Optimize Ultrafiltration Operating Conditions for Reduced Energy Usage

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Background and Objectives

Ultrafiltration (UF) technology has evolved significantly since its inception in the 1960s, transforming from laboratory-scale applications to widespread industrial implementation. This membrane separation process, operating in the 0.01-0.1 μm pore size range, has become a cornerstone technology in various sectors including water treatment, food processing, biotechnology, and pharmaceutical manufacturing. The fundamental principle of ultrafiltration relies on pressure-driven separation where a semi-permeable membrane selectively allows water and small molecules to pass through while retaining larger molecules, colloids, and particulates.

The evolution of ultrafiltration technology has been marked by continuous improvements in membrane materials, module designs, and operational strategies. Early membranes were primarily cellulose-based, but advancements in polymer science have introduced more robust materials such as polysulfone, polyethersulfone, and polyvinylidene fluoride, offering enhanced chemical resistance, thermal stability, and mechanical strength. Module configurations have similarly progressed from simple flat-sheet designs to more efficient hollow fiber and spiral-wound arrangements that maximize surface area while minimizing footprint.

Despite these advancements, energy consumption remains a significant challenge in ultrafiltration operations. The pressure requirements for maintaining adequate flux rates, coupled with the energy needed for feed pumping, backwashing, and cleaning processes, contribute substantially to operational costs. Current industry trends indicate that energy consumption in UF systems typically ranges from 0.1 to 1.0 kWh per cubic meter of treated water, depending on application specifics and system design.

The primary objective of optimizing ultrafiltration operating conditions for reduced energy usage is to develop strategies that maintain or enhance separation efficiency while minimizing energy inputs. This involves a multifaceted approach addressing several key parameters: transmembrane pressure optimization, cross-flow velocity management, filtration cycle duration, backwash frequency and intensity, and chemical cleaning protocols. Additionally, emerging techniques such as pulsed operation, variable frequency drives, and energy recovery devices present promising avenues for further efficiency improvements.

Recent technological trends point toward intelligent control systems that dynamically adjust operating parameters based on real-time monitoring of membrane performance indicators. Machine learning algorithms are increasingly being employed to predict fouling behavior and optimize cleaning schedules, potentially reducing unnecessary energy expenditure. The integration of renewable energy sources to power UF systems also represents a growing area of interest, particularly for decentralized applications in regions with limited grid connectivity.

The evolution of ultrafiltration technology has been marked by continuous improvements in membrane materials, module designs, and operational strategies. Early membranes were primarily cellulose-based, but advancements in polymer science have introduced more robust materials such as polysulfone, polyethersulfone, and polyvinylidene fluoride, offering enhanced chemical resistance, thermal stability, and mechanical strength. Module configurations have similarly progressed from simple flat-sheet designs to more efficient hollow fiber and spiral-wound arrangements that maximize surface area while minimizing footprint.

Despite these advancements, energy consumption remains a significant challenge in ultrafiltration operations. The pressure requirements for maintaining adequate flux rates, coupled with the energy needed for feed pumping, backwashing, and cleaning processes, contribute substantially to operational costs. Current industry trends indicate that energy consumption in UF systems typically ranges from 0.1 to 1.0 kWh per cubic meter of treated water, depending on application specifics and system design.

The primary objective of optimizing ultrafiltration operating conditions for reduced energy usage is to develop strategies that maintain or enhance separation efficiency while minimizing energy inputs. This involves a multifaceted approach addressing several key parameters: transmembrane pressure optimization, cross-flow velocity management, filtration cycle duration, backwash frequency and intensity, and chemical cleaning protocols. Additionally, emerging techniques such as pulsed operation, variable frequency drives, and energy recovery devices present promising avenues for further efficiency improvements.

Recent technological trends point toward intelligent control systems that dynamically adjust operating parameters based on real-time monitoring of membrane performance indicators. Machine learning algorithms are increasingly being employed to predict fouling behavior and optimize cleaning schedules, potentially reducing unnecessary energy expenditure. The integration of renewable energy sources to power UF systems also represents a growing area of interest, particularly for decentralized applications in regions with limited grid connectivity.

