Predictive Maintenance in Vacuum Forming Operations

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming PM Background and Objectives

Predictive maintenance in vacuum forming operations has emerged as a critical technological advancement in the manufacturing industry. This approach leverages data analytics, machine learning, and sensor technologies to anticipate and prevent equipment failures, optimize maintenance schedules, and enhance overall operational efficiency. The evolution of this technology can be traced back to the early 2000s when basic condition monitoring systems were first introduced in vacuum forming processes.

As the industry progressed, the integration of Internet of Things (IoT) devices and advanced analytics capabilities in the 2010s marked a significant milestone in predictive maintenance for vacuum forming. This shift allowed for real-time data collection and analysis, enabling more accurate predictions of equipment failures and performance degradation. The technology has since continued to evolve, incorporating artificial intelligence and machine learning algorithms to improve prediction accuracy and expand the scope of monitored parameters.

The primary objective of predictive maintenance in vacuum forming operations is to minimize unplanned downtime, reduce maintenance costs, and extend equipment lifespan. By continuously monitoring key performance indicators such as temperature, pressure, and vibration, the system can detect subtle changes that may indicate impending failures. This proactive approach allows manufacturers to schedule maintenance activities at optimal times, avoiding costly production interruptions and reducing the risk of catastrophic equipment failures.

Another crucial goal is to optimize the overall equipment effectiveness (OEE) in vacuum forming processes. Predictive maintenance contributes to this by ensuring that machines operate at peak efficiency, reducing scrap rates, and improving product quality. By analyzing historical data and identifying patterns, the system can also provide insights into process optimization, leading to enhanced productivity and resource utilization.

The technology aims to transition from reactive and preventive maintenance strategies to a more sophisticated, data-driven approach. This shift not only improves operational efficiency but also supports sustainability efforts by reducing energy consumption and minimizing waste associated with unnecessary maintenance activities or premature component replacements.

As the vacuum forming industry continues to embrace Industry 4.0 principles, predictive maintenance is expected to play an increasingly vital role in driving operational excellence. Future developments in this field are likely to focus on enhancing prediction accuracy, expanding the range of monitored parameters, and integrating predictive maintenance systems with other smart manufacturing technologies to create fully autonomous and self-optimizing production environments.

As the industry progressed, the integration of Internet of Things (IoT) devices and advanced analytics capabilities in the 2010s marked a significant milestone in predictive maintenance for vacuum forming. This shift allowed for real-time data collection and analysis, enabling more accurate predictions of equipment failures and performance degradation. The technology has since continued to evolve, incorporating artificial intelligence and machine learning algorithms to improve prediction accuracy and expand the scope of monitored parameters.

The primary objective of predictive maintenance in vacuum forming operations is to minimize unplanned downtime, reduce maintenance costs, and extend equipment lifespan. By continuously monitoring key performance indicators such as temperature, pressure, and vibration, the system can detect subtle changes that may indicate impending failures. This proactive approach allows manufacturers to schedule maintenance activities at optimal times, avoiding costly production interruptions and reducing the risk of catastrophic equipment failures.

Another crucial goal is to optimize the overall equipment effectiveness (OEE) in vacuum forming processes. Predictive maintenance contributes to this by ensuring that machines operate at peak efficiency, reducing scrap rates, and improving product quality. By analyzing historical data and identifying patterns, the system can also provide insights into process optimization, leading to enhanced productivity and resource utilization.

The technology aims to transition from reactive and preventive maintenance strategies to a more sophisticated, data-driven approach. This shift not only improves operational efficiency but also supports sustainability efforts by reducing energy consumption and minimizing waste associated with unnecessary maintenance activities or premature component replacements.

As the vacuum forming industry continues to embrace Industry 4.0 principles, predictive maintenance is expected to play an increasingly vital role in driving operational excellence. Future developments in this field are likely to focus on enhancing prediction accuracy, expanding the range of monitored parameters, and integrating predictive maintenance systems with other smart manufacturing technologies to create fully autonomous and self-optimizing production environments.

