Reduce Operational Costs in Direct Lithium Extraction Facilities

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Cost Reduction Objectives

Direct Lithium Extraction (DLE) technology has emerged as a revolutionary approach to lithium production, offering significant advantages over traditional methods such as evaporation ponds and hard rock mining. The technology originated in the 1990s but has gained substantial momentum in the past decade due to the exponential growth in lithium demand driven by electric vehicle batteries and energy storage systems. DLE technologies extract lithium directly from brine resources using selective adsorption, ion exchange, solvent extraction, or membrane processes, dramatically reducing the production timeline from years to days.

Despite its promising potential, DLE facilities currently face substantial operational cost challenges that limit widespread commercial adoption. The primary cost drivers include high energy consumption for pumping and processing brines, expensive ion-exchange materials and membranes with limited lifespans, chemical reagent costs for regeneration cycles, and water management expenses. These factors collectively contribute to operational costs ranging from $3,000 to $7,000 per ton of lithium carbonate equivalent (LCE), significantly higher than the $2,000 to $3,500 per ton for traditional evaporation methods.

The evolution of DLE technology has progressed through several generations, from early proof-of-concept designs to today's more efficient systems. Initial iterations focused primarily on technical feasibility rather than economic viability, while recent developments have increasingly targeted cost optimization. This technological progression reflects the industry's recognition that cost reduction is essential for DLE to achieve mainstream commercial success in lithium production.

The primary cost reduction objectives for DLE facilities include decreasing energy intensity by at least 30% through more efficient pumping systems and heat recovery mechanisms, extending adsorbent and membrane lifespans from current 6-12 months to 3+ years, reducing chemical consumption by 40% through improved regeneration processes, and minimizing freshwater usage by 50% through closed-loop systems. Additionally, there are goals to increase lithium recovery rates from the current 70-90% to consistently above 95%.

These objectives align with broader industry trends toward more sustainable and economically viable lithium production methods. As global lithium demand is projected to increase fourfold by 2030, developing cost-effective DLE technologies has become a strategic priority for both established mining companies and technology startups. Success in reducing operational costs could potentially position DLE as the dominant lithium production method within the next decade, fundamentally transforming the global lithium supply chain.

Despite its promising potential, DLE facilities currently face substantial operational cost challenges that limit widespread commercial adoption. The primary cost drivers include high energy consumption for pumping and processing brines, expensive ion-exchange materials and membranes with limited lifespans, chemical reagent costs for regeneration cycles, and water management expenses. These factors collectively contribute to operational costs ranging from $3,000 to $7,000 per ton of lithium carbonate equivalent (LCE), significantly higher than the $2,000 to $3,500 per ton for traditional evaporation methods.

The evolution of DLE technology has progressed through several generations, from early proof-of-concept designs to today's more efficient systems. Initial iterations focused primarily on technical feasibility rather than economic viability, while recent developments have increasingly targeted cost optimization. This technological progression reflects the industry's recognition that cost reduction is essential for DLE to achieve mainstream commercial success in lithium production.

The primary cost reduction objectives for DLE facilities include decreasing energy intensity by at least 30% through more efficient pumping systems and heat recovery mechanisms, extending adsorbent and membrane lifespans from current 6-12 months to 3+ years, reducing chemical consumption by 40% through improved regeneration processes, and minimizing freshwater usage by 50% through closed-loop systems. Additionally, there are goals to increase lithium recovery rates from the current 70-90% to consistently above 95%.

These objectives align with broader industry trends toward more sustainable and economically viable lithium production methods. As global lithium demand is projected to increase fourfold by 2030, developing cost-effective DLE technologies has become a strategic priority for both established mining companies and technology startups. Success in reducing operational costs could potentially position DLE as the dominant lithium production method within the next decade, fundamentally transforming the global lithium supply chain.

Market Analysis for Cost-Effective Lithium Extraction

The global lithium market has experienced unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the lithium industry at approximately $7.5 billion, with projections indicating potential growth to $18.2 billion by 2030, representing a compound annual growth rate (CAGR) of 9.7%. This remarkable trajectory underscores the critical importance of developing cost-effective lithium extraction methodologies.

