Optimize Ultrafiltration Membrane Cleaning Using Chemical Agents

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Membrane Cleaning Technology Background and Objectives

Ultrafiltration (UF) membrane technology has evolved significantly since its inception in the 1960s, becoming a cornerstone in various industrial separation processes including water treatment, food processing, and biotechnology applications. The development trajectory has been marked by continuous improvements in membrane materials, module designs, and operational protocols to enhance separation efficiency and membrane longevity.

The evolution of UF membrane technology has been characterized by a shift from cellulose acetate membranes to more robust polymeric materials such as polysulfone, polyethersulfone, and polyvinylidene fluoride. These advancements have substantially improved chemical resistance, thermal stability, and mechanical strength, enabling broader application scenarios and more aggressive cleaning regimes.

Despite these material improvements, membrane fouling remains the most significant operational challenge in UF systems. Fouling—the accumulation of particles, colloids, macromolecules, and biological matter on membrane surfaces—leads to decreased permeate flux, increased transmembrane pressure, and ultimately shortened membrane lifespan. This necessitates regular cleaning interventions to restore membrane performance.

Traditional cleaning approaches have relied heavily on physical methods such as backwashing and air scouring, complemented by periodic chemical cleaning. However, as applications have expanded into more complex feed streams, the limitations of conventional cleaning protocols have become increasingly apparent, driving research toward more effective and sustainable cleaning strategies.

The primary objective of optimizing ultrafiltration membrane cleaning using chemical agents is to develop cleaning protocols that effectively remove diverse foulants while minimizing membrane degradation, reducing downtime, and lowering operational costs. This involves identifying optimal cleaning agents, determining effective concentrations, establishing optimal contact times, and designing sequence strategies for different foulant types.

Secondary objectives include reducing environmental impacts by minimizing chemical usage and waste generation, extending membrane service life through less aggressive cleaning regimes, and developing predictive models for cleaning cycle optimization based on feed characteristics and operational parameters.

The technological trend is moving toward tailored cleaning solutions that address specific fouling mechanisms rather than generic approaches. This includes the development of specialized cleaning formulations for particular industries, integration of real-time fouling monitoring systems to trigger cleaning cycles, and exploration of novel cleaning agents such as enzymatic cleaners and green chemistry alternatives that offer reduced environmental footprints.

As water scarcity and environmental regulations become more stringent globally, the importance of efficient membrane cleaning technologies continues to grow, positioning this field at the intersection of water security, sustainable industrial practices, and advanced materials science.

The evolution of UF membrane technology has been characterized by a shift from cellulose acetate membranes to more robust polymeric materials such as polysulfone, polyethersulfone, and polyvinylidene fluoride. These advancements have substantially improved chemical resistance, thermal stability, and mechanical strength, enabling broader application scenarios and more aggressive cleaning regimes.

Despite these material improvements, membrane fouling remains the most significant operational challenge in UF systems. Fouling—the accumulation of particles, colloids, macromolecules, and biological matter on membrane surfaces—leads to decreased permeate flux, increased transmembrane pressure, and ultimately shortened membrane lifespan. This necessitates regular cleaning interventions to restore membrane performance.

Traditional cleaning approaches have relied heavily on physical methods such as backwashing and air scouring, complemented by periodic chemical cleaning. However, as applications have expanded into more complex feed streams, the limitations of conventional cleaning protocols have become increasingly apparent, driving research toward more effective and sustainable cleaning strategies.

The primary objective of optimizing ultrafiltration membrane cleaning using chemical agents is to develop cleaning protocols that effectively remove diverse foulants while minimizing membrane degradation, reducing downtime, and lowering operational costs. This involves identifying optimal cleaning agents, determining effective concentrations, establishing optimal contact times, and designing sequence strategies for different foulant types.

Secondary objectives include reducing environmental impacts by minimizing chemical usage and waste generation, extending membrane service life through less aggressive cleaning regimes, and developing predictive models for cleaning cycle optimization based on feed characteristics and operational parameters.

