic analysis reveals that DLE operations require substantial initial capital investment, ranging from $15-30 million for small-scale operations to over $100 million for large commercial facilities. However, the operational expenditure can be 30-40% lower than traditional evaporation pond methods when optimized systems are implemented, primarily due to reduced land requirements and faster production cycles.

The economic feasibility of DLE is heavily influenced by lithium market prices, which have shown volatility in recent years. At current market prices ($15,000-$20,000 per ton of lithium carbonate equivalent), DLE projects with recovery rates above 75% can achieve positive ROI within 5-7 years. Sensitivity analysis indicates that each 5% improvement in recovery rate translates to approximately 8-12% increase in project NPV.

Infrastructure requirements present another scaling challenge. DLE facilities demand reliable access to electricity (3-5 MW for medium-scale operations), water treatment capabilities, and chemical reagent supply chains. Remote brine field locations often lack this infrastructure, necessitating additional investment that can represent 15-25% of total project costs.

Environmental compliance costs must also be factored into scalability assessments. While DLE offers environmental advantages over evaporation ponds, regulatory requirements for water discharge, chemical handling, and waste management add $2-4 million in annual compliance costs for large-scale operations.

Recent pilot projects by major mining companies demonstrate that modular DLE systems offer the most promising path to scalability. These systems allow for incremental capacity expansion with lower initial capital requirements, though at a 10-15% premium on per-unit production costs compared to optimized large-scale facilities.

The technology readiness level (TRL) of various DLE approaches varies significantly, with ion exchange technologies at TRL 7-8 showing the most immediate commercial scalability, while more experimental approaches like novel selective membranes remain at TRL 4-5, requiring substantial development before economic feasibility at scale can be demonstrated.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!