PA11 for Automotive Applications: Design Considerations and Testing Standards

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PA11 Automotive Evolution

The evolution of PA11 (Polyamide 11) in automotive applications has been marked by significant technological advancements and a growing recognition of its unique properties. Initially developed in the 1940s, PA11 has gradually gained prominence in the automotive industry due to its exceptional combination of mechanical strength, chemical resistance, and thermal stability.

In the early stages of its automotive application, PA11 was primarily used in non-critical components such as interior trim and small under-hood parts. However, as manufacturers began to recognize its potential, the material found its way into more demanding applications. The 1980s and 1990s saw a surge in PA11 usage for fuel lines and brake system components, owing to its excellent resistance to hydrocarbons and other automotive fluids.

The turn of the millennium marked a significant shift in PA11's automotive journey. With the increasing focus on vehicle weight reduction and fuel efficiency, PA11 emerged as a viable alternative to metal in various applications. Its low density, coupled with high strength-to-weight ratio, made it an attractive option for manufacturers seeking to meet stringent emissions regulations without compromising on performance.

The past decade has witnessed a rapid expansion of PA11's role in automotive design. Advanced processing techniques and material formulations have enabled its use in more complex and critical components. Notably, PA11 has found applications in powertrain systems, where its high-temperature resistance and dimensional stability are particularly valuable. The material's compatibility with modern additive manufacturing processes has also opened up new possibilities for creating intricate, lightweight structures that were previously unfeasible with traditional manufacturing methods.

Recent years have seen a growing emphasis on sustainability in the automotive sector, further boosting PA11's appeal. As a bio-based polymer derived from castor oil, PA11 aligns well with the industry's push towards more environmentally friendly materials. This has led to increased adoption in electric and hybrid vehicles, where its low carbon footprint and recyclability contribute to the overall sustainability of the vehicle.

The evolution of PA11 in automotive applications has been characterized by continuous improvement in material properties and processing techniques. Manufacturers have invested heavily in research and development to enhance PA11's performance characteristics, such as impact resistance, long-term heat aging, and chemical compatibility. These advancements have expanded the material's potential applications, enabling its use in increasingly demanding environments within modern vehicles.

Looking ahead, the trajectory of PA11 in automotive design appears promising. As vehicle electrification accelerates and the demand for lightweight, durable, and sustainable materials grows, PA11 is well-positioned to play an even more significant role in future automotive innovations. The ongoing development of PA11 composites and blends is expected to further extend its capabilities, potentially revolutionizing automotive component design and manufacturing processes in the coming years.

In the early stages of its automotive application, PA11 was primarily used in non-critical components such as interior trim and small under-hood parts. However, as manufacturers began to recognize its potential, the material found its way into more demanding applications. The 1980s and 1990s saw a surge in PA11 usage for fuel lines and brake system components, owing to its excellent resistance to hydrocarbons and other automotive fluids.

The turn of the millennium marked a significant shift in PA11's automotive journey. With the increasing focus on vehicle weight reduction and fuel efficiency, PA11 emerged as a viable alternative to metal in various applications. Its low density, coupled with high strength-to-weight ratio, made it an attractive option for manufacturers seeking to meet stringent emissions regulations without compromising on performance.

The past decade has witnessed a rapid expansion of PA11's role in automotive design. Advanced processing techniques and material formulations have enabled its use in more complex and critical components. Notably, PA11 has found applications in powertrain systems, where its high-temperature resistance and dimensional stability are particularly valuable. The material's compatibility with modern additive manufacturing processes has also opened up new possibilities for creating intricate, lightweight structures that were previously unfeasible with traditional manufacturing methods.

Recent years have seen a growing emphasis on sustainability in the automotive sector, further boosting PA11's appeal. As a bio-based polymer derived from castor oil, PA11 aligns well with the industry's push towards more environmentally friendly materials. This has led to increased adoption in electric and hybrid vehicles, where its low carbon footprint and recyclability contribute to the overall sustainability of the vehicle.