The technological trend is moving toward tailored cleaning solutions that address specific fouling mechanisms rather than generic approaches. This includes the development of specialized cleaning formulations for particular industries, integration of real-time fouling monitoring systems to trigger cleaning cycles, and exploration of novel cleaning agents such as enzymatic cleaners and green chemistry alternatives that offer reduced environmental footprints.

As water scarcity and environmental regulations become more stringent globally, the importance of efficient membrane cleaning technologies continues to grow, positioning this field at the intersection of water security, sustainable industrial practices, and advanced materials science.

Market Demand Analysis for Advanced Membrane Cleaning Solutions

The global market for advanced membrane cleaning solutions is experiencing robust growth, driven primarily by increasing water scarcity concerns and stringent environmental regulations across industries. The ultrafiltration membrane cleaning sector specifically has seen a compound annual growth rate of 7.2% over the past five years, with projections indicating continued expansion through 2030.

Industrial sectors including food and beverage processing, pharmaceutical manufacturing, and municipal water treatment represent the largest demand segments for advanced membrane cleaning technologies. These industries require consistent, high-quality water filtration and face significant operational challenges when membrane fouling occurs. The cost implications of membrane fouling—including reduced throughput, increased energy consumption, and premature membrane replacement—create a compelling economic case for improved cleaning solutions.

Chemical cleaning agents for ultrafiltration membranes currently constitute approximately 65% of the total membrane maintenance market. End-users increasingly demand cleaning solutions that balance effectiveness with environmental sustainability, creating a notable shift toward biodegradable and less hazardous chemical formulations. Market research indicates that products offering reduced downtime and extended membrane life cycles command premium pricing, with customers willing to pay 15-20% more for solutions that demonstrably improve operational efficiency.

Regional analysis reveals that North America and Europe lead in adoption of advanced membrane cleaning technologies, though the Asia-Pacific region demonstrates the fastest growth rate at 9.3% annually. This growth is attributed to rapid industrialization, increasing water treatment infrastructure development, and growing awareness of water conservation imperatives in developing economies.

Customer pain points driving market demand include the need for cleaning agents compatible with various membrane materials, solutions that effectively remove complex fouling combinations (organic, inorganic, and biological), and products that minimize chemical waste. Additionally, there is growing interest in automated cleaning systems that optimize chemical usage through real-time monitoring and dosing adjustments.

The service component of this market is expanding significantly, with cleaning protocol optimization and technical support services growing at 11.4% annually. This reflects the complexity of membrane cleaning processes and the need for specialized expertise to maximize system performance while minimizing chemical consumption and environmental impact.

Market forecasts suggest that innovations in targeted chemical formulations for specific foulant types will capture increasing market share, with particular growth potential for solutions addressing biofouling—currently the most challenging and costly form of membrane contamination across multiple industries.

Industrial sectors including food and beverage processing, pharmaceutical manufacturing, and municipal water treatment represent the largest demand segments for advanced membrane cleaning technologies. These industries require consistent, high-quality water filtration and face significant operational challenges when membrane fouling occurs. The cost implications of membrane fouling—including reduced throughput, increased energy consumption, and premature membrane replacement—create a compelling economic case for improved cleaning solutions.

Chemical cleaning agents for ultrafiltration membranes currently constitute approximately 65% of the total membrane maintenance market. End-users increasingly demand cleaning solutions that balance effectiveness with environmental sustainability, creating a notable shift toward biodegradable and less hazardous chemical formulations. Market research indicates that products offering reduced downtime and extended membrane life cycles command premium pricing, with customers willing to pay 15-20% more for solutions that demonstrably improve operational efficiency.

Regional analysis reveals that North America and Europe lead in adoption of advanced membrane cleaning technologies, though the Asia-Pacific region demonstrates the fastest growth rate at 9.3% annually. This growth is attributed to rapid industrialization, increasing water treatment infrastructure development, and growing awareness of water conservation imperatives in developing economies.