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives to traditional evaporation pond methods, offering significant advantages in terms of extraction efficiency and environmental impact. However, operational costs remain a substantial barrier to widespread commercial adoption. Current DLE facilities face operational expenditures ranging from $5,200 to $7,800 per ton of lithium carbonate equivalent (LCE), significantly higher than the $2,500 to $3,500 per ton for conventional brine operations in South America.

Market analysis reveals that energy consumption constitutes 30-40% of total operational costs in DLE facilities, with water treatment and chemical reagent expenses accounting for an additional 25-35%. These cost factors create substantial market pressure for technological innovations that can reduce these operational expenditures while maintaining or improving extraction yields.

The geographical distribution of lithium demand presents additional market considerations. Asia-Pacific currently dominates lithium consumption, accounting for 65% of global demand, primarily driven by battery manufacturing hubs in China, Japan, and South Korea. North America and Europe are experiencing the fastest growth rates in demand, with 18% and 15% year-over-year increases respectively, as these regions accelerate their transition to electric mobility.

Industry stakeholders have identified specific market requirements for next-generation DLE technologies. These include reducing energy consumption by at least 40%, decreasing reagent use by 30%, and achieving water recycling rates above 85%. Technologies that can meet these benchmarks while maintaining extraction efficiencies above 90% are positioned to capture significant market share.

Market segmentation analysis indicates that mid-tier lithium producers, particularly those with access to geothermal brines or unconventional lithium sources, represent the most promising early adopters for cost-optimized DLE technologies. These companies typically operate with capital constraints that make operational cost reductions particularly attractive, yet possess sufficient resources to implement new technological solutions.

The competitive landscape for cost-effective lithium extraction is intensifying, with over 40 technology providers currently developing proprietary DLE solutions. Venture capital investment in this sector has surged, with $1.2 billion deployed across various startups in the past three years, signaling strong market confidence in the potential for breakthrough cost-reduction technologies.

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives to traditional evaporation pond methods, offering significant advantages in terms of extraction efficiency and environmental impact. However, operational costs remain a substantial barrier to widespread commercial adoption. Current DLE facilities face operational expenditures ranging from $5,200 to $7,800 per ton of lithium carbonate equivalent (LCE), significantly higher than the $2,500 to $3,500 per ton for conventional brine operations in South America.

Market analysis reveals that energy consumption constitutes 30-40% of total operational costs in DLE facilities, with water treatment and chemical reagent expenses accounting for an additional 25-35%. These cost factors create substantial market pressure for technological innovations that can reduce these operational expenditures while maintaining or improving extraction yields.

The geographical distribution of lithium demand presents additional market considerations. Asia-Pacific currently dominates lithium consumption, accounting for 65% of global demand, primarily driven by battery manufacturing hubs in China, Japan, and South Korea. North America and Europe are experiencing the fastest growth rates in demand, with 18% and 15% year-over-year increases respectively, as these regions accelerate their transition to electric mobility.

Industry stakeholders have identified specific market requirements for next-generation DLE technologies. These include reducing energy consumption by at least 40%, decreasing reagent use by 30%, and achieving water recycling rates above 85%. Technologies that can meet these benchmarks while maintaining extraction efficiencies above 90% are positioned to capture significant market share.

Market segmentation analysis indicates that mid-tier lithium producers, particularly those with access to geothermal brines or unconventional lithium sources, represent the most promising early adopters for cost-optimized DLE technologies. These companies typically operate with capital constraints that make operational cost reductions particularly attractive, yet possess sufficient resources to implement new technological solutions.

The competitive landscape for cost-effective lithium extraction is intensifying, with over 40 technology providers currently developing proprietary DLE solutions. Venture capital investment in this sector has surged, with $1.2 billion deployed across various startups in the past three years, signaling strong market confidence in the potential for breakthrough cost-reduction technologies.

Current DLE Operational Challenges and Cost Factors

Direct Lithium Extraction (DLE) technologies face significant operational challenges that drive up costs across the lithium production value chain. Energy consumption represents one of the most substantial cost factors, with current DLE processes requiring between 15-40 kWh per kilogram of lithium carbonate equivalent (LCE) produced. This energy intensity primarily stems from pumping operations, pre-treatment processes, and the regeneration of sorbent materials.

Water management presents another critical challenge, as most DLE facilities consume 3-7 cubic meters of fresh water per ton of LCE. The treatment and disposal of wastewater further increases operational expenses, particularly in environmentally sensitive regions where regulatory compliance adds complexity and cost.