The evolution of PA11 in automotive applications has been characterized by continuous improvement in material properties and processing techniques. Manufacturers have invested heavily in research and development to enhance PA11's performance characteristics, such as impact resistance, long-term heat aging, and chemical compatibility. These advancements have expanded the material's potential applications, enabling its use in increasingly demanding environments within modern vehicles.

Looking ahead, the trajectory of PA11 in automotive design appears promising. As vehicle electrification accelerates and the demand for lightweight, durable, and sustainable materials grows, PA11 is well-positioned to play an even more significant role in future automotive innovations. The ongoing development of PA11 composites and blends is expected to further extend its capabilities, potentially revolutionizing automotive component design and manufacturing processes in the coming years.

Market Demand Analysis

The automotive industry's demand for high-performance materials has been steadily increasing, driven by the need for lighter, more fuel-efficient vehicles and the growing electric vehicle market. PA11, a bio-based polyamide, has emerged as a promising material for various automotive applications due to its unique combination of properties. The market demand for PA11 in automotive applications is expected to grow significantly in the coming years.

One of the primary drivers for PA11 adoption in the automotive sector is the push for weight reduction. As automakers strive to meet stringent fuel efficiency and emissions standards, lightweight materials like PA11 offer an attractive solution. PA11's low density compared to traditional engineering plastics and metals makes it an ideal candidate for replacing heavier components, contributing to overall vehicle weight reduction and improved fuel economy.

The shift towards electric vehicles (EVs) has also created new opportunities for PA11 in automotive applications. EVs require materials that can withstand high temperatures and provide excellent electrical insulation properties. PA11's thermal stability and electrical resistance make it suitable for various EV components, including battery housings, connectors, and cable insulation.

Furthermore, the automotive industry's increasing focus on sustainability aligns well with PA11's bio-based nature. Derived from renewable castor oil, PA11 offers a more environmentally friendly alternative to petroleum-based plastics. This aspect appeals to both manufacturers looking to reduce their carbon footprint and environmentally conscious consumers, potentially driving increased demand for vehicles incorporating PA11 components.

The market for PA11 in automotive applications extends beyond passenger vehicles. Commercial vehicles, including trucks and buses, are also potential areas for growth. These vehicles often require materials with high durability and resistance to harsh operating conditions, characteristics that PA11 can provide.

In terms of specific automotive applications, PA11 shows promise in various areas. Fuel lines, air brake tubing, and pneumatic systems benefit from PA11's chemical resistance and flexibility. Interior components such as door handles, seat adjusters, and dashboard elements can leverage PA11's aesthetic qualities and durability. Under-the-hood applications, including air intake manifolds and cooling system components, take advantage of PA11's heat resistance and dimensional stability.

The market demand for PA11 in automotive applications is also influenced by regional factors. Stringent environmental regulations in Europe and North America are likely to drive faster adoption in these regions. Meanwhile, the rapidly growing automotive markets in Asia-Pacific countries present significant opportunities for PA11 adoption, particularly as these markets increasingly focus on electric vehicles and sustainable manufacturing practices.

One of the primary drivers for PA11 adoption in the automotive sector is the push for weight reduction. As automakers strive to meet stringent fuel efficiency and emissions standards, lightweight materials like PA11 offer an attractive solution. PA11's low density compared to traditional engineering plastics and metals makes it an ideal candidate for replacing heavier components, contributing to overall vehicle weight reduction and improved fuel economy.

The shift towards electric vehicles (EVs) has also created new opportunities for PA11 in automotive applications. EVs require materials that can withstand high temperatures and provide excellent electrical insulation properties. PA11's thermal stability and electrical resistance make it suitable for various EV components, including battery housings, connectors, and cable insulation.

