Crosslinked Ethyl Propanoate Polymers in Biomedical Applications

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crosslinked EtPr Polymer Background and Objectives

Crosslinked ethyl propanoate (EtPr) polymers have emerged as a promising class of materials in biomedical applications, offering unique properties that address various challenges in the field. The development of these polymers stems from the need for biocompatible, biodegradable, and versatile materials that can be tailored for specific medical uses. EtPr polymers, when crosslinked, exhibit enhanced mechanical strength, controlled degradation rates, and improved stability in biological environments.

The evolution of crosslinked EtPr polymers can be traced back to the broader field of biodegradable polymers, which gained significant attention in the 1960s and 1970s. As research progressed, scientists recognized the potential of ester-based polymers for biomedical applications due to their hydrolyzable backbone. The specific focus on ethyl propanoate-based systems emerged in the late 1990s, driven by the desire to fine-tune polymer properties for targeted applications.

The primary objective of research on crosslinked EtPr polymers in biomedical applications is to develop advanced materials that can effectively interface with biological systems while providing specific functionalities. These polymers aim to overcome limitations of existing biomaterials, such as poor mechanical properties, uncontrolled degradation, or limited biocompatibility. By manipulating the crosslinking density and incorporating various functional groups, researchers seek to create EtPr-based materials with tailored properties for applications ranging from drug delivery systems to tissue engineering scaffolds.

Key technological goals in this field include optimizing the crosslinking process to achieve desired mechanical and degradation properties, enhancing biocompatibility and cell adhesion, and developing stimuli-responsive EtPr polymers for smart biomedical devices. Additionally, researchers aim to improve the scalability and reproducibility of synthesis methods to facilitate the transition from laboratory-scale production to industrial manufacturing.

The current technological landscape of crosslinked EtPr polymers is characterized by a multidisciplinary approach, combining polymer chemistry, materials science, and bioengineering. Recent advancements have focused on developing novel crosslinking strategies, such as photo-initiated and enzyme-mediated crosslinking, to provide greater control over the final polymer properties. Furthermore, the integration of nanotechnology has opened new avenues for creating EtPr-based nanocomposites with enhanced functionalities.

As research in this field progresses, the overarching goal is to translate these innovative materials into clinically viable products that can significantly improve patient outcomes across various medical domains. This includes developing EtPr-based drug delivery systems with controlled release profiles, creating bioactive scaffolds for tissue regeneration, and designing implantable devices with improved biointegration and reduced foreign body response.

The evolution of crosslinked EtPr polymers can be traced back to the broader field of biodegradable polymers, which gained significant attention in the 1960s and 1970s. As research progressed, scientists recognized the potential of ester-based polymers for biomedical applications due to their hydrolyzable backbone. The specific focus on ethyl propanoate-based systems emerged in the late 1990s, driven by the desire to fine-tune polymer properties for targeted applications.

The primary objective of research on crosslinked EtPr polymers in biomedical applications is to develop advanced materials that can effectively interface with biological systems while providing specific functionalities. These polymers aim to overcome limitations of existing biomaterials, such as poor mechanical properties, uncontrolled degradation, or limited biocompatibility. By manipulating the crosslinking density and incorporating various functional groups, researchers seek to create EtPr-based materials with tailored properties for applications ranging from drug delivery systems to tissue engineering scaffolds.

Key technological goals in this field include optimizing the crosslinking process to achieve desired mechanical and degradation properties, enhancing biocompatibility and cell adhesion, and developing stimuli-responsive EtPr polymers for smart biomedical devices. Additionally, researchers aim to improve the scalability and reproducibility of synthesis methods to facilitate the transition from laboratory-scale production to industrial manufacturing.

The current technological landscape of crosslinked EtPr polymers is characterized by a multidisciplinary approach, combining polymer chemistry, materials science, and bioengineering. Recent advancements have focused on developing novel crosslinking strategies, such as photo-initiated and enzyme-mediated crosslinking, to provide greater control over the final polymer properties. Furthermore, the integration of nanotechnology has opened new avenues for creating EtPr-based nanocomposites with enhanced functionalities.

