Ethyl Propanoate as a Modifier in Polymer Additive Systems

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate Background and Objectives

Ethyl propanoate, also known as ethyl propionate, is an organic compound with the molecular formula C5H10O2. It is a colorless liquid with a fruity odor, commonly used as a flavoring agent in the food industry. In recent years, its potential as a modifier in polymer additive systems has gained significant attention from researchers and industry professionals.

The development of polymer additives has been a crucial area of research in materials science, aiming to enhance the properties and performance of polymeric materials. As the demand for advanced materials with specific characteristics continues to grow, the exploration of novel additives and modifiers has become increasingly important. Ethyl propanoate has emerged as a promising candidate in this field due to its unique chemical properties and potential to improve various aspects of polymer systems.

The primary objective of researching ethyl propanoate as a modifier in polymer additive systems is to investigate its effects on the physical, chemical, and mechanical properties of polymers. This includes studying its impact on factors such as thermal stability, mechanical strength, flexibility, and processability. Additionally, researchers aim to understand the mechanisms by which ethyl propanoate interacts with different polymer matrices and other additives, potentially leading to synergistic effects that could further enhance material performance.

Another key goal of this research is to explore the potential of ethyl propanoate in addressing specific challenges in polymer science. For instance, its use as a plasticizer could offer alternatives to traditional phthalate-based plasticizers, which have raised environmental and health concerns. Furthermore, its potential as a compatibilizer in polymer blends or as a dispersing agent for nanofillers could open up new avenues for creating advanced composite materials with improved properties.

The investigation of ethyl propanoate in polymer systems also aligns with broader trends in sustainable materials development. As a bio-based compound derived from renewable resources, ethyl propanoate presents an opportunity to reduce the environmental footprint of polymer additives. This aspect of the research is particularly relevant given the growing emphasis on eco-friendly and sustainable materials across various industries.

As research in this area progresses, it is expected to contribute to the development of new polymer formulations with enhanced properties and potentially novel applications. The findings from these studies could have far-reaching implications for industries ranging from packaging and automotive to electronics and healthcare, where advanced polymeric materials play a crucial role.

The development of polymer additives has been a crucial area of research in materials science, aiming to enhance the properties and performance of polymeric materials. As the demand for advanced materials with specific characteristics continues to grow, the exploration of novel additives and modifiers has become increasingly important. Ethyl propanoate has emerged as a promising candidate in this field due to its unique chemical properties and potential to improve various aspects of polymer systems.

The primary objective of researching ethyl propanoate as a modifier in polymer additive systems is to investigate its effects on the physical, chemical, and mechanical properties of polymers. This includes studying its impact on factors such as thermal stability, mechanical strength, flexibility, and processability. Additionally, researchers aim to understand the mechanisms by which ethyl propanoate interacts with different polymer matrices and other additives, potentially leading to synergistic effects that could further enhance material performance.

Another key goal of this research is to explore the potential of ethyl propanoate in addressing specific challenges in polymer science. For instance, its use as a plasticizer could offer alternatives to traditional phthalate-based plasticizers, which have raised environmental and health concerns. Furthermore, its potential as a compatibilizer in polymer blends or as a dispersing agent for nanofillers could open up new avenues for creating advanced composite materials with improved properties.

The investigation of ethyl propanoate in polymer systems also aligns with broader trends in sustainable materials development. As a bio-based compound derived from renewable resources, ethyl propanoate presents an opportunity to reduce the environmental footprint of polymer additives. This aspect of the research is particularly relevant given the growing emphasis on eco-friendly and sustainable materials across various industries.

As research in this area progresses, it is expected to contribute to the development of new polymer formulations with enhanced properties and potentially novel applications. The findings from these studies could have far-reaching implications for industries ranging from packaging and automotive to electronics and healthcare, where advanced polymeric materials play a crucial role.

Market Analysis for Polymer Additives

The polymer additives market has been experiencing significant growth, driven by the increasing demand for high-performance plastics across various industries. The global polymer additives market was valued at approximately $51.2 billion in 2020 and is projected to reach $73.8 billion by 2026, growing at a CAGR of 6.3% during the forecast period. This growth is primarily attributed to the rising consumption of plastics in automotive, packaging, construction, and consumer goods sectors.

The market for polymer additives is highly fragmented, with numerous players competing for market share. Key market segments include plasticizers, stabilizers, flame retardants, impact modifiers, and processing aids. Among these, plasticizers hold the largest market share, accounting for about 35% of the total market value. The demand for eco-friendly and sustainable additives is on the rise, driven by stringent environmental regulations and increasing consumer awareness.

