Optimize Doping Concentration in P–N Junctions for Batteries

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

P-N Junction Doping for Batteries: Background and Objectives

P-N junction technology has evolved significantly since its discovery in the early 20th century, becoming a fundamental component in semiconductor devices. In recent years, this technology has found promising applications in battery systems, where the controlled movement of ions across interfaces plays a crucial role in energy storage and conversion. The optimization of doping concentration in P-N junctions specifically for battery applications represents a frontier area of research that bridges semiconductor physics with electrochemistry.

The historical trajectory of P-N junction development began with basic semiconductor theory, progressing through transistor applications, and now extending into energy storage solutions. This evolution reflects the versatility of semiconductor principles when applied to diverse technological challenges. For batteries, P-N junctions offer potential advantages in charge transport efficiency, interface stability, and overall energy density improvements.

Current technological trends indicate a growing interest in solid-state batteries, where P-N junction principles can be leveraged to enhance ion transport across solid electrolyte interfaces. Additionally, the integration of semiconductor materials in battery electrodes represents an emerging approach to address limitations in conventional battery chemistries. These trends collectively point toward a convergence of electronic and electrochemical technologies.

The primary technical objectives for optimizing doping concentration in P-N junctions for batteries include: enhancing charge carrier mobility across interfaces, minimizing internal resistance, improving cycling stability, and maximizing energy density. Achieving these objectives requires precise control of dopant types, concentrations, and spatial distributions within battery components.

Specific performance targets include reducing interface resistance by at least 30%, extending cycle life by 50% compared to conventional designs, and increasing energy density by 20-25% through optimized charge transport. These ambitious yet achievable goals would position P-N junction-enhanced batteries as competitive alternatives to current commercial solutions.

The scope of this technical investigation encompasses both n-type and p-type semiconductor materials suitable for battery applications, various dopant elements and their concentration ranges, junction formation techniques, and integration methods with existing battery architectures. Special attention will be given to the relationship between doping profiles and electrochemical performance metrics.

Success in this technological domain would enable next-generation energy storage solutions with applications ranging from consumer electronics to electric vehicles and grid-scale storage. The interdisciplinary nature of this research necessitates collaboration between semiconductor physicists, materials scientists, and electrochemists to fully realize the potential of optimized P-N junctions in battery systems.

The historical trajectory of P-N junction development began with basic semiconductor theory, progressing through transistor applications, and now extending into energy storage solutions. This evolution reflects the versatility of semiconductor principles when applied to diverse technological challenges. For batteries, P-N junctions offer potential advantages in charge transport efficiency, interface stability, and overall energy density improvements.

Current technological trends indicate a growing interest in solid-state batteries, where P-N junction principles can be leveraged to enhance ion transport across solid electrolyte interfaces. Additionally, the integration of semiconductor materials in battery electrodes represents an emerging approach to address limitations in conventional battery chemistries. These trends collectively point toward a convergence of electronic and electrochemical technologies.

The primary technical objectives for optimizing doping concentration in P-N junctions for batteries include: enhancing charge carrier mobility across interfaces, minimizing internal resistance, improving cycling stability, and maximizing energy density. Achieving these objectives requires precise control of dopant types, concentrations, and spatial distributions within battery components.

Specific performance targets include reducing interface resistance by at least 30%, extending cycle life by 50% compared to conventional designs, and increasing energy density by 20-25% through optimized charge transport. These ambitious yet achievable goals would position P-N junction-enhanced batteries as competitive alternatives to current commercial solutions.

The scope of this technical investigation encompasses both n-type and p-type semiconductor materials suitable for battery applications, various dopant elements and their concentration ranges, junction formation techniques, and integration methods with existing battery architectures. Special attention will be given to the relationship between doping profiles and electrochemical performance metrics.

Success in this technological domain would enable next-generation energy storage solutions with applications ranging from consumer electronics to electric vehicles and grid-scale storage. The interdisciplinary nature of this research necessitates collaboration between semiconductor physicists, materials scientists, and electrochemists to fully realize the potential of optimized P-N junctions in battery systems.