Furthermore, the automotive industry's increasing focus on sustainability aligns well with PA11's bio-based nature. Derived from renewable castor oil, PA11 offers a more environmentally friendly alternative to petroleum-based plastics. This aspect appeals to both manufacturers looking to reduce their carbon footprint and environmentally conscious consumers, potentially driving increased demand for vehicles incorporating PA11 components.

The market for PA11 in automotive applications extends beyond passenger vehicles. Commercial vehicles, including trucks and buses, are also potential areas for growth. These vehicles often require materials with high durability and resistance to harsh operating conditions, characteristics that PA11 can provide.

In terms of specific automotive applications, PA11 shows promise in various areas. Fuel lines, air brake tubing, and pneumatic systems benefit from PA11's chemical resistance and flexibility. Interior components such as door handles, seat adjusters, and dashboard elements can leverage PA11's aesthetic qualities and durability. Under-the-hood applications, including air intake manifolds and cooling system components, take advantage of PA11's heat resistance and dimensional stability.

The market demand for PA11 in automotive applications is also influenced by regional factors. Stringent environmental regulations in Europe and North America are likely to drive faster adoption in these regions. Meanwhile, the rapidly growing automotive markets in Asia-Pacific countries present significant opportunities for PA11 adoption, particularly as these markets increasingly focus on electric vehicles and sustainable manufacturing practices.

Technical Challenges

The adoption of PA11 in automotive applications faces several technical challenges that need to be addressed for successful implementation. One of the primary obstacles is the material's susceptibility to moisture absorption, which can significantly affect its mechanical properties and dimensional stability. This hygroscopic nature requires careful consideration in design and manufacturing processes to ensure consistent performance in varying environmental conditions.

Another challenge lies in achieving the required impact resistance and toughness, especially at low temperatures. While PA11 generally exhibits good impact strength, automotive applications often demand exceptional performance in extreme conditions. Engineers must carefully balance the material composition and processing parameters to meet these stringent requirements without compromising other essential properties.

The long-term durability of PA11 components in automotive environments presents another technical hurdle. Exposure to heat, UV radiation, and various chemicals can potentially degrade the material over time. Developing effective stabilization systems and protective measures is crucial to ensure the longevity of PA11 parts throughout the vehicle's lifecycle.

Achieving consistent and high-quality surface finishes on PA11 components can be challenging, particularly for visible parts. The material's tendency to warp or shrink during cooling can lead to surface defects, requiring precise control of molding parameters and potentially post-processing techniques to meet automotive aesthetic standards.

Compatibility with existing manufacturing processes and equipment is another consideration. While PA11 can be processed using conventional injection molding techniques, optimizing these processes for the specific characteristics of PA11 may require significant adjustments and potentially new tooling investments.

The development of reliable joining and bonding methods for PA11 components with other materials commonly used in automotive construction poses additional technical challenges. Creating strong, durable bonds that can withstand the stresses and environmental conditions typical in automotive applications is essential for the widespread adoption of PA11.

Lastly, ensuring consistent quality and performance across large-scale production runs remains a significant challenge. Variations in raw material properties, processing conditions, and environmental factors can all impact the final product characteristics. Developing robust quality control measures and standardized testing protocols specific to PA11 automotive applications is crucial for meeting the industry's stringent reliability and safety requirements.

Another challenge lies in achieving the required impact resistance and toughness, especially at low temperatures. While PA11 generally exhibits good impact strength, automotive applications often demand exceptional performance in extreme conditions. Engineers must carefully balance the material composition and processing parameters to meet these stringent requirements without compromising other essential properties.

The long-term durability of PA11 components in automotive environments presents another technical hurdle. Exposure to heat, UV radiation, and various chemicals can potentially degrade the material over time. Developing effective stabilization systems and protective measures is crucial to ensure the longevity of PA11 parts throughout the vehicle's lifecycle.