As research in this field progresses, the overarching goal is to translate these innovative materials into clinically viable products that can significantly improve patient outcomes across various medical domains. This includes developing EtPr-based drug delivery systems with controlled release profiles, creating bioactive scaffolds for tissue regeneration, and designing implantable devices with improved biointegration and reduced foreign body response.

Biomedical Market Demand Analysis

The biomedical market for crosslinked ethyl propanoate polymers is experiencing significant growth, driven by increasing demand for advanced biomaterials in various medical applications. These polymers offer unique properties that make them particularly suitable for use in tissue engineering, drug delivery systems, and medical implants.

In the field of tissue engineering, there is a growing need for biocompatible scaffolds that can support cell growth and tissue regeneration. Crosslinked ethyl propanoate polymers have shown promise in this area due to their tunable mechanical properties and biodegradability. The market for tissue engineering products is expected to expand rapidly, with applications in regenerative medicine and wound healing driving demand for these polymers.

Drug delivery systems represent another key area of market demand for crosslinked ethyl propanoate polymers. These materials can be engineered to provide controlled release of therapeutic agents, improving drug efficacy and reducing side effects. The pharmaceutical industry's focus on targeted drug delivery and personalized medicine is fueling research and development in this field, creating opportunities for innovative polymer-based solutions.

The medical implant sector is also showing increased interest in crosslinked ethyl propanoate polymers. These materials offer advantages over traditional implant materials, such as improved biocompatibility and the ability to degrade over time, eliminating the need for removal surgeries. As the aging population grows and the prevalence of chronic diseases increases, the demand for advanced implant materials is expected to rise.

Market analysis indicates that the global biomedical polymers market, which includes crosslinked ethyl propanoate polymers, is projected to grow at a compound annual growth rate (CAGR) of over 13% in the coming years. This growth is attributed to factors such as technological advancements in polymer science, increasing healthcare expenditure, and a rising focus on patient-centric care.

Geographically, North America and Europe currently dominate the market for biomedical polymers, owing to their advanced healthcare infrastructure and significant investment in research and development. However, the Asia-Pacific region is expected to witness the fastest growth, driven by improving healthcare facilities, increasing disposable income, and growing awareness of advanced medical technologies.

Despite the promising outlook, challenges remain in the widespread adoption of crosslinked ethyl propanoate polymers in biomedical applications. These include regulatory hurdles, the need for extensive clinical trials, and the high cost of development and production. However, ongoing research and collaboration between academic institutions and industry players are expected to address these challenges and further expand the market potential of these innovative biomaterials.

In the field of tissue engineering, there is a growing need for biocompatible scaffolds that can support cell growth and tissue regeneration. Crosslinked ethyl propanoate polymers have shown promise in this area due to their tunable mechanical properties and biodegradability. The market for tissue engineering products is expected to expand rapidly, with applications in regenerative medicine and wound healing driving demand for these polymers.

Drug delivery systems represent another key area of market demand for crosslinked ethyl propanoate polymers. These materials can be engineered to provide controlled release of therapeutic agents, improving drug efficacy and reducing side effects. The pharmaceutical industry's focus on targeted drug delivery and personalized medicine is fueling research and development in this field, creating opportunities for innovative polymer-based solutions.

The medical implant sector is also showing increased interest in crosslinked ethyl propanoate polymers. These materials offer advantages over traditional implant materials, such as improved biocompatibility and the ability to degrade over time, eliminating the need for removal surgeries. As the aging population grows and the prevalence of chronic diseases increases, the demand for advanced implant materials is expected to rise.

Market analysis indicates that the global biomedical polymers market, which includes crosslinked ethyl propanoate polymers, is projected to grow at a compound annual growth rate (CAGR) of over 13% in the coming years. This growth is attributed to factors such as technological advancements in polymer science, increasing healthcare expenditure, and a rising focus on patient-centric care.

