Optimizing AGM Battery Heat Dissipation Techniques

AUG 8, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Thermal Management Background

Absorbed Glass Mat (AGM) batteries have become increasingly popular in various applications, including automotive, renewable energy storage, and uninterruptible power supplies. As the demand for high-performance energy storage solutions grows, the importance of effective thermal management in AGM batteries has come to the forefront of research and development efforts.

AGM batteries, a type of lead-acid battery, utilize a fiberglass mat separator to absorb and immobilize the electrolyte. This design offers several advantages, such as improved safety, reduced maintenance requirements, and enhanced cycle life. However, like all batteries, AGM batteries generate heat during charging and discharging processes, which can significantly impact their performance and longevity.

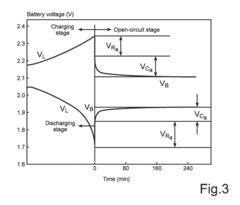

The thermal behavior of AGM batteries is influenced by various factors, including internal resistance, charge/discharge rates, ambient temperature, and battery design. As the battery operates, chemical reactions and electrical resistance generate heat, which, if not properly managed, can lead to accelerated aging, reduced capacity, and even safety hazards. Therefore, understanding and optimizing heat dissipation techniques is crucial for maximizing the efficiency and lifespan of AGM batteries.

Historically, thermal management in AGM batteries has evolved from simple passive cooling methods to more sophisticated active cooling systems. Early approaches relied primarily on natural convection and conduction to dissipate heat. However, as battery technologies advanced and power demands increased, these methods proved insufficient for maintaining optimal operating temperatures, especially in high-performance applications.

The development of thermal management strategies for AGM batteries has been driven by several key factors. First, the automotive industry's shift towards more electrically-powered systems has necessitated better thermal control in vehicle batteries. Second, the growing adoption of renewable energy sources has created a need for reliable and efficient energy storage solutions, capable of operating under diverse environmental conditions. Lastly, the increasing power density of modern electronic devices has pushed the limits of battery performance, requiring more effective heat dissipation techniques.

Recent advancements in materials science, computational modeling, and thermal engineering have opened new avenues for improving AGM battery thermal management. Researchers and engineers are exploring innovative cooling technologies, such as phase change materials, advanced heat spreaders, and intelligent thermal management systems. These developments aim to address the challenges of heat generation and dissipation in AGM batteries, ultimately enhancing their performance, reliability, and safety.

As we delve deeper into the optimization of AGM battery heat dissipation techniques, it is essential to consider the interplay between thermal management and other aspects of battery design and operation. This includes the impact on battery chemistry, structural integrity, and overall system integration. By addressing these interconnected factors, we can develop comprehensive solutions that not only improve heat dissipation but also contribute to the overall advancement of AGM battery technology.

AGM batteries, a type of lead-acid battery, utilize a fiberglass mat separator to absorb and immobilize the electrolyte. This design offers several advantages, such as improved safety, reduced maintenance requirements, and enhanced cycle life. However, like all batteries, AGM batteries generate heat during charging and discharging processes, which can significantly impact their performance and longevity.

The thermal behavior of AGM batteries is influenced by various factors, including internal resistance, charge/discharge rates, ambient temperature, and battery design. As the battery operates, chemical reactions and electrical resistance generate heat, which, if not properly managed, can lead to accelerated aging, reduced capacity, and even safety hazards. Therefore, understanding and optimizing heat dissipation techniques is crucial for maximizing the efficiency and lifespan of AGM batteries.

Historically, thermal management in AGM batteries has evolved from simple passive cooling methods to more sophisticated active cooling systems. Early approaches relied primarily on natural convection and conduction to dissipate heat. However, as battery technologies advanced and power demands increased, these methods proved insufficient for maintaining optimal operating temperatures, especially in high-performance applications.

The development of thermal management strategies for AGM batteries has been driven by several key factors. First, the automotive industry's shift towards more electrically-powered systems has necessitated better thermal control in vehicle batteries. Second, the growing adoption of renewable energy sources has created a need for reliable and efficient energy storage solutions, capable of operating under diverse environmental conditions. Lastly, the increasing power density of modern electronic devices has pushed the limits of battery performance, requiring more effective heat dissipation techniques.