Achieving consistent and high-quality surface finishes on PA11 components can be challenging, particularly for visible parts. The material's tendency to warp or shrink during cooling can lead to surface defects, requiring precise control of molding parameters and potentially post-processing techniques to meet automotive aesthetic standards.

Compatibility with existing manufacturing processes and equipment is another consideration. While PA11 can be processed using conventional injection molding techniques, optimizing these processes for the specific characteristics of PA11 may require significant adjustments and potentially new tooling investments.

The development of reliable joining and bonding methods for PA11 components with other materials commonly used in automotive construction poses additional technical challenges. Creating strong, durable bonds that can withstand the stresses and environmental conditions typical in automotive applications is essential for the widespread adoption of PA11.

Lastly, ensuring consistent quality and performance across large-scale production runs remains a significant challenge. Variations in raw material properties, processing conditions, and environmental factors can all impact the final product characteristics. Developing robust quality control measures and standardized testing protocols specific to PA11 automotive applications is crucial for meeting the industry's stringent reliability and safety requirements.

Current Design Solutions

01 Design considerations for PA11 components

When designing components using Polyamide 11 (PA11), several factors need to be considered. These include the material's mechanical properties, thermal stability, chemical resistance, and processing characteristics. Engineers must account for the specific application requirements, environmental conditions, and potential stress factors to optimize the design for performance and durability.- Design considerations for PA11 components: When designing components using Polyamide 11 (PA11), several factors need to be considered. These include the material's mechanical properties, thermal stability, chemical resistance, and processing characteristics. Engineers must account for the specific requirements of the application, such as stress levels, operating temperatures, and environmental conditions. Proper design considerations can help optimize the performance and longevity of PA11 components.

- Testing standards for PA11 materials: Various testing standards are employed to evaluate the properties and performance of Polyamide 11 materials. These standards may include tests for tensile strength, impact resistance, thermal properties, and chemical resistance. Standardized testing procedures ensure consistency and reliability in assessing PA11 materials across different applications and industries. Compliance with these standards is crucial for quality control and product certification.

- Simulation and modeling of PA11 behavior: Advanced simulation and modeling techniques are used to predict the behavior of Polyamide 11 under various conditions. These computational methods help in optimizing designs, reducing development time, and improving product performance. Finite element analysis and other simulation tools can be employed to assess stress distribution, thermal behavior, and long-term performance of PA11 components before physical prototyping.

- Quality control and failure analysis for PA11: Implementing robust quality control measures and conducting thorough failure analysis are essential for ensuring the reliability of PA11 components. This involves developing inspection protocols, establishing acceptance criteria, and employing advanced testing methods to identify potential defects or weaknesses. Failure analysis techniques help in understanding the root causes of any issues and inform improvements in design and manufacturing processes.

- Environmental and sustainability considerations for PA11: As a bio-based polymer, Polyamide 11 offers potential environmental benefits. Designers and engineers should consider the material's lifecycle impact, including its production, use phase, and end-of-life options. Factors such as recyclability, biodegradability, and carbon footprint should be evaluated when selecting PA11 for specific applications. Sustainable design practices can help maximize the environmental advantages of using this material.

02 Testing standards for PA11 materials

Various testing standards are employed to evaluate the properties and performance of PA11 materials. These may include tests for tensile strength, impact resistance, heat deflection temperature, and chemical resistance. Standardized testing methods ensure consistency and reliability in assessing PA11 materials for different applications.Expand Specific Solutions03 Simulation and modeling of PA11 behavior

Advanced simulation and modeling techniques are used to predict the behavior of PA11 components under various conditions. These computational methods help in optimizing designs, reducing development time, and improving overall performance. Finite element analysis and other simulation tools play a crucial role in understanding the material's response to different stresses and environmental factors.Expand Specific Solutions04 Quality control and inspection methods for PA11 products