Market Demand for Energy-Efficient Filtration Solutions

The global market for energy-efficient filtration solutions has experienced significant growth in recent years, driven by increasing environmental regulations, rising energy costs, and growing industrial awareness of operational efficiency. Ultrafiltration technology, as a key component in various industrial processes, has become a focal point for energy optimization efforts across multiple sectors.

Industrial water treatment represents the largest market segment, with manufacturing facilities seeking to reduce the substantial energy consumption associated with their filtration systems. According to market research, energy costs typically account for 30-40% of the total operational expenses in industrial water treatment facilities, creating a strong economic incentive for optimization.

The municipal water treatment sector has also emerged as a major demand driver, with utilities facing pressure to reduce carbon footprints while managing increasing water treatment volumes. Many municipalities have established specific energy reduction targets for their water infrastructure, creating immediate market opportunities for optimized ultrafiltration solutions.

Food and beverage processing industries represent another significant market segment, where ultrafiltration is extensively used in product concentration, clarification, and wastewater treatment. These industries face dual pressures of maintaining product quality while reducing operational costs, making energy-efficient filtration particularly valuable.

Pharmaceutical manufacturing has shown accelerated demand growth, especially following global supply chain disruptions that highlighted the need for more resilient and cost-effective production processes. Energy optimization in ultrafiltration systems directly impacts production costs in this highly regulated industry.

Market analysis indicates that companies can achieve 15-25% energy savings through optimized ultrafiltration operating conditions, representing substantial cost reductions over system lifetimes. This potential for return on investment has created a receptive market environment for innovative solutions.

Regional market variations are notable, with Europe leading adoption due to stringent energy efficiency regulations and high energy costs. North America follows with strong growth driven by industrial modernization initiatives, while Asia-Pacific represents the fastest-growing market as rapid industrialization creates demand for efficient water treatment technologies.

Customer requirements have evolved beyond simple energy reduction to encompass comprehensive performance metrics including membrane longevity, maintenance requirements, and system reliability. This shift has created market opportunities for integrated optimization solutions that address multiple operational parameters simultaneously.

The market trajectory suggests continued growth as water scarcity concerns intensify globally and energy costs maintain their upward trend. Industries previously less focused on filtration efficiency are now entering the market as they seek comprehensive sustainability improvements across their operations.

Industrial water treatment represents the largest market segment, with manufacturing facilities seeking to reduce the substantial energy consumption associated with their filtration systems. According to market research, energy costs typically account for 30-40% of the total operational expenses in industrial water treatment facilities, creating a strong economic incentive for optimization.

The municipal water treatment sector has also emerged as a major demand driver, with utilities facing pressure to reduce carbon footprints while managing increasing water treatment volumes. Many municipalities have established specific energy reduction targets for their water infrastructure, creating immediate market opportunities for optimized ultrafiltration solutions.

Food and beverage processing industries represent another significant market segment, where ultrafiltration is extensively used in product concentration, clarification, and wastewater treatment. These industries face dual pressures of maintaining product quality while reducing operational costs, making energy-efficient filtration particularly valuable.

Pharmaceutical manufacturing has shown accelerated demand growth, especially following global supply chain disruptions that highlighted the need for more resilient and cost-effective production processes. Energy optimization in ultrafiltration systems directly impacts production costs in this highly regulated industry.

Market analysis indicates that companies can achieve 15-25% energy savings through optimized ultrafiltration operating conditions, representing substantial cost reductions over system lifetimes. This potential for return on investment has created a receptive market environment for innovative solutions.

Regional market variations are notable, with Europe leading adoption due to stringent energy efficiency regulations and high energy costs. North America follows with strong growth driven by industrial modernization initiatives, while Asia-Pacific represents the fastest-growing market as rapid industrialization creates demand for efficient water treatment technologies.