Market Demand for PM in Vacuum Forming

The market demand for Predictive Maintenance (PM) in vacuum forming operations has been steadily increasing in recent years, driven by the growing need for operational efficiency and cost reduction in manufacturing industries. Vacuum forming, a widely used process in the production of plastic products, faces challenges such as equipment downtime, quality issues, and maintenance costs. These factors have created a significant opportunity for PM solutions to address these pain points and optimize production processes.

The global vacuum forming market is projected to expand at a compound annual growth rate (CAGR) of 6.2% from 2021 to 2028, reaching a value of $1.5 billion by the end of the forecast period. This growth is primarily attributed to the increasing demand for lightweight and cost-effective packaging solutions across various industries, including food and beverage, automotive, and healthcare. As the market expands, the need for efficient maintenance strategies becomes more critical, driving the demand for PM solutions.

In the vacuum forming industry, unplanned downtime can result in substantial financial losses and production delays. Studies have shown that implementing PM solutions can reduce downtime by up to 50% and extend equipment lifespan by 20-40%. These potential benefits have sparked interest among manufacturers seeking to improve their operational efficiency and reduce maintenance costs.

The adoption of Industry 4.0 technologies has further fueled the demand for PM in vacuum forming operations. The integration of Internet of Things (IoT) sensors, machine learning algorithms, and data analytics platforms enables real-time monitoring of equipment performance and early detection of potential failures. This proactive approach to maintenance aligns with the industry's shift towards smart manufacturing and digital transformation.

Market research indicates that small and medium-sized enterprises (SMEs) in the vacuum forming sector are increasingly recognizing the value of PM solutions. While large manufacturers have been early adopters, SMEs are now seeking cost-effective PM implementations to remain competitive in the market. This trend is expected to drive the growth of cloud-based PM solutions and software-as-a-service (SaaS) models, making advanced maintenance technologies more accessible to a broader range of businesses.

The COVID-19 pandemic has further accelerated the adoption of PM in vacuum forming operations. As manufacturers face pressure to optimize costs and maintain production continuity amid supply chain disruptions, the importance of efficient maintenance strategies has become more evident. This has led to an increased focus on remote monitoring capabilities and predictive analytics to ensure equipment reliability and minimize on-site interventions.

In conclusion, the market demand for PM in vacuum forming operations is robust and growing, driven by the need for operational efficiency, cost reduction, and technological advancements in the manufacturing sector. As the industry continues to evolve, PM solutions are expected to play a crucial role in shaping the future of vacuum forming processes and contributing to overall productivity improvements.

The global vacuum forming market is projected to expand at a compound annual growth rate (CAGR) of 6.2% from 2021 to 2028, reaching a value of $1.5 billion by the end of the forecast period. This growth is primarily attributed to the increasing demand for lightweight and cost-effective packaging solutions across various industries, including food and beverage, automotive, and healthcare. As the market expands, the need for efficient maintenance strategies becomes more critical, driving the demand for PM solutions.

In the vacuum forming industry, unplanned downtime can result in substantial financial losses and production delays. Studies have shown that implementing PM solutions can reduce downtime by up to 50% and extend equipment lifespan by 20-40%. These potential benefits have sparked interest among manufacturers seeking to improve their operational efficiency and reduce maintenance costs.

The adoption of Industry 4.0 technologies has further fueled the demand for PM in vacuum forming operations. The integration of Internet of Things (IoT) sensors, machine learning algorithms, and data analytics platforms enables real-time monitoring of equipment performance and early detection of potential failures. This proactive approach to maintenance aligns with the industry's shift towards smart manufacturing and digital transformation.

Market research indicates that small and medium-sized enterprises (SMEs) in the vacuum forming sector are increasingly recognizing the value of PM solutions. While large manufacturers have been early adopters, SMEs are now seeking cost-effective PM implementations to remain competitive in the market. This trend is expected to drive the growth of cloud-based PM solutions and software-as-a-service (SaaS) models, making advanced maintenance technologies more accessible to a broader range of businesses.