In the context of ethyl propanoate as a modifier in polymer additive systems, the market potential lies in its ability to enhance the properties of polymers while addressing environmental concerns. Ethyl propanoate, being a bio-based compound, aligns well with the growing trend towards sustainable additives. The global bio-based plasticizers market, which includes modifiers like ethyl propanoate, is expected to grow at a CAGR of 9.8% from 2021 to 2028.

The Asia-Pacific region dominates the polymer additives market, accounting for over 40% of the global market share. This is primarily due to the rapid industrialization, growing automotive and packaging industries, and increasing disposable income in countries like China and India. North America and Europe follow, with a strong focus on technological advancements and stringent regulations promoting the use of environmentally friendly additives.

Key market drivers for polymer additives, including ethyl propanoate-based modifiers, include the growing demand for lightweight materials in automotive applications, increasing use of plastics in food packaging, and the need for improved durability and performance in construction materials. However, challenges such as volatile raw material prices and regulatory constraints on certain additives may impact market growth.

The adoption of ethyl propanoate as a modifier in polymer additive systems is expected to be influenced by factors such as its performance characteristics, cost-effectiveness, and compatibility with existing manufacturing processes. As industries continue to seek innovative solutions to enhance polymer properties while meeting sustainability goals, ethyl propanoate and similar bio-based modifiers are likely to gain traction in the market.

The market for polymer additives is highly fragmented, with numerous players competing for market share. Key market segments include plasticizers, stabilizers, flame retardants, impact modifiers, and processing aids. Among these, plasticizers hold the largest market share, accounting for about 35% of the total market value. The demand for eco-friendly and sustainable additives is on the rise, driven by stringent environmental regulations and increasing consumer awareness.

In the context of ethyl propanoate as a modifier in polymer additive systems, the market potential lies in its ability to enhance the properties of polymers while addressing environmental concerns. Ethyl propanoate, being a bio-based compound, aligns well with the growing trend towards sustainable additives. The global bio-based plasticizers market, which includes modifiers like ethyl propanoate, is expected to grow at a CAGR of 9.8% from 2021 to 2028.

The Asia-Pacific region dominates the polymer additives market, accounting for over 40% of the global market share. This is primarily due to the rapid industrialization, growing automotive and packaging industries, and increasing disposable income in countries like China and India. North America and Europe follow, with a strong focus on technological advancements and stringent regulations promoting the use of environmentally friendly additives.

Key market drivers for polymer additives, including ethyl propanoate-based modifiers, include the growing demand for lightweight materials in automotive applications, increasing use of plastics in food packaging, and the need for improved durability and performance in construction materials. However, challenges such as volatile raw material prices and regulatory constraints on certain additives may impact market growth.

The adoption of ethyl propanoate as a modifier in polymer additive systems is expected to be influenced by factors such as its performance characteristics, cost-effectiveness, and compatibility with existing manufacturing processes. As industries continue to seek innovative solutions to enhance polymer properties while meeting sustainability goals, ethyl propanoate and similar bio-based modifiers are likely to gain traction in the market.

Current Challenges in Polymer Modification

Polymer modification faces several significant challenges in the current landscape of materials science and engineering. One of the primary issues is achieving consistent and uniform dispersion of modifiers throughout the polymer matrix. This is particularly problematic when dealing with nanoparticles or other small-scale additives, as they tend to agglomerate due to their high surface energy. Such agglomeration can lead to inconsistent material properties and reduced overall performance of the modified polymer.

Another major challenge lies in maintaining the balance between enhancing certain properties without compromising others. For instance, improving the mechanical strength of a polymer might inadvertently reduce its flexibility or impact resistance. This trade-off often requires careful optimization and sometimes necessitates the use of multiple modifiers, further complicating the formulation process.

Compatibility between the modifier and the base polymer presents another significant hurdle. Many modifiers, especially those of organic nature, may not readily mix with certain polymers due to differences in polarity or chemical structure. This incompatibility can result in phase separation, leading to weak interfaces and poor overall material performance. Overcoming this often requires the use of compatibilizers or surface treatments, adding complexity and cost to the modification process.

The thermal stability of modifiers during polymer processing is also a critical concern. Many polymers are processed at high temperatures, which can cause degradation of organic modifiers or changes in the structure of inorganic additives. This degradation can not only reduce the effectiveness of the modifier but also potentially introduce unwanted by-products that could affect the polymer's properties or pose safety risks.

