Potential of Electrolytic Cells in Constructing Off-Grid Systems

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Cells Background and Objectives

Electrolytic cells have been a cornerstone of electrochemistry since their inception in the early 19th century. These devices, which use electricity to drive non-spontaneous chemical reactions, have evolved significantly over time, finding applications in various industries. In the context of off-grid systems, electrolytic cells present a promising avenue for energy storage and conversion, particularly in remote or isolated areas where traditional power infrastructure is unavailable or unreliable.

The development of electrolytic cells can be traced back to the work of pioneering scientists such as Michael Faraday and William Nicholson. Their groundbreaking research laid the foundation for understanding the principles of electrolysis and the potential applications of electrolytic cells. Over the years, advancements in materials science, electrochemistry, and engineering have led to more efficient and versatile electrolytic cell designs.

In recent decades, the growing emphasis on renewable energy and sustainable technologies has reignited interest in electrolytic cells, particularly for their potential in energy storage and conversion. The ability of these cells to split water into hydrogen and oxygen, a process known as water electrolysis, has positioned them as a key technology in the emerging hydrogen economy. This application is especially relevant for off-grid systems, where hydrogen can serve as a clean, storable energy carrier.

The primary objective of exploring electrolytic cells in off-grid systems is to develop sustainable, reliable, and efficient energy solutions for areas without access to conventional power grids. This goal aligns with global efforts to increase energy access while reducing carbon emissions and dependence on fossil fuels. By integrating electrolytic cells with renewable energy sources such as solar or wind power, it becomes possible to create self-sustaining energy systems that can operate independently of centralized infrastructure.

Another crucial aim is to overcome the intermittency challenges associated with renewable energy sources. Electrolytic cells can act as energy storage devices, converting excess electricity generated during peak production periods into hydrogen, which can be stored and later used to generate electricity when needed. This capability addresses one of the main limitations of renewable energy systems, enhancing their reliability and viability for off-grid applications.

Furthermore, the development of electrolytic cell technology for off-grid systems seeks to improve the overall efficiency and cost-effectiveness of these solutions. This involves optimizing cell designs, exploring new electrode materials, and enhancing the durability and longevity of components to withstand the often harsh conditions in remote locations. The ultimate goal is to create robust, low-maintenance systems that can provide consistent power over extended periods without requiring frequent interventions or replacements.

The development of electrolytic cells can be traced back to the work of pioneering scientists such as Michael Faraday and William Nicholson. Their groundbreaking research laid the foundation for understanding the principles of electrolysis and the potential applications of electrolytic cells. Over the years, advancements in materials science, electrochemistry, and engineering have led to more efficient and versatile electrolytic cell designs.

In recent decades, the growing emphasis on renewable energy and sustainable technologies has reignited interest in electrolytic cells, particularly for their potential in energy storage and conversion. The ability of these cells to split water into hydrogen and oxygen, a process known as water electrolysis, has positioned them as a key technology in the emerging hydrogen economy. This application is especially relevant for off-grid systems, where hydrogen can serve as a clean, storable energy carrier.

The primary objective of exploring electrolytic cells in off-grid systems is to develop sustainable, reliable, and efficient energy solutions for areas without access to conventional power grids. This goal aligns with global efforts to increase energy access while reducing carbon emissions and dependence on fossil fuels. By integrating electrolytic cells with renewable energy sources such as solar or wind power, it becomes possible to create self-sustaining energy systems that can operate independently of centralized infrastructure.

Another crucial aim is to overcome the intermittency challenges associated with renewable energy sources. Electrolytic cells can act as energy storage devices, converting excess electricity generated during peak production periods into hydrogen, which can be stored and later used to generate electricity when needed. This capability addresses one of the main limitations of renewable energy systems, enhancing their reliability and viability for off-grid applications.

Furthermore, the development of electrolytic cell technology for off-grid systems seeks to improve the overall efficiency and cost-effectiveness of these solutions. This involves optimizing cell designs, exploring new electrode materials, and enhancing the durability and longevity of components to withstand the often harsh conditions in remote locations. The ultimate goal is to create robust, low-maintenance systems that can provide consistent power over extended periods without requiring frequent interventions or replacements.