Customer pain points driving market demand include the need for cleaning agents compatible with various membrane materials, solutions that effectively remove complex fouling combinations (organic, inorganic, and biological), and products that minimize chemical waste. Additionally, there is growing interest in automated cleaning systems that optimize chemical usage through real-time monitoring and dosing adjustments.

The service component of this market is expanding significantly, with cleaning protocol optimization and technical support services growing at 11.4% annually. This reflects the complexity of membrane cleaning processes and the need for specialized expertise to maximize system performance while minimizing chemical consumption and environmental impact.

Market forecasts suggest that innovations in targeted chemical formulations for specific foulant types will capture increasing market share, with particular growth potential for solutions addressing biofouling—currently the most challenging and costly form of membrane contamination across multiple industries.

Current Challenges in Chemical Cleaning of Ultrafiltration Membranes

Ultrafiltration membrane cleaning faces significant challenges despite its widespread application in water treatment, food processing, and pharmaceutical industries. The accumulation of foulants on membrane surfaces, including organic matter, inorganic precipitates, and biological growth, progressively reduces filtration efficiency and increases operational costs. Chemical cleaning, while effective, presents a complex balance between cleaning efficacy and membrane integrity preservation.

One primary challenge is the selection of appropriate chemical agents for specific fouling types. Organic fouling requires alkaline cleaners or oxidizing agents, while inorganic scaling necessitates acidic solutions. However, many industrial applications encounter mixed fouling scenarios, making single-agent cleaning protocols insufficient. The development of universal cleaning formulations remains elusive due to the diverse chemical properties of foulants and membrane materials.

Membrane material compatibility presents another significant hurdle. Polymeric membranes, particularly those made from polysulfone, polyethersulfone, or cellulose acetate, exhibit varying degrees of chemical resistance. Aggressive cleaning agents like strong oxidizers or high-concentration acids can compromise membrane integrity, leading to premature failure. This creates a narrow operational window between effective cleaning and membrane damage.

The optimization of cleaning parameters—concentration, temperature, contact time, and hydrodynamic conditions—remains largely empirical rather than scientifically systematic. Current industry practices often rely on trial-and-error approaches or manufacturer recommendations that may not be optimized for specific operational conditions. The lack of standardized protocols for different fouling scenarios increases operational uncertainty and resource consumption.

Environmental concerns have intensified scrutiny on chemical cleaning processes. Traditional cleaning agents like sodium hypochlorite, citric acid, and sodium hydroxide generate waste streams requiring specialized treatment before discharge. Regulatory frameworks increasingly restrict the use of environmentally persistent chemicals, necessitating the development of green alternatives without compromising cleaning efficiency.

The formation of disinfection by-products (DBPs) during chemical cleaning represents an emerging challenge, particularly when oxidizing agents interact with organic matter. These by-products may compromise permeate quality and pose health risks in drinking water applications. Current monitoring techniques inadequately characterize these transformation products, creating knowledge gaps in risk assessment.

Cleaning frequency optimization remains problematic due to insufficient real-time fouling monitoring capabilities. Premature cleaning wastes resources while delayed intervention allows fouling to become more tenacious. Advanced sensing technologies for fouling characterization are still in developmental stages, limiting predictive maintenance approaches.

The economic evaluation of cleaning protocols lacks standardized metrics that balance immediate cleaning costs against long-term membrane performance benefits. This complicates decision-making processes for operators seeking to optimize total operational expenditure while maintaining treatment objectives.

One primary challenge is the selection of appropriate chemical agents for specific fouling types. Organic fouling requires alkaline cleaners or oxidizing agents, while inorganic scaling necessitates acidic solutions. However, many industrial applications encounter mixed fouling scenarios, making single-agent cleaning protocols insufficient. The development of universal cleaning formulations remains elusive due to the diverse chemical properties of foulants and membrane materials.

Membrane material compatibility presents another significant hurdle. Polymeric membranes, particularly those made from polysulfone, polyethersulfone, or cellulose acetate, exhibit varying degrees of chemical resistance. Aggressive cleaning agents like strong oxidizers or high-concentration acids can compromise membrane integrity, leading to premature failure. This creates a narrow operational window between effective cleaning and membrane damage.