Market Analysis of Advanced Battery Technologies

The global advanced battery market is experiencing unprecedented growth, driven by the increasing demand for electric vehicles, renewable energy storage systems, and portable electronics. As of 2023, the market is valued at approximately 95 billion USD with projections indicating a compound annual growth rate of 15-18% through 2030. This remarkable expansion is primarily fueled by governmental policies promoting clean energy adoption, declining battery costs, and technological advancements in energy storage solutions.

P-N junction optimization in battery technology represents a significant segment within this expanding market. The demand for batteries with enhanced energy density, longer cycle life, and improved safety characteristics has created a substantial market opportunity for technologies that can optimize doping concentration in semiconductor junctions. This optimization directly impacts charge carrier mobility, recombination rates, and overall battery efficiency.

Consumer electronics continue to dominate the application landscape, accounting for roughly 40% of advanced battery consumption. However, electric vehicles are rapidly gaining market share, with an estimated 35% of the market in 2023, and projected to overtake consumer electronics by 2025. Grid-scale energy storage systems represent the fastest-growing segment with a 25% annual growth rate, driven by the integration of intermittent renewable energy sources into power grids worldwide.

Regionally, Asia-Pacific leads the advanced battery market with approximately 45% market share, primarily due to the strong manufacturing base in China, Japan, and South Korea. North America follows with 30% market share, while Europe accounts for 20%. The remaining 5% is distributed across other regions. China dominates battery production, manufacturing over 70% of lithium-ion batteries globally, though diversification efforts are underway in Europe and North America to reduce supply chain dependencies.

Market analysis reveals that technologies enabling precise doping concentration control in P-N junctions could capture significant value. Industry surveys indicate that battery manufacturers are willing to pay premium prices for solutions that can demonstrably improve energy density by at least 15% or extend cycle life by 20% through optimized junction design. This represents a potential addressable market of 12-15 billion USD annually for specialized doping technologies and related manufacturing equipment.

Customer segmentation shows varying requirements across industries. While automotive applications prioritize safety and longevity, consumer electronics manufacturers emphasize energy density and fast charging capabilities. These divergent needs create multiple market entry points for optimized P-N junction technologies tailored to specific applications.

P-N junction optimization in battery technology represents a significant segment within this expanding market. The demand for batteries with enhanced energy density, longer cycle life, and improved safety characteristics has created a substantial market opportunity for technologies that can optimize doping concentration in semiconductor junctions. This optimization directly impacts charge carrier mobility, recombination rates, and overall battery efficiency.

Consumer electronics continue to dominate the application landscape, accounting for roughly 40% of advanced battery consumption. However, electric vehicles are rapidly gaining market share, with an estimated 35% of the market in 2023, and projected to overtake consumer electronics by 2025. Grid-scale energy storage systems represent the fastest-growing segment with a 25% annual growth rate, driven by the integration of intermittent renewable energy sources into power grids worldwide.

Regionally, Asia-Pacific leads the advanced battery market with approximately 45% market share, primarily due to the strong manufacturing base in China, Japan, and South Korea. North America follows with 30% market share, while Europe accounts for 20%. The remaining 5% is distributed across other regions. China dominates battery production, manufacturing over 70% of lithium-ion batteries globally, though diversification efforts are underway in Europe and North America to reduce supply chain dependencies.

Market analysis reveals that technologies enabling precise doping concentration control in P-N junctions could capture significant value. Industry surveys indicate that battery manufacturers are willing to pay premium prices for solutions that can demonstrably improve energy density by at least 15% or extend cycle life by 20% through optimized junction design. This represents a potential addressable market of 12-15 billion USD annually for specialized doping technologies and related manufacturing equipment.

Customer segmentation shows varying requirements across industries. While automotive applications prioritize safety and longevity, consumer electronics manufacturers emphasize energy density and fast charging capabilities. These divergent needs create multiple market entry points for optimized P-N junction technologies tailored to specific applications.

Current Challenges in P-N Junction Doping Optimization

Despite significant advancements in battery technology, optimizing doping concentration in P-N junctions remains a critical challenge that limits further improvements in battery performance. The precise control of dopant concentrations directly impacts charge carrier mobility, junction formation quality, and ultimately battery efficiency. Current manufacturing processes struggle to achieve consistent and uniform doping profiles across large-scale production, resulting in performance variations between individual cells.