Off-Grid System Market Analysis

The off-grid system market has been experiencing significant growth in recent years, driven by increasing energy demand, rising environmental concerns, and the need for reliable power sources in remote areas. Electrolytic cells, particularly in the context of hydrogen production and storage, are emerging as a promising technology for enhancing the capabilities of off-grid systems.

The global off-grid solar market was valued at $1.75 billion in 2020 and is projected to reach $4.5 billion by 2030, growing at a CAGR of 10.2% from 2021 to 2030. This growth is primarily fueled by the increasing adoption of renewable energy sources and the push for rural electrification in developing countries.

Electrolytic cells, when integrated into off-grid systems, offer several advantages. They enable the production of hydrogen through water electrolysis, which can be stored and used as a clean energy carrier. This addresses one of the main challenges of renewable energy sources: intermittency. By converting excess electricity from solar or wind into hydrogen, electrolytic cells provide a means of long-term energy storage, enhancing the reliability and flexibility of off-grid systems.

The market for electrolyzers, a key component of electrolytic cells, is also expanding rapidly. The global electrolyzer market size was valued at $0.26 billion in 2021 and is expected to grow at a CAGR of 24.6% from 2022 to 2030. This growth is closely tied to the increasing demand for green hydrogen and the development of hydrogen infrastructure worldwide.

In the context of off-grid systems, the integration of electrolytic cells is particularly relevant for remote communities, islands, and industrial applications where grid connection is challenging or economically unfeasible. These systems can provide a sustainable and reliable power source, reducing dependence on diesel generators and other fossil fuel-based solutions.

The market potential for electrolytic cells in off-grid systems is further bolstered by supportive government policies and initiatives promoting clean energy adoption. Many countries are implementing regulations and incentives to encourage the development and deployment of renewable energy technologies, including hydrogen-based solutions.

However, challenges remain in terms of cost-effectiveness and technological maturity. The high capital costs associated with electrolyzers and hydrogen storage systems currently limit widespread adoption. As technology advances and economies of scale are achieved, these costs are expected to decrease, making electrolytic cell-based off-grid systems more competitive in the market.

The global off-grid solar market was valued at $1.75 billion in 2020 and is projected to reach $4.5 billion by 2030, growing at a CAGR of 10.2% from 2021 to 2030. This growth is primarily fueled by the increasing adoption of renewable energy sources and the push for rural electrification in developing countries.

Electrolytic cells, when integrated into off-grid systems, offer several advantages. They enable the production of hydrogen through water electrolysis, which can be stored and used as a clean energy carrier. This addresses one of the main challenges of renewable energy sources: intermittency. By converting excess electricity from solar or wind into hydrogen, electrolytic cells provide a means of long-term energy storage, enhancing the reliability and flexibility of off-grid systems.

The market for electrolyzers, a key component of electrolytic cells, is also expanding rapidly. The global electrolyzer market size was valued at $0.26 billion in 2021 and is expected to grow at a CAGR of 24.6% from 2022 to 2030. This growth is closely tied to the increasing demand for green hydrogen and the development of hydrogen infrastructure worldwide.

In the context of off-grid systems, the integration of electrolytic cells is particularly relevant for remote communities, islands, and industrial applications where grid connection is challenging or economically unfeasible. These systems can provide a sustainable and reliable power source, reducing dependence on diesel generators and other fossil fuel-based solutions.

The market potential for electrolytic cells in off-grid systems is further bolstered by supportive government policies and initiatives promoting clean energy adoption. Many countries are implementing regulations and incentives to encourage the development and deployment of renewable energy technologies, including hydrogen-based solutions.

However, challenges remain in terms of cost-effectiveness and technological maturity. The high capital costs associated with electrolyzers and hydrogen storage systems currently limit widespread adoption. As technology advances and economies of scale are achieved, these costs are expected to decrease, making electrolytic cell-based off-grid systems more competitive in the market.

Electrolytic Cell Technology Status

Electrolytic cell technology has made significant strides in recent years, positioning itself as a promising solution for off-grid energy systems. The current state of this technology is characterized by a blend of mature applications and emerging innovations, with ongoing research aimed at enhancing efficiency and scalability.