The optimization of cleaning parameters—concentration, temperature, contact time, and hydrodynamic conditions—remains largely empirical rather than scientifically systematic. Current industry practices often rely on trial-and-error approaches or manufacturer recommendations that may not be optimized for specific operational conditions. The lack of standardized protocols for different fouling scenarios increases operational uncertainty and resource consumption.

Environmental concerns have intensified scrutiny on chemical cleaning processes. Traditional cleaning agents like sodium hypochlorite, citric acid, and sodium hydroxide generate waste streams requiring specialized treatment before discharge. Regulatory frameworks increasingly restrict the use of environmentally persistent chemicals, necessitating the development of green alternatives without compromising cleaning efficiency.

The formation of disinfection by-products (DBPs) during chemical cleaning represents an emerging challenge, particularly when oxidizing agents interact with organic matter. These by-products may compromise permeate quality and pose health risks in drinking water applications. Current monitoring techniques inadequately characterize these transformation products, creating knowledge gaps in risk assessment.

Cleaning frequency optimization remains problematic due to insufficient real-time fouling monitoring capabilities. Premature cleaning wastes resources while delayed intervention allows fouling to become more tenacious. Advanced sensing technologies for fouling characterization are still in developmental stages, limiting predictive maintenance approaches.

The economic evaluation of cleaning protocols lacks standardized metrics that balance immediate cleaning costs against long-term membrane performance benefits. This complicates decision-making processes for operators seeking to optimize total operational expenditure while maintaining treatment objectives.

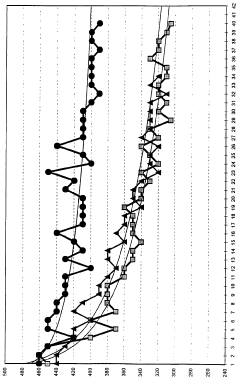

Current Chemical Cleaning Methodologies and Protocols

01 Chemical cleaning methods for ultrafiltration membranes

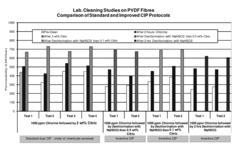

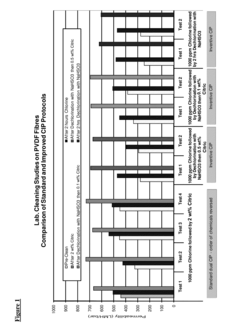

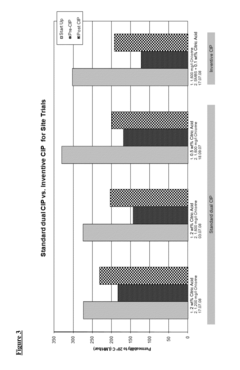

Various chemical agents can be used to clean ultrafiltration membranes effectively. These include acids for removing inorganic fouling, alkaline solutions for organic fouling, and oxidizing agents like hydrogen peroxide for biological fouling. The optimization of chemical concentration, temperature, and contact time is crucial for maximizing cleaning efficiency while minimizing membrane damage. Sequential cleaning with different chemicals can address complex fouling scenarios.- Chemical cleaning methods for ultrafiltration membranes: Various chemical agents can be used to clean ultrafiltration membranes effectively. These include acids for removing inorganic fouling, alkaline solutions for organic fouling, and oxidizing agents for biological fouling. The optimization of chemical cleaning involves selecting appropriate cleaning agents, determining optimal concentrations, and establishing effective contact times to maximize cleaning efficiency while minimizing membrane damage.

- Physical cleaning techniques for membrane fouling removal: Physical cleaning methods such as backwashing, air scouring, and ultrasonic cleaning can be optimized to enhance ultrafiltration membrane performance. These techniques use mechanical forces to dislodge foulants from membrane surfaces without chemical agents. Parameters such as backwash frequency, duration, pressure, and air flow rate can be optimized to achieve effective cleaning while minimizing energy consumption and membrane stress.