Environmental and regulatory challenges are becoming increasingly prominent in polymer modification. There is growing pressure to develop sustainable and eco-friendly modifiers that can replace traditional additives, many of which have been found to have negative environmental impacts. This shift towards green chemistry requires significant research and development efforts to find alternatives that are both environmentally benign and economically viable.

Lastly, the scalability of laboratory-developed modification techniques to industrial production levels remains a persistent challenge. What works well in small-scale experiments may face unforeseen difficulties when scaled up, such as changes in mixing efficiency, heat transfer issues, or unexpected chemical interactions. Bridging this gap between lab-scale success and industrial viability is crucial for the practical implementation of new polymer modification technologies.

Another major challenge lies in maintaining the balance between enhancing certain properties without compromising others. For instance, improving the mechanical strength of a polymer might inadvertently reduce its flexibility or impact resistance. This trade-off often requires careful optimization and sometimes necessitates the use of multiple modifiers, further complicating the formulation process.

Compatibility between the modifier and the base polymer presents another significant hurdle. Many modifiers, especially those of organic nature, may not readily mix with certain polymers due to differences in polarity or chemical structure. This incompatibility can result in phase separation, leading to weak interfaces and poor overall material performance. Overcoming this often requires the use of compatibilizers or surface treatments, adding complexity and cost to the modification process.

The thermal stability of modifiers during polymer processing is also a critical concern. Many polymers are processed at high temperatures, which can cause degradation of organic modifiers or changes in the structure of inorganic additives. This degradation can not only reduce the effectiveness of the modifier but also potentially introduce unwanted by-products that could affect the polymer's properties or pose safety risks.

Environmental and regulatory challenges are becoming increasingly prominent in polymer modification. There is growing pressure to develop sustainable and eco-friendly modifiers that can replace traditional additives, many of which have been found to have negative environmental impacts. This shift towards green chemistry requires significant research and development efforts to find alternatives that are both environmentally benign and economically viable.

Lastly, the scalability of laboratory-developed modification techniques to industrial production levels remains a persistent challenge. What works well in small-scale experiments may face unforeseen difficulties when scaled up, such as changes in mixing efficiency, heat transfer issues, or unexpected chemical interactions. Bridging this gap between lab-scale success and industrial viability is crucial for the practical implementation of new polymer modification technologies.

Existing Ethyl Propanoate Applications

01 Synthesis and production methods of ethyl propanoate

Various methods for synthesizing and producing ethyl propanoate are described, including esterification reactions, catalytic processes, and continuous production techniques. These methods aim to improve yield, efficiency, and purity of the final product.- Synthesis of ethyl propanoate: Ethyl propanoate can be synthesized through various methods, including esterification of propionic acid with ethanol, or by the reaction of ethyl alcohol with propionyl chloride. These processes often involve catalysts and specific reaction conditions to optimize yield and purity.

- Applications in flavor and fragrance industry: Ethyl propanoate is widely used in the flavor and fragrance industry due to its fruity, rum-like odor. It is commonly employed as a flavoring agent in food products and as a fragrance component in perfumes and cosmetics.

- Use as a solvent and intermediate: Ethyl propanoate serves as an important solvent in various industrial applications, including paints, inks, and coatings. It is also used as an intermediate in the production of pharmaceuticals, agrochemicals, and other organic compounds.

- Production methods and process improvements: Research focuses on developing more efficient and environmentally friendly methods for producing ethyl propanoate. This includes exploring new catalysts, optimizing reaction conditions, and implementing continuous flow processes to enhance yield and reduce waste.

- Analytical methods and quality control: Various analytical techniques are employed to determine the purity and composition of ethyl propanoate. These methods are crucial for quality control in industrial production and for ensuring compliance with regulatory standards in different applications.