Customer requirements have evolved beyond simple energy reduction to encompass comprehensive performance metrics including membrane longevity, maintenance requirements, and system reliability. This shift has created market opportunities for integrated optimization solutions that address multiple operational parameters simultaneously.

The market trajectory suggests continued growth as water scarcity concerns intensify globally and energy costs maintain their upward trend. Industries previously less focused on filtration efficiency are now entering the market as they seek comprehensive sustainability improvements across their operations.

Current Ultrafiltration Challenges and Energy Constraints

Ultrafiltration (UF) technology faces significant challenges in energy efficiency despite its widespread adoption in water treatment, food processing, and pharmaceutical industries. Current UF systems typically consume between 1-3 kWh per cubic meter of processed fluid, with energy costs representing 30-40% of operational expenses. This high energy demand stems primarily from maintaining transmembrane pressure (TMP) and overcoming membrane fouling resistance.

Membrane fouling remains the most persistent challenge in UF operations, causing gradual flux decline and necessitating increased energy input to maintain production rates. Conventional systems often operate at suboptimal flux rates (15-25 LMH) to mitigate fouling, sacrificing efficiency for operational stability. Studies indicate that fouling can increase energy consumption by 20-80% compared to clean membrane conditions, depending on feed characteristics and operating parameters.

Temperature dependency presents another significant constraint, as UF performance typically decreases 2-3% per degree Celsius below optimal temperature ranges. Many facilities compensate by increasing feed temperature through heating or applying higher pressures, both energy-intensive approaches that compromise sustainability goals.

Cross-flow velocity management represents a critical energy trade-off. Higher velocities (typically 2-4 m/s) effectively control concentration polarization and surface fouling but require substantial pumping energy. This creates a complex optimization challenge where reducing cross-flow to save energy often results in accelerated fouling and subsequent energy penalties during cleaning cycles.

Cleaning procedures further compound energy concerns. Chemical cleaning-in-place (CIP) sequences consume significant energy through heating cleaning solutions (often to 40-50°C), pumping, and subsequent rinse cycles. A typical CIP procedure requires 0.5-1.5 kWh per square meter of membrane area, with facilities performing these operations weekly or monthly depending on fouling rates.

System design inefficiencies exacerbate these challenges. Many existing UF installations utilize oversized pumps operating at partial capacity, resulting in poor energy efficiency. Studies reveal that pump oversizing can waste 15-30% of energy input. Additionally, pressure drop across manifolds, valves, and piping can account for 10-25% of total energy consumption in poorly designed systems.

Monitoring and control limitations further constrain optimization efforts. Traditional UF systems often lack real-time performance analytics, resulting in conservative operation with excessive safety margins. This approach typically increases energy consumption by 10-20% compared to systems with advanced monitoring capabilities that enable dynamic adjustment of operating parameters.

Membrane fouling remains the most persistent challenge in UF operations, causing gradual flux decline and necessitating increased energy input to maintain production rates. Conventional systems often operate at suboptimal flux rates (15-25 LMH) to mitigate fouling, sacrificing efficiency for operational stability. Studies indicate that fouling can increase energy consumption by 20-80% compared to clean membrane conditions, depending on feed characteristics and operating parameters.

Temperature dependency presents another significant constraint, as UF performance typically decreases 2-3% per degree Celsius below optimal temperature ranges. Many facilities compensate by increasing feed temperature through heating or applying higher pressures, both energy-intensive approaches that compromise sustainability goals.

Cross-flow velocity management represents a critical energy trade-off. Higher velocities (typically 2-4 m/s) effectively control concentration polarization and surface fouling but require substantial pumping energy. This creates a complex optimization challenge where reducing cross-flow to save energy often results in accelerated fouling and subsequent energy penalties during cleaning cycles.

Cleaning procedures further compound energy concerns. Chemical cleaning-in-place (CIP) sequences consume significant energy through heating cleaning solutions (often to 40-50°C), pumping, and subsequent rinse cycles. A typical CIP procedure requires 0.5-1.5 kWh per square meter of membrane area, with facilities performing these operations weekly or monthly depending on fouling rates.

