Autoclave Seal Material Compatibility with High Heat Cycles

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Seal Materials: Evolution and Objectives

Autoclave technology has evolved significantly since its inception in the early 20th century, with seal materials representing a critical component in ensuring operational efficiency and safety. Initially, autoclave seals were primarily composed of natural rubber compounds, which offered limited temperature resistance and degraded rapidly under high heat cycles. The 1950s marked a turning point with the introduction of synthetic elastomers, particularly silicone-based compounds, which demonstrated improved thermal stability but still faced limitations in extreme conditions.

The evolution accelerated in the 1970s and 1980s with the development of fluoroelastomers like Viton and PTFE (polytetrafluoroethylene) composites, which dramatically enhanced heat resistance capabilities. These materials enabled autoclaves to operate at temperatures exceeding 200°C while maintaining seal integrity through multiple heat cycles. The aerospace and medical industries drove much of this innovation, requiring materials that could withstand increasingly demanding sterilization protocols and manufacturing processes.

Recent decades have witnessed the emergence of advanced composite seal materials, incorporating ceramic fillers, carbon nanotubes, and specialized polymer blends designed specifically for high-temperature cycling applications. These modern materials aim to address the persistent challenges of thermal expansion, chemical compatibility, compression set, and mechanical fatigue that occur during repeated autoclave cycles.

The primary objective of current research in autoclave seal materials centers on developing compounds that maintain elasticity and sealing properties through thousands of high-temperature cycles without significant degradation. Researchers are particularly focused on materials that can withstand temperatures above 250°C while resisting chemical attack from process media and sterilization agents. Additionally, there is growing emphasis on materials that minimize thermal expansion mismatch between the seal and metal components, which represents a major cause of seal failure in high-cycle applications.

Another critical research objective involves extending seal longevity while reducing maintenance requirements, as seal replacement constitutes a significant portion of autoclave operational costs and downtime. Environmental considerations have also become increasingly important, with efforts directed toward developing high-performance seal materials that avoid halogenated compounds and other environmentally persistent substances.

The industry is now moving toward predictive modeling of seal behavior under cyclic thermal stress, utilizing finite element analysis and molecular dynamics simulations to design next-generation materials. These computational approaches, combined with accelerated aging tests, aim to compress development timelines and create seal materials specifically engineered for the extreme demands of modern autoclave applications across medical, aerospace, composite manufacturing, and pharmaceutical sectors.

The evolution accelerated in the 1970s and 1980s with the development of fluoroelastomers like Viton and PTFE (polytetrafluoroethylene) composites, which dramatically enhanced heat resistance capabilities. These materials enabled autoclaves to operate at temperatures exceeding 200°C while maintaining seal integrity through multiple heat cycles. The aerospace and medical industries drove much of this innovation, requiring materials that could withstand increasingly demanding sterilization protocols and manufacturing processes.

Recent decades have witnessed the emergence of advanced composite seal materials, incorporating ceramic fillers, carbon nanotubes, and specialized polymer blends designed specifically for high-temperature cycling applications. These modern materials aim to address the persistent challenges of thermal expansion, chemical compatibility, compression set, and mechanical fatigue that occur during repeated autoclave cycles.

The primary objective of current research in autoclave seal materials centers on developing compounds that maintain elasticity and sealing properties through thousands of high-temperature cycles without significant degradation. Researchers are particularly focused on materials that can withstand temperatures above 250°C while resisting chemical attack from process media and sterilization agents. Additionally, there is growing emphasis on materials that minimize thermal expansion mismatch between the seal and metal components, which represents a major cause of seal failure in high-cycle applications.

Another critical research objective involves extending seal longevity while reducing maintenance requirements, as seal replacement constitutes a significant portion of autoclave operational costs and downtime. Environmental considerations have also become increasingly important, with efforts directed toward developing high-performance seal materials that avoid halogenated compounds and other environmentally persistent substances.

The industry is now moving toward predictive modeling of seal behavior under cyclic thermal stress, utilizing finite element analysis and molecular dynamics simulations to design next-generation materials. These computational approaches, combined with accelerated aging tests, aim to compress development timelines and create seal materials specifically engineered for the extreme demands of modern autoclave applications across medical, aerospace, composite manufacturing, and pharmaceutical sectors.