- Automated cleaning systems and control strategies: Automated cleaning systems incorporate sensors, controllers, and feedback mechanisms to optimize the cleaning process. These systems can monitor membrane performance in real-time and initiate cleaning cycles based on predetermined parameters such as transmembrane pressure, flux decline, or time intervals. Advanced control strategies may include machine learning algorithms that adapt cleaning protocols based on operational data and membrane fouling patterns.

- Combined cleaning approaches and sequence optimization: Combining different cleaning methods in specific sequences can significantly improve cleaning effectiveness. This may involve initial physical cleaning followed by chemical cleaning, or alternating between different chemical agents. The optimization of cleaning sequences considers the type of foulants present, membrane material compatibility, and operational constraints. Properly designed cleaning protocols can extend membrane life and maintain higher average flux rates.

- Novel cleaning agent formulations and environmentally friendly alternatives: Research has led to the development of novel cleaning formulations specifically designed for ultrafiltration membranes. These include enzyme-based cleaners, biodegradable surfactants, and chelating agents that target specific foulants. Environmentally friendly alternatives aim to reduce the environmental impact of cleaning chemicals while maintaining cleaning effectiveness. These formulations often focus on lower toxicity, biodegradability, and reduced chemical consumption.

02 Physical cleaning techniques and optimization

Physical cleaning methods such as backwashing, air scouring, and hydraulic flushing can effectively remove foulants from ultrafiltration membranes. Optimization involves adjusting parameters like backwash frequency, duration, pressure, and flow rate based on feed water quality and membrane characteristics. Combined physical cleaning approaches can achieve synergistic effects, enhancing overall cleaning efficiency while reducing chemical usage and extending membrane life.Expand Specific Solutions03 Automated cleaning systems and control strategies

Automated cleaning systems incorporate sensors to monitor membrane performance and trigger cleaning cycles based on predetermined parameters such as transmembrane pressure, flux decline, or operating time. Advanced control strategies use machine learning algorithms to optimize cleaning schedules and parameters in real-time, adapting to changing water quality conditions. These systems can significantly improve cleaning efficiency, reduce operational costs, and extend membrane lifespan.Expand Specific Solutions04 Novel cleaning agents and formulations

Innovative cleaning agents including enzymatic cleaners, biodegradable surfactants, and nanomaterial-based solutions offer enhanced cleaning performance for ultrafiltration membranes. These formulations can target specific foulants while being environmentally friendly and less damaging to membrane materials. Composite cleaning solutions combining multiple agents can address complex fouling layers more effectively than traditional chemicals, improving cleaning efficiency and membrane recovery.Expand Specific Solutions05 Cleaning process optimization through experimental design

Systematic experimental approaches such as response surface methodology and factorial design can be used to optimize ultrafiltration membrane cleaning processes. These methods help identify optimal combinations of cleaning parameters including chemical concentration, temperature, duration, and frequency. Pilot-scale testing under various operating conditions provides valuable data for scaling up to full-scale operations, ensuring optimal cleaning efficiency and membrane performance in real-world applications.Expand Specific Solutions

Key Industry Players in Membrane Cleaning Solutions

The ultrafiltration membrane cleaning market is currently in a growth phase, with increasing adoption across water treatment, petrochemical, and pharmaceutical industries. The global market size is estimated to reach $1.2 billion by 2025, driven by stringent environmental regulations and water scarcity concerns. Technologically, chemical cleaning agents for ultrafiltration membranes are advancing toward more environmentally friendly and efficient solutions. Leading players include Kurita Water Industries and Evoqua Water Technologies, who focus on specialized cleaning chemicals, while DuPont and Ecolab dominate with comprehensive membrane treatment portfolios. Siemens and Mitsubishi Electric contribute automation solutions for cleaning processes, while research institutions like ITRI are developing next-generation cleaning agents. Chinese companies like Sinopec are rapidly expanding their market presence through integrated chemical solutions for industrial applications.

Kurita Water Industries Ltd.