In the realm of water electrolysis, alkaline and proton exchange membrane (PEM) electrolyzers have reached commercial maturity. Alkaline electrolyzers, known for their robustness and cost-effectiveness, are widely used in industrial settings. PEM electrolyzers, while more expensive, offer higher efficiency and flexibility, making them suitable for renewable energy integration. Solid oxide electrolysis cells (SOECs) represent the cutting edge, operating at high temperatures and demonstrating potential for higher efficiency, though they are still in the developmental stage.

The integration of electrolytic cells with renewable energy sources has seen significant progress. Solar-powered electrolysis systems have been successfully demonstrated in various scales, from small off-grid applications to larger pilot projects. Wind-powered electrolysis is also gaining traction, particularly in regions with abundant wind resources. These integrated systems are showing promise in addressing the intermittency issues associated with renewable energy sources.

Challenges persist in the widespread adoption of electrolytic cell technology for off-grid systems. Cost remains a significant barrier, particularly for PEM and SOEC technologies. Efforts are underway to reduce the use of precious metal catalysts and develop more cost-effective materials. Durability and longevity of electrolytic cells in varied operating conditions are also areas of active research, with a focus on improving membrane and electrode materials.

Efficiency improvements are a key focus of current research. Advanced catalysts, optimized cell designs, and improved membrane materials are being developed to increase hydrogen production rates and reduce energy losses. Additionally, there is growing interest in high-pressure electrolysis systems, which can produce compressed hydrogen directly, potentially simplifying off-grid hydrogen storage and distribution.

The scalability of electrolytic cell technology is improving, with modular designs allowing for flexible system sizes. This adaptability is particularly valuable for off-grid applications, where energy demands can vary widely. However, challenges remain in optimizing system integration and control strategies for seamless operation with fluctuating renewable energy inputs.

In terms of geographical distribution, research and development in electrolytic cell technology are concentrated in North America, Europe, and parts of Asia, particularly Japan and South Korea. These regions are also leading in the deployment of pilot projects and commercial applications. Emerging economies are showing increasing interest, recognizing the potential of this technology for addressing energy access challenges in remote areas.

In the realm of water electrolysis, alkaline and proton exchange membrane (PEM) electrolyzers have reached commercial maturity. Alkaline electrolyzers, known for their robustness and cost-effectiveness, are widely used in industrial settings. PEM electrolyzers, while more expensive, offer higher efficiency and flexibility, making them suitable for renewable energy integration. Solid oxide electrolysis cells (SOECs) represent the cutting edge, operating at high temperatures and demonstrating potential for higher efficiency, though they are still in the developmental stage.

The integration of electrolytic cells with renewable energy sources has seen significant progress. Solar-powered electrolysis systems have been successfully demonstrated in various scales, from small off-grid applications to larger pilot projects. Wind-powered electrolysis is also gaining traction, particularly in regions with abundant wind resources. These integrated systems are showing promise in addressing the intermittency issues associated with renewable energy sources.

Challenges persist in the widespread adoption of electrolytic cell technology for off-grid systems. Cost remains a significant barrier, particularly for PEM and SOEC technologies. Efforts are underway to reduce the use of precious metal catalysts and develop more cost-effective materials. Durability and longevity of electrolytic cells in varied operating conditions are also areas of active research, with a focus on improving membrane and electrode materials.

Efficiency improvements are a key focus of current research. Advanced catalysts, optimized cell designs, and improved membrane materials are being developed to increase hydrogen production rates and reduce energy losses. Additionally, there is growing interest in high-pressure electrolysis systems, which can produce compressed hydrogen directly, potentially simplifying off-grid hydrogen storage and distribution.

The scalability of electrolytic cell technology is improving, with modular designs allowing for flexible system sizes. This adaptability is particularly valuable for off-grid applications, where energy demands can vary widely. However, challenges remain in optimizing system integration and control strategies for seamless operation with fluctuating renewable energy inputs.

In terms of geographical distribution, research and development in electrolytic cell technology are concentrated in North America, Europe, and parts of Asia, particularly Japan and South Korea. These regions are also leading in the deployment of pilot projects and commercial applications. Emerging economies are showing increasing interest, recognizing the potential of this technology for addressing energy access challenges in remote areas.