System design inefficiencies exacerbate these challenges. Many existing UF installations utilize oversized pumps operating at partial capacity, resulting in poor energy efficiency. Studies reveal that pump oversizing can waste 15-30% of energy input. Additionally, pressure drop across manifolds, valves, and piping can account for 10-25% of total energy consumption in poorly designed systems.

Monitoring and control limitations further constrain optimization efforts. Traditional UF systems often lack real-time performance analytics, resulting in conservative operation with excessive safety margins. This approach typically increases energy consumption by 10-20% compared to systems with advanced monitoring capabilities that enable dynamic adjustment of operating parameters.

Current Energy-Saving Ultrafiltration Operating Strategies

01 Energy optimization in ultrafiltration systems

Various methods and systems are employed to optimize energy usage in ultrafiltration processes. These include advanced control algorithms that adjust operational parameters based on real-time data, predictive maintenance to prevent energy-wasting failures, and intelligent scheduling of filtration cycles. By implementing these optimization techniques, ultrafiltration systems can achieve significant energy savings while maintaining performance standards.- Energy optimization in ultrafiltration systems: Various methods and systems are employed to optimize energy usage in ultrafiltration processes. These include advanced control algorithms, real-time monitoring of system parameters, and adaptive operational strategies that adjust filtration parameters based on feed characteristics. By implementing these optimization techniques, ultrafiltration systems can achieve significant energy savings while maintaining filtration efficiency and product quality.

- Energy consumption monitoring and analytics for ultrafiltration: Monitoring and analyzing energy consumption in ultrafiltration processes involves the use of sensors, meters, and analytical tools to track power usage patterns. These systems collect data on energy consumption during different operational phases and provide insights for identifying inefficiencies. Advanced analytics platforms can process this data to generate recommendations for reducing energy usage while maintaining filtration performance.

- Energy-efficient membrane technologies for ultrafiltration: Innovative membrane technologies are being developed to reduce energy requirements in ultrafiltration processes. These include novel membrane materials with improved permeability, anti-fouling properties, and longer operational lifespans. Some designs incorporate energy recovery devices or utilize alternative driving forces to minimize power consumption while maintaining separation efficiency.

- Predictive maintenance to reduce energy waste in ultrafiltration: Predictive maintenance strategies help minimize energy waste in ultrafiltration systems by identifying potential issues before they lead to inefficient operation. These approaches use condition monitoring, machine learning algorithms, and historical performance data to predict when components might fail or when membrane fouling is likely to occur. By addressing these issues proactively, systems can maintain optimal energy efficiency throughout their operational lifecycle.

- Integration of renewable energy sources with ultrafiltration systems: Ultrafiltration systems can be integrated with renewable energy sources to reduce reliance on conventional power grids and decrease overall energy costs. These hybrid systems may incorporate solar panels, wind turbines, or other renewable energy technologies to power filtration processes. Smart control systems manage the variable nature of renewable energy inputs, ensuring consistent ultrafiltration performance while maximizing the use of clean energy sources.

02 Energy monitoring and management for ultrafiltration

Energy monitoring systems specifically designed for ultrafiltration processes enable real-time tracking of energy consumption patterns. These systems incorporate sensors and meters that collect data on power usage across different components of the filtration system. Advanced analytics then process this information to identify inefficiencies and suggest improvements, allowing operators to make informed decisions about energy management strategies.Expand Specific Solutions03 Energy-efficient membrane technologies

Innovations in membrane technology have led to more energy-efficient ultrafiltration processes. These advancements include membranes with optimized pore structures that reduce pressure requirements, anti-fouling surface treatments that maintain performance with less cleaning, and novel membrane materials that offer better flux rates at lower energy inputs. Such improvements directly translate to reduced energy consumption in ultrafiltration operations.Expand Specific Solutions04 Automated control systems for energy reduction