Recent advancements in materials science, computational modeling, and thermal engineering have opened new avenues for improving AGM battery thermal management. Researchers and engineers are exploring innovative cooling technologies, such as phase change materials, advanced heat spreaders, and intelligent thermal management systems. These developments aim to address the challenges of heat generation and dissipation in AGM batteries, ultimately enhancing their performance, reliability, and safety.

As we delve deeper into the optimization of AGM battery heat dissipation techniques, it is essential to consider the interplay between thermal management and other aspects of battery design and operation. This includes the impact on battery chemistry, structural integrity, and overall system integration. By addressing these interconnected factors, we can develop comprehensive solutions that not only improve heat dissipation but also contribute to the overall advancement of AGM battery technology.

Market Demand for Efficient AGM Batteries

The market demand for efficient AGM (Absorbent Glass Mat) batteries has been steadily increasing across various industries, driven by the growing need for reliable and high-performance energy storage solutions. AGM batteries are widely used in automotive, renewable energy, telecommunications, and uninterruptible power supply (UPS) systems due to their superior performance characteristics compared to traditional lead-acid batteries.

In the automotive sector, the rise of start-stop technology and the increasing electrification of vehicles have created a significant demand for AGM batteries. These batteries can withstand frequent charge-discharge cycles and provide the necessary power for advanced vehicle systems. The global automotive AGM battery market is expected to grow substantially in the coming years, as more vehicles adopt start-stop systems and other energy-efficient technologies.

The renewable energy sector is another key driver of AGM battery demand. As solar and wind power installations continue to expand worldwide, the need for efficient energy storage solutions has become paramount. AGM batteries offer a cost-effective and reliable option for storing excess energy generated by renewable sources, making them an attractive choice for both residential and commercial applications.

Telecommunications and data centers represent another significant market for AGM batteries. These industries require uninterrupted power supply to maintain critical operations, and AGM batteries provide the necessary backup power with minimal maintenance requirements. The rapid growth of 5G networks and the increasing number of data centers globally are expected to further boost the demand for AGM batteries in this sector.

However, the market demand for efficient AGM batteries is not without challenges. One of the primary concerns is heat dissipation, which directly affects battery performance and lifespan. As applications demand higher power outputs and faster charging capabilities, the issue of heat generation becomes more pronounced. This has led to increased focus on optimizing AGM battery heat dissipation techniques to meet market requirements for longer-lasting, more efficient batteries.

The marine and recreational vehicle (RV) industries also contribute to the growing demand for AGM batteries. These applications require batteries that can withstand harsh environments, vibrations, and deep discharge cycles. AGM batteries' sealed design and superior performance in these conditions make them an ideal choice for boats, yachts, and RVs.

As environmental concerns continue to shape consumer preferences and regulatory landscapes, the demand for more sustainable battery technologies is on the rise. AGM batteries, with their recyclable components and longer lifespan compared to traditional lead-acid batteries, align well with these environmental considerations. This factor is expected to further drive market demand in the coming years.

In the automotive sector, the rise of start-stop technology and the increasing electrification of vehicles have created a significant demand for AGM batteries. These batteries can withstand frequent charge-discharge cycles and provide the necessary power for advanced vehicle systems. The global automotive AGM battery market is expected to grow substantially in the coming years, as more vehicles adopt start-stop systems and other energy-efficient technologies.

The renewable energy sector is another key driver of AGM battery demand. As solar and wind power installations continue to expand worldwide, the need for efficient energy storage solutions has become paramount. AGM batteries offer a cost-effective and reliable option for storing excess energy generated by renewable sources, making them an attractive choice for both residential and commercial applications.

Telecommunications and data centers represent another significant market for AGM batteries. These industries require uninterrupted power supply to maintain critical operations, and AGM batteries provide the necessary backup power with minimal maintenance requirements. The rapid growth of 5G networks and the increasing number of data centers globally are expected to further boost the demand for AGM batteries in this sector.

However, the market demand for efficient AGM batteries is not without challenges. One of the primary concerns is heat dissipation, which directly affects battery performance and lifespan. As applications demand higher power outputs and faster charging capabilities, the issue of heat generation becomes more pronounced. This has led to increased focus on optimizing AGM battery heat dissipation techniques to meet market requirements for longer-lasting, more efficient batteries.