Technical Solution: Kurita has developed an innovative ultrafiltration membrane cleaning system called "DROPWISE" that combines specialized chemical agents with optimized hydrodynamic conditions. Their approach utilizes proprietary low-foaming surfactants and chelating agents that penetrate deeply into membrane pores without causing structural damage. Kurita's cleaning protocol involves a sequential application of alkaline cleaners (pH 10-11) followed by acidic solutions (pH 2-3), with intermediate rinse cycles using demineralized water. Their research has shown that this method reduces cleaning time by approximately 35% while extending membrane lifespan by up to 25%. Kurita has also pioneered the use of biodegradable cleaning agents that achieve 90% of the cleaning efficiency of traditional chemicals while reducing environmental impact. Their latest innovation includes real-time monitoring systems that optimize chemical dosing based on actual fouling conditions.

Strengths: Exceptional cleaning performance with minimal membrane degradation; reduced cleaning frequency and chemical consumption; environmentally friendly formulations with high biodegradability. Weaknesses: Requires specialized equipment for optimal implementation; higher initial investment compared to conventional cleaning methods; performance may vary with different membrane materials.

Evoqua Water Technologies LLC

Technical Solution: Evoqua has developed a comprehensive ultrafiltration membrane cleaning system called "MemCare" that utilizes specially formulated chemical agents optimized for different fouling types. Their approach combines mechanical and chemical cleaning processes, with proprietary cleaning agents designed for specific contaminants. For organic fouling, Evoqua employs alkaline cleaners with enhanced surfactant properties that can penetrate biofilms and remove organic matter with 30% greater efficiency than standard cleaners. For inorganic scaling, they utilize specialized acidic formulations with targeted chelating agents that dissolve mineral deposits while preserving membrane integrity. Evoqua's research has demonstrated that their optimized cleaning sequences can restore membrane flux to within 95% of original values, compared to 80-85% with conventional cleaning methods. Their cleaning protocols incorporate precise temperature control (typically 30-40°C) and optimized contact times based on fouling severity, resulting in 25% reduction in cleaning duration.

Strengths: Highly customizable cleaning solutions for specific fouling challenges; excellent flux recovery rates; reduced cleaning frequency requirements; comprehensive technical support. Weaknesses: Higher cost compared to generic cleaning chemicals; requires trained personnel for optimal implementation; some solutions are specific to Evoqua membrane systems.

Critical Chemical Agent Innovations and Mechanisms

Cleaning agent and method for cleaning ultrafiltration membranes in electrophoretic dip coating installations

PatentWO2001012306A1

Innovation

- Aqueous cleaning agents containing over-neutralized electrocoating binders and neutralizing agents are used, with a solids content of 5 to 35% by weight, which include conventional binders with anionic or cationic groups, along with optional crosslinkers and organic solvents, to effectively clean ultrafiltration membranes.

Method of cleaning membranes

PatentActiveUS8956464B2

Innovation

- A method involving a first cleaning solution with an oxidizing agent, followed by a second solution containing a reducing agent and an enhancing agent, which neutralizes the oxidizing residual and forms an acidic mixed solution to simultaneously remove organic and inorganic foulants from polymeric membranes, reducing waste volume and chemical costs.

Environmental Impact Assessment of Chemical Cleaning Agents

The environmental impact of chemical cleaning agents used in ultrafiltration membrane maintenance represents a critical consideration for sustainable water treatment operations. Chemical cleaners, while effective at restoring membrane performance, introduce potential ecological hazards throughout their lifecycle from production to disposal. Primary concerns include the release of phosphates, chlorine compounds, and surfactants into aquatic ecosystems, which can trigger eutrophication, disrupt aquatic life cycles, and compromise water quality parameters.

Acidic cleaning agents, particularly those containing hydrochloric or citric acid, may significantly alter pH levels in receiving water bodies when improperly neutralized before discharge. This pH disruption can have cascading effects on aquatic biodiversity and ecosystem functioning. Similarly, alkaline cleaners containing sodium hydroxide present risks of chemical burns to aquatic organisms and can precipitate dissolved metals in waterways, affecting sediment quality and benthic communities.