Geographically, North America and Europe currently dominate the market for biomedical polymers, owing to their advanced healthcare infrastructure and significant investment in research and development. However, the Asia-Pacific region is expected to witness the fastest growth, driven by improving healthcare facilities, increasing disposable income, and growing awareness of advanced medical technologies.

Despite the promising outlook, challenges remain in the widespread adoption of crosslinked ethyl propanoate polymers in biomedical applications. These include regulatory hurdles, the need for extensive clinical trials, and the high cost of development and production. However, ongoing research and collaboration between academic institutions and industry players are expected to address these challenges and further expand the market potential of these innovative biomaterials.

Current Challenges in Polymer Crosslinking

The field of crosslinked ethyl propanoate polymers in biomedical applications faces several significant challenges that hinder their widespread adoption and optimal performance. One of the primary obstacles is achieving precise control over the crosslinking density and distribution within the polymer network. This challenge directly impacts the mechanical properties, degradation rate, and drug release kinetics of the resulting biomaterials.

Another critical issue is the potential cytotoxicity of unreacted crosslinking agents or byproducts formed during the crosslinking process. Ensuring complete reaction of these agents and minimizing harmful residues is crucial for maintaining biocompatibility and preventing adverse tissue responses. Researchers are actively exploring alternative crosslinking methods and biocompatible crosslinking agents to address this concern.

The stability of crosslinked ethyl propanoate polymers under physiological conditions presents another hurdle. These materials must maintain their structural integrity and functional properties in the presence of enzymes, varying pH levels, and mechanical stresses encountered in the body. Developing crosslinking strategies that enhance the polymer's resistance to hydrolysis and enzymatic degradation while still allowing for controlled biodegradation is an ongoing challenge.

Scalability and reproducibility of the crosslinking process pose significant obstacles for industrial production and clinical translation. Achieving consistent crosslinking density and properties across large batches of material is essential for ensuring reliable performance in biomedical applications. This challenge is particularly pronounced when dealing with complex 3D structures or when incorporating bioactive molecules into the polymer matrix.

The integration of crosslinked ethyl propanoate polymers with other biomaterials or living tissues presents additional challenges. Improving the adhesion and interface compatibility between these polymers and biological substrates is crucial for applications such as tissue engineering scaffolds or drug-eluting implants. Researchers are exploring various surface modification techniques and hybrid material approaches to enhance integration and bioactivity.

Furthermore, the characterization and quality control of crosslinked polymer networks remain challenging. Current analytical techniques often struggle to provide comprehensive information about the crosslinking density, network homogeneity, and spatial distribution of functional groups within the material. Developing more advanced characterization methods is essential for optimizing polymer design and ensuring consistent performance in biomedical applications.

Lastly, the long-term in vivo behavior and fate of crosslinked ethyl propanoate polymers require further investigation. Understanding the degradation mechanisms, metabolic pathways, and potential long-term effects of degradation products is crucial for ensuring the safety and efficacy of these materials in clinical applications. This challenge necessitates extensive preclinical studies and the development of improved in vitro models that can accurately predict in vivo performance.

Another critical issue is the potential cytotoxicity of unreacted crosslinking agents or byproducts formed during the crosslinking process. Ensuring complete reaction of these agents and minimizing harmful residues is crucial for maintaining biocompatibility and preventing adverse tissue responses. Researchers are actively exploring alternative crosslinking methods and biocompatible crosslinking agents to address this concern.

The stability of crosslinked ethyl propanoate polymers under physiological conditions presents another hurdle. These materials must maintain their structural integrity and functional properties in the presence of enzymes, varying pH levels, and mechanical stresses encountered in the body. Developing crosslinking strategies that enhance the polymer's resistance to hydrolysis and enzymatic degradation while still allowing for controlled biodegradation is an ongoing challenge.