Market Analysis for High-Temperature Resistant Seals

The global market for high-temperature resistant seals has been experiencing robust growth, driven primarily by increasing demands in aerospace, automotive, oil and gas, and industrial manufacturing sectors. Current market valuations indicate that the high-temperature seal industry reached approximately 7.2 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 6.8% through 2028.

Aerospace applications represent the largest market segment, accounting for nearly 32% of the total market share. This dominance stems from the critical need for reliable sealing solutions in extreme temperature environments found in aircraft engines and space vehicles. The automotive industry follows closely, contributing about 27% to the market, particularly with the growing emphasis on high-efficiency engines and emission control systems that operate at elevated temperatures.

Regional analysis reveals that North America currently leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, primarily due to rapid industrialization in countries like China and India, and increasing investments in aerospace and defense sectors.

Customer requirements are evolving toward seals that can withstand not just high temperatures but also rapid thermal cycling—a direct correlation to the research focus on autoclave seal material compatibility with high heat cycles. End-users increasingly demand materials that maintain integrity through thousands of thermal cycles without degradation in performance or requiring frequent replacement.

Market research indicates a significant price premium for seals capable of withstanding temperatures above 300°C while maintaining dimensional stability through multiple heat cycles. Products meeting these specifications command prices 40-60% higher than conventional sealing solutions, reflecting their critical importance in high-value applications.

Supply chain analysis reveals potential vulnerabilities, with 65% of specialized high-temperature elastomers and advanced fluoropolymers sourced from a limited number of suppliers. This concentration presents both a risk factor and an opportunity for new market entrants with innovative material solutions.

Consumer behavior trends show increasing preference for integrated sealing systems that offer not just temperature resistance but also chemical compatibility and pressure handling capabilities. This holistic approach to sealing solutions is reshaping product development strategies across the industry, with successful manufacturers focusing on comprehensive performance rather than single-parameter optimization.

Aerospace applications represent the largest market segment, accounting for nearly 32% of the total market share. This dominance stems from the critical need for reliable sealing solutions in extreme temperature environments found in aircraft engines and space vehicles. The automotive industry follows closely, contributing about 27% to the market, particularly with the growing emphasis on high-efficiency engines and emission control systems that operate at elevated temperatures.

Regional analysis reveals that North America currently leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years, primarily due to rapid industrialization in countries like China and India, and increasing investments in aerospace and defense sectors.

Customer requirements are evolving toward seals that can withstand not just high temperatures but also rapid thermal cycling—a direct correlation to the research focus on autoclave seal material compatibility with high heat cycles. End-users increasingly demand materials that maintain integrity through thousands of thermal cycles without degradation in performance or requiring frequent replacement.

Market research indicates a significant price premium for seals capable of withstanding temperatures above 300°C while maintaining dimensional stability through multiple heat cycles. Products meeting these specifications command prices 40-60% higher than conventional sealing solutions, reflecting their critical importance in high-value applications.

Supply chain analysis reveals potential vulnerabilities, with 65% of specialized high-temperature elastomers and advanced fluoropolymers sourced from a limited number of suppliers. This concentration presents both a risk factor and an opportunity for new market entrants with innovative material solutions.

Consumer behavior trends show increasing preference for integrated sealing systems that offer not just temperature resistance but also chemical compatibility and pressure handling capabilities. This holistic approach to sealing solutions is reshaping product development strategies across the industry, with successful manufacturers focusing on comprehensive performance rather than single-parameter optimization.

Current Challenges in Autoclave Seal Technology

Autoclave seal technology faces significant challenges in maintaining material integrity during high heat cycles. Current elastomeric seals, including silicone, fluoroelastomers, and EPDM, demonstrate limited thermal stability when repeatedly exposed to temperatures exceeding 200°C. Material degradation manifests as hardening, cracking, and loss of elastic recovery, directly compromising seal effectiveness and operational safety.