The marine and recreational vehicle (RV) industries also contribute to the growing demand for AGM batteries. These applications require batteries that can withstand harsh environments, vibrations, and deep discharge cycles. AGM batteries' sealed design and superior performance in these conditions make them an ideal choice for boats, yachts, and RVs.

As environmental concerns continue to shape consumer preferences and regulatory landscapes, the demand for more sustainable battery technologies is on the rise. AGM batteries, with their recyclable components and longer lifespan compared to traditional lead-acid batteries, align well with these environmental considerations. This factor is expected to further drive market demand in the coming years.

Current Heat Dissipation Challenges

AGM (Absorbent Glass Mat) batteries, widely used in various applications including automotive and renewable energy systems, face significant heat dissipation challenges that can impact their performance and lifespan. The current heat dissipation techniques for AGM batteries are struggling to keep pace with the increasing demands for higher power output and faster charging capabilities.

One of the primary challenges is the inherent design of AGM batteries, which limits the effectiveness of traditional cooling methods. The tightly packed internal structure, while beneficial for electrolyte retention and vibration resistance, restricts the flow of heat from the core to the exterior. This results in localized hot spots within the battery, particularly during high-current discharge or rapid charging cycles.

The thermal management of AGM batteries is further complicated by the exothermic nature of the chemical reactions occurring during charge and discharge processes. As the battery operates, heat is generated internally, and without efficient dissipation, this can lead to a cascading effect of increased temperature, accelerated chemical reactions, and further heat generation. This cycle can potentially result in thermal runaway, a dangerous condition that can cause battery failure or even fire.

Current cooling solutions often rely on passive heat dissipation through the battery casing, which becomes increasingly inadequate as power demands rise. Active cooling systems, such as forced air or liquid cooling, present their own set of challenges. These systems add complexity, weight, and cost to the overall battery package, which can be prohibitive in many applications, especially in mobile or space-constrained environments.

Another significant challenge is the uneven heat distribution within AGM batteries. The cells closest to the exterior tend to cool more efficiently than those in the center, leading to temperature gradients across the battery pack. This temperature imbalance can cause uneven aging and performance degradation of individual cells, reducing the overall lifespan and reliability of the battery system.

The environmental conditions in which AGM batteries operate also pose heat dissipation challenges. In high-temperature environments or enclosed spaces with poor ventilation, the ambient heat exacerbates the internal heating issues. Conversely, in extremely cold conditions, the battery may require heating to maintain optimal performance, adding another layer of complexity to thermal management strategies.

As the demand for higher energy density and faster charging capabilities continues to grow, these heat dissipation challenges become increasingly critical. The industry is actively seeking innovative solutions to address these issues, exploring advanced materials, novel battery designs, and sophisticated thermal management systems. However, balancing improved heat dissipation with cost-effectiveness, simplicity, and maintaining the core benefits of AGM technology remains a significant challenge for researchers and engineers in the field.

One of the primary challenges is the inherent design of AGM batteries, which limits the effectiveness of traditional cooling methods. The tightly packed internal structure, while beneficial for electrolyte retention and vibration resistance, restricts the flow of heat from the core to the exterior. This results in localized hot spots within the battery, particularly during high-current discharge or rapid charging cycles.

The thermal management of AGM batteries is further complicated by the exothermic nature of the chemical reactions occurring during charge and discharge processes. As the battery operates, heat is generated internally, and without efficient dissipation, this can lead to a cascading effect of increased temperature, accelerated chemical reactions, and further heat generation. This cycle can potentially result in thermal runaway, a dangerous condition that can cause battery failure or even fire.

Current cooling solutions often rely on passive heat dissipation through the battery casing, which becomes increasingly inadequate as power demands rise. Active cooling systems, such as forced air or liquid cooling, present their own set of challenges. These systems add complexity, weight, and cost to the overall battery package, which can be prohibitive in many applications, especially in mobile or space-constrained environments.

Another significant challenge is the uneven heat distribution within AGM batteries. The cells closest to the exterior tend to cool more efficiently than those in the center, leading to temperature gradients across the battery pack. This temperature imbalance can cause uneven aging and performance degradation of individual cells, reducing the overall lifespan and reliability of the battery system.

The environmental conditions in which AGM batteries operate also pose heat dissipation challenges. In high-temperature environments or enclosed spaces with poor ventilation, the ambient heat exacerbates the internal heating issues. Conversely, in extremely cold conditions, the battery may require heating to maintain optimal performance, adding another layer of complexity to thermal management strategies.