Scalability and reproducibility of the crosslinking process pose significant obstacles for industrial production and clinical translation. Achieving consistent crosslinking density and properties across large batches of material is essential for ensuring reliable performance in biomedical applications. This challenge is particularly pronounced when dealing with complex 3D structures or when incorporating bioactive molecules into the polymer matrix.

The integration of crosslinked ethyl propanoate polymers with other biomaterials or living tissues presents additional challenges. Improving the adhesion and interface compatibility between these polymers and biological substrates is crucial for applications such as tissue engineering scaffolds or drug-eluting implants. Researchers are exploring various surface modification techniques and hybrid material approaches to enhance integration and bioactivity.

Furthermore, the characterization and quality control of crosslinked polymer networks remain challenging. Current analytical techniques often struggle to provide comprehensive information about the crosslinking density, network homogeneity, and spatial distribution of functional groups within the material. Developing more advanced characterization methods is essential for optimizing polymer design and ensuring consistent performance in biomedical applications.

Lastly, the long-term in vivo behavior and fate of crosslinked ethyl propanoate polymers require further investigation. Understanding the degradation mechanisms, metabolic pathways, and potential long-term effects of degradation products is crucial for ensuring the safety and efficacy of these materials in clinical applications. This challenge necessitates extensive preclinical studies and the development of improved in vitro models that can accurately predict in vivo performance.

Existing Crosslinked EtPr Solutions

01 Synthesis of crosslinked ethyl propanoate polymers

Methods for synthesizing crosslinked ethyl propanoate polymers, including polymerization techniques and crosslinking agents. These processes aim to create polymers with specific properties for various applications.- Synthesis of crosslinked ethyl propanoate polymers: Methods for synthesizing crosslinked ethyl propanoate polymers, including polymerization techniques and crosslinking agents. These processes aim to create polymers with specific properties for various applications.

- Applications in electronic devices: Utilization of crosslinked ethyl propanoate polymers in electronic devices, such as batteries, capacitors, and semiconductors. These polymers can serve as electrolytes, separators, or insulating materials, enhancing device performance and durability.

- Biomedical and pharmaceutical applications: Implementation of crosslinked ethyl propanoate polymers in biomedical and pharmaceutical fields. These polymers can be used for drug delivery systems, tissue engineering scaffolds, or as components in medical devices due to their biocompatibility and controlled degradation properties.

- Coating and adhesive formulations: Incorporation of crosslinked ethyl propanoate polymers in coating and adhesive formulations. These polymers can improve durability, chemical resistance, and adhesion properties in various industrial and consumer products.

- Environmental and sustainability applications: Use of crosslinked ethyl propanoate polymers in environmental and sustainability-focused applications. These may include biodegradable materials, water treatment technologies, or renewable energy systems, leveraging the polymer's unique properties for eco-friendly solutions.

02 Applications in electronic devices

Utilization of crosslinked ethyl propanoate polymers in electronic components, such as batteries, capacitors, and semiconductor devices. These polymers can enhance performance and durability in electronic applications.Expand Specific Solutions03 Biomedical and pharmaceutical uses

Implementation of crosslinked ethyl propanoate polymers in biomedical devices, drug delivery systems, and pharmaceutical formulations. These materials offer biocompatibility and controlled release properties.Expand Specific Solutions04 Coating and adhesive applications

Development of coatings and adhesives using crosslinked ethyl propanoate polymers. These materials provide improved durability, chemical resistance, and adhesion properties for various industrial and consumer products.Expand Specific Solutions05 Environmental and sustainability aspects

Research into environmentally friendly production methods and biodegradable formulations of crosslinked ethyl propanoate polymers. This includes studies on their lifecycle impact and potential for sustainable applications.Expand Specific Solutions