Automated control systems play a crucial role in minimizing energy usage in ultrafiltration processes. These systems utilize artificial intelligence and machine learning algorithms to continuously optimize operational parameters such as pressure, flow rate, and backwash frequency. By dynamically adjusting these parameters based on feed water quality and filtration requirements, these systems can significantly reduce energy consumption while maintaining filtration efficiency.Expand Specific Solutions05 Energy recovery and sustainable practices in ultrafiltration

Energy recovery devices and sustainable practices are increasingly being integrated into ultrafiltration systems to improve overall energy efficiency. These include pressure exchangers that recover energy from reject streams, renewable energy integration for powering filtration systems, and waste heat recovery mechanisms. Additionally, comprehensive life cycle assessments are being used to identify opportunities for energy conservation throughout the entire ultrafiltration process.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Ultrafiltration

Ultrafiltration energy optimization is currently in a growth phase, with the global market expanding as industries prioritize sustainable water treatment solutions. The market is projected to reach significant scale due to increasing water scarcity concerns and stringent environmental regulations. Technologically, the field shows moderate maturity with ongoing innovations focused on energy efficiency. Leading players like Veolia Water Solutions, Ecolab, and Siemens have established strong positions through advanced membrane technologies, while companies such as Hitachi, Gambro Lundia, and Nomura Micro Science are making notable advancements in process optimization. Industrial conglomerates including Robert Bosch and Huawei are leveraging their automation expertise to develop intelligent control systems that further reduce energy consumption in ultrafiltration operations.

Gambro Lundia AB

Technical Solution: Gambro Lundia AB has developed an advanced ultrafiltration optimization system that dynamically adjusts operating parameters based on real-time monitoring of transmembrane pressure (TMP) and permeate flux. Their technology incorporates a proprietary algorithm that continuously analyzes filtration performance metrics and automatically modifies cross-flow velocity, backwash frequency, and pressure gradients to maintain optimal efficiency. The system employs a dual-phase approach where initial high-pressure operation rapidly establishes filtration, followed by a controlled reduction to the minimum effective pressure required for sustained performance. This approach has demonstrated energy savings of 20-30% compared to conventional fixed-parameter operations while maintaining equivalent filtration quality.

Strengths: Specialized expertise in medical-grade ultrafiltration systems with precise control requirements; technology is particularly effective in applications with variable feed compositions. Weakness: Higher initial implementation costs and primarily optimized for healthcare applications rather than industrial-scale operations.

Veolia Water Solutions & Technologies Support SAS

Technical Solution: Veolia has pioneered an integrated ultrafiltration energy optimization platform that combines membrane fouling prediction algorithms with variable frequency drive (VFD) pump control systems. Their solution utilizes machine learning to analyze historical performance data and predict optimal cleaning cycles, significantly reducing unnecessary backwashing operations that consume substantial energy. The system incorporates a proprietary "Smart Flux" technology that maintains optimal flux rates based on feed water quality variations, temperature fluctuations, and membrane age. Field implementations have demonstrated energy consumption reductions of up to 40% compared to conventional systems. Veolia's approach also includes innovative low-pressure membrane materials that achieve equivalent filtration at operating pressures 15-25% lower than industry standards, further reducing pumping energy requirements.

Strengths: Comprehensive solution that addresses multiple energy consumption factors simultaneously; extensive field validation across diverse water treatment applications. Weakness: Complex implementation requiring significant system integration and specialized technical support for optimal performance.

Key Innovations in Membrane Technology and Process Control

Optimised concentrate processing (OTC)

PatentWO2019147191A1

Innovation

- The process integrates ultrafiltration membranes with anti-scalants and an energy recuperator, optimizing concentrate treatment by achieving maximum supersaturation without clogging and reducing energy use through pressure exchange systems.

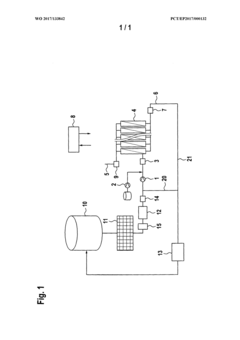

Method of processing circulating water in circulation systems

PatentWO2017133842A1

Innovation

- A method that controls the mass flow of a partial water flow via a bypass through ultra- and/or microfiltration, adjusting based on parameters like turbidity, dissolved iron, and aluminum content, using sensors and controlled dosing of iron and aluminum salts, and other chemicals to optimize water treatment and reduce energy consumption.