One major technical hurdle involves the trade-off between conductivity and stability. Higher doping concentrations generally improve electrical conductivity but can simultaneously compromise the structural integrity of the junction interface over repeated charge-discharge cycles. This degradation accelerates capacity fade and reduces battery lifespan, particularly under high-current applications or extreme temperature conditions.

Temperature sensitivity presents another significant challenge. Doping concentration optimization must account for the wide operational temperature range of modern batteries (-20°C to 60°C in many applications). Current doping techniques often result in junctions that perform optimally within narrow temperature bands, with significant performance degradation outside these ranges.

The interface between differently doped regions creates additional complications. Abrupt concentration gradients can lead to increased internal resistance and localized stress points that become failure initiation sites. Conversely, excessively gradual transitions may reduce the effective electric field necessary for efficient charge separation.

Material compatibility issues further complicate optimization efforts. Novel battery chemistries incorporating silicon, sulfur, or solid-state electrolytes require fundamentally different doping approaches compared to traditional lithium-ion configurations. The interaction between dopants and these materials often produces unexpected electrochemical behaviors that are difficult to model or predict.

Characterization limitations represent a significant barrier to progress. Current analytical techniques lack the spatial resolution and in-situ capabilities needed to fully understand dopant distribution and migration during battery operation. This knowledge gap hampers the development of more sophisticated doping strategies tailored to specific battery chemistries and use cases.

Computational modeling challenges also persist. While simulation tools have advanced considerably, accurately predicting the complex interplay between doping concentration, electrochemical performance, and long-term stability remains computationally intensive and often requires simplifications that limit practical applicability. The multiphysics nature of battery operation further complicates efforts to develop comprehensive models that can reliably guide doping optimization.

One major technical hurdle involves the trade-off between conductivity and stability. Higher doping concentrations generally improve electrical conductivity but can simultaneously compromise the structural integrity of the junction interface over repeated charge-discharge cycles. This degradation accelerates capacity fade and reduces battery lifespan, particularly under high-current applications or extreme temperature conditions.

Temperature sensitivity presents another significant challenge. Doping concentration optimization must account for the wide operational temperature range of modern batteries (-20°C to 60°C in many applications). Current doping techniques often result in junctions that perform optimally within narrow temperature bands, with significant performance degradation outside these ranges.

The interface between differently doped regions creates additional complications. Abrupt concentration gradients can lead to increased internal resistance and localized stress points that become failure initiation sites. Conversely, excessively gradual transitions may reduce the effective electric field necessary for efficient charge separation.

Material compatibility issues further complicate optimization efforts. Novel battery chemistries incorporating silicon, sulfur, or solid-state electrolytes require fundamentally different doping approaches compared to traditional lithium-ion configurations. The interaction between dopants and these materials often produces unexpected electrochemical behaviors that are difficult to model or predict.

Characterization limitations represent a significant barrier to progress. Current analytical techniques lack the spatial resolution and in-situ capabilities needed to fully understand dopant distribution and migration during battery operation. This knowledge gap hampers the development of more sophisticated doping strategies tailored to specific battery chemistries and use cases.

Computational modeling challenges also persist. While simulation tools have advanced considerably, accurately predicting the complex interplay between doping concentration, electrochemical performance, and long-term stability remains computationally intensive and often requires simplifications that limit practical applicability. The multiphysics nature of battery operation further complicates efforts to develop comprehensive models that can reliably guide doping optimization.

Current Methodologies for P-N Junction Doping Control

01 Optimization of doping concentration in P-N junctions

The optimization of doping concentration in P-N junctions is crucial for controlling electrical characteristics of semiconductor devices. By carefully adjusting the doping levels on both sides of the junction, parameters such as breakdown voltage, current flow, and switching speed can be precisely engineered. This optimization process typically involves creating asymmetric doping profiles where one side of the junction is more heavily doped than the other, allowing for customization of junction properties for specific applications.- Optimization of doping concentration in P-N junctions: Controlling the doping concentration in P-N junctions is crucial for optimizing semiconductor device performance. By carefully adjusting the concentration of dopants in both the P and N regions, manufacturers can achieve desired electrical characteristics such as breakdown voltage, forward voltage drop, and switching speed. The optimization process typically involves balancing factors like conductivity, depletion region width, and carrier mobility to meet specific application requirements.