As the demand for higher energy density and faster charging capabilities continues to grow, these heat dissipation challenges become increasingly critical. The industry is actively seeking innovative solutions to address these issues, exploring advanced materials, novel battery designs, and sophisticated thermal management systems. However, balancing improved heat dissipation with cost-effectiveness, simplicity, and maintaining the core benefits of AGM technology remains a significant challenge for researchers and engineers in the field.

Existing Heat Dissipation Solutions

01 Heat dissipation through structural design

AGM batteries can be designed with specific structural features to enhance heat dissipation. This includes the use of heat-conductive materials, optimized cell arrangement, and the incorporation of cooling channels or fins within the battery casing. These design elements help to efficiently transfer heat away from the battery cells, maintaining optimal operating temperatures and prolonging battery life.- Heat dissipation structures for AGM batteries: Various structural designs are implemented to enhance heat dissipation in AGM batteries. These include the use of heat sinks, cooling fins, and specialized casings that promote better airflow and thermal management. Such structures help to efficiently remove heat generated during battery operation, maintaining optimal performance and extending battery life.

- Thermal management systems for AGM batteries: Advanced thermal management systems are developed for AGM batteries, incorporating active cooling mechanisms such as liquid cooling, forced air circulation, or thermoelectric cooling. These systems actively regulate battery temperature, preventing overheating and ensuring consistent performance across various operating conditions.

- Heat-dissipating materials in AGM battery construction: Innovative materials with superior thermal conductivity are integrated into AGM battery construction. These materials, such as graphene-based composites or advanced polymers, are used in electrodes, separators, or casings to facilitate efficient heat transfer and dissipation, improving overall battery thermal management.

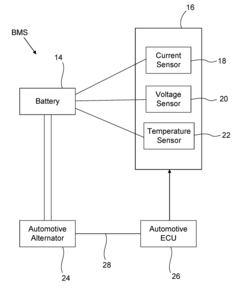

- Smart thermal management for AGM batteries: Intelligent thermal management systems are developed, incorporating sensors, microcontrollers, and adaptive algorithms. These systems continuously monitor battery temperature and adjust cooling mechanisms in real-time, optimizing heat dissipation based on operating conditions and battery state of charge.

- Battery pack design for improved heat dissipation: Optimized battery pack designs are created to enhance overall heat dissipation in AGM battery systems. These designs focus on efficient cell arrangement, improved inter-cell spacing, and strategic placement of cooling channels or heat-dissipating elements within the pack structure, ensuring uniform temperature distribution and effective thermal management.

02 Active cooling systems

Implementation of active cooling systems can significantly improve heat dissipation in AGM batteries. These systems may include forced air cooling, liquid cooling, or thermoelectric cooling methods. By actively removing heat from the battery, these systems help maintain consistent performance and prevent thermal runaway, especially in high-demand applications or extreme environmental conditions.Expand Specific Solutions03 Thermal management materials

Incorporating specialized thermal management materials within the AGM battery structure can enhance heat dissipation. These materials may include phase change materials, heat-absorbing compounds, or thermally conductive polymers. By strategically placing these materials within the battery, heat can be more effectively distributed and dissipated, reducing hot spots and improving overall thermal performance.Expand Specific Solutions04 Battery management systems for thermal control

Advanced battery management systems can be employed to monitor and control the thermal conditions of AGM batteries. These systems use sensors to detect temperature variations and can adjust charging rates, load distribution, or activate cooling mechanisms as needed. By proactively managing thermal conditions, these systems help prevent overheating and ensure optimal battery performance and longevity.Expand Specific Solutions05 Innovative electrode and separator designs

Developing new electrode and separator designs can contribute to improved heat dissipation in AGM batteries. This may involve using materials with higher thermal conductivity, creating porous structures that facilitate heat transfer, or designing electrode patterns that minimize heat generation. These innovations at the cell level can significantly impact the overall thermal management of the battery.Expand Specific Solutions

Key Players in AGM Battery Industry

The AGM battery heat dissipation technology market is in a growth phase, driven by increasing demand for high-performance batteries in automotive and energy storage applications. The market size is expanding rapidly, with key players like Fengfan, Tianneng Battery Group, and BYD Co., Ltd. leading innovation efforts. These companies are investing heavily in R&D to improve heat dissipation techniques, indicating a moderate level of technological maturity. However, the involvement of major automotive manufacturers such as Toyota and Kia suggests that the technology is still evolving, with potential for significant advancements. The competitive landscape is diverse, including specialized battery manufacturers, automotive giants, and research institutions, fostering a dynamic environment for technological progress.