To ensure the reliability and consistency of PA11 products, various quality control and inspection methods are implemented. These may include non-destructive testing techniques, dimensional analysis, and surface inspection. Advanced imaging and scanning technologies are often employed to detect defects and ensure compliance with specifications.Expand Specific Solutions05 Environmental and sustainability considerations for PA11

As a bio-based polymer, PA11 offers certain environmental advantages. Design considerations often include assessing the material's lifecycle impact, recyclability, and potential for biodegradation. Sustainable design practices may involve optimizing material usage, exploring recycling options, and considering end-of-life scenarios for PA11 components.Expand Specific Solutions

Key Industry Players

The automotive industry's adoption of PA11 for automotive applications is in a growth phase, with increasing market size driven by demand for lightweight, sustainable materials. The technology's maturity is advancing, as evidenced by major players like GM Global Technology Operations, Robert Bosch, and Volkswagen AG investing in research and development. Companies such as Evonik Operations and Toyota Motor Corp. are at the forefront of PA11 application, focusing on design considerations and testing standards to meet stringent automotive requirements. The competitive landscape is diverse, with both established automotive manufacturers and chemical companies vying for market share in this emerging field.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced PA11-based solutions for automotive applications, focusing on high-performance fuel line systems. Their PA11 compounds are engineered to withstand extreme temperatures and chemical exposure, meeting stringent automotive standards. Bosch's PA11 formulations incorporate proprietary additives to enhance long-term durability and resistance to hydrolysis, crucial for fuel system components[1]. They have implemented rigorous testing protocols, including accelerated aging tests simulating 15+ years of vehicle life, to ensure compliance with SAE and ISO standards for fuel permeation and mechanical properties[3].

Strengths: Extensive automotive expertise, advanced material formulation capabilities, and comprehensive testing facilities. Weaknesses: Higher cost compared to traditional materials, potential supply chain dependencies for bio-based PA11 raw materials.

Volkswagen AG

Technical Solution: Volkswagen has integrated PA11 into their vehicle designs, particularly for fuel line systems and interior components. Their approach focuses on lightweight construction and sustainability. VW's PA11 applications undergo extensive testing, including long-term exposure to biofuels and extreme temperature cycling. They have developed specific design guidelines for PA11 parts, considering factors such as creep resistance and impact strength at low temperatures[2]. VW's testing standards for PA11 components include dynamic fatigue tests simulating real-world driving conditions and accelerated weathering tests to assess long-term performance[4].

Strengths: Strong focus on sustainability, extensive vehicle integration experience, and comprehensive in-house testing capabilities. Weaknesses: Potential challenges in scaling PA11 use across diverse vehicle platforms, higher initial costs compared to traditional materials.

Critical PA11 Innovations

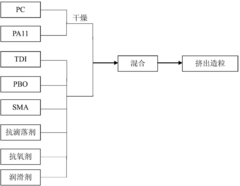

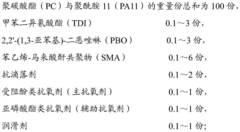

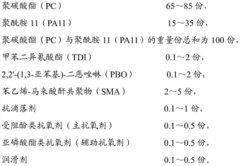

PC/PA 11 (polycarbonate/polyamide 11) composition and preparation method thereof

PatentActiveCN103937192A

Innovation

- Using an in-situ reaction compatibilization method, polycarbonate and polyamide 11 are melt-blended with monomers containing dual reactive functional groups in a parallel twin-screw extruder to generate compatibilizers, improve compatibility, and prepare PC/PA11 composition with good mechanical properties, high flame retardancy, chemical resistance and good processing performance.

Low-temperature reinforced nylon composite tube used for automobile

PatentInactiveCN101555964A

Innovation

- It adopts a structure composed of an inner lining tube, a braided layer and an outer protective layer. The inner lining tube is made of nylon composite material, the braided layer is made of high-strength polyester fiber braid, and the outer protective layer is made of PA11 elastomer material. Through specific formula design and continuous Dynamic vacuum shaping process forms nylon composite pipe that is resistant to low temperature and high pressure.