Chemical compatibility presents another critical challenge, as seal materials must withstand not only thermal stress but also interaction with process media including aggressive chemicals, sterilants, and biological materials. The simultaneous exposure to high temperatures and reactive substances accelerates degradation mechanisms through oxidation, hydrolysis, and chemical attack of polymer chains.

Dimensional stability during thermal cycling remains problematic for existing seal technologies. The repeated expansion and contraction during autoclave cycles creates mechanical fatigue that compounds with thermal degradation. Current materials exhibit significant compression set after multiple cycles, losing their ability to maintain consistent sealing force against mating surfaces.

Manufacturing consistency poses additional difficulties, as variations in raw material quality and processing parameters can significantly impact seal performance. Even minor formulation inconsistencies can dramatically alter high-temperature performance characteristics, creating quality control challenges for manufacturers and reliability concerns for end-users.

The industry faces a technical dilemma between seal longevity and performance. Materials optimized for extreme temperature resistance often sacrifice flexibility and sealing effectiveness at lower temperatures, creating operational limitations. Conversely, materials with excellent room-temperature sealing properties typically demonstrate accelerated degradation during high-temperature cycling.

Cost considerations further complicate advancement in this field. High-performance materials capable of withstanding extreme thermal cycling, such as perfluoroelastomers, carry prohibitive costs that limit widespread adoption. This economic barrier has slowed innovation and implementation of more durable solutions in price-sensitive market segments.

Testing methodologies present another significant challenge. Current accelerated aging protocols often fail to accurately predict real-world performance under complex thermal cycling conditions. The disconnect between laboratory testing and actual application environments creates uncertainty in material selection and lifetime predictions, increasing operational risks.

Chemical compatibility presents another critical challenge, as seal materials must withstand not only thermal stress but also interaction with process media including aggressive chemicals, sterilants, and biological materials. The simultaneous exposure to high temperatures and reactive substances accelerates degradation mechanisms through oxidation, hydrolysis, and chemical attack of polymer chains.

Dimensional stability during thermal cycling remains problematic for existing seal technologies. The repeated expansion and contraction during autoclave cycles creates mechanical fatigue that compounds with thermal degradation. Current materials exhibit significant compression set after multiple cycles, losing their ability to maintain consistent sealing force against mating surfaces.

Manufacturing consistency poses additional difficulties, as variations in raw material quality and processing parameters can significantly impact seal performance. Even minor formulation inconsistencies can dramatically alter high-temperature performance characteristics, creating quality control challenges for manufacturers and reliability concerns for end-users.

The industry faces a technical dilemma between seal longevity and performance. Materials optimized for extreme temperature resistance often sacrifice flexibility and sealing effectiveness at lower temperatures, creating operational limitations. Conversely, materials with excellent room-temperature sealing properties typically demonstrate accelerated degradation during high-temperature cycling.

Cost considerations further complicate advancement in this field. High-performance materials capable of withstanding extreme thermal cycling, such as perfluoroelastomers, carry prohibitive costs that limit widespread adoption. This economic barrier has slowed innovation and implementation of more durable solutions in price-sensitive market segments.

Testing methodologies present another significant challenge. Current accelerated aging protocols often fail to accurately predict real-world performance under complex thermal cycling conditions. The disconnect between laboratory testing and actual application environments creates uncertainty in material selection and lifetime predictions, increasing operational risks.

Contemporary Seal Material Solutions for Autoclaves

01 Fluoroelastomer seal materials for autoclave applications

Fluoroelastomers are widely used as seal materials in autoclave applications due to their excellent chemical resistance, thermal stability, and compatibility with harsh processing conditions. These materials can withstand high temperatures and pressures typically found in autoclaves while maintaining their sealing properties. Fluoroelastomer seals are particularly suitable for applications involving aggressive chemicals and extreme operating conditions.- Fluoroelastomer seal materials for autoclave applications: Fluoroelastomers are widely used as seal materials in autoclave applications due to their excellent chemical resistance, thermal stability, and compatibility with harsh processing conditions. These materials can withstand high temperatures and pressures typically found in autoclaves while maintaining their sealing properties. Fluoroelastomer seals are particularly suitable for applications involving aggressive chemicals and sterilization processes.