Toyota Motor Corp.

Technical Solution: Toyota has developed a sophisticated approach to AGM battery heat dissipation, focusing on both active and passive cooling techniques. Their system incorporates a dual-layer cooling structure, where a coolant circulates through channels surrounding the battery cells, while a secondary air cooling system manages the overall battery pack temperature. Toyota's design also includes phase-change materials (PCMs) integrated into the battery structure, which absorb excess heat during high-load operations and release it gradually during cooler periods. This helps maintain a more consistent battery temperature, reducing thermal stress on the cells. Furthermore, Toyota has implemented advanced thermal modeling and simulation techniques to optimize the placement of cooling channels and heat-dissipating materials within the battery pack, ensuring uniform temperature distribution[3][4].

Strengths: Comprehensive thermal management, improved battery longevity, and enhanced performance in extreme conditions. Weaknesses: Increased system complexity and potential for higher maintenance requirements.

BYD Co., Ltd.

Technical Solution: BYD has developed an innovative Blade Battery technology, which incorporates AGM (Absorbent Glass Mat) principles for enhanced heat dissipation. The Blade Battery utilizes a unique cell-to-pack design, eliminating the need for module housings and reducing the battery pack's overall size. This design allows for better heat distribution and dissipation throughout the battery pack. BYD's approach includes the use of advanced thermal management systems, incorporating liquid cooling channels integrated directly into the battery structure. This system efficiently removes heat from the cells, maintaining optimal operating temperatures even under high-load conditions. Additionally, BYD has implemented smart battery management systems that continuously monitor cell temperatures and adjust charging and discharging rates to prevent overheating[1][2].

Strengths: Improved energy density, enhanced safety, and efficient thermal management. Weaknesses: Potentially higher manufacturing costs and complexity in production scaling.

Innovative Thermal Management Techniques

Battery heat-dissipation processing method, electronic device, and storage medium

PatentPendingEP4571947A1

Innovation

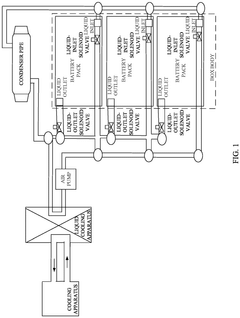

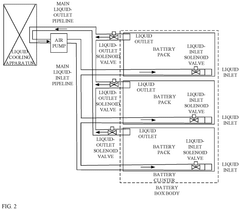

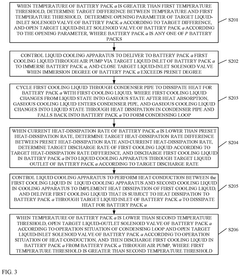

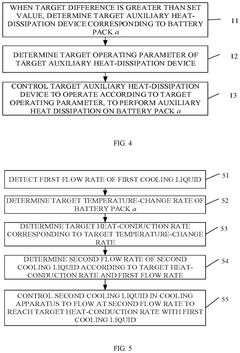

- A battery heat-dissipation processing method and apparatus that utilize a liquid cooling system with a condenser pipe, solenoid valves, and a cooling apparatus to control the flow and cycling of a first cooling liquid, optimizing heat dissipation through controlled immersion and condensation loops.

Method for Charging a Battery Having a Plurality of Battery Cells

PatentActiveUS20180134168A1

Innovation

- A battery management system (BMS) that dynamically controls the charging process using sensors for real-time monitoring of battery current, voltage, and temperature, implementing a multi-stage charging strategy including bulk charging, absorption, equalization, and float phases, with adaptive voltage and current adjustments to optimize charging efficiency and prevent overcharging and undercharging.

Environmental Impact of AGM Battery Production

The production of AGM (Absorbent Glass Mat) batteries, while offering numerous advantages in terms of performance and reliability, carries significant environmental implications that warrant careful consideration. The manufacturing process involves several stages that can potentially impact the environment, from raw material extraction to the final assembly of the battery components.