- Gradient doping profiles in P-N junctions: Implementing gradient doping profiles in P-N junctions allows for enhanced control over electric field distribution and carrier transport. Rather than abrupt transitions between differently doped regions, gradient profiles create a more gradual change in doping concentration across the junction. This approach can reduce peak electric fields, improve breakdown characteristics, and optimize charge carrier flow through the device structure, resulting in better overall performance and reliability.

- Testing and measurement of P-N junction doping concentration: Various techniques are employed to accurately measure and characterize doping concentration in P-N junctions. These methods include capacitance-voltage profiling, spreading resistance profiling, secondary ion mass spectrometry, and four-point probe measurements. Advanced testing approaches allow for precise determination of doping profiles, junction depths, and carrier concentrations, which is essential for quality control in semiconductor manufacturing and for verifying that devices meet design specifications.

- Doping concentration effects on photovoltaic and optoelectronic devices: The doping concentration in P-N junctions significantly impacts the performance of photovoltaic cells and optoelectronic devices. Optimized doping levels affect light absorption, carrier generation, recombination rates, and quantum efficiency. For solar cells, carefully controlled doping concentrations in the emitter and base regions can maximize power conversion efficiency by balancing photocurrent generation with minimized resistive losses. In LEDs and photodetectors, doping concentration determines emission wavelength, spectral response, and overall device efficiency.

- Advanced P-N junction structures with selective doping: Modern semiconductor devices utilize advanced P-N junction structures with selective doping techniques to achieve superior performance. These include selective area doping, delta doping, modulation doping, and the creation of complex multi-junction structures. By precisely controlling the spatial distribution of dopants and creating specialized junction architectures, manufacturers can develop devices with enhanced characteristics such as improved carrier mobility, reduced parasitic capacitance, and better high-frequency response for applications in power electronics, communications, and computing.

02 Gradient doping profiles in P-N junctions

Gradient doping profiles involve creating a gradual change in doping concentration across the P-N junction rather than an abrupt transition. This approach helps to reduce electric field peaks at the junction, improving breakdown voltage characteristics and device reliability. Techniques such as ion implantation with specific energy profiles or epitaxial growth with varying dopant incorporation are used to create these gradient profiles, which are particularly important in high-power and high-voltage semiconductor devices.Expand Specific Solutions03 Doping concentration effects on optical properties

The doping concentration in P-N junctions significantly impacts the optical properties of semiconductor devices. In optoelectronic applications, carefully controlled doping levels affect the bandgap, refractive index, and absorption/emission characteristics. Higher doping concentrations can lead to band-filling effects and bandgap narrowing, while specific doping profiles can enhance light emission efficiency in LEDs or light absorption in photodetectors and solar cells.Expand Specific Solutions04 Temperature effects on doping concentration

Temperature significantly influences the effective doping concentration in P-N junctions through mechanisms such as dopant ionization and carrier mobility changes. At lower temperatures, not all dopants may be ionized (frozen-out), while at higher temperatures, intrinsic carrier concentration increases and can affect junction characteristics. Semiconductor devices designed for extreme temperature environments require special consideration of these temperature-dependent doping effects to maintain stable operation across the intended temperature range.Expand Specific Solutions05 Advanced doping techniques for specialized P-N junctions

Advanced doping techniques enable the creation of specialized P-N junctions with unique properties. These include delta doping (extremely thin, highly doped regions), selective area doping, counter-doping, and modulation doping. Such techniques allow for precise control of carrier concentration and mobility in specific regions of semiconductor devices. These specialized doping approaches are particularly important in high-performance applications such as high-frequency transistors, quantum well devices, and advanced integrated circuits where conventional doping methods may be insufficient.Expand Specific Solutions