Sorbent materials, essential to the selective extraction of lithium ions, contribute significantly to operational costs. Current ion-exchange materials and adsorbents have limited lifespans, typically requiring replacement after 200-500 cycles. With costs ranging from $200-800 per kilogram for high-quality sorbents, this represents a recurring capital expenditure that impacts overall economics.

Chemical consumption for regeneration processes and pH adjustment constitutes approximately 15-25% of operational expenses. Most facilities utilize acids, bases, and other reagents that not only represent direct costs but also necessitate specialized handling equipment and safety protocols, further increasing infrastructure requirements.

Maintenance and downtime issues plague many DLE operations, with facilities experiencing 15-20% downtime annually due to equipment failures, sorbent degradation, and scaling problems. This translates directly to reduced production capacity and increased labor costs for maintenance activities.

Scale formation and membrane fouling accelerate equipment deterioration and reduce extraction efficiency. Current anti-scaling treatments add $50-100 per ton of LCE to production costs, while membrane replacement can represent 5-10% of annual operational expenses in membrane-based DLE systems.

Process control inefficiencies result from the complex interplay of variables affecting extraction performance. Many facilities operate with suboptimal parameters due to insufficient real-time monitoring capabilities, resulting in yield losses of 5-15% compared to theoretical maximums.

Labor costs remain high due to the specialized knowledge required for DLE operations. Facilities typically employ 0.5-1.0 full-time employees per 1,000 tons of annual production capacity, with skilled technicians commanding premium salaries in remote lithium-rich regions.

Water management presents another critical challenge, as most DLE facilities consume 3-7 cubic meters of fresh water per ton of LCE. The treatment and disposal of wastewater further increases operational expenses, particularly in environmentally sensitive regions where regulatory compliance adds complexity and cost.

Sorbent materials, essential to the selective extraction of lithium ions, contribute significantly to operational costs. Current ion-exchange materials and adsorbents have limited lifespans, typically requiring replacement after 200-500 cycles. With costs ranging from $200-800 per kilogram for high-quality sorbents, this represents a recurring capital expenditure that impacts overall economics.

Chemical consumption for regeneration processes and pH adjustment constitutes approximately 15-25% of operational expenses. Most facilities utilize acids, bases, and other reagents that not only represent direct costs but also necessitate specialized handling equipment and safety protocols, further increasing infrastructure requirements.

Maintenance and downtime issues plague many DLE operations, with facilities experiencing 15-20% downtime annually due to equipment failures, sorbent degradation, and scaling problems. This translates directly to reduced production capacity and increased labor costs for maintenance activities.

Scale formation and membrane fouling accelerate equipment deterioration and reduce extraction efficiency. Current anti-scaling treatments add $50-100 per ton of LCE to production costs, while membrane replacement can represent 5-10% of annual operational expenses in membrane-based DLE systems.

Process control inefficiencies result from the complex interplay of variables affecting extraction performance. Many facilities operate with suboptimal parameters due to insufficient real-time monitoring capabilities, resulting in yield losses of 5-15% compared to theoretical maximums.

Labor costs remain high due to the specialized knowledge required for DLE operations. Facilities typically employ 0.5-1.0 full-time employees per 1,000 tons of annual production capacity, with skilled technicians commanding premium salaries in remote lithium-rich regions.

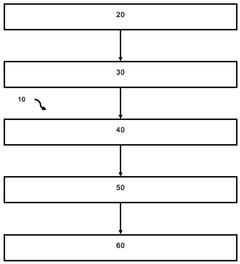

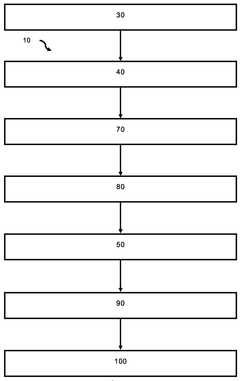

Current Cost Optimization Solutions for DLE Operations

01 Energy consumption optimization in DLE processes

Direct Lithium Extraction (DLE) processes can be optimized to reduce operational costs through energy consumption management. This includes implementing energy-efficient extraction technologies, heat recovery systems, and renewable energy sources to power the extraction operations. By minimizing energy requirements during adsorption, desorption, and regeneration cycles, the overall operational expenses can be significantly reduced while maintaining extraction efficiency.- Energy consumption optimization in DLE processes: Energy consumption is a significant operational cost factor in Direct Lithium Extraction (DLE) processes. Various technologies focus on optimizing energy usage through improved heat management, efficient pumping systems, and recovery of thermal energy. These innovations can substantially reduce electricity costs, which typically represent 20-30% of operational expenses in DLE operations. Advanced energy recovery systems and process integration techniques help minimize the energy footprint while maintaining extraction efficiency.