One of the primary environmental concerns associated with AGM battery production is the extraction and processing of lead, a key component in these batteries. Lead mining and smelting operations can result in soil and water contamination, as well as air pollution through the release of toxic particulates. Furthermore, the energy-intensive nature of lead processing contributes to increased carbon emissions, exacerbating climate change concerns.

The production of sulfuric acid, another essential component in AGM batteries, also poses environmental risks. The manufacturing process can release sulfur dioxide and other harmful gases into the atmosphere, contributing to air pollution and potentially leading to acid rain formation. Proper containment and treatment of acid waste are crucial to mitigate these risks and prevent soil and water contamination.

The glass mat used in AGM batteries, while recyclable, requires energy-intensive production processes. The manufacturing of glass fibers involves high-temperature furnaces, which consume significant amounts of energy and contribute to greenhouse gas emissions. Additionally, the use of chemical binders in the glass mat production can result in the release of volatile organic compounds (VOCs) into the environment.

Water consumption and wastewater management are also critical environmental factors in AGM battery production. The manufacturing process requires substantial amounts of water for cooling, cleaning, and chemical processes. Proper treatment and disposal of wastewater are essential to prevent the release of contaminants into local water systems and ecosystems.

The use of plastic components in AGM batteries, such as casings and separators, contributes to the overall plastic waste problem. While efforts are being made to increase the recyclability of these components, the production of plastics still relies heavily on fossil fuels and generates significant carbon emissions.

To address these environmental concerns, the battery industry is increasingly focusing on sustainable production practices. This includes implementing more efficient manufacturing processes, increasing the use of recycled materials, and improving waste management systems. Additionally, research into alternative materials and production methods that reduce environmental impact is ongoing, with the aim of developing more eco-friendly battery technologies.

In conclusion, while AGM batteries offer important benefits in various applications, including those related to heat dissipation, the environmental impact of their production remains a significant challenge. Balancing the need for high-performance energy storage solutions with environmental sustainability will be crucial for the future development of battery technologies.

One of the primary environmental concerns associated with AGM battery production is the extraction and processing of lead, a key component in these batteries. Lead mining and smelting operations can result in soil and water contamination, as well as air pollution through the release of toxic particulates. Furthermore, the energy-intensive nature of lead processing contributes to increased carbon emissions, exacerbating climate change concerns.

The production of sulfuric acid, another essential component in AGM batteries, also poses environmental risks. The manufacturing process can release sulfur dioxide and other harmful gases into the atmosphere, contributing to air pollution and potentially leading to acid rain formation. Proper containment and treatment of acid waste are crucial to mitigate these risks and prevent soil and water contamination.

The glass mat used in AGM batteries, while recyclable, requires energy-intensive production processes. The manufacturing of glass fibers involves high-temperature furnaces, which consume significant amounts of energy and contribute to greenhouse gas emissions. Additionally, the use of chemical binders in the glass mat production can result in the release of volatile organic compounds (VOCs) into the environment.

Water consumption and wastewater management are also critical environmental factors in AGM battery production. The manufacturing process requires substantial amounts of water for cooling, cleaning, and chemical processes. Proper treatment and disposal of wastewater are essential to prevent the release of contaminants into local water systems and ecosystems.

The use of plastic components in AGM batteries, such as casings and separators, contributes to the overall plastic waste problem. While efforts are being made to increase the recyclability of these components, the production of plastics still relies heavily on fossil fuels and generates significant carbon emissions.

To address these environmental concerns, the battery industry is increasingly focusing on sustainable production practices. This includes implementing more efficient manufacturing processes, increasing the use of recycled materials, and improving waste management systems. Additionally, research into alternative materials and production methods that reduce environmental impact is ongoing, with the aim of developing more eco-friendly battery technologies.

In conclusion, while AGM batteries offer important benefits in various applications, including those related to heat dissipation, the environmental impact of their production remains a significant challenge. Balancing the need for high-performance energy storage solutions with environmental sustainability will be crucial for the future development of battery technologies.

Safety Regulations for AGM Battery Systems

Safety regulations for AGM battery systems are crucial for ensuring the safe operation and handling of these energy storage devices. The primary focus of these regulations is to mitigate potential risks associated with heat generation, electrical hazards, and chemical exposure. Regulatory bodies such as the International Electrotechnical Commission (IEC) and the Underwriters Laboratories (UL) have established comprehensive standards for AGM battery safety.