The COVID-19 pandemic has further accelerated the adoption of PM in vacuum forming operations. As manufacturers face pressure to optimize costs and maintain production continuity amid supply chain disruptions, the importance of efficient maintenance strategies has become more evident. This has led to an increased focus on remote monitoring capabilities and predictive analytics to ensure equipment reliability and minimize on-site interventions.

In conclusion, the market demand for PM in vacuum forming operations is robust and growing, driven by the need for operational efficiency, cost reduction, and technological advancements in the manufacturing sector. As the industry continues to evolve, PM solutions are expected to play a crucial role in shaping the future of vacuum forming processes and contributing to overall productivity improvements.

Current PM Challenges in Vacuum Forming

Vacuum forming operations in manufacturing face several challenges when implementing predictive maintenance (PM) strategies. One of the primary issues is the complexity of the vacuum forming process itself, which involves multiple variables such as temperature, pressure, and material properties. These variables can interact in unpredictable ways, making it difficult to establish reliable predictive models.

The lack of comprehensive sensor data is another significant challenge. Many vacuum forming machines, especially older models, are not equipped with the necessary sensors to capture real-time data on critical parameters. This data deficiency hampers the ability to develop accurate predictive algorithms and limits the effectiveness of PM initiatives.

Maintenance teams often struggle with interpreting the available data due to the absence of standardized benchmarks for vacuum forming equipment performance. Without clear reference points, it becomes challenging to distinguish between normal operational variations and early signs of potential failures.

The diverse range of materials used in vacuum forming further complicates PM efforts. Different materials behave uniquely under varying conditions, requiring adaptive maintenance strategies. This variability makes it difficult to create a one-size-fits-all predictive model for vacuum forming operations.

Environmental factors, such as humidity and ambient temperature, can significantly impact the vacuum forming process and equipment performance. These external variables are often not adequately accounted for in current PM models, leading to reduced accuracy in failure predictions.

The high-speed nature of modern vacuum forming operations poses another challenge. The rapid cycling of machines leaves little room for error in PM predictions, as even minor disruptions can result in significant production losses. This time pressure demands highly accurate and timely predictive models.

Integration of PM systems with existing production management software is often problematic. Many facilities use legacy systems that are not easily compatible with modern predictive maintenance solutions, creating data silos and hindering the holistic approach needed for effective PM.

Lastly, there is a skills gap in many manufacturing facilities. Implementing and maintaining advanced PM systems for vacuum forming requires a combination of process knowledge, data analysis skills, and machine learning expertise. This skill set is not always readily available in traditional manufacturing environments, posing a significant challenge to the successful implementation of predictive maintenance strategies in vacuum forming operations.

The lack of comprehensive sensor data is another significant challenge. Many vacuum forming machines, especially older models, are not equipped with the necessary sensors to capture real-time data on critical parameters. This data deficiency hampers the ability to develop accurate predictive algorithms and limits the effectiveness of PM initiatives.

Maintenance teams often struggle with interpreting the available data due to the absence of standardized benchmarks for vacuum forming equipment performance. Without clear reference points, it becomes challenging to distinguish between normal operational variations and early signs of potential failures.

The diverse range of materials used in vacuum forming further complicates PM efforts. Different materials behave uniquely under varying conditions, requiring adaptive maintenance strategies. This variability makes it difficult to create a one-size-fits-all predictive model for vacuum forming operations.

Environmental factors, such as humidity and ambient temperature, can significantly impact the vacuum forming process and equipment performance. These external variables are often not adequately accounted for in current PM models, leading to reduced accuracy in failure predictions.

The high-speed nature of modern vacuum forming operations poses another challenge. The rapid cycling of machines leaves little room for error in PM predictions, as even minor disruptions can result in significant production losses. This time pressure demands highly accurate and timely predictive models.

Integration of PM systems with existing production management software is often problematic. Many facilities use legacy systems that are not easily compatible with modern predictive maintenance solutions, creating data silos and hindering the holistic approach needed for effective PM.