Oxidizing agents such as sodium hypochlorite and hydrogen peroxide, while effective for biofouling control, pose risks through the formation of disinfection by-products (DBPs) including trihalomethanes and haloacetic acids, many of which demonstrate carcinogenic properties. The persistence of these compounds in the environment varies significantly, with some maintaining toxicity for extended periods.

Energy consumption associated with chemical cleaning processes represents another environmental dimension. The production, transportation, and application of cleaning chemicals contribute to carbon emissions, while the energy required for heating cleaning solutions and operating cleaning systems adds to the overall carbon footprint of membrane maintenance operations.

Regulatory frameworks governing chemical discharge are increasingly stringent globally, with the European Water Framework Directive and the US Clean Water Act establishing strict parameters for effluent quality. These regulations necessitate comprehensive treatment of cleaning waste streams before environmental release, often requiring additional neutralization, precipitation, or advanced oxidation processes.

Recent innovations in green chemistry have yielded environmentally preferable alternatives, including enzymatic cleaners, biodegradable surfactants, and plant-derived organic acids. These alternatives demonstrate reduced ecotoxicity profiles while maintaining cleaning efficacy. Life cycle assessment (LCA) studies indicate that these bio-based alternatives typically exhibit 30-50% lower environmental impact scores across categories including global warming potential, aquatic toxicity, and resource depletion.

Implementation of closed-loop cleaning systems represents a promising approach to mitigate environmental impacts, enabling the recovery and reuse of cleaning chemicals while minimizing discharge volumes. Such systems have demonstrated chemical consumption reductions of up to 60% in industrial applications, with corresponding decreases in wastewater treatment requirements and associated environmental benefits.

Acidic cleaning agents, particularly those containing hydrochloric or citric acid, may significantly alter pH levels in receiving water bodies when improperly neutralized before discharge. This pH disruption can have cascading effects on aquatic biodiversity and ecosystem functioning. Similarly, alkaline cleaners containing sodium hydroxide present risks of chemical burns to aquatic organisms and can precipitate dissolved metals in waterways, affecting sediment quality and benthic communities.

Oxidizing agents such as sodium hypochlorite and hydrogen peroxide, while effective for biofouling control, pose risks through the formation of disinfection by-products (DBPs) including trihalomethanes and haloacetic acids, many of which demonstrate carcinogenic properties. The persistence of these compounds in the environment varies significantly, with some maintaining toxicity for extended periods.

Energy consumption associated with chemical cleaning processes represents another environmental dimension. The production, transportation, and application of cleaning chemicals contribute to carbon emissions, while the energy required for heating cleaning solutions and operating cleaning systems adds to the overall carbon footprint of membrane maintenance operations.

Regulatory frameworks governing chemical discharge are increasingly stringent globally, with the European Water Framework Directive and the US Clean Water Act establishing strict parameters for effluent quality. These regulations necessitate comprehensive treatment of cleaning waste streams before environmental release, often requiring additional neutralization, precipitation, or advanced oxidation processes.

Recent innovations in green chemistry have yielded environmentally preferable alternatives, including enzymatic cleaners, biodegradable surfactants, and plant-derived organic acids. These alternatives demonstrate reduced ecotoxicity profiles while maintaining cleaning efficacy. Life cycle assessment (LCA) studies indicate that these bio-based alternatives typically exhibit 30-50% lower environmental impact scores across categories including global warming potential, aquatic toxicity, and resource depletion.

Implementation of closed-loop cleaning systems represents a promising approach to mitigate environmental impacts, enabling the recovery and reuse of cleaning chemicals while minimizing discharge volumes. Such systems have demonstrated chemical consumption reductions of up to 60% in industrial applications, with corresponding decreases in wastewater treatment requirements and associated environmental benefits.

Regulatory Compliance for Industrial Membrane Cleaning Processes

Regulatory compliance for industrial membrane cleaning processes is a critical consideration when optimizing ultrafiltration membrane cleaning with chemical agents. The landscape of regulations governing these processes is complex and varies significantly across different regions and industries.