Current Off-Grid Electrolytic Solutions

01 Electrolytic cell design and structure

Electrolytic cells are designed with specific structures to facilitate efficient electrolysis. These designs may include features such as electrode arrangements, membrane separators, and cell compartments to optimize the electrochemical process. The structure of the cell can significantly impact its performance and the quality of the products obtained.- Design and structure of electrolytic cells: Electrolytic cells are designed with specific structures to facilitate electrochemical reactions. These designs may include specialized electrodes, membranes, and compartments to optimize the electrolysis process. The structure of the cell can significantly impact its efficiency and the purity of the products obtained.

- Electrode materials and configurations: The choice of electrode materials and their configurations play a crucial role in electrolytic cell performance. Various materials, such as metals, alloys, and coated electrodes, are used to enhance conductivity, catalytic activity, and durability. Electrode configurations may include planar, cylindrical, or mesh designs to maximize surface area and reaction efficiency.

- Electrolyte composition and management: The composition of the electrolyte solution is critical for the operation of electrolytic cells. Proper management of electrolyte concentration, pH, and temperature is essential for maintaining optimal cell performance. Some designs incorporate systems for continuous electrolyte circulation or replenishment to ensure consistent operation.

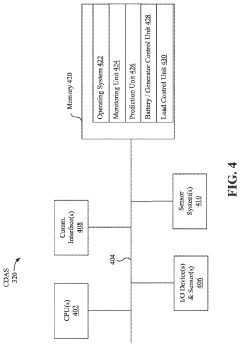

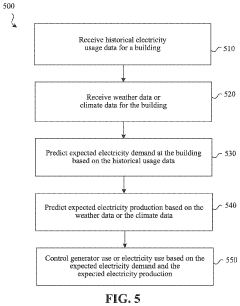

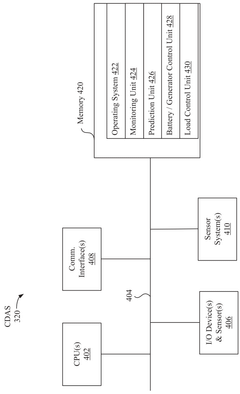

- Control and monitoring systems: Advanced electrolytic cells often incorporate sophisticated control and monitoring systems. These systems regulate parameters such as voltage, current, temperature, and pressure to maintain optimal operating conditions. Real-time monitoring and data analysis can help improve process efficiency and product quality.

- Applications and specialized designs: Electrolytic cells are used in various applications, including water treatment, metal production, and energy storage. Specialized designs cater to specific industrial needs, such as high-pressure electrolysis for hydrogen production or membrane-based cells for chlor-alkali processes. These designs often incorporate unique features to address the challenges of their respective applications.

02 Electrode materials and configurations

The choice of electrode materials and their configurations play a crucial role in electrolytic cell performance. Various materials, such as metals, alloys, and coated electrodes, are used to enhance conductivity, catalytic activity, and durability. Electrode configurations may include planar, cylindrical, or mesh designs to maximize surface area and improve reaction efficiency.Expand Specific Solutions03 Electrolyte composition and management

The composition of the electrolyte solution is critical for the operation of electrolytic cells. Proper management of electrolyte concentration, pH, and temperature is essential for maintaining optimal cell performance. Some cells may incorporate systems for electrolyte circulation, replenishment, or purification to ensure consistent operation over extended periods.Expand Specific Solutions04 Control systems and monitoring

Advanced control systems and monitoring equipment are often integrated into electrolytic cells to regulate voltage, current, temperature, and other operational parameters. These systems may include sensors, data acquisition units, and automated control mechanisms to optimize cell performance, ensure safety, and maintain product quality.Expand Specific Solutions05 Applications and specialized cell designs

Electrolytic cells are used in various applications, including water treatment, metal production, and energy storage. Specialized cell designs are developed to meet the specific requirements of different industries. These may include high-pressure cells, membrane cells, or cells optimized for particular chemical reactions or product outputs.Expand Specific Solutions