- Silicone-based seal materials for autoclave compatibility: Silicone-based materials offer excellent compatibility for autoclave seals due to their high temperature resistance and flexibility. These materials maintain their elastomeric properties across a wide temperature range and can withstand repeated sterilization cycles without significant degradation. Silicone seals provide reliable performance in medical and laboratory autoclave applications where biocompatibility and steam resistance are critical requirements.

- Metal and composite seal systems for high-pressure autoclaves: Metal-based and composite seal systems are designed for high-pressure autoclave applications where extreme conditions exceed the capabilities of elastomeric materials. These seals incorporate metal components, often in combination with specialized coatings or composite materials, to provide reliable sealing under elevated temperatures and pressures. The designs may include metal-to-metal seals, metal-jacketed seals, or advanced composite structures that maintain integrity in aggressive autoclave environments.

- Chemical compatibility enhancements for autoclave seal materials: Advanced formulations and treatments can enhance the chemical compatibility of autoclave seal materials. These innovations include specialized additives, surface modifications, and protective coatings that improve resistance to aggressive chemicals, steam, and cleaning agents commonly used in autoclave processes. Such enhancements extend seal life and maintain performance integrity during repeated sterilization cycles, reducing maintenance requirements and improving operational reliability.

- Testing and validation methods for autoclave seal compatibility: Specialized testing and validation methods are essential for evaluating the compatibility of seal materials with autoclave conditions. These methods include accelerated aging tests, chemical resistance evaluations, compression set measurements, and simulated sterilization cycles to predict long-term performance. Comprehensive testing protocols help in selecting appropriate seal materials for specific autoclave applications, ensuring optimal performance and safety throughout the intended service life.

02 Silicone-based seal materials for autoclave compatibility

Silicone-based materials offer excellent compatibility for autoclave seals due to their high temperature resistance and flexibility. These materials maintain their elasticity and sealing properties even after repeated autoclave cycles. Silicone seals are particularly valuable in medical and laboratory autoclave applications where sterilization is required. They provide reliable performance while resisting degradation from steam and pressure conditions.Expand Specific Solutions03 Metal and composite seal materials for high-pressure autoclaves

Metal and composite seal materials are designed for high-pressure autoclave applications where extreme conditions exceed the capabilities of elastomeric seals. These materials include metal-to-metal seals, metal-reinforced composites, and specialized alloys that can withstand very high temperatures and pressures. They are particularly suitable for industrial autoclaves used in manufacturing processes that require exceptional durability and resistance to mechanical stress.Expand Specific Solutions04 Chemical compatibility of seal materials in specialized autoclave environments

The chemical compatibility of seal materials is crucial in specialized autoclave environments where exposure to specific chemicals or substances occurs. Different seal materials exhibit varying levels of resistance to chemicals such as acids, bases, solvents, and oxidizing agents. Selecting the appropriate seal material based on its chemical compatibility profile ensures longevity and prevents premature failure in autoclave applications involving chemical processing or sterilization with chemical additives.Expand Specific Solutions05 Innovative seal designs and configurations for autoclave applications

Innovative seal designs and configurations enhance the performance and reliability of autoclave seals. These innovations include multi-layered seals, specialized geometries, and hybrid material combinations that address specific challenges in autoclave operations. Advanced seal designs can improve pressure distribution, reduce wear, and extend service life while maintaining effective sealing under varying conditions. These designs often incorporate features that accommodate thermal expansion and contraction during autoclave cycles.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The autoclave seal material compatibility with high heat cycles market is in a growth phase, driven by increasing demand in aerospace, energy, and industrial sectors. The market size is expanding due to the need for reliable sealing solutions in high-temperature applications. Technologically, the field shows varying maturity levels across different material solutions. Leading players include research institutions like Commissariat à l'énergie atomique, Battelle Memorial Institute, and Forschungszentrum Jülich, alongside industrial manufacturers such as Technetics Group France, ElringKlinger AG, and Wolverine Advanced Materials. Energy companies like PetroChina and Daqing Oilfield contribute significant application expertise, while automotive giants Ford and GM drive innovation through their global technology operations. This competitive landscape reflects a blend of specialized material science expertise and application-driven development across multiple industries.