One of the key aspects of safety regulations is thermal management. AGM batteries must comply with specific temperature limits during operation and charging. For instance, the IEC 60896-21 standard stipulates that the maximum temperature rise of AGM batteries should not exceed 30°C above ambient temperature during discharge. This requirement directly relates to the need for effective heat dissipation techniques, as excessive heat can lead to reduced battery life and potential safety hazards.

Electrical safety is another critical component of AGM battery regulations. Standards such as UL 1989 outline requirements for insulation, short-circuit protection, and proper terminal design. These regulations aim to prevent electrical accidents and ensure the safe integration of AGM batteries into various applications, including uninterruptible power supplies (UPS) and renewable energy systems.

Chemical safety is also addressed in AGM battery regulations. Although AGM batteries are considered safer than flooded lead-acid batteries due to their sealed design, they still contain hazardous materials. Regulations mandate proper labeling, handling procedures, and disposal methods to minimize environmental and health risks associated with these chemicals.

Ventilation requirements form an essential part of safety regulations for AGM battery systems. While AGM batteries produce minimal gas emissions compared to flooded lead-acid batteries, proper ventilation is still necessary to prevent the accumulation of hydrogen gas during charging. Standards specify minimum airflow rates and ventilation system designs to ensure safe operation in enclosed spaces.

Regulations also cover the structural integrity of AGM batteries. Drop tests, vibration tests, and pressure relief valve performance tests are mandated to ensure that batteries can withstand physical stresses without compromising safety. These requirements are particularly important for applications in transportation and portable equipment.

Monitoring and control systems are increasingly becoming part of safety regulations for AGM battery systems. Advanced battery management systems (BMS) are often required to monitor temperature, voltage, and current, providing real-time data and implementing safety measures such as automatic shutdown in case of abnormal conditions.

As the demand for energy storage solutions grows, safety regulations for AGM batteries continue to evolve. Recent updates have focused on addressing emerging challenges such as thermal runaway prevention and improved fire resistance. These ongoing developments in safety regulations play a crucial role in supporting the widespread adoption of AGM battery technology while ensuring the protection of users and the environment.

One of the key aspects of safety regulations is thermal management. AGM batteries must comply with specific temperature limits during operation and charging. For instance, the IEC 60896-21 standard stipulates that the maximum temperature rise of AGM batteries should not exceed 30°C above ambient temperature during discharge. This requirement directly relates to the need for effective heat dissipation techniques, as excessive heat can lead to reduced battery life and potential safety hazards.

Electrical safety is another critical component of AGM battery regulations. Standards such as UL 1989 outline requirements for insulation, short-circuit protection, and proper terminal design. These regulations aim to prevent electrical accidents and ensure the safe integration of AGM batteries into various applications, including uninterruptible power supplies (UPS) and renewable energy systems.

Chemical safety is also addressed in AGM battery regulations. Although AGM batteries are considered safer than flooded lead-acid batteries due to their sealed design, they still contain hazardous materials. Regulations mandate proper labeling, handling procedures, and disposal methods to minimize environmental and health risks associated with these chemicals.

Ventilation requirements form an essential part of safety regulations for AGM battery systems. While AGM batteries produce minimal gas emissions compared to flooded lead-acid batteries, proper ventilation is still necessary to prevent the accumulation of hydrogen gas during charging. Standards specify minimum airflow rates and ventilation system designs to ensure safe operation in enclosed spaces.

Regulations also cover the structural integrity of AGM batteries. Drop tests, vibration tests, and pressure relief valve performance tests are mandated to ensure that batteries can withstand physical stresses without compromising safety. These requirements are particularly important for applications in transportation and portable equipment.

Monitoring and control systems are increasingly becoming part of safety regulations for AGM battery systems. Advanced battery management systems (BMS) are often required to monitor temperature, voltage, and current, providing real-time data and implementing safety measures such as automatic shutdown in case of abnormal conditions.

As the demand for energy storage solutions grows, safety regulations for AGM batteries continue to evolve. Recent updates have focused on addressing emerging challenges such as thermal runaway prevention and improved fire resistance. These ongoing developments in safety regulations play a crucial role in supporting the widespread adoption of AGM battery technology while ensuring the protection of users and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!