Lastly, there is a skills gap in many manufacturing facilities. Implementing and maintaining advanced PM systems for vacuum forming requires a combination of process knowledge, data analysis skills, and machine learning expertise. This skill set is not always readily available in traditional manufacturing environments, posing a significant challenge to the successful implementation of predictive maintenance strategies in vacuum forming operations.

Existing PM Approaches for Vacuum Forming

01 Data-driven predictive maintenance systems

Advanced systems that utilize data analytics, machine learning, and IoT sensors to predict equipment failures and optimize maintenance schedules. These systems analyze real-time and historical data to identify patterns and anomalies, enabling proactive maintenance interventions and reducing downtime.- Data-driven predictive maintenance systems: Advanced systems that utilize data analytics, machine learning, and IoT sensors to predict equipment failures and optimize maintenance schedules. These systems analyze real-time and historical data to identify patterns and anomalies, enabling proactive maintenance interventions and reducing downtime.

- Condition monitoring for industrial equipment: Techniques for continuous monitoring of industrial equipment using various sensors and diagnostic tools. This approach helps in assessing the current state of machinery, detecting early signs of wear or malfunction, and scheduling maintenance activities based on actual equipment condition rather than fixed intervals.

- AI-powered maintenance decision support: Integration of artificial intelligence and expert systems to assist in maintenance decision-making processes. These systems can analyze complex data sets, recommend optimal maintenance strategies, and even automate certain maintenance tasks, improving efficiency and reducing human error.

- Remote monitoring and maintenance solutions: Development of remote monitoring and maintenance capabilities, allowing experts to diagnose and sometimes resolve issues from a distance. This approach leverages cloud computing, secure connectivity, and advanced visualization tools to enable efficient maintenance operations across geographically dispersed assets.

- Predictive maintenance for specific industries: Tailored predictive maintenance solutions for specific industries such as aerospace, automotive, and energy sectors. These specialized systems take into account unique industry requirements, regulatory standards, and critical failure modes to provide highly accurate and relevant maintenance predictions.

02 Condition monitoring for industrial equipment

Techniques for continuous monitoring of industrial equipment using various sensors and diagnostic tools. This approach helps in assessing the current state of machinery, detecting early signs of wear or malfunction, and scheduling maintenance activities based on actual equipment condition rather than fixed intervals.Expand Specific Solutions03 AI-powered maintenance decision support

Integration of artificial intelligence and expert systems to assist in maintenance decision-making processes. These systems can analyze complex data sets, recommend optimal maintenance strategies, and even automate certain maintenance tasks, improving overall efficiency and reducing human error.Expand Specific Solutions04 Remote monitoring and maintenance solutions

Development of remote monitoring and maintenance capabilities, allowing experts to diagnose and sometimes resolve issues from a distance. This approach leverages cloud computing, secure connectivity, and advanced sensors to enable real-time monitoring and rapid response to potential equipment issues across multiple locations.Expand Specific Solutions05 Predictive maintenance for specific industries

Tailored predictive maintenance solutions for specific industries such as aerospace, automotive, and energy sectors. These specialized systems take into account unique industry requirements, regulatory standards, and critical equipment characteristics to provide highly accurate and relevant maintenance predictions and recommendations.Expand Specific Solutions

Key Players in Vacuum Forming PM Solutions

The predictive maintenance market in vacuum forming operations is in a growth phase, driven by increasing adoption of Industry 4.0 technologies. The global market size for predictive maintenance is expected to reach $23.5 billion by 2024, with a CAGR of 39%. The technology maturity varies across different players, with established companies like IBM, Hitachi, and Siemens leading in advanced analytics and AI-driven solutions. Emerging players such as Husky Injection Molding Systems and Edwards Ltd. are focusing on industry-specific applications, while research institutions like Tsinghua University and National Cheng Kung University are contributing to technological advancements. The competitive landscape is characterized by a mix of large industrial conglomerates, specialized equipment manufacturers, and innovative startups, all vying to capture market share in this rapidly evolving field.

Husky Injection Molding Systems Ltd.