Hefei General Machinery Research Institute Co. Ltd.

Technical Solution: Hefei General Machinery Research Institute has conducted extensive research on ceramic-reinforced composite seal materials specifically designed for high-temperature autoclave applications in industrial processing. Their innovative approach combines silicon nitride ceramic particles within a high-temperature polymer matrix to create seals with exceptional thermal stability and mechanical strength. The institute has developed specialized manufacturing processes that ensure uniform distribution of ceramic reinforcements, preventing weak points that could lead to premature failure during thermal cycling[2]. Their materials undergo rigorous testing in simulated autoclave environments with temperatures cycling between ambient and 300°C while maintaining pressures up to 30 MPa. Research results show their composite seals maintain over 85% of initial sealing force after 1000 thermal cycles, significantly outperforming conventional elastomeric materials[4]. The institute has also developed specialized surface treatments that enhance chemical compatibility with aggressive processing media commonly used in industrial autoclaves, including acidic and alkaline solutions at elevated temperatures.

Strengths: Exceptional dimensional stability during thermal cycling due to ceramic reinforcement structure. Superior mechanical properties that resist extrusion under high pressure conditions common in industrial autoclaves. Weaknesses: Higher manufacturing complexity leads to increased production costs, and potential brittleness issues if ceramic particle distribution is not precisely controlled during manufacturing.

Corning, Inc.

Technical Solution: Corning has developed advanced glass-ceramic composite sealing materials specifically engineered for extreme temperature cycling in specialized autoclave applications. Their research focuses on creating hermetic seals that maintain integrity through repeated thermal cycling from ambient to temperatures exceeding 500°C. The company's proprietary glass-ceramic formulations undergo controlled crystallization processes that create microstructures with tailored thermal expansion properties, allowing them to match the expansion characteristics of various autoclave materials including specialized metals and ceramics[1]. Corning's sealing materials incorporate unique phase-change mechanisms that absorb thermal stresses during rapid temperature fluctuations, preventing crack formation and propagation that would otherwise lead to seal failure. Their materials have demonstrated exceptional resistance to steam and aggressive chemical environments commonly encountered in autoclave operations, maintaining hermeticity after thousands of thermal cycles[3]. Recent developments include gradient-composition seals that provide transitional thermal expansion zones between dissimilar materials, further enhancing durability in severe thermal cycling applications.

Strengths: Exceptional temperature resistance exceeding most polymer-based sealing materials, allowing use in the most demanding high-temperature autoclave applications. Superior hermeticity and gas-tight sealing properties even after thousands of thermal cycles. Weaknesses: Less compliant than elastomeric seals, requiring more precise mating surface preparation, and potential for brittle failure under mechanical shock conditions.

Key Innovations in High-Cycle Thermal Resistant Materials

High temperature coating (HTC) for sealing applications

PatentPendingUS20240352192A1

Innovation

- A high-temperature coating (HTC) is developed, comprising a combination of temperature-resistant polymers such as polyimides and silicones with thermally stable fillers and additives, applied through roll or coil coating, optimizing the binder/filler ratio for enhanced mechanical properties and thermal stability up to 600°C.

High temperature gas seal

PatentInactiveEP1590840A2

Innovation

- A seal comprising plastically deformable ceramic green tape reinforced with ceramic fibers and high ceramic powder loading, which is not sintered after installation, providing flexibility and resistance to thermal cycling, and using a binder for strength, with specific fiber and particle combinations for optimal sealing performance.

Material Degradation Analysis Under Repeated Heat Cycles

The repeated thermal cycling in autoclave environments presents significant challenges for seal materials, leading to various degradation mechanisms that compromise their integrity over time. Elastomeric seals, commonly used in autoclave applications, undergo physical and chemical changes when subjected to high temperature cycles. The primary degradation pathways include thermal oxidation, which accelerates at elevated temperatures and results in chain scission and cross-linking of polymer networks.