- Sorbent material efficiency and regeneration: The selection, performance, and regeneration of sorbent materials significantly impact operational costs in DLE. Innovations focus on developing sorbents with higher lithium selectivity, longer operational lifespans, and more efficient regeneration cycles. Improved sorbent technologies reduce chemical consumption, minimize replacement frequency, and lower waste treatment costs. Advanced regeneration methods using optimized chemical formulations or novel physical processes can extend sorbent life while maintaining high lithium recovery rates.

- Water management and brine processing efficiency: Water usage represents a major operational cost in DLE processes, particularly in arid regions where lithium resources are often located. Innovations focus on closed-loop water systems, brine recycling technologies, and reduced freshwater consumption. Advanced filtration, membrane technologies, and evaporation reduction techniques help minimize water losses and associated costs. Efficient brine management systems also reduce pumping expenses and extend equipment life by preventing scaling and corrosion issues.

- Chemical consumption reduction strategies: Chemical reagents used in extraction, purification, and regeneration processes constitute a significant operational expense in DLE operations. Innovations focus on reducing chemical consumption through more selective reactions, recycling of reagents, and development of alternative extraction chemistries. Advanced process control systems optimize reagent dosing based on real-time monitoring of brine composition and process conditions. These improvements reduce not only direct chemical costs but also associated waste treatment and environmental compliance expenses.

- Automation and process control optimization: Implementation of advanced automation, monitoring systems, and process control technologies significantly impacts operational costs in DLE facilities. Smart sensors, real-time analytics, and AI-driven optimization reduce labor requirements while improving process efficiency and resource utilization. Predictive maintenance systems minimize downtime and extend equipment life. Integrated control platforms enable precise adjustment of operational parameters to maximize lithium recovery while minimizing energy, water, and chemical consumption across the entire extraction process.

02 Sorbent material selection and regeneration

The choice and management of sorbent materials significantly impact the operational costs of DLE processes. Advanced sorbent materials with high selectivity for lithium, extended lifespan, and efficient regeneration capabilities can reduce replacement frequency and chemical consumption. Optimizing regeneration processes to minimize chemical usage and maximize sorbent reusability contributes to lower operational expenses and sustainable extraction operations.Expand Specific Solutions03 Water management and recycling systems

Efficient water management is crucial for reducing operational costs in DLE processes. Implementing closed-loop water recycling systems, minimizing freshwater consumption, and treating process water for reuse can significantly lower expenses. Advanced filtration and purification technologies enable the recovery and reuse of process water, reducing both environmental impact and operational costs associated with water procurement and disposal.Expand Specific Solutions04 Chemical consumption reduction strategies

Minimizing chemical consumption in DLE processes is essential for operational cost reduction. This includes optimizing reagent dosing, developing selective extraction processes that require fewer chemicals, and implementing precise process control systems. Advanced monitoring technologies enable real-time adjustment of chemical inputs based on brine composition and extraction conditions, preventing wastage and reducing overall chemical expenses.Expand Specific Solutions05 Process automation and monitoring systems

Implementing advanced automation and monitoring systems can significantly reduce labor costs and improve operational efficiency in DLE processes. Smart sensors, real-time analytics, and artificial intelligence-driven control systems optimize extraction parameters, predict maintenance needs, and prevent costly downtime. These technologies enable precise control of extraction conditions, reducing variability and ensuring consistent lithium recovery rates while minimizing human intervention requirements.Expand Specific Solutions