Sustainability Metrics and Environmental Impact Assessment

Sustainability metrics for ultrafiltration processes provide essential frameworks for evaluating environmental performance and guiding optimization efforts. When assessing energy reduction strategies in ultrafiltration operations, comprehensive metrics must include energy intensity (kWh/m³ of processed water), carbon footprint (CO₂e), and resource efficiency indicators. These metrics enable meaningful comparisons between different operating conditions and support data-driven decision-making for sustainable process improvements.

Environmental impact assessment of ultrafiltration systems reveals that energy consumption represents 30-50% of the total operational environmental burden. Optimized operating conditions can significantly reduce this impact through decreased pumping requirements, extended membrane lifespans, and minimized chemical usage. Life Cycle Assessment (LCA) studies demonstrate that energy optimization in ultrafiltration can reduce greenhouse gas emissions by 15-25% compared to conventional operations.

Water-energy nexus considerations are particularly relevant, as ultrafiltration processes simultaneously address water purification while consuming energy resources. The environmental trade-offs must be carefully balanced through metrics that capture both dimensions. For instance, the Water-Energy Intensity Ratio (WEIR) measures the volume of water treated per unit of energy consumed, providing insights into overall system efficiency.

Chemical usage reduction resulting from optimized operating conditions delivers additional environmental benefits beyond energy savings. Decreased chemical consumption for membrane cleaning and maintenance reduces aquatic toxicity potential by 10-20% and lowers the embedded carbon footprint associated with chemical manufacturing and transportation. These secondary benefits should be incorporated into comprehensive sustainability assessments.

Regulatory compliance frameworks increasingly incorporate sustainability metrics for water treatment facilities. The European Union's Best Available Techniques Reference Documents (BREFs) and the United States EPA's Energy Star program for water utilities establish benchmarks for energy performance in filtration processes. Optimized ultrafiltration operations that meet or exceed these standards not only reduce environmental impact but also ensure regulatory alignment and potential certification benefits.

Long-term environmental impact projections indicate that implementing optimized ultrafiltration conditions across municipal and industrial applications could reduce global water treatment energy consumption by approximately 5-8% annually. This represents a significant contribution to climate change mitigation efforts while simultaneously improving water security through more efficient treatment processes.

Environmental impact assessment of ultrafiltration systems reveals that energy consumption represents 30-50% of the total operational environmental burden. Optimized operating conditions can significantly reduce this impact through decreased pumping requirements, extended membrane lifespans, and minimized chemical usage. Life Cycle Assessment (LCA) studies demonstrate that energy optimization in ultrafiltration can reduce greenhouse gas emissions by 15-25% compared to conventional operations.

Water-energy nexus considerations are particularly relevant, as ultrafiltration processes simultaneously address water purification while consuming energy resources. The environmental trade-offs must be carefully balanced through metrics that capture both dimensions. For instance, the Water-Energy Intensity Ratio (WEIR) measures the volume of water treated per unit of energy consumed, providing insights into overall system efficiency.

Chemical usage reduction resulting from optimized operating conditions delivers additional environmental benefits beyond energy savings. Decreased chemical consumption for membrane cleaning and maintenance reduces aquatic toxicity potential by 10-20% and lowers the embedded carbon footprint associated with chemical manufacturing and transportation. These secondary benefits should be incorporated into comprehensive sustainability assessments.

Regulatory compliance frameworks increasingly incorporate sustainability metrics for water treatment facilities. The European Union's Best Available Techniques Reference Documents (BREFs) and the United States EPA's Energy Star program for water utilities establish benchmarks for energy performance in filtration processes. Optimized ultrafiltration operations that meet or exceed these standards not only reduce environmental impact but also ensure regulatory alignment and potential certification benefits.