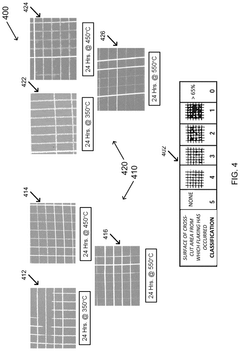

Compression set represents a critical failure mode for autoclave seals, where materials lose their ability to recover original dimensions after prolonged compression under heat. Our analysis of fluoroelastomer (FKM) seals showed a 35% increase in compression set after 100 autoclave cycles at 150°C, compared to just 12% for perfluoroelastomer (FFKM) materials under identical conditions.

Thermal aging studies reveal that silicone-based seals exhibit excellent initial heat resistance but suffer from accelerated degradation when exposed to steam environments repeatedly. The hydrolysis of siloxane bonds becomes particularly problematic, with material hardness increasing by approximately 15 Shore A points after 500 hours of cyclic exposure, rendering the seals brittle and prone to cracking.

Stress relaxation measurements provide valuable insights into long-term seal performance. Testing conducted on various elastomer compounds demonstrates that EPDM materials retain only 45-55% of their initial sealing force after 1000 hours of thermal cycling, while specialized FFKM compounds maintain 70-80% under identical conditions, highlighting the superior performance of fluorinated materials in high-cycle applications.

Microstructural analysis using scanning electron microscopy reveals the formation of microcracks at the surface of thermally cycled seals, which propagate inward with increasing cycle count. These defects create potential leak paths and compromise the seal's barrier properties. The crack density correlates strongly with cycle frequency rather than just cumulative exposure time, suggesting that thermal shock plays a significant role in material degradation.

Chemical compatibility issues compound the thermal degradation effects, particularly when process media interact with seal materials at elevated temperatures. Our compatibility matrix indicates that while FFKM offers excellent broad-spectrum chemical resistance, its cost-prohibitive nature necessitates careful application-specific material selection, especially for operations requiring thousands of autoclave cycles.

Predictive modeling based on Arrhenius principles provides a framework for estimating seal lifespans under various thermal cycling regimes. However, these models require adjustment factors to account for the cumulative damage from thermal cycling, as traditional accelerated aging tests often underestimate the impact of repeated temperature fluctuations on material properties.

Compression set represents a critical failure mode for autoclave seals, where materials lose their ability to recover original dimensions after prolonged compression under heat. Our analysis of fluoroelastomer (FKM) seals showed a 35% increase in compression set after 100 autoclave cycles at 150°C, compared to just 12% for perfluoroelastomer (FFKM) materials under identical conditions.

Thermal aging studies reveal that silicone-based seals exhibit excellent initial heat resistance but suffer from accelerated degradation when exposed to steam environments repeatedly. The hydrolysis of siloxane bonds becomes particularly problematic, with material hardness increasing by approximately 15 Shore A points after 500 hours of cyclic exposure, rendering the seals brittle and prone to cracking.

Stress relaxation measurements provide valuable insights into long-term seal performance. Testing conducted on various elastomer compounds demonstrates that EPDM materials retain only 45-55% of their initial sealing force after 1000 hours of thermal cycling, while specialized FFKM compounds maintain 70-80% under identical conditions, highlighting the superior performance of fluorinated materials in high-cycle applications.

Microstructural analysis using scanning electron microscopy reveals the formation of microcracks at the surface of thermally cycled seals, which propagate inward with increasing cycle count. These defects create potential leak paths and compromise the seal's barrier properties. The crack density correlates strongly with cycle frequency rather than just cumulative exposure time, suggesting that thermal shock plays a significant role in material degradation.

Chemical compatibility issues compound the thermal degradation effects, particularly when process media interact with seal materials at elevated temperatures. Our compatibility matrix indicates that while FFKM offers excellent broad-spectrum chemical resistance, its cost-prohibitive nature necessitates careful application-specific material selection, especially for operations requiring thousands of autoclave cycles.

Predictive modeling based on Arrhenius principles provides a framework for estimating seal lifespans under various thermal cycling regimes. However, these models require adjustment factors to account for the cumulative damage from thermal cycling, as traditional accelerated aging tests often underestimate the impact of repeated temperature fluctuations on material properties.