02 Applications of ethyl propanoate in fragrances and flavors

Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity, rum-like odor. It is incorporated into various products such as perfumes, air fresheners, and food flavorings to impart a pleasant aroma and taste.Expand Specific Solutions03 Use of ethyl propanoate as a solvent or intermediate

Ethyl propanoate serves as a versatile solvent and intermediate in various chemical processes. It is used in the production of pharmaceuticals, polymers, and other organic compounds, offering advantages such as low toxicity and good solvency properties.Expand Specific Solutions04 Purification and quality control of ethyl propanoate

Various techniques and methods are employed for the purification and quality control of ethyl propanoate. These include distillation, chromatography, and spectroscopic analysis to ensure high purity and consistent quality of the product for different applications.Expand Specific Solutions05 Environmental and safety considerations in ethyl propanoate production

The production and handling of ethyl propanoate involve environmental and safety considerations. Processes and equipment are designed to minimize environmental impact, reduce waste, and ensure safe handling of the compound in industrial settings.Expand Specific Solutions

Key Players in Polymer Industry

The research on Ethyl Propanoate as a modifier in polymer additive systems is in a relatively early stage of development, with the market still emerging. The competitive landscape is characterized by a mix of established chemical companies and specialized research institutions. Major players like BASF, Dow, and LG Chem are likely investing in this area, leveraging their extensive R&D capabilities and market presence. The technology's maturity is still evolving, with companies like The Lubrizol Corp. and Mitsui Chemicals potentially leading in application-specific developments. Academic institutions such as the Karlsruhe Institute of Technology are contributing to fundamental research, while government labs like the Naval Research Laboratory may be exploring specialized applications.

The Lubrizol Corp.

Technical Solution: Lubrizol has developed a novel polymer additive system incorporating ethyl propanoate as a modifier. Their approach involves using ethyl propanoate to enhance the dispersion and compatibility of other additives within the polymer matrix. The company has conducted extensive research on the synergistic effects between ethyl propanoate and various polymer types, optimizing the concentration and blending processes to achieve improved mechanical properties and thermal stability[1]. Lubrizol's technology also focuses on the role of ethyl propanoate in reducing the overall viscosity of the polymer system, thereby improving processability and energy efficiency during manufacturing[3].

Strengths: Improved additive dispersion, enhanced polymer properties, and better processability. Weaknesses: Potential volatility issues of ethyl propanoate, may require specialized handling and storage.

BASF Corp.

Technical Solution: BASF has pioneered a sustainable approach to using ethyl propanoate in polymer additive systems. Their research focuses on bio-based sources of ethyl propanoate, aligning with green chemistry principles. BASF's technology incorporates ethyl propanoate as both a solvent and a reactive modifier, creating multifunctional additive systems. They have developed a proprietary process that allows for in-situ generation of ethyl propanoate within the polymer matrix, ensuring uniform distribution and minimizing loss through evaporation[2]. Additionally, BASF has explored the use of ethyl propanoate in conjunction with nanoparticles to create advanced composite materials with enhanced barrier properties and flame retardancy[4].

Strengths: Sustainable sourcing, multifunctional approach, and advanced composite development. Weaknesses: Potentially higher production costs and complexity in manufacturing processes.

Core Innovations in Modifier Technology

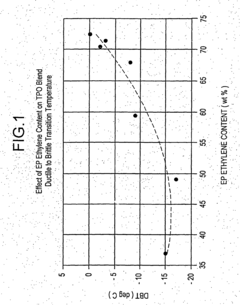

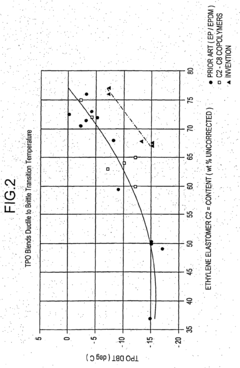

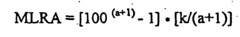

Polyolefin compositions having improved low temperature toughness and methods therefor

PatentInactiveEP1280853B1

Innovation

- Development of a branched copolymer of ethylene and an alpha-olefin with high ethylene content (74-95 mole %) and sufficient long-chain branching, allowing for non-agglomerating pellet production and improved impact modification when blended with propylene-based polymers, reducing dependence on costly raw materials.

Ethylene polymer and modified vinyl esters. by grafting, methods for their preparation, and their application as additives. to improve those properties of liquid hydrocarbons at low temperatures.

PatentInactiveTH108884A

Innovation

- Novel synthesis of ethylene and vinyl ester-based polymers modified by conjugation to enhance solubility in liquid hydrocarbons.

- Dual-purpose additives that simultaneously improve filterability and flow of liquid hydrocarbons at low temperatures.

- Specific application for centrally distilled liquids from petroleum and crude oil refinery processes.

Environmental Impact Assessment

The environmental impact assessment of ethyl propanoate as a modifier in polymer additive systems is a crucial aspect of its research and potential implementation. This compound, while offering promising benefits in polymer modification, requires careful evaluation of its ecological footprint throughout its lifecycle.