Key Players in Biomedical Polymers

The research on crosslinked ethyl propanoate polymers in biomedical applications is in an early development stage, with a growing market potential due to increasing demand for advanced biomaterials. The technology is still maturing, with key players like Dow Global Technologies, Ethicon, and 3M Innovative Properties leading research efforts. Companies such as Alcon, Genzyme, and DuPont are also contributing to advancements in this field. The competitive landscape is characterized by a mix of established chemical and medical device companies, alongside specialized biotech firms, indicating a diverse and dynamic market with opportunities for innovation and collaboration.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed a novel approach to crosslinked ethyl propanoate polymers for biomedical applications. Their research focuses on creating biocompatible and biodegradable materials with tunable mechanical properties. The company has engineered a proprietary crosslinking process that allows for precise control over the polymer's structure and degradation rate[1]. This technology enables the creation of scaffolds for tissue engineering, drug delivery systems, and wound healing materials. Dow's polymers demonstrate excellent biocompatibility and can be tailored to match the mechanical properties of various tissues[3]. The company has also developed methods to incorporate bioactive molecules into the polymer matrix, enhancing their functionality in regenerative medicine applications[5].

Strengths: Highly customizable polymer properties, excellent biocompatibility, and versatile applications in tissue engineering and drug delivery. Weaknesses: Potential challenges in scaling up production and ensuring consistent quality across batches.

Ethicon, Inc.

Technical Solution: Ethicon, a subsidiary of Johnson & Johnson, has made significant strides in the development of crosslinked ethyl propanoate polymers for surgical applications. Their research focuses on creating advanced surgical materials with improved mechanical strength and controlled degradation profiles. Ethicon's proprietary crosslinking technology allows for the production of sutures and surgical meshes with enhanced durability and tissue integration properties[2]. The company has also developed a novel drug-eluting polymer system that can be incorporated into surgical implants, providing localized drug delivery to promote healing and reduce complications[4]. Ethicon's crosslinked ethyl propanoate polymers have shown promising results in reducing post-operative adhesions and improving patient outcomes in various surgical procedures[6].

Strengths: Extensive experience in surgical materials, strong focus on clinical applications, and established distribution networks. Weaknesses: Potential regulatory hurdles for novel materials and competition from alternative biomaterials.

Core Innovations in Crosslinking Technology

Crosslinked polyolefins for biomedical applications and method of making same

PatentActiveUS10766987B2

Innovation

- A polymeric composition utilizing alkenes and benzocyclobutene-functional olefins that are polymerizable via living carbocationic chemistry, providing biostability, increased tensile strength, and the ability to withstand high-temperature sterilization without releasing toxic molecules, and offering improved creep resistance and dimensional stability.

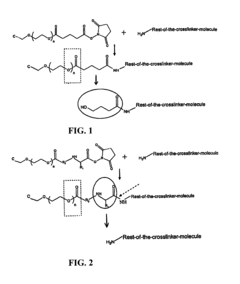

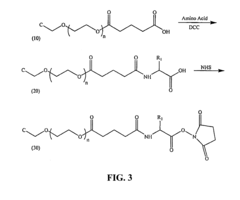

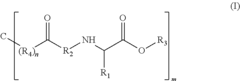

Crosslinked Polymers with the Crosslinker as Therapeutic for Sustained Release

PatentActiveUS20130225857A1

Innovation

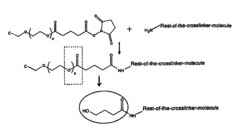

- Development of crosslinked polymers formed from at least two precursors, where one precursor is a therapeutic agent that can be released in its original, unmodified form upon degradation, using electrophilic and nucleophilic functional groups for crosslinking reactions, allowing for controlled release through enzymatic or hydrolytic cleavage.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations are paramount in the development and application of crosslinked ethyl propanoate polymers for biomedical use. These polymers must undergo rigorous testing to ensure they do not elicit adverse biological responses when in contact with living tissues or bodily fluids.

One of the primary concerns is the potential for these polymers to induce inflammation or immune responses. Extensive in vitro and in vivo studies are necessary to evaluate the polymer's interaction with various cell types, including fibroblasts, endothelial cells, and immune cells. These studies should assess cell viability, proliferation, and potential cytotoxic effects.