Key Players in Electrolytic Cell Industry

The electrolytic cell market for off-grid systems is in an early growth stage, with increasing interest driven by the global push for renewable energy solutions. Market size is expanding, though still relatively small compared to traditional energy sectors. Technological maturity varies among key players, with companies like Siemens Energy, Robert Bosch, and Industrie De Nora leading in innovation. Emerging players such as Hysata and Atmonia are developing novel electrolysis technologies, while established firms like Toyota and Nissan are exploring applications in the automotive sector. Research institutions like DICP and Forschungszentrum Jülich are contributing to advancements in electrolytic cell efficiency and scalability.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed advanced electrolysis technologies for off-grid systems, focusing on both Proton Exchange Membrane (PEM) and Alkaline electrolyzers. Their Silyzer series, particularly the Silyzer 300, offers modular and scalable solutions for industrial-scale hydrogen production [5]. The system can achieve efficiencies of up to 75% and can be integrated with renewable energy sources for green hydrogen production [6]. Siemens Energy is also working on high-temperature electrolysis using solid oxide electrolysis cells (SOEC), which can potentially achieve even higher efficiencies of up to 84% [7]. The company's electrolyzers are designed to handle fluctuating power inputs from renewable sources, making them suitable for off-grid applications.

Strengths: Established technology with proven track record, scalable solutions, high efficiency. Weaknesses: High initial investment costs, requires significant infrastructure for large-scale deployment.

Industrie De Nora SpA

Technical Solution: De Nora specializes in electrochemical technologies and has developed advanced electrode coatings and catalysts for water electrolysis. Their NexGen™ electrode technology significantly enhances the efficiency and durability of alkaline water electrolyzers [8]. De Nora's electrolysis systems can achieve hydrogen production rates of up to 760 Nm3/h with high purity (99.9%) [9]. The company has also developed the CECHLO-MS™ system, a modular chlor-alkali electrolysis technology that can be adapted for off-grid applications in remote areas [10]. This system can produce chlorine, caustic soda, and hydrogen simultaneously, offering versatility for various industrial applications.

Strengths: Advanced electrode technology, high efficiency and purity in hydrogen production, versatile electrolysis solutions. Weaknesses: Primary focus on industrial-scale applications, may require adaptation for smaller off-grid systems.

Innovative Electrolytic Cell Patents

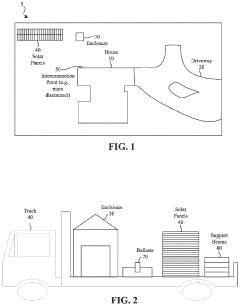

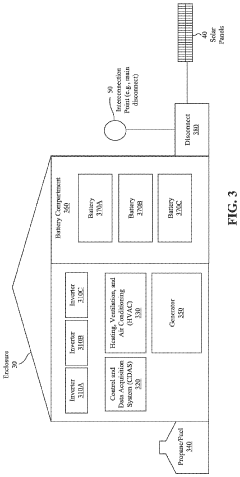

Off-grid electrical power system

PatentActiveUS20200409325A1

Innovation

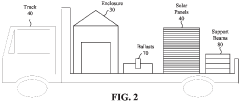

- The development of off-grid electrical power systems that include solar panel racks, battery enclosures, and inverters configured to convert DC to AC electricity, which can connect directly to a building's main electrical panel, along with a control and data acquisition system to manage energy usage and production based on historical and weather data.

Off-grid electrical power system

PatentActiveNZ756190A

Innovation

- An off-grid electrical power system that includes solar panel racks generating electricity stored in separate batteries, with inverters converting DC to AC, and a control and data acquisition system predicting energy demand and production to manage generator use, allowing for standalone operation without connecting to the utility grid, with components installed outside the building to avoid interior disruptions.

Environmental Impact Assessment

The implementation of electrolytic cells in off-grid systems presents both potential benefits and environmental challenges that require careful consideration. These systems, while offering a promising solution for energy storage and production in remote areas, also have significant environmental implications that must be thoroughly assessed.

One of the primary environmental concerns associated with electrolytic cells is the production of hydrogen gas. While hydrogen is a clean fuel source when used, its production through electrolysis can be energy-intensive. The environmental impact of this process largely depends on the source of electricity used to power the electrolytic cells. If renewable energy sources such as solar or wind power are utilized, the overall environmental footprint can be significantly reduced. However, if the electricity is derived from fossil fuels, it may negate some of the environmental benefits of the off-grid system.