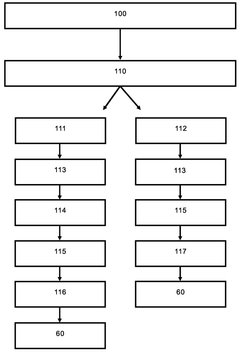

Leading Companies in DLE Technology Development

The direct lithium extraction (DLE) market is in an early growth phase, characterized by rapid technological innovation aimed at reducing operational costs. The global market is expanding significantly due to increasing demand for lithium in battery production, with projections showing substantial growth potential. Technologically, the field remains in development with varying maturity levels across different approaches. Leading players include Koch Technology Solutions and Lilac Solutions focusing on ion-exchange technologies, Evove and Watercycle Technologies developing advanced membrane systems, while established energy companies like Schlumberger and POSCO are leveraging their industrial expertise. Academic institutions such as The University of Manchester and Chinese Academy of Sciences are contributing fundamental research to improve extraction efficiency and sustainability, creating a competitive landscape balancing commercial deployment with ongoing innovation.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed an advanced Direct Lithium Extraction (DLE) technology called Li-Pro™, which utilizes a proprietary ion exchange process to selectively extract lithium from brine resources. Their system employs specialized adsorbent materials that can selectively capture lithium ions while rejecting competing ions like sodium, magnesium, and calcium. The process operates in a continuous flow configuration with multiple adsorption columns working in parallel, allowing for uninterrupted operation and reduced downtime. To reduce operational costs, Koch has implemented energy recovery systems that capture and reuse thermal energy from various process streams, significantly reducing the overall energy consumption. Their technology also incorporates advanced water recycling capabilities, with up to 98% of process water being recovered and reused, dramatically reducing freshwater requirements and associated costs[1][3]. Additionally, Koch has developed automated control systems that optimize reagent usage based on real-time monitoring of brine composition, further reducing chemical consumption and associated costs.

Strengths: Highly selective ion exchange materials reduce purification costs downstream; advanced water recycling capabilities minimize freshwater consumption and disposal costs; automated control systems optimize reagent usage. Weaknesses: The specialized adsorbent materials require periodic replacement, adding to maintenance costs; the system complexity requires skilled operators; initial capital investment is higher than conventional evaporation pond methods.

Qinghai Institute of Salt Lakes, Chinese Academy of Sciences

Technical Solution: The Qinghai Institute of Salt Lakes has developed a comprehensive Direct Lithium Extraction technology specifically tailored for the unique high-altitude, high-magnesium salt lake brines found in the Qinghai-Tibet Plateau. Their approach combines selective adsorption with an innovative electrochemical regeneration process that significantly reduces chemical reagent consumption. The institute's technology employs composite adsorbent materials with hierarchical pore structures that demonstrate exceptional lithium selectivity even in brines with Li/Mg ratios as low as 1:1000. To address the operational cost challenges of high-altitude operations, they've developed a low-temperature adsorption process that functions efficiently at temperatures as low as 5°C, eliminating the need for energy-intensive heating in the harsh plateau environment[9]. Their system also incorporates a closed-loop water recycling system that recovers over 95% of process water, critical for operations in water-scarce regions. Additionally, the institute has pioneered a solar-thermal integration approach that harnesses the abundant solar resources of the Qinghai plateau to provide thermal energy for the elution and concentration processes, reducing conventional energy consumption by up to 60%[10]. The technology has been successfully implemented at industrial scale in multiple salt lakes across Qinghai Province, demonstrating consistent lithium recovery rates above 85% while operating at significantly lower costs than traditional evaporation methods.

Strengths: Specialized design for high-magnesium brines eliminates costly pre-treatment steps; low-temperature operation reduces energy requirements; solar-thermal integration significantly reduces conventional energy costs; closed-loop water system minimizes freshwater consumption in water-scarce regions. Weaknesses: Technology is highly specialized for specific brine compositions found in Qinghai salt lakes; the electrochemical regeneration process requires specialized equipment and expertise; high-altitude operation presents unique logistical challenges that may increase maintenance and labor costs.

Key Innovations in Energy-Efficient DLE Processes

Pressure control in a system and process for extracting lithium enriched eluates from an untreated brine

PatentWO2025036580A1

Innovation

- A system and process that directly injects untreated geothermal brine into a direct lithium extraction unit, utilizing a pressure control unit to manage pressure and optimize lithium extraction, thereby eliminating the need for pre-treatment and reducing costs and environmental impact.