Technical Solution: Husky, while primarily known for injection molding, has expanded its predictive maintenance capabilities to include vacuum forming operations. Their solution leverages their expertise in plastics processing to provide a tailored approach to predictive maintenance. The system employs a combination of embedded sensors and external monitoring devices to collect data on critical parameters such as mold temperature, vacuum pressure, and material flow[13]. This data is analyzed using Husky's proprietary algorithms, which are specifically designed to understand the nuances of plastic forming processes. The solution also incorporates machine learning models that can adapt to different materials and product designs, improving predictive accuracy over time. Husky's system integrates with their Shotscope NX process and production monitoring software, providing a comprehensive view of equipment health and production efficiency[14]. Additionally, the platform offers remote monitoring capabilities, allowing Husky's experts to provide real-time support and recommendations to maintenance teams.

Strengths: Specialized knowledge in plastics processing; Adaptive algorithms for different materials and products; Integration with comprehensive production monitoring software. Weaknesses: May have less experience with vacuum forming compared to injection molding; Potential limitations in integrating with non-Husky equipment.

International Business Machines Corp.

Technical Solution: IBM's predictive maintenance solution for vacuum forming operations leverages their Watson IoT platform and advanced analytics capabilities. The system employs a network of sensors to collect real-time data on equipment performance, environmental conditions, and production metrics[5]. This data is then processed using IBM's cognitive computing algorithms, which can identify patterns and anomalies that may indicate impending equipment failures[6]. The solution also incorporates machine learning models that continuously improve their predictive accuracy over time. IBM's system integrates with existing enterprise asset management software, allowing for seamless scheduling of maintenance activities and spare parts procurement[7]. Furthermore, the platform includes a user-friendly dashboard that provides maintenance teams with actionable insights and prioritized recommendations for preventive actions.

Strengths: Powerful cognitive computing and machine learning capabilities; Seamless integration with existing enterprise systems; Continuous improvement of predictive models. Weaknesses: May require significant customization for specific vacuum forming processes; Potential dependency on IBM's ecosystem for optimal functionality.

Core Innovations in Vacuum Forming PM

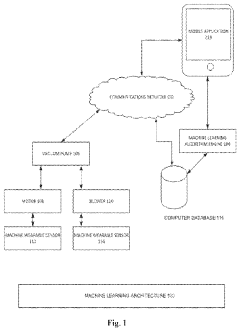

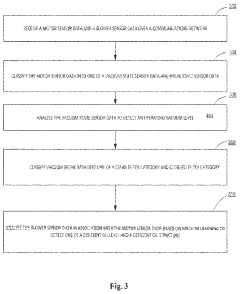

Real time machine learning based predictive and preventive maintenance of vacuum pump

PatentInactiveUS11002269B2

Innovation

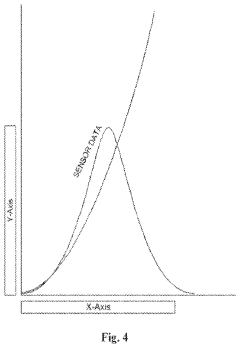

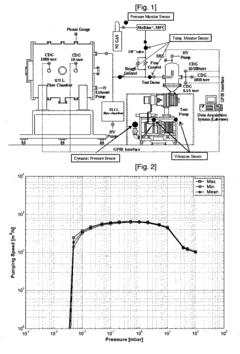

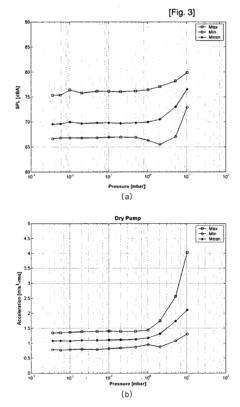

- A machine learning architecture that utilizes machine wearable sensors like vibration, temperature, and magnetic field sensors to classify sensor data, detect anomalies, and raise alarms for vacuum state and filter issues, and analyze blower sensor data to detect oil levels, integrated with an IoT system for automated control commands.