In the United States, the Environmental Protection Agency (EPA) regulates chemical discharge through the Clean Water Act, which directly impacts the selection and disposal of membrane cleaning agents. Facilities must obtain National Pollutant Discharge Elimination System (NPDES) permits when chemical cleaning waste is discharged into public waterways. Additionally, the Occupational Safety and Health Administration (OSHA) enforces strict guidelines regarding worker exposure to hazardous cleaning chemicals, requiring proper ventilation, personal protective equipment, and safety protocols.

The European Union implements more stringent regulations through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, which requires comprehensive documentation of all chemical substances used in industrial processes. For membrane cleaning operations, this means detailed safety data sheets, exposure scenarios, and risk management measures must be maintained and regularly updated.

Food and beverage industries face additional regulatory hurdles, as cleaning chemicals must comply with FDA regulations in the US or equivalent food safety authorities elsewhere. These regulations specify which chemicals are approved for food-contact applications and mandate thorough rinsing procedures to prevent contamination of food products.

Pharmaceutical manufacturers must adhere to Good Manufacturing Practice (GMP) guidelines, which impose strict validation requirements for cleaning processes. This includes demonstrating the effectiveness of the cleaning method and ensuring no harmful residues remain that could compromise product quality or patient safety.

Water treatment facilities utilizing ultrafiltration membranes must comply with drinking water standards such as those set by the World Health Organization (WHO) or local regulatory bodies. These standards limit the types and concentrations of chemicals that can be used in processes that ultimately produce potable water.

Emerging regulations increasingly focus on environmental sustainability, pushing industries toward greener cleaning solutions with lower environmental impact. This trend is driving innovation in biodegradable cleaning agents and processes that minimize water consumption and waste generation.

Compliance documentation requirements have also become more comprehensive, with many jurisdictions requiring detailed record-keeping of cleaning procedures, chemical usage, waste disposal methods, and employee training. Regular audits by regulatory authorities necessitate robust compliance management systems to track and demonstrate adherence to applicable regulations.

In the United States, the Environmental Protection Agency (EPA) regulates chemical discharge through the Clean Water Act, which directly impacts the selection and disposal of membrane cleaning agents. Facilities must obtain National Pollutant Discharge Elimination System (NPDES) permits when chemical cleaning waste is discharged into public waterways. Additionally, the Occupational Safety and Health Administration (OSHA) enforces strict guidelines regarding worker exposure to hazardous cleaning chemicals, requiring proper ventilation, personal protective equipment, and safety protocols.

The European Union implements more stringent regulations through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, which requires comprehensive documentation of all chemical substances used in industrial processes. For membrane cleaning operations, this means detailed safety data sheets, exposure scenarios, and risk management measures must be maintained and regularly updated.

Food and beverage industries face additional regulatory hurdles, as cleaning chemicals must comply with FDA regulations in the US or equivalent food safety authorities elsewhere. These regulations specify which chemicals are approved for food-contact applications and mandate thorough rinsing procedures to prevent contamination of food products.

Pharmaceutical manufacturers must adhere to Good Manufacturing Practice (GMP) guidelines, which impose strict validation requirements for cleaning processes. This includes demonstrating the effectiveness of the cleaning method and ensuring no harmful residues remain that could compromise product quality or patient safety.

Water treatment facilities utilizing ultrafiltration membranes must comply with drinking water standards such as those set by the World Health Organization (WHO) or local regulatory bodies. These standards limit the types and concentrations of chemicals that can be used in processes that ultimately produce potable water.

Emerging regulations increasingly focus on environmental sustainability, pushing industries toward greener cleaning solutions with lower environmental impact. This trend is driving innovation in biodegradable cleaning agents and processes that minimize water consumption and waste generation.

Compliance documentation requirements have also become more comprehensive, with many jurisdictions requiring detailed record-keeping of cleaning procedures, chemical usage, waste disposal methods, and employee training. Regular audits by regulatory authorities necessitate robust compliance management systems to track and demonstrate adherence to applicable regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!