Lithium extraction method

PatentWO2025137291A1

Innovation

- A process combining separation technologies such as lithium adsorbents, nanofiltration, and reverse osmosis to selectively extract lithium from brine solutions with reduced energy consumption and improved water utilization.

Environmental Impact Assessment of DLE Operations

Direct Lithium Extraction (DLE) technologies, while promising significant improvements in lithium production efficiency, carry notable environmental implications that require thorough assessment. The environmental footprint of DLE operations extends across multiple dimensions, with water usage being a primary concern. Unlike traditional evaporation methods, DLE significantly reduces water consumption—potentially by 50-90%—representing a crucial advantage in water-stressed regions where lithium resources are often located.

Land disturbance presents another critical environmental factor. DLE facilities typically require substantially smaller land footprints compared to traditional evaporation ponds, which can span thousands of hectares. This reduced spatial requirement minimizes habitat disruption and preserves natural landscapes, particularly valuable in ecologically sensitive areas.

Chemical usage in DLE processes introduces potential environmental risks that demand careful management. The sorbents, solvents, and other reagents employed in various DLE methods may pose contamination threats if improperly handled or disposed of. Advanced treatment systems and closed-loop designs are increasingly being implemented to mitigate these risks, though their long-term effectiveness remains under evaluation.

Energy consumption represents a significant operational cost driver with corresponding environmental implications. DLE methods typically require more energy than conventional evaporation techniques, primarily for pumping, processing, and regeneration operations. This increased energy demand translates to higher carbon emissions unless renewable energy sources are integrated into facility operations.

Waste management challenges are particularly noteworthy in DLE operations. The processing of brines generates various waste streams, including depleted brines that must be carefully managed to prevent soil and groundwater contamination. Some DLE technologies are advancing toward zero liquid discharge systems, though these solutions often increase operational costs while reducing environmental impact.

Biodiversity impacts, while generally less severe than those associated with traditional mining operations, still require monitoring. Groundwater extraction can affect local ecosystems, particularly in arid regions where water resources are already stressed. Comprehensive baseline studies and ongoing monitoring programs are essential components of responsible DLE implementation.

Carbon footprint considerations are increasingly important as the lithium industry faces scrutiny regarding its role in enabling green technologies. Life cycle assessments indicate that DLE methods, despite higher energy requirements, may offer lower overall carbon emissions when considering the reduced land use and transportation requirements compared to conventional methods.

Land disturbance presents another critical environmental factor. DLE facilities typically require substantially smaller land footprints compared to traditional evaporation ponds, which can span thousands of hectares. This reduced spatial requirement minimizes habitat disruption and preserves natural landscapes, particularly valuable in ecologically sensitive areas.

Chemical usage in DLE processes introduces potential environmental risks that demand careful management. The sorbents, solvents, and other reagents employed in various DLE methods may pose contamination threats if improperly handled or disposed of. Advanced treatment systems and closed-loop designs are increasingly being implemented to mitigate these risks, though their long-term effectiveness remains under evaluation.

Energy consumption represents a significant operational cost driver with corresponding environmental implications. DLE methods typically require more energy than conventional evaporation techniques, primarily for pumping, processing, and regeneration operations. This increased energy demand translates to higher carbon emissions unless renewable energy sources are integrated into facility operations.

Waste management challenges are particularly noteworthy in DLE operations. The processing of brines generates various waste streams, including depleted brines that must be carefully managed to prevent soil and groundwater contamination. Some DLE technologies are advancing toward zero liquid discharge systems, though these solutions often increase operational costs while reducing environmental impact.

Biodiversity impacts, while generally less severe than those associated with traditional mining operations, still require monitoring. Groundwater extraction can affect local ecosystems, particularly in arid regions where water resources are already stressed. Comprehensive baseline studies and ongoing monitoring programs are essential components of responsible DLE implementation.

Carbon footprint considerations are increasingly important as the lithium industry faces scrutiny regarding its role in enabling green technologies. Life cycle assessments indicate that DLE methods, despite higher energy requirements, may offer lower overall carbon emissions when considering the reduced land use and transportation requirements compared to conventional methods.