Water consumption is another critical factor to consider in the environmental impact assessment of electrolytic cells. The electrolysis process requires a substantial amount of water, which could strain local water resources, particularly in arid or water-scarce regions. Implementing water recycling systems and optimizing the electrolysis process for water efficiency could help mitigate this impact.

The materials used in the construction and operation of electrolytic cells also warrant environmental scrutiny. Some electrolytic cells require rare earth elements or precious metals as catalysts, the mining and processing of which can have significant environmental consequences. Developing more sustainable material sourcing practices and exploring alternative, more abundant materials for catalysts could help address this concern.

End-of-life considerations for electrolytic cells and associated off-grid system components are crucial for a comprehensive environmental impact assessment. Proper disposal and recycling protocols must be established to prevent the release of potentially harmful materials into the environment. Additionally, the longevity and durability of these systems should be factored into their overall environmental impact, as longer-lasting components reduce the need for frequent replacements and associated resource consumption.

The potential for local ecosystem disruption during the installation and operation of off-grid systems with electrolytic cells should also be evaluated. This includes assessing the impact on wildlife habitats, vegetation, and soil quality. Implementing best practices for site selection and system design can help minimize these ecological disturbances.

Lastly, the environmental benefits of electrolytic cells in off-grid systems should be weighed against their potential drawbacks. These systems can reduce reliance on fossil fuels, decrease greenhouse gas emissions, and provide clean energy access to remote areas. However, a holistic life-cycle assessment is necessary to accurately determine their net environmental impact and ensure that the implementation of these systems aligns with broader sustainability goals.

One of the primary environmental concerns associated with electrolytic cells is the production of hydrogen gas. While hydrogen is a clean fuel source when used, its production through electrolysis can be energy-intensive. The environmental impact of this process largely depends on the source of electricity used to power the electrolytic cells. If renewable energy sources such as solar or wind power are utilized, the overall environmental footprint can be significantly reduced. However, if the electricity is derived from fossil fuels, it may negate some of the environmental benefits of the off-grid system.

Water consumption is another critical factor to consider in the environmental impact assessment of electrolytic cells. The electrolysis process requires a substantial amount of water, which could strain local water resources, particularly in arid or water-scarce regions. Implementing water recycling systems and optimizing the electrolysis process for water efficiency could help mitigate this impact.

The materials used in the construction and operation of electrolytic cells also warrant environmental scrutiny. Some electrolytic cells require rare earth elements or precious metals as catalysts, the mining and processing of which can have significant environmental consequences. Developing more sustainable material sourcing practices and exploring alternative, more abundant materials for catalysts could help address this concern.

End-of-life considerations for electrolytic cells and associated off-grid system components are crucial for a comprehensive environmental impact assessment. Proper disposal and recycling protocols must be established to prevent the release of potentially harmful materials into the environment. Additionally, the longevity and durability of these systems should be factored into their overall environmental impact, as longer-lasting components reduce the need for frequent replacements and associated resource consumption.

The potential for local ecosystem disruption during the installation and operation of off-grid systems with electrolytic cells should also be evaluated. This includes assessing the impact on wildlife habitats, vegetation, and soil quality. Implementing best practices for site selection and system design can help minimize these ecological disturbances.

Lastly, the environmental benefits of electrolytic cells in off-grid systems should be weighed against their potential drawbacks. These systems can reduce reliance on fossil fuels, decrease greenhouse gas emissions, and provide clean energy access to remote areas. However, a holistic life-cycle assessment is necessary to accurately determine their net environmental impact and ensure that the implementation of these systems aligns with broader sustainability goals.

Regulatory Framework for Off-Grid Systems

The regulatory framework for off-grid systems utilizing electrolytic cells is a complex and evolving landscape. As these systems gain traction in various applications, governments and regulatory bodies are working to establish guidelines that ensure safety, reliability, and environmental sustainability.