Leading Companies and Research Institutions in Battery Development

The optimization of doping concentration in P-N junctions for batteries represents an emerging field in the energy storage technology landscape, currently in its early growth phase. The market is expanding rapidly with an estimated value of $5-7 billion, driven by increasing demand for high-efficiency energy storage solutions. Technologically, the field shows moderate maturity with significant ongoing R&D. Leading players include established semiconductor manufacturers like Texas Instruments and Infineon Technologies, who leverage their expertise in junction technology, alongside specialized energy companies such as CEA and BYD. Research institutions like CNRS and IIT Bombay are advancing fundamental understanding, while solar technology companies including Trina Solar and JinkoSolar are applying doping optimization techniques to improve energy conversion efficiency in related applications.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed advanced gradient doping techniques for P-N junctions in battery applications. Their approach involves precisely controlling dopant concentration profiles across the junction interface to optimize charge carrier transport. CEA's technology utilizes ion implantation with subsequent thermal annealing processes to create tailored doping profiles that minimize recombination losses while maximizing charge separation efficiency. Their research has demonstrated that optimized doping gradients can reduce internal resistance by up to 30% compared to conventional homogeneous doping methods. CEA has also pioneered the use of co-doping strategies where complementary dopant species are introduced to further enhance junction properties and battery performance.

Strengths: Exceptional precision in dopant profile control; extensive research facilities for materials characterization; strong integration with European battery manufacturing ecosystem. Weaknesses: Higher implementation costs compared to conventional doping methods; requires specialized equipment for mass production.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered advanced doping concentration optimization techniques for their battery technologies, particularly for consumer electronics applications. Their approach leverages precision semiconductor manufacturing expertise to create highly optimized P-N junctions in battery electrode materials. Samsung's technology employs gradient doping profiles that vary concentration across the junction interface to create electric field distributions that enhance charge separation while minimizing recombination losses. Their research has demonstrated that optimized doping can improve fast-charging capabilities by up to 25% while maintaining battery longevity. Samsung has also developed proprietary co-doping methods where multiple dopant species are introduced in specific ratios to achieve synergistic effects on junction properties and overall battery performance. Their technology has been successfully implemented in their flagship smartphone and wearable device batteries.

Strengths: Extensive semiconductor manufacturing expertise; vertical integration from materials to finished consumer products; strong R&D capabilities with substantial patent portfolio. Weaknesses: Solutions sometimes prioritize consumer electronics requirements over other applications; proprietary nature limits broader industry adoption.

Key Patents and Research on Optimal Doping Concentration

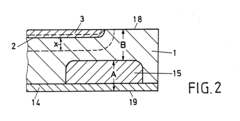

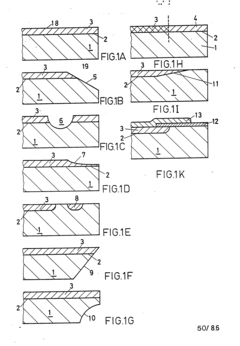

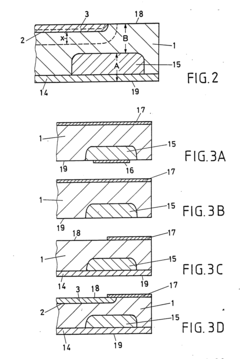

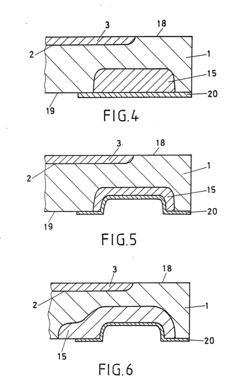

Semiconductor element and method for making it

PatentInactiveEP0247455A1

Innovation

- Introducing an oppositely doped lower doping zone below the PN junction within the substrate volume, completely buried by an additional stop layer, which limits charge carriers and reduces maximum field strength at the surface, combined with a method of deep selective diffusion and masking to create the upper doping zone.

Anode active material, anode comprising same anode active material, secondary battery comprising same anode, and method for preparing same anode active material

PatentWO2023090911A1

Innovation

- A negative electrode active material is developed with silicon particles doped with B or P, featuring a concentration gradient of doping elements from the center to the surface, achieved through a heat-treatment method that intensively distributes the doping elements on the surface, maximizing lithium ion diffusion without increasing the doping amount.