Regulatory Compliance

Regulatory compliance is a critical aspect of implementing PA11 in automotive applications. As the automotive industry increasingly adopts sustainable materials, manufacturers must navigate a complex landscape of regulations and standards to ensure their PA11-based components meet all necessary requirements.

In the European Union, the End-of-Life Vehicles (ELV) Directive plays a significant role in shaping the use of materials like PA11 in automotive applications. This directive aims to reduce the environmental impact of end-of-life vehicles by promoting recyclability and limiting the use of hazardous substances. PA11, being a bio-based and recyclable material, aligns well with the ELV Directive's objectives, potentially offering manufacturers an advantage in meeting regulatory requirements.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation is another crucial consideration for PA11 use in automotive applications. Manufacturers must ensure that PA11 and any additives used in its formulation comply with REACH requirements, including registration of substances and adherence to restrictions on certain chemicals.

In the United States, the Corporate Average Fuel Economy (CAFE) standards indirectly impact the adoption of PA11 in automotive applications. As these standards push for improved fuel efficiency, lightweight materials like PA11 become increasingly attractive to manufacturers seeking to reduce vehicle weight and improve fuel economy.

Safety regulations, such as those set by the National Highway Traffic Safety Administration (NHTSA) in the US and the European New Car Assessment Programme (Euro NCAP), also influence the use of PA11 in automotive components. Manufacturers must demonstrate that PA11-based parts meet or exceed safety performance requirements in areas such as crash resistance and fire safety.

Environmental regulations, including emissions standards and recycling requirements, further shape the regulatory landscape for PA11 in automotive applications. The material's bio-based nature and recyclability can contribute to meeting these environmental targets, but manufacturers must still ensure compliance with specific regional and national regulations.

To navigate this complex regulatory environment, automotive manufacturers and suppliers working with PA11 must implement robust compliance management systems. These systems should include regular monitoring of regulatory changes, comprehensive testing programs to ensure ongoing compliance, and documentation processes to demonstrate adherence to all applicable standards and regulations.

In the European Union, the End-of-Life Vehicles (ELV) Directive plays a significant role in shaping the use of materials like PA11 in automotive applications. This directive aims to reduce the environmental impact of end-of-life vehicles by promoting recyclability and limiting the use of hazardous substances. PA11, being a bio-based and recyclable material, aligns well with the ELV Directive's objectives, potentially offering manufacturers an advantage in meeting regulatory requirements.

The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation is another crucial consideration for PA11 use in automotive applications. Manufacturers must ensure that PA11 and any additives used in its formulation comply with REACH requirements, including registration of substances and adherence to restrictions on certain chemicals.

In the United States, the Corporate Average Fuel Economy (CAFE) standards indirectly impact the adoption of PA11 in automotive applications. As these standards push for improved fuel efficiency, lightweight materials like PA11 become increasingly attractive to manufacturers seeking to reduce vehicle weight and improve fuel economy.

Safety regulations, such as those set by the National Highway Traffic Safety Administration (NHTSA) in the US and the European New Car Assessment Programme (Euro NCAP), also influence the use of PA11 in automotive components. Manufacturers must demonstrate that PA11-based parts meet or exceed safety performance requirements in areas such as crash resistance and fire safety.

Environmental regulations, including emissions standards and recycling requirements, further shape the regulatory landscape for PA11 in automotive applications. The material's bio-based nature and recyclability can contribute to meeting these environmental targets, but manufacturers must still ensure compliance with specific regional and national regulations.

To navigate this complex regulatory environment, automotive manufacturers and suppliers working with PA11 must implement robust compliance management systems. These systems should include regular monitoring of regulatory changes, comprehensive testing programs to ensure ongoing compliance, and documentation processes to demonstrate adherence to all applicable standards and regulations.