Ethyl propanoate, being an organic ester, is generally considered to have a lower environmental impact compared to many traditional polymer additives. Its production process typically involves the esterification of propionic acid with ethanol, both of which can be derived from renewable resources. This potential for bio-based sourcing contributes to a reduced carbon footprint and aligns with sustainability goals in the polymer industry.

However, the environmental implications of ethyl propanoate extend beyond its production. Its use in polymer systems may affect the recyclability and biodegradability of the final products. Initial studies suggest that ethyl propanoate, when used as a modifier, does not significantly impair the recyclability of common polymers. This is a positive attribute, as it allows for the continued circular use of materials, reducing waste and resource consumption.

The volatility of ethyl propanoate is another factor to consider in its environmental assessment. While its low boiling point (99°C) can be advantageous in certain applications, it also raises concerns about potential atmospheric emissions during processing and use. Proper handling and containment measures are essential to mitigate any air quality impacts and minimize contributions to volatile organic compound (VOC) levels.

Aquatic toxicity is an important consideration, as chemical additives can potentially leach from polymer products during use or disposal. Preliminary ecotoxicological studies indicate that ethyl propanoate has relatively low acute toxicity to aquatic organisms. However, long-term studies on chronic exposure and bioaccumulation potential are still needed to fully understand its environmental fate.

The biodegradability of ethyl propanoate is generally favorable, with the compound showing good susceptibility to microbial degradation under both aerobic and anaerobic conditions. This characteristic reduces the risk of long-term environmental persistence and accumulation. However, the rate and extent of biodegradation may vary depending on environmental conditions and the specific polymer matrix in which it is used.

Life cycle assessment (LCA) studies are crucial for a comprehensive understanding of ethyl propanoate's environmental impact. These assessments should consider energy consumption, resource depletion, and emissions associated with its production, use, and end-of-life scenarios. Comparative LCAs with alternative polymer additives can provide valuable insights into the relative environmental benefits of ethyl propanoate.

In conclusion, while ethyl propanoate shows promise as an environmentally friendlier option in polymer additive systems, ongoing research and monitoring are essential. Future studies should focus on long-term environmental fate, potential synergistic effects with other additives, and comprehensive life cycle analyses to ensure its sustainable integration into polymer technologies.

Ethyl propanoate, being an organic ester, is generally considered to have a lower environmental impact compared to many traditional polymer additives. Its production process typically involves the esterification of propionic acid with ethanol, both of which can be derived from renewable resources. This potential for bio-based sourcing contributes to a reduced carbon footprint and aligns with sustainability goals in the polymer industry.

However, the environmental implications of ethyl propanoate extend beyond its production. Its use in polymer systems may affect the recyclability and biodegradability of the final products. Initial studies suggest that ethyl propanoate, when used as a modifier, does not significantly impair the recyclability of common polymers. This is a positive attribute, as it allows for the continued circular use of materials, reducing waste and resource consumption.

The volatility of ethyl propanoate is another factor to consider in its environmental assessment. While its low boiling point (99°C) can be advantageous in certain applications, it also raises concerns about potential atmospheric emissions during processing and use. Proper handling and containment measures are essential to mitigate any air quality impacts and minimize contributions to volatile organic compound (VOC) levels.

Aquatic toxicity is an important consideration, as chemical additives can potentially leach from polymer products during use or disposal. Preliminary ecotoxicological studies indicate that ethyl propanoate has relatively low acute toxicity to aquatic organisms. However, long-term studies on chronic exposure and bioaccumulation potential are still needed to fully understand its environmental fate.

The biodegradability of ethyl propanoate is generally favorable, with the compound showing good susceptibility to microbial degradation under both aerobic and anaerobic conditions. This characteristic reduces the risk of long-term environmental persistence and accumulation. However, the rate and extent of biodegradation may vary depending on environmental conditions and the specific polymer matrix in which it is used.

Life cycle assessment (LCA) studies are crucial for a comprehensive understanding of ethyl propanoate's environmental impact. These assessments should consider energy consumption, resource depletion, and emissions associated with its production, use, and end-of-life scenarios. Comparative LCAs with alternative polymer additives can provide valuable insights into the relative environmental benefits of ethyl propanoate.

In conclusion, while ethyl propanoate shows promise as an environmentally friendlier option in polymer additive systems, ongoing research and monitoring are essential. Future studies should focus on long-term environmental fate, potential synergistic effects with other additives, and comprehensive life cycle analyses to ensure its sustainable integration into polymer technologies.