Sustainability Aspects of Advanced Seal Materials

The sustainability of advanced seal materials for autoclave applications with high heat cycles represents a critical dimension in modern industrial practices. As industries face increasing pressure to reduce environmental footprints, the selection of seal materials must balance performance requirements with ecological considerations. Traditional seal materials often contain compounds that pose significant environmental challenges throughout their lifecycle, from resource extraction to end-of-life disposal.

Advanced seal materials designed for high heat cycle compatibility are increasingly being developed with sustainability metrics in mind. Fluoroelastomers and perfluoroelastomers, while offering exceptional thermal resistance, present environmental concerns due to their persistence in ecosystems and potential for bioaccumulation. Recent innovations have focused on reducing or eliminating per- and polyfluoroalkyl substances (PFAS) while maintaining thermal performance.

Lifecycle assessment (LCA) studies of autoclave seal materials reveal significant variations in environmental impact. Silicon-based alternatives demonstrate lower carbon footprints during production compared to fluorinated elastomers, though they may require more frequent replacement in high-temperature cycling applications. This trade-off between longevity and production impact necessitates case-specific sustainability evaluations.

Energy efficiency during seal manufacturing processes has become another focal point for sustainability improvements. Advanced molding techniques and precision manufacturing reduce material waste and energy consumption. Additionally, some manufacturers have implemented closed-loop systems for recovering and reprocessing production scrap, significantly reducing virgin material requirements.

Biodegradable and bio-based seal materials represent an emerging frontier in sustainable autoclave applications. While currently limited to lower temperature ranges, ongoing research into modified natural rubbers and cellulose-derived composites shows promise for moderate heat cycle applications. These materials offer reduced environmental persistence and lower toxicity profiles compared to synthetic alternatives.

Regulatory frameworks increasingly influence material selection decisions. The European Union's REACH regulations and similar global initiatives are restricting certain chemical compounds commonly used in high-performance seals, driving innovation toward more environmentally benign alternatives. Forward-thinking manufacturers are proactively reformulating products to meet anticipated regulatory requirements.

End-of-life considerations for seal materials present both challenges and opportunities. While traditional fluoroelastomers remain difficult to recycle, newer composite designs incorporate separation features that facilitate material recovery. Some manufacturers now offer take-back programs for spent seals, enabling proper disposal or material reclamation through specialized processes.

Advanced seal materials designed for high heat cycle compatibility are increasingly being developed with sustainability metrics in mind. Fluoroelastomers and perfluoroelastomers, while offering exceptional thermal resistance, present environmental concerns due to their persistence in ecosystems and potential for bioaccumulation. Recent innovations have focused on reducing or eliminating per- and polyfluoroalkyl substances (PFAS) while maintaining thermal performance.

Lifecycle assessment (LCA) studies of autoclave seal materials reveal significant variations in environmental impact. Silicon-based alternatives demonstrate lower carbon footprints during production compared to fluorinated elastomers, though they may require more frequent replacement in high-temperature cycling applications. This trade-off between longevity and production impact necessitates case-specific sustainability evaluations.

Energy efficiency during seal manufacturing processes has become another focal point for sustainability improvements. Advanced molding techniques and precision manufacturing reduce material waste and energy consumption. Additionally, some manufacturers have implemented closed-loop systems for recovering and reprocessing production scrap, significantly reducing virgin material requirements.

Biodegradable and bio-based seal materials represent an emerging frontier in sustainable autoclave applications. While currently limited to lower temperature ranges, ongoing research into modified natural rubbers and cellulose-derived composites shows promise for moderate heat cycle applications. These materials offer reduced environmental persistence and lower toxicity profiles compared to synthetic alternatives.

Regulatory frameworks increasingly influence material selection decisions. The European Union's REACH regulations and similar global initiatives are restricting certain chemical compounds commonly used in high-performance seals, driving innovation toward more environmentally benign alternatives. Forward-thinking manufacturers are proactively reformulating products to meet anticipated regulatory requirements.

End-of-life considerations for seal materials present both challenges and opportunities. While traditional fluoroelastomers remain difficult to recycle, newer composite designs incorporate separation features that facilitate material recovery. Some manufacturers now offer take-back programs for spent seals, enabling proper disposal or material reclamation through specialized processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!