Environmental Impact

The environmental impact of PA11 in automotive applications is a crucial consideration in the industry's shift towards more sustainable materials. PA11, derived from renewable castor oil, offers significant advantages in terms of carbon footprint reduction compared to traditional petroleum-based polymers. The production process of PA11 requires less energy and generates fewer greenhouse gas emissions, contributing to a lower overall environmental impact throughout its lifecycle.

One of the key environmental benefits of PA11 is its biodegradability. Unlike many conventional plastics, PA11 can decompose naturally over time, reducing long-term environmental pollution. This characteristic is particularly important in the automotive sector, where end-of-life vehicle management is a growing concern. The use of PA11 in automotive components can potentially simplify recycling processes and reduce the amount of non-biodegradable waste in landfills.

PA11's durability and resistance to various environmental factors also contribute to its positive environmental profile. The material's ability to withstand harsh conditions and maintain its properties over time means that components made from PA11 may have longer lifespans, reducing the need for frequent replacements and the associated environmental costs of manufacturing and disposal.

In terms of fuel efficiency, the lightweight nature of PA11 can lead to reduced vehicle weight, potentially improving fuel economy and decreasing emissions during the use phase of the vehicle. This aligns with global efforts to reduce the carbon footprint of the transportation sector and meet increasingly stringent environmental regulations.

However, it's important to note that the environmental impact of PA11 is not entirely without challenges. The cultivation of castor plants, the source of PA11's raw material, requires land and water resources. Sustainable farming practices and responsible land use are essential to ensure that the production of PA11 does not lead to deforestation or compete with food crops.

Additionally, the end-of-life management of PA11 components in vehicles requires careful consideration. While biodegradable, the material may not decompose efficiently in all disposal environments. Proper recycling and waste management systems need to be in place to fully realize the environmental benefits of PA11 in automotive applications.

Overall, the adoption of PA11 in the automotive industry represents a step towards more environmentally friendly material choices. Its renewable source, reduced carbon footprint, and potential for biodegradation offer significant environmental advantages. However, ongoing research and development are necessary to optimize its production, use, and disposal to maximize its positive environmental impact throughout its entire lifecycle in automotive applications.

One of the key environmental benefits of PA11 is its biodegradability. Unlike many conventional plastics, PA11 can decompose naturally over time, reducing long-term environmental pollution. This characteristic is particularly important in the automotive sector, where end-of-life vehicle management is a growing concern. The use of PA11 in automotive components can potentially simplify recycling processes and reduce the amount of non-biodegradable waste in landfills.

PA11's durability and resistance to various environmental factors also contribute to its positive environmental profile. The material's ability to withstand harsh conditions and maintain its properties over time means that components made from PA11 may have longer lifespans, reducing the need for frequent replacements and the associated environmental costs of manufacturing and disposal.

In terms of fuel efficiency, the lightweight nature of PA11 can lead to reduced vehicle weight, potentially improving fuel economy and decreasing emissions during the use phase of the vehicle. This aligns with global efforts to reduce the carbon footprint of the transportation sector and meet increasingly stringent environmental regulations.

However, it's important to note that the environmental impact of PA11 is not entirely without challenges. The cultivation of castor plants, the source of PA11's raw material, requires land and water resources. Sustainable farming practices and responsible land use are essential to ensure that the production of PA11 does not lead to deforestation or compete with food crops.

Additionally, the end-of-life management of PA11 components in vehicles requires careful consideration. While biodegradable, the material may not decompose efficiently in all disposal environments. Proper recycling and waste management systems need to be in place to fully realize the environmental benefits of PA11 in automotive applications.

Overall, the adoption of PA11 in the automotive industry represents a step towards more environmentally friendly material choices. Its renewable source, reduced carbon footprint, and potential for biodegradation offer significant environmental advantages. However, ongoing research and development are necessary to optimize its production, use, and disposal to maximize its positive environmental impact throughout its entire lifecycle in automotive applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!