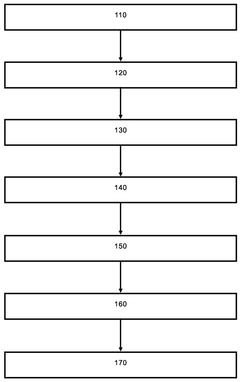

Supply Chain Optimization for DLE Facilities

Supply chain optimization represents a critical factor in reducing operational costs for Direct Lithium Extraction (DLE) facilities. The complex nature of DLE operations requires a well-coordinated supply chain strategy that addresses multiple aspects of the production process, from raw material sourcing to final product distribution.

Efficient procurement strategies form the foundation of supply chain optimization in DLE facilities. By establishing long-term contracts with suppliers of key chemicals and materials, companies can secure favorable pricing and ensure consistent quality. Strategic supplier relationships also enable just-in-time delivery systems, reducing inventory holding costs while maintaining operational continuity.

Transportation logistics present significant opportunities for cost reduction in DLE operations. The geographical distribution of lithium resources often necessitates complex logistics networks spanning multiple regions or countries. Implementing multi-modal transportation solutions that combine rail, road, and sea transport can optimize delivery times and reduce fuel consumption. Advanced route planning algorithms further enhance efficiency by minimizing distance traveled and maximizing vehicle utilization.

Inventory management systems tailored to DLE operations can substantially decrease working capital requirements. Real-time monitoring technologies enable precise tracking of chemical reagents, replacement parts, and finished lithium products. Predictive analytics tools help forecast demand patterns, allowing facilities to maintain optimal inventory levels that balance stockout risks against carrying costs.

Vertical integration strategies merit consideration for larger DLE operations. By controlling multiple stages of the supply chain—from extraction to processing and potentially to battery material production—companies can eliminate intermediary margins and reduce transaction costs. However, this approach requires significant capital investment and must be evaluated against the flexibility benefits of a more distributed supply chain model.

Digital supply chain solutions offer transformative potential for DLE facilities. Blockchain technology can enhance traceability and transparency across the entire supply chain, while Internet of Things (IoT) devices enable real-time monitoring of material flows and equipment performance. These technologies facilitate data-driven decision making that optimizes resource allocation and identifies inefficiencies before they impact operations.

Collaborative supply chain networks represent an emerging approach in the lithium industry. By sharing transportation resources, warehousing facilities, or even processing capacity with other operators in the region, DLE facilities can achieve economies of scale that would be unattainable individually. Such collaboration requires careful coordination but can yield substantial cost benefits while improving overall industry sustainability.

Efficient procurement strategies form the foundation of supply chain optimization in DLE facilities. By establishing long-term contracts with suppliers of key chemicals and materials, companies can secure favorable pricing and ensure consistent quality. Strategic supplier relationships also enable just-in-time delivery systems, reducing inventory holding costs while maintaining operational continuity.

Transportation logistics present significant opportunities for cost reduction in DLE operations. The geographical distribution of lithium resources often necessitates complex logistics networks spanning multiple regions or countries. Implementing multi-modal transportation solutions that combine rail, road, and sea transport can optimize delivery times and reduce fuel consumption. Advanced route planning algorithms further enhance efficiency by minimizing distance traveled and maximizing vehicle utilization.

Inventory management systems tailored to DLE operations can substantially decrease working capital requirements. Real-time monitoring technologies enable precise tracking of chemical reagents, replacement parts, and finished lithium products. Predictive analytics tools help forecast demand patterns, allowing facilities to maintain optimal inventory levels that balance stockout risks against carrying costs.

Vertical integration strategies merit consideration for larger DLE operations. By controlling multiple stages of the supply chain—from extraction to processing and potentially to battery material production—companies can eliminate intermediary margins and reduce transaction costs. However, this approach requires significant capital investment and must be evaluated against the flexibility benefits of a more distributed supply chain model.

Digital supply chain solutions offer transformative potential for DLE facilities. Blockchain technology can enhance traceability and transparency across the entire supply chain, while Internet of Things (IoT) devices enable real-time monitoring of material flows and equipment performance. These technologies facilitate data-driven decision making that optimizes resource allocation and identifies inefficiencies before they impact operations.

Collaborative supply chain networks represent an emerging approach in the lithium industry. By sharing transportation resources, warehousing facilities, or even processing capacity with other operators in the region, DLE facilities can achieve economies of scale that would be unattainable individually. Such collaboration requires careful coordination but can yield substantial cost benefits while improving overall industry sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!