A precision diagnostic method for the failure protection and predictive maintenance of a vacuum pump and a precision diagnostic system therefor

PatentInactiveEP1836576B1

Innovation

- A precision diagnostic method and system that uses a linear parametric model-based active algorithm to estimate pump operation characteristic values and evaluate performance indicators in-situ, employing a dedicated signal conditioning unit, high-speed data acquisition system, and dual-processed PC system to collect and analyze mechanical vibration, sound pressure, and electrical signals, enabling real-time monitoring and predictive maintenance.

Cost-Benefit Analysis of PM Implementation

Implementing predictive maintenance (PM) in vacuum forming operations requires a thorough cost-benefit analysis to justify the investment and demonstrate its long-term value. The initial costs of PM implementation can be substantial, including hardware investments for sensors and monitoring equipment, software development or acquisition, and staff training. These upfront expenses may range from $50,000 to $500,000, depending on the scale of operations and the sophistication of the PM system.

However, the benefits of PM often outweigh these initial costs over time. One of the primary advantages is the reduction in unplanned downtime. Vacuum forming machines that undergo PM can see a 30-50% decrease in unexpected failures, translating to significant savings in production losses and emergency repair costs. For a medium-sized vacuum forming operation, this could result in annual savings of $100,000 to $300,000.

Energy efficiency improvements are another key benefit of PM. By maintaining equipment at optimal performance levels, energy consumption can be reduced by 10-15%. In energy-intensive processes like vacuum forming, this can lead to substantial cost savings, potentially $20,000 to $50,000 annually for a typical facility.

PM also extends the lifespan of vacuum forming equipment. Regular maintenance and early detection of potential issues can increase machine longevity by 20-30%, delaying the need for costly replacements. This benefit alone can save hundreds of thousands of dollars over the equipment's lifetime.

Quality improvements resulting from PM can lead to reduced scrap rates and fewer customer returns. A conservative estimate suggests a 5-10% reduction in quality-related costs, which could save $30,000 to $100,000 annually for a medium-sized operation.

Labor costs associated with maintenance activities can be optimized through PM. By shifting from reactive to predictive maintenance, labor efficiency can improve by 20-30%, allowing for better allocation of maintenance personnel and reducing overtime costs.

When considering the return on investment (ROI), most companies implementing PM in vacuum forming operations report a payback period of 12-24 months. After this initial period, the ongoing benefits typically result in a positive ROI of 10-30% annually.

It's important to note that the full benefits of PM may not be immediately apparent and often accrue over time. A phased implementation approach can help manage costs and allow for iterative improvements based on early results.

However, the benefits of PM often outweigh these initial costs over time. One of the primary advantages is the reduction in unplanned downtime. Vacuum forming machines that undergo PM can see a 30-50% decrease in unexpected failures, translating to significant savings in production losses and emergency repair costs. For a medium-sized vacuum forming operation, this could result in annual savings of $100,000 to $300,000.

Energy efficiency improvements are another key benefit of PM. By maintaining equipment at optimal performance levels, energy consumption can be reduced by 10-15%. In energy-intensive processes like vacuum forming, this can lead to substantial cost savings, potentially $20,000 to $50,000 annually for a typical facility.

PM also extends the lifespan of vacuum forming equipment. Regular maintenance and early detection of potential issues can increase machine longevity by 20-30%, delaying the need for costly replacements. This benefit alone can save hundreds of thousands of dollars over the equipment's lifetime.

Quality improvements resulting from PM can lead to reduced scrap rates and fewer customer returns. A conservative estimate suggests a 5-10% reduction in quality-related costs, which could save $30,000 to $100,000 annually for a medium-sized operation.

Labor costs associated with maintenance activities can be optimized through PM. By shifting from reactive to predictive maintenance, labor efficiency can improve by 20-30%, allowing for better allocation of maintenance personnel and reducing overtime costs.

When considering the return on investment (ROI), most companies implementing PM in vacuum forming operations report a payback period of 12-24 months. After this initial period, the ongoing benefits typically result in a positive ROI of 10-30% annually.

It's important to note that the full benefits of PM may not be immediately apparent and often accrue over time. A phased implementation approach can help manage costs and allow for iterative improvements based on early results.