Long-term environmental impact projections indicate that implementing optimized ultrafiltration conditions across municipal and industrial applications could reduce global water treatment energy consumption by approximately 5-8% annually. This represents a significant contribution to climate change mitigation efforts while simultaneously improving water security through more efficient treatment processes.

Economic Analysis of Energy-Optimized Ultrafiltration Systems

The economic implications of energy-optimized ultrafiltration systems extend far beyond simple utility cost reductions. When properly implemented, these systems can deliver substantial financial benefits through multiple channels. Initial investment in energy-efficient ultrafiltration technology typically requires 15-30% higher capital expenditure compared to conventional systems, but this premium is generally recovered within 2-4 years through operational savings.

Energy consumption represents approximately 30-40% of the total operational costs in conventional ultrafiltration processes. By implementing optimized operating conditions—including pressure modulation, flux rate optimization, and advanced fouling control—facilities can achieve energy reductions of 20-45%, depending on application specifics and system scale. For large industrial installations, this translates to annual savings of $50,000-$200,000 per installation.

The economic value proposition becomes more compelling when considering the complete lifecycle cost analysis. Energy-optimized systems demonstrate extended membrane lifespans of 30-50% due to reduced mechanical stress and improved fouling management. This extension significantly decreases replacement costs and maintenance downtime, contributing an additional 10-15% to overall economic benefits beyond direct energy savings.

Market analysis indicates that industries with high-volume ultrafiltration requirements—such as dairy processing, pharmaceutical manufacturing, and municipal water treatment—stand to gain the most substantial economic advantages. For instance, a medium-sized dairy processing plant implementing energy-optimized ultrafiltration can realize ROI within 18-24 months, with cumulative five-year savings exceeding $1 million.

The economic case strengthens further when factoring in emerging carbon pricing mechanisms and sustainability incentives. In regions with carbon taxes or cap-and-trade systems, energy-optimized ultrafiltration can provide additional financial benefits of $15,000-$60,000 annually through reduced carbon liabilities. Moreover, various governmental incentive programs offer subsidies covering 10-30% of capital costs for energy-efficient industrial process improvements.

Sensitivity analysis reveals that energy price volatility significantly impacts the economic proposition. With projected energy cost increases of 3-5% annually in most industrial markets, the value of optimization will likely appreciate over time, potentially accelerating payback periods by 15-20% compared to current calculations.

Energy consumption represents approximately 30-40% of the total operational costs in conventional ultrafiltration processes. By implementing optimized operating conditions—including pressure modulation, flux rate optimization, and advanced fouling control—facilities can achieve energy reductions of 20-45%, depending on application specifics and system scale. For large industrial installations, this translates to annual savings of $50,000-$200,000 per installation.

The economic value proposition becomes more compelling when considering the complete lifecycle cost analysis. Energy-optimized systems demonstrate extended membrane lifespans of 30-50% due to reduced mechanical stress and improved fouling management. This extension significantly decreases replacement costs and maintenance downtime, contributing an additional 10-15% to overall economic benefits beyond direct energy savings.

Market analysis indicates that industries with high-volume ultrafiltration requirements—such as dairy processing, pharmaceutical manufacturing, and municipal water treatment—stand to gain the most substantial economic advantages. For instance, a medium-sized dairy processing plant implementing energy-optimized ultrafiltration can realize ROI within 18-24 months, with cumulative five-year savings exceeding $1 million.

The economic case strengthens further when factoring in emerging carbon pricing mechanisms and sustainability incentives. In regions with carbon taxes or cap-and-trade systems, energy-optimized ultrafiltration can provide additional financial benefits of $15,000-$60,000 annually through reduced carbon liabilities. Moreover, various governmental incentive programs offer subsidies covering 10-30% of capital costs for energy-efficient industrial process improvements.

Sensitivity analysis reveals that energy price volatility significantly impacts the economic proposition. With projected energy cost increases of 3-5% annually in most industrial markets, the value of optimization will likely appreciate over time, potentially accelerating payback periods by 15-20% compared to current calculations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!