The degradation profile of crosslinked ethyl propanoate polymers is another critical aspect to consider. As these materials break down within the body, it is essential to ensure that the degradation products are non-toxic and can be safely metabolized or excreted. Long-term studies are required to monitor the polymer's degradation rate and the body's ability to process the resulting compounds without adverse effects.

Hemocompatibility is a crucial factor for polymers intended for use in blood-contacting applications. Evaluations must be conducted to assess the polymer's potential to induce thrombosis, hemolysis, or platelet activation. Surface modifications may be necessary to enhance the material's blood compatibility and reduce the risk of clot formation.

The mechanical properties of crosslinked ethyl propanoate polymers must also be carefully evaluated to ensure they meet the specific requirements of their intended biomedical applications. This includes assessing factors such as tensile strength, elasticity, and fatigue resistance to prevent material failure during use.

Sterilization compatibility is another important consideration. The chosen sterilization method must effectively eliminate microbial contamination without compromising the polymer's structural integrity or biocompatibility. Common sterilization techniques, such as ethylene oxide treatment, gamma irradiation, or autoclaving, should be tested to determine their impact on the material's properties.

Regulatory compliance is a critical aspect of biocompatibility and safety considerations. Researchers and manufacturers must adhere to guidelines set forth by regulatory bodies such as the FDA and EMA. This includes conducting standardized biocompatibility tests as outlined in ISO 10993 and providing comprehensive documentation of safety and efficacy data.

Long-term implantation studies are essential for polymers intended for extended use within the body. These studies should evaluate the potential for chronic inflammation, fibrosis, or other adverse tissue responses that may not be apparent in short-term assessments. Additionally, the polymer's resistance to enzymatic degradation and its stability in various physiological environments must be thoroughly investigated.

One of the primary concerns is the potential for these polymers to induce inflammation or immune responses. Extensive in vitro and in vivo studies are necessary to evaluate the polymer's interaction with various cell types, including fibroblasts, endothelial cells, and immune cells. These studies should assess cell viability, proliferation, and potential cytotoxic effects.

The degradation profile of crosslinked ethyl propanoate polymers is another critical aspect to consider. As these materials break down within the body, it is essential to ensure that the degradation products are non-toxic and can be safely metabolized or excreted. Long-term studies are required to monitor the polymer's degradation rate and the body's ability to process the resulting compounds without adverse effects.

Hemocompatibility is a crucial factor for polymers intended for use in blood-contacting applications. Evaluations must be conducted to assess the polymer's potential to induce thrombosis, hemolysis, or platelet activation. Surface modifications may be necessary to enhance the material's blood compatibility and reduce the risk of clot formation.

The mechanical properties of crosslinked ethyl propanoate polymers must also be carefully evaluated to ensure they meet the specific requirements of their intended biomedical applications. This includes assessing factors such as tensile strength, elasticity, and fatigue resistance to prevent material failure during use.

Sterilization compatibility is another important consideration. The chosen sterilization method must effectively eliminate microbial contamination without compromising the polymer's structural integrity or biocompatibility. Common sterilization techniques, such as ethylene oxide treatment, gamma irradiation, or autoclaving, should be tested to determine their impact on the material's properties.

Regulatory compliance is a critical aspect of biocompatibility and safety considerations. Researchers and manufacturers must adhere to guidelines set forth by regulatory bodies such as the FDA and EMA. This includes conducting standardized biocompatibility tests as outlined in ISO 10993 and providing comprehensive documentation of safety and efficacy data.

Long-term implantation studies are essential for polymers intended for extended use within the body. These studies should evaluate the potential for chronic inflammation, fibrosis, or other adverse tissue responses that may not be apparent in short-term assessments. Additionally, the polymer's resistance to enzymatic degradation and its stability in various physiological environments must be thoroughly investigated.