At the federal level, the U.S. Department of Energy (DOE) plays a crucial role in shaping policies for off-grid energy systems. The DOE's Office of Electricity oversees research and development initiatives related to grid modernization and energy storage, which directly impact the integration of electrolytic cells in off-grid applications. Additionally, the Federal Energy Regulatory Commission (FERC) has jurisdiction over interstate electricity transmission and wholesale power markets, potentially affecting larger-scale off-grid systems that may interact with the broader energy infrastructure.

State-level regulations vary significantly across the United States. Some states have implemented favorable policies to encourage the adoption of off-grid systems, including those incorporating electrolytic cells. For instance, California's Self-Generation Incentive Program (SGIP) provides financial incentives for behind-the-meter energy storage systems, which could include hydrogen-based storage utilizing electrolytic cells. Other states have introduced net metering policies that allow off-grid system owners to sell excess energy back to the grid, although the applicability to electrolytic cell-based systems may require further clarification.

Safety standards for off-grid systems are primarily governed by organizations such as the National Fire Protection Association (NFPA) and the International Electrotechnical Commission (IEC). These bodies have developed specific codes and standards for energy storage systems, including those based on hydrogen technologies. For example, NFPA 855 provides installation requirements for stationary energy storage systems, which would apply to electrolytic cell installations in off-grid configurations.

Environmental regulations also play a significant role in the deployment of off-grid systems using electrolytic cells. The Environmental Protection Agency (EPA) oversees air quality standards and emissions regulations that may impact the operation of these systems, particularly if they involve the production and storage of hydrogen. Local zoning laws and building codes further influence the installation and operation of off-grid systems, with some jurisdictions requiring special permits or environmental impact assessments for larger installations.

As the technology advances, regulatory frameworks are likely to evolve to address specific challenges and opportunities presented by electrolytic cells in off-grid systems. This may include updates to existing energy storage regulations, the development of new standards for hydrogen production and storage, and the creation of incentive programs to promote clean, decentralized energy solutions. Stakeholders in this field must stay informed about these regulatory developments to ensure compliance and maximize the potential of electrolytic cell technology in off-grid applications.

At the federal level, the U.S. Department of Energy (DOE) plays a crucial role in shaping policies for off-grid energy systems. The DOE's Office of Electricity oversees research and development initiatives related to grid modernization and energy storage, which directly impact the integration of electrolytic cells in off-grid applications. Additionally, the Federal Energy Regulatory Commission (FERC) has jurisdiction over interstate electricity transmission and wholesale power markets, potentially affecting larger-scale off-grid systems that may interact with the broader energy infrastructure.

State-level regulations vary significantly across the United States. Some states have implemented favorable policies to encourage the adoption of off-grid systems, including those incorporating electrolytic cells. For instance, California's Self-Generation Incentive Program (SGIP) provides financial incentives for behind-the-meter energy storage systems, which could include hydrogen-based storage utilizing electrolytic cells. Other states have introduced net metering policies that allow off-grid system owners to sell excess energy back to the grid, although the applicability to electrolytic cell-based systems may require further clarification.

Safety standards for off-grid systems are primarily governed by organizations such as the National Fire Protection Association (NFPA) and the International Electrotechnical Commission (IEC). These bodies have developed specific codes and standards for energy storage systems, including those based on hydrogen technologies. For example, NFPA 855 provides installation requirements for stationary energy storage systems, which would apply to electrolytic cell installations in off-grid configurations.

Environmental regulations also play a significant role in the deployment of off-grid systems using electrolytic cells. The Environmental Protection Agency (EPA) oversees air quality standards and emissions regulations that may impact the operation of these systems, particularly if they involve the production and storage of hydrogen. Local zoning laws and building codes further influence the installation and operation of off-grid systems, with some jurisdictions requiring special permits or environmental impact assessments for larger installations.

As the technology advances, regulatory frameworks are likely to evolve to address specific challenges and opportunities presented by electrolytic cells in off-grid systems. This may include updates to existing energy storage regulations, the development of new standards for hydrogen production and storage, and the creation of incentive programs to promote clean, decentralized energy solutions. Stakeholders in this field must stay informed about these regulatory developments to ensure compliance and maximize the potential of electrolytic cell technology in off-grid applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!