Integration with Industry 4.0 Technologies

The integration of predictive maintenance in vacuum forming operations with Industry 4.0 technologies represents a significant leap forward in manufacturing efficiency and reliability. This convergence leverages advanced data analytics, Internet of Things (IoT) connectivity, and artificial intelligence to create a more responsive and intelligent production environment.

At the core of this integration is the implementation of smart sensors throughout the vacuum forming process. These sensors continuously monitor critical parameters such as temperature, pressure, material thickness, and machine vibrations. The data collected is transmitted in real-time to centralized cloud platforms or edge computing systems, enabling immediate analysis and response.

Machine learning algorithms play a crucial role in processing this vast amount of data. They can identify patterns and anomalies that might indicate potential equipment failures or quality issues. Over time, these algorithms become increasingly accurate in predicting maintenance needs, allowing for more precise scheduling of downtime and reduction of unexpected breakdowns.

Digital twin technology is another key component of this integration. By creating virtual replicas of vacuum forming machines and processes, manufacturers can simulate various scenarios and optimize operations without disrupting actual production. This capability is particularly valuable for testing new maintenance strategies or assessing the impact of equipment modifications.

The implementation of augmented reality (AR) in maintenance procedures enhances technician efficiency. AR devices can overlay diagnostic information and repair instructions directly onto the technician's field of view, reducing errors and accelerating maintenance tasks. This technology also facilitates remote expert assistance, allowing specialists to guide on-site personnel through complex procedures.

Blockchain technology is being explored to enhance the traceability and security of maintenance records. This ensures the integrity of maintenance history and can be particularly useful in industries with strict regulatory requirements or when dealing with multiple suppliers and service providers.

The integration of predictive maintenance with Industry 4.0 technologies also extends to supply chain management. By connecting maintenance systems with inventory management and supplier networks, companies can automate the ordering of spare parts and consumables, ensuring they are available precisely when needed.

As these technologies mature, we can expect to see more sophisticated AI-driven decision-making systems that not only predict maintenance needs but also autonomously adjust production parameters to extend equipment life and optimize output quality. This level of automation and intelligence promises to revolutionize vacuum forming operations, leading to unprecedented levels of efficiency, quality, and cost-effectiveness.

At the core of this integration is the implementation of smart sensors throughout the vacuum forming process. These sensors continuously monitor critical parameters such as temperature, pressure, material thickness, and machine vibrations. The data collected is transmitted in real-time to centralized cloud platforms or edge computing systems, enabling immediate analysis and response.

Machine learning algorithms play a crucial role in processing this vast amount of data. They can identify patterns and anomalies that might indicate potential equipment failures or quality issues. Over time, these algorithms become increasingly accurate in predicting maintenance needs, allowing for more precise scheduling of downtime and reduction of unexpected breakdowns.

Digital twin technology is another key component of this integration. By creating virtual replicas of vacuum forming machines and processes, manufacturers can simulate various scenarios and optimize operations without disrupting actual production. This capability is particularly valuable for testing new maintenance strategies or assessing the impact of equipment modifications.

The implementation of augmented reality (AR) in maintenance procedures enhances technician efficiency. AR devices can overlay diagnostic information and repair instructions directly onto the technician's field of view, reducing errors and accelerating maintenance tasks. This technology also facilitates remote expert assistance, allowing specialists to guide on-site personnel through complex procedures.

Blockchain technology is being explored to enhance the traceability and security of maintenance records. This ensures the integrity of maintenance history and can be particularly useful in industries with strict regulatory requirements or when dealing with multiple suppliers and service providers.

The integration of predictive maintenance with Industry 4.0 technologies also extends to supply chain management. By connecting maintenance systems with inventory management and supplier networks, companies can automate the ordering of spare parts and consumables, ensuring they are available precisely when needed.

As these technologies mature, we can expect to see more sophisticated AI-driven decision-making systems that not only predict maintenance needs but also autonomously adjust production parameters to extend equipment life and optimize output quality. This level of automation and intelligence promises to revolutionize vacuum forming operations, leading to unprecedented levels of efficiency, quality, and cost-effectiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!