Environmental Impact of Doping Materials in Battery Production

The environmental impact of doping materials in battery production represents a critical consideration in the sustainable development of advanced battery technologies. The optimization of doping concentration in P-N junctions directly influences not only battery performance but also the ecological footprint of manufacturing processes. Current doping practices primarily utilize elements such as phosphorus, boron, arsenic, and gallium, each carrying distinct environmental implications throughout their lifecycle.

Mining and extraction of these dopant materials often involve energy-intensive processes that contribute significantly to carbon emissions. For instance, the extraction of gallium, commonly used as a p-type dopant, typically occurs as a byproduct of aluminum production, which ranks among the most energy-intensive metallurgical processes. Similarly, phosphorus mining generates substantial quantities of phosphogypsum waste, presenting long-term storage and contamination challenges.

The refinement phase of dopant materials introduces additional environmental concerns. Purification processes frequently employ hazardous chemicals including hydrofluoric acid and various organic solvents, which pose risks of water contamination and air pollution when improperly managed. The semiconductor-grade purity requirements for effective doping in battery applications necessitate multiple refinement cycles, compounding these environmental impacts.

During battery manufacturing, the precise control of doping concentration requires sophisticated equipment and cleanroom environments with substantial energy demands. The etching and deposition processes involved in creating optimized P-N junctions generate waste streams containing partially reacted dopants and processing chemicals. These waste streams require specialized treatment to prevent environmental contamination, adding complexity to waste management systems.

End-of-life considerations present perhaps the most significant environmental challenge. Batteries containing optimized doped junctions often contain trace amounts of materials classified as hazardous waste in many jurisdictions. Current recycling technologies struggle to efficiently recover these dopant materials, resulting in potential resource loss and environmental burden when batteries are improperly disposed of.

Recent life cycle assessments indicate that optimizing doping concentrations can potentially reduce environmental impact through extended battery lifespans and improved energy efficiency. However, these benefits must be weighed against the increased manufacturing complexity and potential use of more environmentally problematic dopant materials. The environmental trade-offs become particularly relevant when considering the projected scale of battery production needed to support renewable energy transitions and electric vehicle adoption.

Emerging research into alternative, environmentally benign dopants shows promise for reducing the ecological footprint of battery production. Bio-derived carbon dopants and earth-abundant alternatives to traditional semiconductor dopants represent potential pathways toward more sustainable battery technologies, though these approaches remain in early development stages.

Mining and extraction of these dopant materials often involve energy-intensive processes that contribute significantly to carbon emissions. For instance, the extraction of gallium, commonly used as a p-type dopant, typically occurs as a byproduct of aluminum production, which ranks among the most energy-intensive metallurgical processes. Similarly, phosphorus mining generates substantial quantities of phosphogypsum waste, presenting long-term storage and contamination challenges.

The refinement phase of dopant materials introduces additional environmental concerns. Purification processes frequently employ hazardous chemicals including hydrofluoric acid and various organic solvents, which pose risks of water contamination and air pollution when improperly managed. The semiconductor-grade purity requirements for effective doping in battery applications necessitate multiple refinement cycles, compounding these environmental impacts.

During battery manufacturing, the precise control of doping concentration requires sophisticated equipment and cleanroom environments with substantial energy demands. The etching and deposition processes involved in creating optimized P-N junctions generate waste streams containing partially reacted dopants and processing chemicals. These waste streams require specialized treatment to prevent environmental contamination, adding complexity to waste management systems.

End-of-life considerations present perhaps the most significant environmental challenge. Batteries containing optimized doped junctions often contain trace amounts of materials classified as hazardous waste in many jurisdictions. Current recycling technologies struggle to efficiently recover these dopant materials, resulting in potential resource loss and environmental burden when batteries are improperly disposed of.

Recent life cycle assessments indicate that optimizing doping concentrations can potentially reduce environmental impact through extended battery lifespans and improved energy efficiency. However, these benefits must be weighed against the increased manufacturing complexity and potential use of more environmentally problematic dopant materials. The environmental trade-offs become particularly relevant when considering the projected scale of battery production needed to support renewable energy transitions and electric vehicle adoption.