Regulatory Landscape for Biomedical Materials

The regulatory landscape for biomedical materials is complex and constantly evolving, reflecting the critical importance of safety and efficacy in medical applications. For crosslinked ethyl propanoate polymers in biomedical applications, regulatory considerations are paramount to ensure patient safety and product effectiveness.

In the United States, the Food and Drug Administration (FDA) plays a central role in regulating biomedical materials. The FDA's Center for Devices and Radiological Health (CDRH) oversees medical devices, including those incorporating novel polymeric materials. Depending on the intended use and risk profile, crosslinked ethyl propanoate polymers may be classified under different regulatory pathways, such as 510(k) clearance or premarket approval (PMA).

The European Union employs the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) to govern biomedical materials. These regulations emphasize rigorous clinical evidence, post-market surveillance, and traceability throughout the product lifecycle. Manufacturers must obtain CE marking to market their products in the EU, demonstrating compliance with essential requirements for safety and performance.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) regulates biomedical materials under the Pharmaceutical and Medical Device Act. The PMDA's approach focuses on quality management systems and product-specific requirements, with a streamlined review process for certain low-risk devices.

International standards, such as ISO 10993 for biocompatibility evaluation, play a crucial role in harmonizing regulatory requirements across different regions. These standards provide a framework for assessing the biological safety of materials used in medical devices, including novel polymers like crosslinked ethyl propanoate.

Regulatory bodies increasingly emphasize the importance of risk management throughout the product development process. Manufacturers must conduct thorough risk assessments, implement appropriate mitigation strategies, and maintain comprehensive documentation to support regulatory submissions.

As the field of biomedical materials advances, regulatory agencies are adapting their approaches to accommodate innovative technologies. This includes the development of guidance documents specific to novel materials and the use of real-world evidence to support regulatory decision-making. For crosslinked ethyl propanoate polymers, manufacturers should engage early with regulatory authorities to discuss potential challenges and requirements specific to their applications.

Environmental considerations are also becoming more prominent in the regulatory landscape for biomedical materials. Regulations addressing the environmental impact of medical devices, including their disposal and potential for biodegradation, are likely to influence the development and approval of new polymeric materials in the future.

In the United States, the Food and Drug Administration (FDA) plays a central role in regulating biomedical materials. The FDA's Center for Devices and Radiological Health (CDRH) oversees medical devices, including those incorporating novel polymeric materials. Depending on the intended use and risk profile, crosslinked ethyl propanoate polymers may be classified under different regulatory pathways, such as 510(k) clearance or premarket approval (PMA).

The European Union employs the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) to govern biomedical materials. These regulations emphasize rigorous clinical evidence, post-market surveillance, and traceability throughout the product lifecycle. Manufacturers must obtain CE marking to market their products in the EU, demonstrating compliance with essential requirements for safety and performance.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) regulates biomedical materials under the Pharmaceutical and Medical Device Act. The PMDA's approach focuses on quality management systems and product-specific requirements, with a streamlined review process for certain low-risk devices.

International standards, such as ISO 10993 for biocompatibility evaluation, play a crucial role in harmonizing regulatory requirements across different regions. These standards provide a framework for assessing the biological safety of materials used in medical devices, including novel polymers like crosslinked ethyl propanoate.

Regulatory bodies increasingly emphasize the importance of risk management throughout the product development process. Manufacturers must conduct thorough risk assessments, implement appropriate mitigation strategies, and maintain comprehensive documentation to support regulatory submissions.

As the field of biomedical materials advances, regulatory agencies are adapting their approaches to accommodate innovative technologies. This includes the development of guidance documents specific to novel materials and the use of real-world evidence to support regulatory decision-making. For crosslinked ethyl propanoate polymers, manufacturers should engage early with regulatory authorities to discuss potential challenges and requirements specific to their applications.

Environmental considerations are also becoming more prominent in the regulatory landscape for biomedical materials. Regulations addressing the environmental impact of medical devices, including their disposal and potential for biodegradation, are likely to influence the development and approval of new polymeric materials in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!