Regulatory Compliance for Additives

Regulatory compliance for additives in polymer systems is a critical aspect of product development and commercialization. In the context of using ethyl propanoate as a modifier in polymer additive systems, manufacturers must adhere to various regulations and standards set by governing bodies worldwide. The primary regulatory frameworks to consider include the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, the United States' FDA (Food and Drug Administration) guidelines, and similar regulatory bodies in other major markets.

REACH compliance is particularly important for manufacturers intending to sell products in the European market. Under REACH, ethyl propanoate must be registered if it is produced or imported in quantities of one tonne or more per year. The registration process involves submitting detailed information about the substance's properties, potential risks, and safe use guidelines. Additionally, if ethyl propanoate is used in polymer additives for food contact materials, it must comply with specific EU regulations on food contact materials.

In the United States, the FDA regulates additives used in food contact materials. If ethyl propanoate is intended for use in polymer additives that may come into contact with food, it must comply with FDA regulations, including those outlined in 21 CFR (Code of Federal Regulations) Parts 170-199. Manufacturers must ensure that the use of ethyl propanoate in their polymer additive systems meets the FDA's safety standards and does not adversely affect the characteristics of the food it may contact.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), also play a role in regulatory compliance. Manufacturers must ensure proper classification, labeling, and safety data sheet (SDS) preparation for ethyl propanoate and any products containing it as an additive. This includes providing accurate information on hazards, handling precautions, and emergency response procedures.

Environmental regulations are another crucial aspect of compliance. Many countries have implemented restrictions on volatile organic compounds (VOCs) emissions, which may affect the use of ethyl propanoate in certain applications. Manufacturers must consider these regulations when developing and marketing products containing this modifier.

Occupational health and safety regulations must also be addressed. This includes providing appropriate personal protective equipment (PPE) for workers handling ethyl propanoate, implementing proper ventilation systems, and establishing safe handling procedures. Compliance with standards set by organizations such as OSHA (Occupational Safety and Health Administration) in the United States is essential.

To ensure ongoing compliance, manufacturers should implement robust quality management systems and maintain detailed documentation of their compliance efforts. Regular audits and updates to regulatory knowledge are necessary to adapt to evolving regulations and maintain market access. Collaboration with regulatory experts and participation in industry associations can help manufacturers stay informed about regulatory changes and best practices for compliance in the use of ethyl propanoate as a modifier in polymer additive systems.

REACH compliance is particularly important for manufacturers intending to sell products in the European market. Under REACH, ethyl propanoate must be registered if it is produced or imported in quantities of one tonne or more per year. The registration process involves submitting detailed information about the substance's properties, potential risks, and safe use guidelines. Additionally, if ethyl propanoate is used in polymer additives for food contact materials, it must comply with specific EU regulations on food contact materials.

In the United States, the FDA regulates additives used in food contact materials. If ethyl propanoate is intended for use in polymer additives that may come into contact with food, it must comply with FDA regulations, including those outlined in 21 CFR (Code of Federal Regulations) Parts 170-199. Manufacturers must ensure that the use of ethyl propanoate in their polymer additive systems meets the FDA's safety standards and does not adversely affect the characteristics of the food it may contact.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), also play a role in regulatory compliance. Manufacturers must ensure proper classification, labeling, and safety data sheet (SDS) preparation for ethyl propanoate and any products containing it as an additive. This includes providing accurate information on hazards, handling precautions, and emergency response procedures.

Environmental regulations are another crucial aspect of compliance. Many countries have implemented restrictions on volatile organic compounds (VOCs) emissions, which may affect the use of ethyl propanoate in certain applications. Manufacturers must consider these regulations when developing and marketing products containing this modifier.

Occupational health and safety regulations must also be addressed. This includes providing appropriate personal protective equipment (PPE) for workers handling ethyl propanoate, implementing proper ventilation systems, and establishing safe handling procedures. Compliance with standards set by organizations such as OSHA (Occupational Safety and Health Administration) in the United States is essential.

To ensure ongoing compliance, manufacturers should implement robust quality management systems and maintain detailed documentation of their compliance efforts. Regular audits and updates to regulatory knowledge are necessary to adapt to evolving regulations and maintain market access. Collaboration with regulatory experts and participation in industry associations can help manufacturers stay informed about regulatory changes and best practices for compliance in the use of ethyl propanoate as a modifier in polymer additive systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!