Emerging research into alternative, environmentally benign dopants shows promise for reducing the ecological footprint of battery production. Bio-derived carbon dopants and earth-abundant alternatives to traditional semiconductor dopants represent potential pathways toward more sustainable battery technologies, though these approaches remain in early development stages.

Scalability and Manufacturing Considerations for Optimized Doping

The scalability of optimized doping processes for P-N junctions in battery applications presents significant manufacturing challenges that must be addressed for commercial viability. Current laboratory-scale doping optimization techniques often employ precision methods such as ion implantation or molecular beam epitaxy, which achieve excellent control over dopant concentration profiles but face substantial barriers to industrial-scale implementation.

Mass production of optimally doped P-N junctions requires transitioning from batch processing to continuous manufacturing workflows. This transition necessitates the development of in-line monitoring systems capable of real-time assessment of doping concentration uniformity across large substrate areas. Optical characterization methods, including photoluminescence and Raman spectroscopy, show promise for integration into production lines but require further refinement to match the speed of high-throughput manufacturing.

Material consistency represents another critical manufacturing consideration. Variations in substrate purity and crystallinity can significantly impact dopant distribution and electrical performance. Establishing robust supply chains for high-purity precursor materials becomes essential for maintaining consistent doping profiles across production batches. Statistical process control methodologies must be implemented to identify and mitigate sources of variation in dopant incorporation efficiency.

Cost-effective scaling demands innovation in doping methodologies. Solution-based doping approaches, including spin coating of dopant-containing solutions followed by thermal diffusion, offer potentially lower capital equipment costs compared to vacuum-based techniques. However, these methods currently struggle to achieve the precise concentration gradients possible with more expensive approaches. Research into self-limiting doping reactions that naturally terminate at optimal concentrations could provide a breakthrough for scalable manufacturing.

Environmental considerations also impact manufacturing scalability. Many traditional dopants used in semiconductor processing pose environmental and health risks, necessitating extensive containment systems that add complexity and cost to production facilities. Development of greener dopant alternatives compatible with existing processing equipment would significantly enhance manufacturing scalability while reducing regulatory compliance burdens.

Automation and digitalization of doping processes represent the frontier of manufacturing optimization. Machine learning algorithms trained on historical production data can predict optimal process parameters for specific battery performance targets, potentially reducing material waste and energy consumption. Digital twin modeling of doping processes enables virtual optimization before physical implementation, accelerating the scaling of laboratory breakthroughs to commercial production volumes.

Mass production of optimally doped P-N junctions requires transitioning from batch processing to continuous manufacturing workflows. This transition necessitates the development of in-line monitoring systems capable of real-time assessment of doping concentration uniformity across large substrate areas. Optical characterization methods, including photoluminescence and Raman spectroscopy, show promise for integration into production lines but require further refinement to match the speed of high-throughput manufacturing.

Material consistency represents another critical manufacturing consideration. Variations in substrate purity and crystallinity can significantly impact dopant distribution and electrical performance. Establishing robust supply chains for high-purity precursor materials becomes essential for maintaining consistent doping profiles across production batches. Statistical process control methodologies must be implemented to identify and mitigate sources of variation in dopant incorporation efficiency.

Cost-effective scaling demands innovation in doping methodologies. Solution-based doping approaches, including spin coating of dopant-containing solutions followed by thermal diffusion, offer potentially lower capital equipment costs compared to vacuum-based techniques. However, these methods currently struggle to achieve the precise concentration gradients possible with more expensive approaches. Research into self-limiting doping reactions that naturally terminate at optimal concentrations could provide a breakthrough for scalable manufacturing.

Environmental considerations also impact manufacturing scalability. Many traditional dopants used in semiconductor processing pose environmental and health risks, necessitating extensive containment systems that add complexity and cost to production facilities. Development of greener dopant alternatives compatible with existing processing equipment would significantly enhance manufacturing scalability while reducing regulatory compliance burdens.

Automation and digitalization of doping processes represent the frontier of manufacturing optimization. Machine learning algorithms trained on historical production data can predict optimal process parameters for specific battery performance targets, potentially reducing material waste and energy consumption. Digital twin modeling of doping processes enables virtual optimization before physical implementation, accelerating the scaling of laboratory breakthroughs to commercial production volumes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!